The heating system cannot be called an engineering communication, which is simple in design and balancing. Each of its components performs a specific function, and the absence of any element can lead to interruptions in the operation of heating equipment, as well as to a significant decrease in its energy efficiency. In our project “A HOUSE IN A YEAR” you can see how we made the heating system. In this article, among other things, we will understand the basic principles of balancing a heating system with the help of specialists from the GRUNDFOS company.

As for balancing: it ensures stable operation of the system and guarantees compliance with the specified temperature regime in all heated rooms.

Having a professional design for the heating system is the key to its effective functioning. For those who are not going to spend time and money on heating design, we will give several recommendations on its creation and proper configuration.

In this article we will consider the following questions:

- What elements should be included in the piping of simple and multi-circuit heating systems.

- Installation rules and sequence of arrangement of the main elements of the harness.

- What functions should a modern circulation pump have?

- How can you balance your home heating system?

The listed topics will be discussed using the example of closed heating systems. After all, they have complex piping and a large number of elements that make it possible to ensure a stable thermal regime in the room.

Wiring of simple heating systems

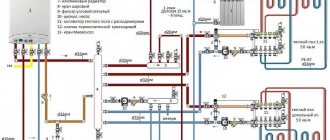

The piping of a heating boiler is usually called all the elements of the system that are installed between the boiler and the heating circuits (meaning radiator and underfloor heating circuits, as well as hot water supply circuits).

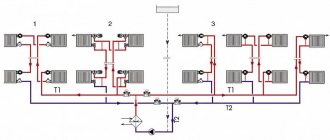

A heating system can be called simple if it contains one direct circuit. A direct circuit means a line into which coolant is supplied from the boiler without changing the initial temperature. Some radiator heating systems are simple. They can be single-pipe, double-pipe or mixed. The most practical type of simple radiator heating is a two-pipe system based on a supply and return line.

And if its balancing is done correctly, such a system will ensure uniform heating of the radiators along the entire heating perimeter.

Evgeniy Kruchinin Engineer of the Household Equipment Department of GRUNDFOS LLC

An unbalanced heating system will make itself felt almost immediately. Pipes will make noise due to suboptimal flow rates, rooms will be either too hot or too cold, and heating bills will be 20% higher every time.

Let's consider the main elements of the system and their functions.

Heats by steam

The operating principle is similar to water heating. But instead of water, steam passes through the pipes. This type of heating was extremely popular just a few decades ago. But now they hardly use it. First of all, due to the high risk during operation. Heating devices used in this scheme become very hot. In case of accidents of steam equipment, people nearby receive severe burns.

Expansion tank

A closed expansion tank is a tank equipped with a rubber membrane that divides the device into two parts (the lower half contains the coolant, and the upper half contains inert gas). When the temperature in the heating system increases, part of the coolant enters it, thereby smoothing out the pressure difference in the supply and return lines.

The expansion tank is built into the return line in front of the circulation pump (if the pump is placed in front of the tank, it will constantly pump coolant into the expansion chamber).

The tank can be installed in close proximity to the heating boiler. Additional shut-off valves (ball valve) installed in front of the tank entrance will make it easy to disconnect the tank from the system if there is a need to repair or replace it.

Autonomous water supply

Let's start by getting acquainted with devices that can provide the house with water from an autonomous source.

Submersible pump

Varieties:

| Image | Description |

| A diaphragm (vibration) pump operates due to cyclic oscillations of an elastic membrane driven by a solenoid. Water transportation is ensured by a system of check valves. The advantage of the solution is the low price, the disadvantages are the limited service life of the membrane (it has to be changed every two years) and silting of the well/well due to vibration of the pump housing. |

| A vortex centrifugal pump with one working chamber creates a pressure of up to 100-130 meters due to the minimum gap between the chamber and the impeller. The size of the gap makes the pump sensitive to the amount of suspended matter in the water. |

| Multistage pumps do not have this disadvantage. They create a pressure of up to 300 meters due to the serial connection of the working chambers with impellers on a common electric motor shaft. |

Functions: All types of submersible pumps are designed to lift water from underground sources. The distance from the ground surface to the water surface is determined only by the characteristics of the pump.

Connection:

- A check valve is installed at the outlet pipe of the device, making the movement of water in the water supply inlet unidirectional;

- An inlet or any section of the water supply system inside the house is equipped with a membrane hydraulic accumulator, which acts as a damper smoothing out pressure surges and allows the pump to idle with low water flow;

- The pump is powered by a mechanical or electronic pressure switch.

Water supply with submersible pump

Surface pump

All surface pumps used in water supply are centrifugal, with one impeller on a common shaft with an electric motor. The advantage of a surface pump over a submersible pump is ease of maintenance and repair, the disadvantage is a higher noise level during operation.

- Functions: supplying water to the internal water supply from sources with a shallow water surface depth.

- Comment: the suction depth of a surface pump is limited by atmospheric pressure at 8-9 meters. The limitation is successfully avoided by pumps with an external ejector immersed in a well or well - an open nozzle, to which water is supplied through a pressure pipe. The flow of water from the nozzle carries the surrounding water masses into the suction pipe.

Diagram of operation of a surface pump with an external ejector

- Connection: the piping is completely identical to that used for a submersible pump. The inlet pipe is equipped with a rigid suction pipe. A check valve (usually with a screen to keep out debris) is mounted on the submerged end.

Pumping station

Under this name appears a ready-made solution for water supply to a building - a surface pump with an automatic relay and a membrane tank. The station is connected directly to the internal water supply and is equipped with a suction pipe with a bottom valve.

Pumping station in the backup water supply system

Please note: using a pumping station, you can provide uninterrupted water supply to your home from a container. To do this, the pump inlet pipe is connected to a tap into the tank and is equipped with a check valve.

Connecting the pumping station to the reserve tank

Hydraulic accumulator

A membrane HA is a steel tank with a pear-shaped elastic membrane in it. The membrane divides the accumulator into air and water compartments. The air compartment is equipped with a nipple for inflation, and the water compartment is equipped with a pipe for connecting to the water supply.

Vertical accumulator

Functions:

- Creating a water supply;

- Combating water hammer that occurs when the state of shut-off valves quickly changes (for example, when a ball valve closes or opens);

- Smoothing out pressure surges when turning the pump on/off.

Connection: to any water supply point. At the inlet before inserting the membrane tank there must be a check valve, without which air pressure will force the water back into the container, well or well.

Pressure switch

Varieties: mechanical and electronic (with piezoresistive sensor).

Mechanical relay

Functions: turning the pump on and off depending on the pressure in the internal water supply and accumulator.

Connection: monoblock relays are mounted at the input near the membrane tank. An electronic relay with an external pressure sensor can be installed at a certain distance from it, limited by the length of the wire. The relay breaks the zero and phase power lines of the pump.

Check valve

Varieties: water supply and heating equipment uses ball and spring check valves. In the first, the role of the shutter is performed by a brass or cast iron ball, in the second - by a brass or plastic barrel with a return spring.

In the photo - spring valve DN 25

Functions: blocking the counterflow of water in the piping of pumps, hydraulic accumulators and boilers.

Installation: into a water pipe break. An arrow on the valve body indicates the direction of water flow.

Security group

The security group consists of three elements connected in series or to one housing:

- An emergency safety valve that allows you to discharge excess coolant when the pressure in the system increases. The discharge can be placed in a transparent container (for example, a plastic bottle). This will make the device safer and will notify you that an emergency has occurred (even if no one was home).

- Automatic air vent - removes air from the coolant, which, if present in the heating system, can render it inoperative.

- Pressure gauge - allows you to visually monitor the coolant pressure in the supply line.

The safety group crashes into the supply line immediately at the outlet of the heating boiler. This is done in order to primarily protect the boiler, which has the highest temperature.

If it is possible to install protection directly on the boiler body, then this feature of the heating device should be used.

The safety group is installed strictly vertically, and it must be located above the level of the heating boiler.

There should be no shut-off valves between the safety group and the boiler. After all, if you accidentally close the tap, thereby isolating the protection from the rest of the heating, you can cause a rupture of the boiler or other elements of the system.

Evgeniy FORUMHOUSE user

Ignorance, inattention, haste, fatigue and other human factors can lead to accidents. For example, I changed the pressure gauge, but forgot to turn the tap, etc.

An additional automatic air release valve should be installed at the highest point of the system. Air will definitely enter the system during its refueling (refueling), and this device will help stabilize the operation of the system, avoid stagnation of the coolant due to air accumulation and extend the life of the circulation pump.

krim FORUMHOUSE user

We install the air vent at the top point of the system. It doesn't have to be on the security group.

Need pipes

This component is an integral part of the heating system, requiring considerable investment. Pipes are distinguished by diameter and material of manufacture.

Until recently, there was little choice. All utility networks were laid with metal pipes (steel or galvanized iron). They were also used in private housing construction. Steel pipes are connected to each other by welding. Over time, these seams begin to leak water. In particularly cold winters, the steel system freezes and fails.

Galvanized pipes are much more reliable and have a threaded connection. Copper pipes are distinguished by their high durability and high price. They are not subject to corrosion, withstand high pressure well, and are connected by soldering. But, despite their advantages, they are rarely used due to price.

The modern choice of consumers, attractive for their cost-effectiveness and ease of installation, remains with pipes made of various plastics (metal-plastic, polypropylene, polyethylene). They are not expensive and do not require special knowledge during installation. Other attractive properties include: small diameter and weight, not susceptible to corrosion or clogging.

The welding method is hot pressing, which is easy to learn. The disadvantage of metal-plastic is its short service life.

After a couple of years, pipes made from this material begin to leak. The new generation metal-polymer pipe has a flexible structure, which is an advantage for installation in hard-to-reach places.

The required pipe footage depends on the heating area, the thermal insulation of the building, and the connection diagram (one or two pipe system). Pipes are laid along or inside walls and floors, at such a height so as not to damage them when fastening baseboards.

System recharge

Closed-type heating systems are equipped with outlets for recharging the circuit with coolant. If water is used as the coolant, the return heating circuit can be connected directly to the water supply. The replenishment will be done through shut-off valves and a mud filter (a softener filter will also be useful here).

A pressure gauge will help track the pressure difference in the forward and return lines.

If antifreeze is used as a coolant, then a special branch is made in the circuit for pumping antifreeze. Also, do not forget about the coolant drain taps, which cut into the lowest point of the system.

Radiator control and shut-off valves

Heating radiators are equipped with half-turn ball valves, which allow you to completely shut off or, conversely, open the coolant supply to the radiator. Taps are placed at the entrance to the device. Sometimes thermostatic radiator valves (without presetting) are used instead, which automatically shut off the coolant supply when the room temperature exceeds the set values.

The listed devices cannot be used to balance the system. Balancing valves (valves) and thermostatic valves with presetting serve these purposes.

Filters

Mud filters are essential elements of modern heating systems. When installing mud filters, it is important to take into account the rules for their installation, since it is during installation that mistakes are often made. It is also important to remember to clean them from time to time. Sometimes it is enough to install one dirt filter into a closed heating system. It is installed on the section of the main line through which all the coolant passes. Such a place could be, for example, the area in front of the main circulation pump.

Basic rules for installing mud filters:

- It is preferable to install the filter on horizontal sections of the pipeline.

- When installing the filter, it is important to ensure that the direction of movement of the coolant coincides with the marks marked on the body of the device.

- The tap branch, equipped with a screen, nut (or drain cock), should be located at the bottom.

- The dirt filter must be installed in a place that is easily accessible for maintenance.

- Shut-off valves (half-turn valves) should be installed at the inlet to the filter, as well as at the outlet.

How to make a choice

The following brief overview allows you to understand the difficulties encountered when creating a heating system. There are many recommendations and reviews describing the merits of this or that element, but do not forget that heating a house is a difficult task, and if you do it incorrectly, it will be you, and not the authors of the reviews, who will freeze in the cold. Therefore, when designing a heating system, it is necessary to use the services of specialists who have been involved in this matter for a long time.

Well, any reviews should be assessed precisely as reference material that allows you to better understand the tasks at hand.

The equipment used to create heating cannot be considered in isolation from the system itself. It is the principles of its operation, type and construction options that mainly determine what equipment needs to be used.

Piping a multi-circuit heating system

If the heating system has two or more circuits (we are talking about systems with heated floors, with an indirect heating boiler, etc.), in addition to the main pump, each circuit is equipped with a separate circulation pump and additional shut-off valves.

Heating circuits that require temperature control are equipped with the devices presented below.

Automatic faucets

Three-way mixing valves are devices that allow you to automatically reduce/regulate the temperature in the supply line by mixing cooled coolant from the return line into it. The fact is that the boiler sends coolant with the same temperature to all heating circuits. At the same time, heated floors have strict requirements for maintaining temperature conditions, and the temperature in the heating radiator circuit is usually higher than in the heated floor circuit. Mixing valves allow all circuits of the system to reach the desired temperature.

Two-pipe scheme

Has no disadvantages as described above. Here, hot water moves through one pipe, and cooled water returns to the boiler through the other. Both pipes are connected to each battery. The thermostat makes it possible to supply as much heat to the room as you want.

However, the increased pipe consumption with this option makes it quite expensive. Pipes are connected to radiators in a vertical, horizontal and diagonal way.

Collectors

The collector groups separate the main heating circuits, as well as individual circuits of the underfloor heating system.

This is what a heated floor manifold assembly with a three-way mixing valve looks like.

In addition to the above cases, collector units are used in radiant heating systems.

A lot of controversy arises about where to install circulation pumps in collector systems, as well as in simple heating systems - on the supply or return? Here's what experts say about this.

Evgeniy Kruchinin

By and large, it makes no difference where the circulation pump is installed - in the supply or in the return. It is important that the pump is easy to maintain - this is perhaps the main criterion for choosing an installation location. An exception is the case when the temperature of the coolant in the heating system may exceed the maximum temperature for which the circulation pump is designed. In this case, it is recommended to install the pump on the return line, where the coolant temperature is lower.

Multi-circuit heating is a cumbersome engineering communication with many elements that must be correctly calculated, installed and combined into a single system.

In order to make the piping scheme simpler, more reliable and aesthetically pleasing, experts recommend using pump groups (quick installation groups), which are completely ready for installation and are sold already assembled. They include circulation pumps and piping elements that may be needed in one case or another.

Pump groups can be used as part of simple and complex heating systems.

Evgeniy Kruchinin

Pumping groups are easy to install and operate. All strapping elements included in the quick installation group have already been selected according to their characteristics and assembled into a single structure. Moreover, each pump group produced is necessarily tested by pressure testing at the factory, which makes it a much more reliable solution than pump piping assembled “from scratch” from the market. This greatly simplifies life for both installers and residents. In addition, compact pumping groups, having an aesthetic appearance, fit perfectly into the interior of a modern boiler room.

Infrared radiation in service

The action of long-wave rays is similar to sunlight. Devices operating on their basis consume much less electricity than all other types of heaters. The infrared heating panel is mounted to the ceiling.

The main thing when using this system is to carry out the electrical wiring correctly. Often such panels are used as an additional means of heating a home.

Balancing the heating system

An important step towards effective balancing is the correct choice of circulation pump. For example, circulation pumps that have the function of automatically adjusting pressure and flow will constantly regulate the pressure difference between the supply line and the return line. Thanks to this, there is no need to integrate additional piping elements into the system (bypass valves, differential pressure regulators, bypasses connecting the supply to the return, etc.).

Most often, balancing heating systems is carried out in three ways:

- Calculated – takes into account the design coolant flow in each section of the system.

- Balancing based on the actual temperature of heating devices (radiators, underfloor heating circuits, etc.).

- Electronic balancing is the most accurate way to ensure the system is set up correctly the first time. This is done using a special mobile application, shut-off valves and adjustment functions built into the circulation pump.

Before starting balancing, it is necessary to check and clean all dirt filters built into the heating system, and also make sure that there is no air in the system.

Heat pumps

A fairly new solution on the market of modern, economical heating systems. Our land is, in fact, a free source of thermal energy. All that remains is to figure out how to do it. To do this, they came up with a new heating solution - a heat pump.

Geothermal energy has long been successfully used for heating homes in foreign countries. Such equipment goes well with the “warm floor” system and helps save on utility bills. The heating design includes several components:

- heat collection probe (standard coil);

- heat pump (thermal energy extraction);

- heating system with a heat exchange chamber.

The main types of installations are: “water-to-air”, “air-to-air”, “water-to-water”, “ground-to-water” and “air-to-water”. The last option belongs to the budget category, which does not require too expensive excavation work. The minimum payback period for such equipment is five years.

The use of a heat pump with fan coils provides a comfortable microclimate in private households using one piece of equipment all year round. The combination of a heat exchanger and a fan with pumping equipment can be supplemented with special filters, remote or built-in control panels.

The conversion coefficient of such devices can reach a value of 1 to 6. That is, by spending 1 kW of electricity you can get 6 kW of thermal energy.

Balancing according to design calculations

The easiest way is to balance the system using the data specified in the heating project. The essence of balancing, regardless of the chosen method, comes down to setting the required coolant flow in various parts of the system. The flow is regulated using balancing valves or thermostatic valves with presetting.

The balancing valve has its own gradation. In this case, the different positions of the control valve correspond to a certain volume of coolant that is capable of passing through the device per unit time at a given pressure.

If you have a project for a heating system, you can properly balance it quite simply: by setting the coolant flow rate in accordance with existing calculations.

Evgeniy Kruchinin

But it is important to take into account the fact that often design calculations differ from the actual parameters of the heating system. For example, the hydraulic resistance of a heating circuit can be easily changed by adding or removing an element from the system. But, in general, a good and correct project is a rarity for private houses.

Therefore, even if there is a project, the balancing methods presented below do not lose their relevance.

When choosing a solid fuel boiler for your dacha, consider the following aspects:

- what rate of heating of the room suits you;

- what is the duration of operation of the boiler with a single filling;

- Is it possible to connect a hot water system to the boiler?

- what is the fuel consumption;

- Is it convenient and practical to operate the equipment in country living conditions?

As a rule, the most common boiler connection schemes are used, with forced and natural circulation.

Most modern models produced by domestic and foreign companies are compact and economical products. The units are specially designed for quick heating of residential premises in field conditions, if you can say so about a dacha. In terms of price-quality ratio, foreign models look preferable to domestic products. In terms of functionality, solid fuel boilers for dachas can vary greatly, depending on the chosen model.

Temperature balancing

To balance the system by temperature, we will need the already familiar balancing valves (or thermal heads with presetting) and an electronic thermometer for non-contact measurement of surface temperature.

Balancing begins with the balancing valves on the last and penultimate radiator being fully opened. The coolant flow rate on the first, as well as on subsequent radiators from the boiler, is set to minimum values (with an increase in flow rate as the radiators move away from the boiler).

For example, if there are 8 radiators installed in the system, and the balancing valve screw is adjusted within 4.5 turns, then the first radiator from the boiler is first completely closed, then its balancing valve is unscrewed by 1.5 turns. The regulator of the second radiator is unscrewed by 2 turns, the third by 2.5, and so on. The coolant flow on the last and penultimate radiator in most cases remains maximum. If possible, adjustments are made only on those radiators that are closest to the boiler (the distance is measured from the beginning of the supply line).

It is not recommended to unscrew the regulator less than 1.5 turns. After all, if you turn down the throttle opening of the valve too much, the device will quickly become clogged with scale or other debris.

Fine adjustments are made according to the readings of the thermometer. The main goal of balancing in this case is to achieve approximately the same temperature difference at the inlet and outlet of each radiator.

If the temperature difference at the inlet and outlet of a single radiator reaches 10ºС, it is not recommended to close its balancing valve even more.

And one more thing: noise in the radiator during operation of the heating system indicates that the coolant flow should be reduced.

The boiler is the basis of everything

This is the main component of most heating systems. To avoid many mistakes, take his choice seriously. This is the case when the stingy pays twice. If you want to save money and purchase a boiler of insufficient power, you will doom yourself and your household to a chilly life. You will have to use additional heat sources, which will lead to unnecessary expenses.

Boilers are distinguished by the type of fuel that, when burned, heats the coolant, as well as by power. The efficiency and safety of the boiler operation is important. Ease of use. Quiet operation.

The design of all boilers is, in general, the same. Consists of a combustion chamber and a heat exchanger. The first contains fuel raw materials, the second serves to heat antifreeze or water.

You will have to immediately determine whether you need a boiler only for heating. Or with an additional function for producing hot water. This problem is solved by a double-circuit boiler.

The boiler installation location must be spacious, bright and dry. Usually, a basement is used for these purposes or a separate room is built - a boiler room.

There should be no difficulties connecting the necessary communications to the boiler. If you are using a boiler that runs on coal or wood, provide a place for storing raw materials. A chimney is required.

The issue of ash disposal will have to be resolved. If liquid fuel boilers are used, find a large container for storing diesel fuel and place it safely, away from sources of open flame. On the heating equipment market you can find modern models that run on fuel oil, light grades of oil and even waste engine oil.

To change fuel, just select the right burner. Electric boilers are the easiest to operate, do not pollute the atmosphere with harmful emissions, are silent and safe. The disadvantage is that electricity tariffs are increasing every year. In this sense, a gas boiler is much more economical.