Home » Building a house

Alexander Korovaev 03/28/2020

16941 Views 2 comments

Thermal insulation materials for a residential building are selected depending on the type of structure and the type of future cladding. We will tell you in detail how to insulate a private house with your own hands in each specific case.

Is it possible to insulate a house from the inside?

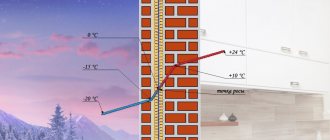

If you do not want to live in a room where the humidity exceeds all permissible limits, and the corners are covered with layers of frost and black fungus, never insulate the building from the inside. Freezing of the walls in this case will occur due to a shift in the boundary of the dew point - a section of a certain temperature at which the steam floating in the air begins to condense and turn into water.

Moisture loss always occurs at the boundary between cold and warm air. Proper thermal insulation implies the obligatory displacement of this area outside the building. When insulating a building from the outside, a sharp temperature difference will be observed somewhere at the boundary of the insulation, that is, outside the room.

When laying a heat insulator inside the house, the dew point will be located between the cold wall and the warm cladding, that is, in the building itself, which is unacceptable.

Dew point in the wall of a building

It is not very successful to choose a thin layer of insulation for small wall thicknesses. In this case, the dew point will be closer to the center of the wall, which can also lead to freezing of the corners and condensation in the house.

Do-it-yourself insulation

Before starting work, it is important to calculate everything carefully, otherwise the rework will require more money and time. In a private house, only walls that border the street can be insulated.

- If you start insulating the walls between rooms, this will cause the area of the room to decrease and the dew point to shift.

- This will make the room damp and may cause mold to form. This will harm both the building and the health of the residents.

Choose vapor-permeable materials. Moisture will still be absorbed into the insulation, so it should easily allow it to pass through. Also, the rule of vapor permeability should be taken into account when laying the material so that the distance between it and the frame remains free.

If vapor permeability is impaired or absent altogether, fungus will begin to appear. As a result, this will damage both the premises and the residents of the house. Especially take this into account when insulating the ceiling, because warm and humid air will rise towards it.

How to choose the thickness of insulation?

To reduce heat loss and ensure an acceptable temperature in the premises when insulating, the thickness of the walls, their heat-insulating properties, type of foundation, climate of the area and prevailing wind loads are taken into account. If the walls are thick enough, made of materials with high heat-insulating properties (for example, made of brick or logs), insulating the facade is not necessary.

The thermal insulation of a house assembled from cinder blocks should be maximum - this material is not capable of retaining heat for a long time. When calculating the thickness of the walls, the thermal conductivity coefficient of the insulation itself is taken into account. The best characteristics are provided by materials such as polyurethane foam, polystyrene, and mineral wool.

For example, a 50 mm layer of polyurethane can retain heat in the same way as 1720 mm of brick.

Thermal conductivity of materials

Professional builders use quite complex formulas to calculate the thickness of insulation. When choosing a heat insulator for a private home, it is convenient to use online calculators. You only need to indicate your region of residence, the size of the building, the types of basement and attic floors, the thickness and material of the walls, and the type of roof.

Even with significant wall thickness, a small layer of insulation along the facade is still worth laying. After all, upon contact with cold air and temperature changes, cracks form on their surface over time, leading to premature destruction.

Comparative analysis of insulation inside and outside

High-quality insulation of walls, foundation and ceiling will make it possible to maintain good conditions in the house. You have to choose between two installation methods for thermal insulation materials:

External insulation - installed on the outer part of the building, its advantages include:

- protection of the surface from the influence of atmospheric conditions, extending the service life;

- the dew point remains on the outside of the room and the walls are not covered with condensation;

- heat supply costs are significantly reduced;

- the internal area of the house remains unchanged;

- a large number of thermal insulators create a layer of sound insulation and reduce the level of penetrating noise;

- there is an opportunity to adjust the architectural image of the house to your own taste.

Among the bad qualities:

- high price of materials;

- The thermal insulation process depends on the weather - work cannot be performed at low temperatures or during rain.

Insulation inside - installed inside

Houses.

This option has a lot of negative factors, but it provides a temperature increase in the room by a couple of degrees. Thermal insulation is installed inside

in several cases:

- if access to the surface from the outside is difficult (high-rise buildings);

- you need to preserve the appearance of the house’s exterior, for example, wood decor.

Disadvantages of insulation inside:

- the required area is lost;

- condensation will appear between the wall surface and the heat insulator at the dew point, provoking the growth of fungus and mold;

- the walls are not protected from the influence of the external environment, they freeze and become unusable.

A comparison demonstrates that external insulation is better than internal insulation. It more effectively maintains high temperature and optimal moisture, increases the service life of load-bearing structures. Thermal insulation placed inside

, loses on all counts, not counting the ability to do it whenever you want. But you cannot refuse it; for most owners of living space and houses, this is the only option to reduce heat loss.

When can you start insulating a building?

There is a basic rule in construction - it is necessary to begin finishing work on buildings after the house has completely settled. This may take about a year. Moreover, shrinkage occurs not only in wooden houses, but also in brick, monolithic frame buildings, etc.

Installation of thermal insulation is preferably carried out in dry weather - the house is well dried beforehand. The house should already have a roof, external waterproofing of the foundation, ventilation, windows, doors.

All work on finishing a log house begins only after it has settled

You should not start work either in frost or heat - you must wait until the temperature reaches above zero of 5-25°C. The optimal time to start finishing the facade is late spring or early autumn.

Features of use

Each insulating material has its own degree of permeability to water vapor. This is the main indicator that determines the suitability of a material for internal or external installation. The basic rule applies here: the degree of vapor permeability of materials should increase as they are removed outside. This means that impermeable insulation should be used only for indoor installation, and permeable insulation for outdoor installation.

If the material parameters are chosen incorrectly, water vapor will not be able to overcome the boundary of different layers and will begin to accumulate on the transition plane. For example, if mineral wool is installed inside a house, steam will be absorbed into it, but will not be able to pass through a concrete (or brick) wall, since the partial pressure energy will be weakened.

Insulation of the facade. Basic methods

Ventilated curtain façade with siding

There are several ways to decorate walls:

- by creating ventilated curtain facades: by attaching facing materials to the frame; a ventilation gap is formed between the insulation and the wall, protecting them from condensation and moisture accumulation

- plastering method: the system consists of 3 layers, a heat-insulating layer (most often inexpensive foam plastic is used, which is attached to a special adhesive composition), a reinforcing mesh and a decorative layer (plaster)

- through ready-made plaster systems (thermal panels) , heat-insulating materials with a decorative layer already applied

- using siding (high-strength stacked panels): in essence, the method is a type of ventilated facades.

Preparing the surface of external walls for treatment with insulation

When the user has chosen how to insulate the walls of the house from the outside, it is necessary to understand the stages of preparation. It is recommended to use the following instructions:

- removal of primary finishing material, removal of plaster;

- alignment of irregularities, depressions, chips;

- squeezing of bulges;

- cleaning from dust and debris that may have formed after removing the plaster;

- surface primer;

- applying beacons and plumb lines to achieve the formation of an even layer;

- drying the wall.

If the surface is carefully prepared, the insulation process will be quick.

Removing plaster

What materials can be used to insulate a facade?

Materials used for thermal insulation of walls must have a number of technical characteristics:

- sufficiently low thermal conductivity coefficient: reliably store and do not lose heat

- low degree of water absorption - after all, when moisture is absorbed, they almost completely lose their thermal insulation properties

- rot-resistant

- sufficient vapor permeability: the walls of the house must “breathe”, that is, allow air to pass through and give off moisture; When the walls are covered with insulation that has low vapor permeability, the humidity in the house will always be increased

- strength and resistance to wind loads and other physical influences

- fire resistance: they should not be highly flammable

- long service life

Types of insulation

Unfortunately, there are no universal insulation materials that fully meet these requirements.

Each of them has both undeniable advantages and disadvantages:

- polystyrene foam: capable of storing heat for a long time, but is very vulnerable to ultraviolet radiation, plus it has low strength and fire resistance, so it requires additional finishing; moisture absorption is average

- penoplex: has a low thermal conductivity coefficient, moisture resistant, fire resistant; There are two disadvantages - poor vapor permeability and a fairly significant price compared to polystyrene foam.

- mineral wool: its undoubted advantages include low thermal conductivity and high fire resistance; but, since this material quickly absorbs moisture, it requires mandatory waterproofing

- warm plaster: a cement-based mixture in which sand is replaced with heat-insulating components - sawdust, vermiculite, perlite, pumice or foam granules; subsequently covered with a layer of decorative plaster

- penoizol: in fact, it is liquid polystyrene - lightweight insulation that excellently stores heat, applied by spraying; its main disadvantages are poor resistance to aggressive chemical environments and fire

- liquid polyurethane foam: also applied by spraying using special devices, filling every crack; it is very convenient to work with it on inclined planes when insulating the roof; but its cost is quite high

Finishing with foam plastic followed by plastering

When insulating a facade with foam plastic, to increase the fire safety of a building, the so-called method of cutting slabs using fire-resistant mineral wool is often used.

Thermal insulation materials - new products on the market

In recent years, a variety of raw materials have been produced to preserve heat in the house. For example, Multipor. Its feature is as follows:

- maintenance of stone slabs that serve as insulation;

- possibility of gluing from the outside and inside, to the roof;

- the total wall thickness becomes 65 cm, which complies with the standards;

- absence of cold bridges.

Mineral fiberglass insulation Terra was launched. It has thermal insulation, low price, lack of flammability, and moisture resistance.

Materials for foundation insulation

The foundation, which separates the soil and the structure, is considered one of the main sources of heat loss. However, not all types of materials can be used to insulate it. Mineral wool or basalt slabs are not suitable for these purposes - they will absorb moisture from the soil and quickly become unusable.

Foundation insulation with expanded clay

The most common foundation insulation materials are:

- expanded polystyrene: perhaps the ideal option in terms of price-quality ratio; if it is not practical to use it for wall decoration due to low vapor permeability, then for insulating the base, a material that is not afraid of rotting is ideal; plus it is light in weight and easy to install; high flammability in this case is not significant - after all, it is laid underground;

- expanded clay: excellent environmentally friendly heat insulator; due to its high porosity, it forms an air cushion that reliably protects the base of the building from the cold; requires additional waterproofing with coating or roll materials; but the high cost does not allow it to be widely used as foundation insulation;

- liquid polyurethane foam: similar in properties to expanded polystyrene, but without special equipment it is impossible to use it independently.

Styrofoam

Polystyrene foam has poor vapor permeability, so it is not advisable to use it for wooden buildings.

To avoid the greenhouse effect, you need to consider ventilation.

The material also has its advantages:

- It is lightweight and easy to install;

- Safe, easy to cut;

- It is inexpensive and lasts a long time;

- No rotting, does not lose its shape.

Polystyrene foam is placed in slabs on a flat surface. You don’t have to prepare the screed, the main thing is that the elements do not protrude. The material is simple in that it can simply be glued without further fastening. True, some still attach it with self-tapping screws for reliability.

The joints of the plates must be sealed with polyurethane foam, the excess parts are cut off. Bare and loose parts also need to be sealed.

Thermal insulating materials for roofing

As you know, warm air tends only upward. If the roof covering is not insulated enough, it will go away unhindered, and the house will quickly dry out. If up to 15-20% of the heat evaporates through the walls, then about 10-20% escapes through the roof. This fact should not be neglected.

Thermal insulation of the roof with polyurethane foam

For thermal insulation of roofs, any types of materials can be used, from mineral wool to slag or sawdust. When using expanded clay, it is most often mixed with foam granules - this helps reduce the weight of the insulation and enhance its effect.

Rolled eco-, glass, mineral wool, as well as liquid polyurethane foam are used mainly for inclined surfaces. Rigid slabs and bulk insulation are used for laying on floor slabs.

Thermal insulation of the roof must be thought out even before laying the structure - after all, when using heavy backfill materials, the load on the foundation will increase significantly.

Insulation with mineral wool

Here you cannot do without a wooden or metal sheathing, since it is in the cells of the frame that the mineral wool is placed. Moreover, the distance between the slats should be slightly less than the width of the slabs.

Photo: extrawool.ru

The slats go vertically and horizontally so that the wool does not sag. It can also be secured with “fungi” dowels, like polystyrene foam. A vapor barrier membrane is laid on top, always with an overlap of 10 cm at the joints. Secure it with a stapler or double-sided tape.

Photo: Instagram timatalo

The second layer of sheathing above the vapor barrier will create an air gap between the insulation and the finishing (and then you will get a ventilated façade) for reliable moisture removal.

Range of thermal insulators

The range of heat-insulating materials sold on the market today is quite wide.

Let's consider only the main ones:

Foam plastic (cellular plastic)

Inexpensive material made from foamed plastic (mainly polystyrene). The excellent thermal insulation properties of polystyrene foam are explained by the presence of multiple individual granule cells, separated by partitions and filled with gas. An 8 cm thick slab is equivalent in thermal protection to 25 cm of wood or a 1.5 m brick wall.

Polystyrene foam is lightweight, easy to cut, and easy to install. Plates made from it are quite elastic and, unlike rolled materials, do not sag over time.

External foam insulation

The density and strength of polystyrene foam depend on the technology of its processing and the type of raw materials. For façade cladding, it is better to use high-density material - it crumbles less when cutting and has a longer service life.

Despite the fact that the foam itself does not rot, colonies of microorganisms can easily attach to its rough surface and can spread to other structural elements.

Due to its tendency to ignite, as well as the ability to be destroyed under the influence of sunlight, this insulation must be covered with a layer of plaster or used in ventilated facades.

Extruded polystyrene foam

Despite the fact that expanded polystyrene, like polystyrene foam, is made on the basis of polystyrene, its technical characteristics differ significantly. If foam foaming occurs under the influence of steam, then in polystyrene bulk granules are obtained by introducing a foaming reagent and then pressing it through an extruder. As a result, the material acquires a more uniform structure and strength.

All of its air granules are closed and have the same size, which is why polystyrene foam is less fragile than polystyrene foam.

Foundation insulation with polystyrene foam

The service life of this material is up to 40 years. It has minimal water absorption (up to 0.4%) and lower thermal conductivity - on average it is 0.029-0.034 W/(m K). The thermal insulation properties of polystyrene foam are very high - even a thin sheet is enough to create a reliable barrier to the cold.

But still, polystyrene foam is not able to “breathe”; it is better not to use it for wall decoration, otherwise they will get wet. The main purpose of expanded polystyrene is thermal insulation of plinths and foundation blind areas. A special high-strength, high-density material is used in construction as auxiliary or even load-bearing structures.

Why is external insulation needed, not internal?

At the design stage, they think about how to insulate the house and what methods to use for this.

Many users know that heat from inside the structure goes outside through the wall. However, they have no idea about the level of heat loss, so when they hear the value of 30-40% they are very surprised.

The exact parameters depend on the following wall characteristics:

- thickness;

- material;

- presence or absence of cracks.

Builders recommend external insulation for the following reasons:

- preservation of internal space:

- removing the load from the foundation and walls, since the materials used are light in weight;

- improving the external qualities of the house, the insulation can be plastered and painted;

- lack of impregnation with condensate released after precipitation, evaporation, snow melting;

- protection against sudden temperature fluctuations that can cause microcracks in the surface of the walls;

- protection of the material from the influence of sub-zero temperatures;

- extending the service life of an apartment or private building;

- reducing transmittance for sounds entering the room from outside.

When builders decide how to insulate a structure, finishing from the inside is carried out only in two cases - the impossibility of external work due to technical features, or the structure being classified as an architectural monument.

Material attachment scheme

The feasibility of external wall insulation

In addition to the reasons listed, the main factor for which it is recommended to insulate a building from the outside is savings. You can choose cheap materials that will maintain thermal insulation and soundproofing.

The main savings are lower heating costs. If you cover your house, your gas consumption will be much less.

To implement the technique correctly, a thermal engineering calculation is first performed. It includes identifying climatic characteristics and moisture resistance of materials that are selected for the structure.

Types of mineral wool

Mineral wool is a group of materials with a fibrous structure, which includes:

- rock wool: obtained from molten rock minerals; it is what is most often called mineral wool; one of its varieties includes more moisture-resistant basalt wool

- glass wool: fine fibers obtained from molten glass or sand by heating at extremely high temperatures

- slag wool: the cheapest material, which is based on blast furnace slag; due to increased hygroscopicity, it is not used for insulation of buildings

The advantages of mineral wool include:

- high thermal insulation properties

- low flammability

- rot resistance

- reasonable cost

Types of mineral wool

Most types of mineral wool absorb moisture and have low mechanical strength, so it must be covered with a layer of vapor barrier and then sheathed with airtight sheathing.

It is not advisable to use rolled mineral wool for finishing facades - it has less thermal protection and shrinks, forming “cold bridges” over time. For finishing the building, it is better to use material in the form of dense slabs.

Stone mineral wool

Excellent technical characteristics plus a reasonable price ensured sufficient demand for this material. This type of mineral wool has low thermal conductivity, almost does not absorb moisture, and thanks to its cellular structure it is able to “breathe”, that is, allow air to pass through and condensate to escape.

Stone mineral wool

Depending on the type of raw materials and production method, it may have varying degrees of hardness. Stone wool is produced in the form of sheets, semi-rigid mats or high-strength slabs. Due to its high fire resistance and high degree of thermal insulation, it is widely used in construction - it is used as insulation and sound insulator for facades and roofs of buildings that have an increased risk of fire.

It is allowed to use stone wool to insulate underground communications, chimneys, and cladding rooms with installed stoves or boilers.

To avoid the appearance of “cold bridges” when using any type of slab insulation, all seams must be additionally taped.

Glass wool

Due to its low density and increased hygroscopicity, it is not recommended to be used for finishing facades. Plus, glass wool can melt under the influence of elevated temperatures, completely losing its thermal insulation properties.

Glass wool

This inexpensive rolled material is most often used for thermal insulation of pipelines and technical premises.

When working with it, special care is required - thin fibers break off and get on the skin, causing irritation. When inhaled into the lungs, small particles of glass wool can cause inflammation.

Basalt wool

This material is more expensive than ordinary stone wool, but it is more durable and voluminous. Another advantage is the lower degree of moisture absorption and shrinkage. Formaldehyde, which is part of basalt sheets, can repel rodents that often live in insulation.

They easily tolerate significant temperature changes without loss of quality, do not rot, and do not ignite. Their heat-insulating properties are also high.

Basalt wool

Basalt wool has a significant drawback - high fragility. Therefore, you need to work with it carefully, always wearing protective clothing, goggles and a respirator. The dust generated when sawing it causes irritation to the skin. It can also settle in the lungs.

Just as in the case of stone wool, for cladding facades it is better to use more durable slab material rather than rolled material. Basalt wool is also applied by spraying using a special technique - in this case, a special type of material is used in the form of granules.

Methods and procedures for wall insulation

It turns out that a change in the weather outside will provoke a change in the humidity inside. Moreover, the changes will be significant - condensation will form on the walls, which will not have the opportunity to dry. Hence a number of negative aspects, including the development of mold and mildew.

This is why it is so important to insulate walls from the outside. In total, there are 3 different technologies that are used to insulate capital structures. It seems reasonable to dwell on each of them in more detail.

Method No. 1 - well

This is one of the most ancient ways to insulate the walls of your home from the outside. Indeed, everything is logical: main load-bearing walls are built, and after that, retreating a little, they are lined with another row of bricks - for example, half a brick thick.

Between the main and external, let's call it decorative, walls, a void is formed - a “well”, which creates the effect of a thermos.

The distance from the decorative wall to the main one is adjusted using special connecting steel anchors, or a reinforcing mesh is laid. It covers the section of the well and simultaneously serves as reinforcement to strengthen the outer wall.

To avoid the creation of cold bridges from the decorative wall to the interior wall, anchors should be selected with the smallest possible cross-section or, in general, use a plastic mesh

In this case, dew will fall on the inner surface of the decorative wall. It is more thermally conductive than the air in the well, which, moreover, is heated by the internal load-bearing wall.

Thus, condensation will inevitably form on a wall cooled by a colder external environment. However, the presence of free space will allow the air inside the well to circulate and the condensate will evaporate again.

The distance between the load-bearing and decorative walls should not be too small because:

- firstly , this will increase heat transfer from the internal wall to the external one;

- and secondly , it will impede the convection of air inside, therefore the drying of the condensate will take longer.

Therefore, for normal air circulation, it is recommended to leave free space at least half a brick wide.

But be that as it may, in this case the insulation is carried out with air, and to many this seems insufficient.

The technology allows the additional use of any type of insulation, be it extruded polystyrene foam, polystyrene foam, polyurethane, polyurethane foam or mineral wool.

It is important not to make a mistake about which surface to attach this insulation to. Therefore, it is worth remembering that the insulating material must be attached exclusively to the internal, permanent wall. Next there should be an obligatory layer of air - a well, and then a decorative wall.

In this case, the temperature difference on the inner surface of the decorative wall will be less, because the air space in the layer will receive an order of magnitude less heat from the inner wall covered with insulator. This means that the volume of condensate falling on its surface will be less.

When using multilayer technology, expanded clay can be used as insulation, which is poured between the main and decorative walls

Well insulation technology for a private house implies the absence of blown ventilation in the air gap. That is, its own microclimate must be formed inside, which should not exchange moisture with the external environment.

Therefore, when constructing such a multilayer wall, special attention should be paid to ensure that no holes are formed in the decorative wall, for example, in masonry. After all, only the moisture contained in the blocked air will fall onto its inner surface.

And if gas exchange with the environment is present, then the amount of moisture will increase, which will ultimately lead to the insulation getting wet.

Method No. 2 - wet plaster

This technique is interesting due to two features: the problem of dew loss is solved on its own, and work on insulating the house from the outside is highly economical.

The algorithm of actions when using this technology of external thermal insulation in a house is as follows. Insulation boards are installed on the main walls from bottom to top.

If a decision is made to use expanded polystyrene or penoplex, then this insulation requires that the main wall be leveled beforehand and even puttied, or at least all cracks and crevices should be covered.

If the unevenness is left, the insulation will not be able to press tightly to the surface - there will be voids where moisture will begin to accumulate, mold and mildew will begin to grow, or insects will appear.

In order for the bottom layer to stand up straight, you initially need to install a stop strip on the wall as the bottom edge, no matter what material it is made of. Each insulation board must be attached to the wall with at least five clamps on dowels - 4 in the corners and 1 in the center.

Then, using an adhesive solution, a layer of reinforcing polymer mesh is attached to the insulation. First, the insulation boards are coated with epoxy glue, then the mesh is attached and a layer of glue is applied again.

Next, a layer of plaster is applied to the prepared surface - no more than 5 cm thick. These can be mixtures: cement or polymer-cement, cement-lime, silicate, based on epoxy resins. After drying, the plastered surface is painted.

Such a “layer cake” of insulation does not imply the presence of any voids inside, where air can be found in significant volumes, as, for example, in the “well” technology. Therefore, there is simply nowhere for dew to fall.

In addition to thermal insulation of the room, the technology of applying wet plaster is indispensable from an aesthetic point of view. For example, in cases where it is necessary to preserve the historical appearance of brick buildings.

The wet plaster technology is more labor-intensive, but there is no need to additionally load the foundation with another layer of brickwork

Method No. 3 - ventilated facades

The installation of ventilated facades allows not only to efficiently insulate the house from the outside, but also to give the building a completely different appearance. As a rule, artificial stone tiles of various textures, colors and shades are used, but even wooden lining can be used.

At its core, the technology of ventilated facades is very similar to well technology, but at the same time it has a number of significant differences. Let's look at the algorithm in more detail.

First of all, vertical metal guides are mounted on the insulated walls of the building. The pitch should be selected based on the width of the insulation slabs, which, in fact, will be attached in 5 places with holders on dowels to the walls between the guides. This needs to be done as tightly as possible.

It is necessary to ensure that no gaps or voids form between the main walls and the insulation slabs, for which the surface must be leveled and, if necessary, puttied

Then the outer surface of the insulation is covered with a vapor and moisture protective membrane, which can be an ordinary polyethylene film.

Why is this membrane not used in the case of well technology, but in the formation of ventilated facades it is in great demand - more on this below.

The height of the guides must be calculated in such a way that there is a gap of at least 8 cm from the membrane to the inner surface of the decorative panels. Decorative panels are attached to the guides using special clamps. The seams between them are not sealed at all.

In this case, dew will fall on the inside of the decorative panels. Moreover, there will be relatively a lot of it. This is explained by the fact that the façade is ventilated precisely through the numerous gaps between the panels.

Unlike well technology, due to the gaps between the cladding, the volume of air between the panels and the wall of the structure is constantly different. This means that along with new air comes new humidity.

It is precisely in order to protect the insulation layer from the destructive effects of high humidity levels that a vapor barrier membrane is required.

In well technology, when forming a decorative wall, it is required to retreat from the surface of the wall or insulation (if used) no less than half a brick - 12.5 cm. So why are the standards for ventilated facades lowered - only at least 8 cm of space is required?

The answer is ventilation intensity. In the well, condensate evaporation occurs due to convection in the internal cavity of the wall. And in the case of a ventilated facade, moisture is literally blown out by a draft formed by the external environment.

The technology of ventilated facades requires greater care and responsibility when performing all stages, from marking guides to installing decorative tile panels. As a result, the technology of all three listed is the most expensive, but with its help you can literally transform outdated, shabby buildings

Thermal panels

Facade thermal panels are ready-made systems consisting of two layers: thermal protection and facing. They do not require any additional finishing or painting. Polyurethane foam or polystyrene foam is often used as insulation.

The decorative layer is usually made of brick-like clinker tiles or colored marble chips. Recently, products with porcelain stoneware finishes have also been produced. Thermal panels can be mounted on any type of wall from concrete, brick to timber or cinder blocks.

Their technical characteristics and service life depend on the material of manufacture. Installation of such structures is simple - they are simply attached to profiles.

Facade thermal panels do not require additional finishing

Improved versions of thermal panels have a tongue-and-groove side fastening, which eliminates the appearance of cold bridges. Such panels do not require additional processing of the seams or filling them with mortar.

Through poorly insulated windows and doors, up to 20-30% of the heated air can escape from the house, so do not forget about careful finishing and plastering of the slopes. It is also necessary to think about the ventilation system - if it is installed incorrectly, up to 30-35% of the heat can be lost.

Reviews about different types of insulation

The rating of insulation for wooden houses is headed by TechnoNIKOL Rocklight basalt house insulation. Users note the ease of installation and a wide range of operating temperatures. Plus, this insulation is recognized by users as the best safe insulation.

Penoplex Comfort is recognized as the best insulation for walls and floors. Users note the possibility of self-installation of this material, as well as its good thermal insulation characteristics.

Users choose Bronya Nord as liquid thermal insulation for its durability, low consumption and low cost.

Thermal insulation plaster

This type of heat insulator is another novelty in the construction market. The main binder in it is lime or Portland cement. Various stabilizers and plasticizers are also added to them. But the main component (up to 40-75%) in heat-insulating plaster is porous insulation in the form of foamed perlite, vermiculite or foam balls.

A layer of such a mixture of only 50 mm is equal in its thermal insulation properties to a masonry of 2 bricks. Plus, you can use it, just like a regular one, to level walls and use it as a decorative finish. Moreover, it weighs 3-4 times less than ordinary plaster. Warm plaster can be used for ceilings, walls, window and door slopes, pipelines, as well as interior finishing work.

A layer of thermal insulation plaster

The technology for applying heat-insulating plaster is almost identical to the usual method - the mixture is distributed using a conventional spatula or mechanical sprayers. It adheres well to the surface, so a small layer can be applied even without a reinforcing mesh.

This material is able to “breathe”, allowing steam to pass through, and has sufficient water-repellent properties. Due to the absence of seams, warm plaster does not form cold bridges. In addition, it is non-flammable and can protect buildings from accidental fire.

Insulation from the inside, how to avoid condensation

When it is not possible to install thermal insulation from the outside, it is installed from the inside. The main task is to avoid the appearance of condensation and moisture that is harmful to materials. Why do water drops appear on the wall?

This occurs when cold material comes into contact with warm steam from the room. In order for the wall to remain dry, it must be insulated from steam penetration. To do this you need:

- use insulation with minimal vapor permeability, it is desirable that its value be lower than that of the wall; perform high-quality finishing from moisture-resistant plasterboard; use waterproofing fabric when installing insulation; reduce the humidity in the room using ventilation.

When choosing a material for thermal insulation, it is worth focusing on vapor-tight products: polystyrene foam, extruded polystyrene foam, polyurethane foam. It is possible to use mineral wool, but its installation will require a lot of effort:

- it is necessary to fix the waterproofing to the wall surface; make a frame from wooden blocks impregnated with an antiseptic, or a galvanized profile; lay mineral wool, preferably with a glued layer of foil; perform a vapor barrier; install plasterboard trim.

Penoplex, consisting of foamed polyethylene and aluminum foil, can be used as a vapor barrier material. The canvases are laid end-to-end and fastened with staples; at the joints they are taped with foil tape.

Polyurethane foam is a synthetic two-component composition sprayed onto the wall. It is moisture-resistant, vapor-tight, and creates a monolithic surface without cold bridges. Insulation is used for any surface and effectively resists energy loss. A layer of material 5 cm thick is considered effective.

From the side of the room it is closed with a plasterboard partition. The disadvantage of this method is the high cost of services for applying polyurethane foam. Polystyrene foam and extruded polystyrene foam are more often used than other insulation materials for thermal insulation of walls from the inside. The work is divided into several stages. Preparation of the surface, including removal of the old finish, cleaning and priming with an antifungal agent. On insulation boards, glue is applied over the entire surface, and not pointwise as on the outside. For better adhesion to the wall, the surface of the polystyrene foam is pierced with a needle roller. There must be enough glue thick to fill small irregularities. The slabs are pressed tightly against the wall.

The installation is carried out end-to-end. After the glue has dried, after 3-4 days, the fastening is reinforced with umbrella dowels. The joints of the plates are treated with polyurethane foam. Using glue, a reinforcing mesh is attached to the surface of the insulation. Plaster is applied over the dried layer. Having compared the two methods, we can confidently say that external insulation is more appropriate. It significantly reduces heat loss and protects the walls of the house from premature destruction.

https://youtube.com/watch?v=6KlLQrO5-IUrel%3D0%26controls%3D0%26showinfo%3D0

- shop.rockwool.ru

- dachnoe-delo.ru

- remontami.ru

Penoizol

Liquid carbamide foam plastic (penoizol) is convenient because it can be poured directly at a construction site. It perfectly fills all irregularities and voids without expanding in volume. However, it is possible to obtain a high-quality coating without cracks only at temperatures up to +5°C.

Working in the cold with it is strictly prohibited.

Carbamide foam is also produced in the form of slabs or crumbs, called thermal wool, blown into hollow frames. The absence of seams is the most important advantage of the material. It is used to insulate walls, attics, roof spaces or as a layer in brick walls.

Thermal insulation with foam insulation

In terms of service life, it exceeds conventional foam plastic or extruded polystyrene foam - the service life can be up to 80 years. Builders often complain about its low strength, but this is due to the use of penoizol of insufficient density. The improved material is not inferior in strength to flexible and dense polystyrene foam.

The porous structure of carbamide foam allows for good vapor removal. However, due to its ability to absorb liquid, it requires moisture protection. Not only film followed by finishing with durable panels, but also cement-sand plaster can serve as waterproofing.

The better way to insulate a house from the outside, depending on the wall material

What is the best way to insulate a house from the outside so that heat does not escape from it? And you can insulate it from the outside with special raw materials. There are a large number of materials that can cope with this task. Insulation for the external walls of a house differs from those used inside, and there are several varieties that are considered the main and most popular, for example, polystyrene foam, basalt wool, glass wool, extruded polystyrene foam, mineral wool.

Insulating walls with plaster is considered relatively cheap, but also quite ineffective. Wooden houses and country houses are often insulated by installing a double frame. To do this, any of the listed insulation is fixed to the surface, and a cladding is made on top. This method allows you to maintain an “air cushion” for free air movement.

You can insulate a house from the outside with your own hands, if you have certain knowledge and skills.

Liquid polyurethane foam

Application of liquid polyurethane foam

This material is produced using two components: a polyol and a polyisocyanate. The release of carbon dioxide during their interaction makes it possible to obtain surfaces with a foam structure.

Polyurethane foam is available in two modifications:

- with closed voids: has better strength and heat-insulating characteristics, but removes moisture from the walls worse; it, like slab polyurethane, is best used for insulating foundations

- with open voids: widely used for finishing walls, roofs, attics, especially inclined structures

Liquid polyurethane foam is more expensive than penoizol, but has better technical characteristics. It is more durable and elastic, absorbs less moisture. According to manufacturers, this heat insulator, subject to application technology and proper operation, can last up to 50 years.

The disadvantages of liquid polyurethane foam include poor resistance to ultraviolet radiation - surfaces filled with it cannot be left open for a long time. It also does not adhere well to cold walls, so it is necessary to work with it only at positive temperatures. Just like sheet polyurethane foam, the material is flammable and therefore requires additional protection.

Basic principles of internal thermal insulation

The correct choice of thermal conductivity of insulation makes work on internal insulation as effective as creating an external thermal layer, provided that the heat barrier is correctly placed.

Not every heat-insulating material is suitable for insulating a house from the inside. It must meet certain properties to achieve the assigned tasks:

- Low permeability.

- No secretions harmful to human health.

- Waterproof.

- Ability to maintain configuration under mechanical loads.

It is important to know! The vapor permeability of insulating materials should decrease, that is, the insulation must provide more reliable protection for vapor than a wall. This purpose guarantees the free exit of moist air through the thickness of the wall to the outside.

To avoid problems with insulation from the inside, first of all, you need to determine the location of the dew point. Its correct position should be in the wall or insulation, but not at the junction between them.

Changing the location of the dew point

If this happens, then the accumulation of moisture and, as a result, rot, mold and mildew on the surface is inevitable. This situation is possible due to the large thickness of the insulation, since the wall is completely insulated from internal heat.

This also happens as a result of low vapor permeability. Walls made of brick and concrete are especially susceptible to this phenomenon. In this regard, internal thermal insulation in such houses is justified only in non-alternative options.

But in buildings made of timber or logs, such a layer of insulation is quite acceptable; you just need to maintain a gap between the wall and the insulation. Therefore, in order to meet all the requirements for internal insulation, you must first make a frame on the wall from a vertically located beam along the width of the insulation size.

Then a waterproofing film is spread and secured along the wall and insulation material is placed between the slats. It, in turn, is fixed with transverse strips and then a vapor barrier film is stretched on top.

With internal wall insulation, such a “pie” is created

Granular thermal insulators

This group of thermal insulators includes expanded clay, perlite and vermiculite, which have the form of granules filled with air. In the first case, the cellular structure is obtained by swelling of low-melting clay. Perlite granules are obtained by heat treatment of rocks of volcanic origin.

Vermiculite is a thermal insulating bulk material with a cellular structure, the production of which uses mica (volcanic glass). The advantages of granular materials include high sound and heat insulation properties, environmental safety, and frost resistance. Such bulk materials are used mainly for insulating floors and ceilings.

When using expanded clay, it is recommended to use three types of fractions - granules ranging in size from 0.5 (the smallest), 0.2 and 0.4 cm. In this case, cold air layers will not form between the granules.

Roof insulation with expanded clay

Vermiculite is more expensive than expanded clay, but has higher thermal insulation properties compared to other materials . Moreover, even when moisture is absorbed, they hardly change. After drying, it completely restores its properties.

Vermiculite has less weight than expanded clay, which is important when insulating roof slabs . Since its granules are very small, a much smaller layer of backfill is required to create a reliable layer of thermal protection.

The main disadvantage of all granular heat insulators is the need to use reliable waterproofing, because they have a high degree of water absorption. Since such materials are prone to dust formation, they are used indoors only in screeds.

For example, perlite, like vermiculite, does not lose its properties after absorbing water. However, since it is capable of absorbing up to 300% of liquid (in this perlite is seriously inferior to expanded clay and permiculite), its weight increases many times over.

Comparison of perlite and vermiculite

According to the author of this video, not all house structures need insulation. In his video, he gives a detailed description of heat transfer methods and talks about the main mistakes that arise when installing insulation.

Insulation of the house

Types of materials and selection criteria

There are several types of insulation that are suitable for indoor use. But to know which insulation is best to use, you first need to be guided by their performance characteristics:

- Thermal conductivity;

- Vapor permeability;

- Environmental cleanliness;

- Durability;

- Sound insulation level;

- Fire resistance;

- Ability to maintain original dimensions throughout the entire service life.

The best polystyrene foam insulation

Technicol XPS Technoplex

Brand of a Russian manufacturer, ranked first in its category. The packaging is in a memorable white and green color. The material is produced in the form of slabs with a thickness of 20 to 100 mm; according to the craftsmen, this allows you to select the optimal cross-section for different parts of the house. Technicol XPS Technoplex insulation is quite suitable for the bathroom, as well as in the kitchen, because it is capable of transmitting steam with a coefficient of 0.01 mg/(mchPa). At the same time, the surface does not absorb water, preventing the development of fungus. It has a compressive strength of 0.1 MPa at 10% deformation.

Technicol XPS Technoplex

Thus, the material will bear any load and will allow the floors to be insulated along the joists. Also, if you want to make warm floors in your house, then insulation will do the job perfectly when laying pipes or cables. This effect was achieved by adding nanocarbon, with a characteristic light gray tint. Therefore, this brand is one of the best insulation materials for your home.

ADVANTAGES:

- wide range of thickness from 20 to 100 mm;

- low thermal conductivity 0.032 W/(m*K);

- L-shaped edge for easy installation under structures;

- almost does not absorb water (0.1%); high vibration resistance.

FLAWS :

- high price;

- the substance burns and smokes heavily;

- produced only in slabs.

Which insulation for home is better?

The choice of material depends on what kind of coating you are going to insulate. Since one thing is suitable for walls, another for a field, and a third for pipes. It is also important to take into account the location factor: where the insulation will be used - indoors or outdoors.

Types of insulation

The next step, when determining which insulation for your home is best, is to choose which types have the properties you need:

- mineral ones are environmentally friendly and non-flammable;

- extruded polystyrene retains its properties in conditions of high humidity;

- liquid insulation is an innovative material that increases fire safety and allows you to experiment with design;

- Foamed polyethylene can withstand high compressive loads, is chemically resistant, and has good sound insulation qualities.

Choosing insulation for your home is a crucial step and depends on many factors.

Ways to insulate a cold attic: 10 popular and effective materials

Technical characteristics of insulation (1-10)

In addition, the technical characteristics of the material are taken into account:

- soundproofing properties;

- lowest thermal conductivity coefficient;

- fastening method;

- vapor permeability. Insulation materials are divided into vapor-permeable and impermeable. The value of the former ranges from 0.1 to 0.7 mg/(m.h.Pa)

- shrinkage. Over time, a number of insulation materials lose volume or shape under the influence of their own weight. This requires more frequent fixation points during installation (partitions, clamping strips) or use them only in a horizontal position.

- mass and density. Density indicates insulating properties. The value varies from 11 to 220 kg/m3. The higher it is, the better. But there is one proportion: the greater the density of the insulation, the correspondingly greater its weight, which must be taken into account when loading building structures.

- water absorption (hygroscopicity). If the insulation is exposed to direct water (accidental spillage on the floor, roof leakage), it can either withstand this without harm, or become deformed and deteriorate. There are materials that absorb water from 0.095 to 1.7% by weight in 24 hours, and those that do not.

- Operating temperature range. The insulation placed next to the fireplace or roof or directly behind the heating boiler must be resistant to withstanding elevated temperatures while maintaining the properties of the material. The value of some varies from -60 to +400 degrees, while others reach -180...+1000 degrees.

- flammability. Insulation materials for the home are: non-flammable, low-flammable and highly flammable. What affects the protection of a building in the event of an accidental fire or intentional arson.

- thickness. The cross-section of the layer or roll insulation can be from 10 to 200 mm. This affects how much space will need to be allocated in the structure for its placement.

Technical characteristics of insulation (11-14)

- durability. Some insulation materials last up to 50 years, others only up to 20.

- ease of installation. For soft materials, the cut of the insulation can be cut with a small margin and they will tightly fill the niche in the wall or floor. While for solid insulation the pattern must be exactly the same size so as not to leave “cold bridges”.

- environmental friendliness. Implies the ability to release vapors into the living space during operation. Often these are binder resins (of natural origin), that is, most of the materials are environmentally friendly. But during installation, some types can create an abundant dust cloud, harmful to the respiratory system, and prick your hands if you do not wear protective gloves.

- chemical resistance. Using it you can determine whether it is worth laying plaster over the insulation and painting the surface. Some species are completely stable, others lose from 6 to 24% of their weight when in contact with alkalis or an acidic environment.

When determining which insulation is best for your home, it is a good idea to consult with specialists. Because a competent choice of thermal insulation material requires a certain skill and knowledge. Therefore, the easiest way is to find suitable insulation on specialized forums on the Internet (in sections where everything for insulating a house is discussed). There are also consultants in construction companies and stores.

In the tables below you can compare the types of thermal insulation materials:

Table N1. Comparison of types of thermal insulation materials

Table N2. Comparison of types of thermal insulation materials

Selecting insulation for walls based on the origin of raw materials

ISOVER is the only manufacturer in Russia that produces both types of insulation.

Quartz

Quartz-based wall insulation is one of the most modern and high-quality thermal insulation materials. At ISOVER factories it is made from quartz melt using crimpling - corrugating the structure - resulting in products with increased strength characteristics. And the innovative TEL technology will make it possible to obtain long and especially elastic fibers, which during the production process are placed into slabs and rolls in a chaotic manner. As a result, the material for quartz walls is particularly light, performs the functions of heat and sound insulation better than others, and today is successfully used in both professional and private construction.

Basalt

Basalt wool is a classic solution for thermal insulation. It is made from rock – basalt – at a temperature of 1500 °C. This is a reliable and durable material for walls, roofing and technical communications; it has been used for decades. For walls, basalt insulation acts as heat and sound protection, and increased fire safety makes stone wool in demand in all segments of construction - from residential to office and industrial. Basalt-based insulation is easy to work with, and buildings in which basalt wool is used are safe and efficient to operate.

What should be insulated?

If you look at the thermal imager, we will notice that the roofs of houses, especially during periods of snow melting, produce large heat losses in the attic.

Let's remember the elementary rule of physics: warm air goes up, cold air goes down. Therefore, it is recommended to insulate floors and walls, especially if the building does not have a base and it stands on the ground.

Windows also bring large heat losses if they are not foamed.

Calculation of house insulation. Thermal insulation calculator

In countries with harsh climates, maximum attention is paid to heat conservation issues. Therefore, before starting to insulate a house, it is necessary to choose the right insulation and correctly calculate its thickness.

Thermal insulation calculations can be performed in several ways. The easiest and most reliable way to use an online calculator, which can be found on thematic Internet resources. He will take into account all the nuances, starting with the material from which the walls and other structural elements of the house are made, and ending with the climatic features of the region. The thermal insulation calculator will determine not only the required thickness of the insulation, but also select the optimal brand and even calculate the required amount of material.

You can also calculate the insulation using formulas. The fact is that each building material has its own thermal conductivity index. It is determined by the manufacturer during laboratory tests. Materials that conduct heat well are characterized by low thermal resistance. For insulation, insulators are chosen that have minimal thermal conductivity and maximum thermal resistance. You can find out the characteristics of the building material in the document called SNiP No. 2-3-79. Then you should apply a special formula and use it to determine the required thickness of the heat insulator. This is not so easy to do, so it is better to use a special online calculator.

Selecting insulation for walls according to functional purpose.

Thermal insulation from inside the house.

Wall insulation is installed both outside and inside the building. High-quality thermal insulation can be carried out in both cases, however, experts recommend giving preference to the external insulation option. When thermal insulation is located internally, during periods of negative temperatures both the external enclosing structure and partly the insulating material itself freezes. In addition, conditions arise for the formation of condensation at the boundary between the thermal insulation and the load-bearing wall. Difficulties arise when isolating joints between floors and external enclosing structures - “cold bridges” form at the joints. If, for some reason, it is possible to insulate a house only from the inside, it is necessary to calculate the annual balance of moisture accumulation. And also provide effective ventilation in the rooms and additional vapor barrier between the gypsum building board and the insulation.

Thermal insulation outside the house.

When the insulation is installed from the street side, temperature changes in the wall occur slowly and gradually, and the coldest point is located in the outer layers of the external thermal insulation. In such a wall sandwich, the hard and dense layers face inward, and the soft, porous layers face outward. This improves convection and natural vapor exchange, preventing moisture from accumulating in the thickness of the walls. Additionally, you can insulate the facade with a membrane from rain and snow, then, thanks to the protection of the insulation with a material with hydrophobic properties, the entire structure will retain its characteristics even better. The method of external cladding with thermal insulation material or, in other words, insulating the house along the facades is the best choice for residential buildings.

Ceiling

Heat loss from the ceiling in cold weather is about 10 percent. Not much, but noticeable. When choosing materials, it is worth choosing environmentally friendly materials that, in the event of a fire, would not emit choking smoke.

Recommended materials are ecowool, mineral wool, different types of films. All of them are not expensive, but are highly effective.

The best basalt insulation

Rockwool

Among basalt insulation, this insulation clearly takes first place in the rating. The product of the Danish company for the home looks like cotton wool and is available in rolls and slabs; when installed on joists or when embedded in walls, this creates additional convenience. The material is applicable for both internal and external insulation of the house. Thickness for any choice: from 50 to 100 mm with a density of 37 kg/m3. In addition, stone wool is a non-flammable material, so it can be laid in a residential building without fear.

Rockwool made from basalt insulation is in first place in the ranking

According to the experts in the reviews, you can buy such cotton wool in various packaging, 6-12 sheets per package, so for different scales of insulation you can choose the appropriate volume. Suitable for all building materials. Cotton wool fibers can withstand temperatures up to 1000 degrees, so even the walls of a fireplace can be lined with it. Experts also appreciate this insulation for its new Flexi technology. It means that one of the edges of the sheet is springy and further expands after installation. This edge is specially marked by manufacturers and improves the tightness of the installation, which is why the product was included in the rating of the best.

ADVANTAGES:

- does not crumble during installation;

- excellent sound insulation;

- easy to install;

- has low weight with a density of 37 kg/m3.

FLAWS:

- if the material gets on the body it causes itching;

- thermal conductivity increases when wet;

- absorbs water up to 1 kg per m2;

- requires more supports when installed vertically.

Hotrock Smart

A worthy second place in the ranking goes to the product of a Russian manufacturer. Hotrock Smart insulation is available in the form of slabs 50-100 mm thick, its thermal conductivity is 0.036 W/(m*K). Since no more than 2.5% organic substances (resins) were used in the production of this insulation, no harmful odors are emitted in the house during operation. An insulating layer with a fire retardant system is perfect as a fire barrier in metal doors.

A balanced combination of price and quality, a guaranteed service life of insulation in the house of up to 50 years - all this makes Hotrock Smart a favorite among the best. In addition, basalt slabs are produced using German equipment, and a new furnace is used to melt the rock. The material also has a compressibility of up to 50%, versus 30% for others, due to this the masonry is more dense and the insulating layer takes up less space in the room.

ADVANTAGES:

- light weight - with dimensions of 1200x600 mm, the slab weighs less than a kilogram;

- completely non-flammable;

- low thermal conductivity;

- certificates (3 pieces) for safety in Russia;

- Suitable for cold attics, pitched roofs and floor insulation.

FLAWS:

- water absorption 1.5%;

- loss of shape without proper fixation;

- density 22 kg/m3 loses to competitors;

- not recommended for house walls.