One of the main requirements for a private residential building is comfortable living. This concept also includes room temperature at which residents feel comfortable. But, cold floors in a private house, what should an enterprising owner do? Floor insulation is an incomplete solution to the problem if the heating is not working well. Therefore, the only way to achieve a comfortable temperature for the human body in the premises of a house of at least 18°C is to turn cold floors into a warm surface while simultaneously revising the heating system.

Eliminating the cold floor problem

If the floor in a private house is cold, then you should not rush to call repairmen - you can fix the problem yourself. The correct option is floor insulation. Several simple technologies have been developed for this:

- Before choosing a method for insulating the floor surface, it is recommended to check the ventilation system in the basement level of the building. At the beginning of autumn it is tightly closed. It doesn’t hurt to check the connecting level between the base and the walls of the house for any cracks, gaps or cracks. If necessary, insulate them with caulk, construction foam or other methods, for example, pouring a concrete solution;

- Check the ceiling surface in the same way. Warm air always rises to the ceiling, and there it is much easier for it to find a gap for leakage to the street. Therefore, if the floor in a private house is cold, then first of all it is necessary to insulate the ceiling;

- Insulate cold floors with available thermal insulators. We will talk about them below;

- Install “warm floors” based on liquid coolant or electric heating. But, if the insulation of the floor, ceiling and walls is not done or is carried out poorly, the heat transfer efficiency of the heated floor will tend to zero.

For concrete and wooden floors, the insulation scheme and the thermal insulation materials used will be different, so you should not replace them!

Stages of work on installing thermal insulation

The house is installed directly on the ground.

- make a layer of sand or crushed stone under the ceiling;

- build a wooden floor as a rough option;

- a layer of waterproofing is laid;

- place a heat insulator between the joists (parallel wooden boards).

- a vapor barrier layer must be installed on top.

- finished floor with the obligatory leaving of a gap for ventilation between it and the heat insulator.

The cold floor is located above the basement. In this case, it is necessary to increase the floor by a few centimeters.

Thermal insulation materials for arranging cold floors

The “warm floor” system is a last resort if the apartment has a cold floor. It is recommended to first carry out high-quality insulation of surfaces, starting with the ceiling and floor. How can you insulate cold floors?

- Mineral wool is the most popular insulation material due to its low coefficient of thermal conductivity and noise insulation, ease of installation and low cost. The only difficulty when working with mineral wool is the need to equip an additional waterproofing layer, since mineral wool has high vapor permeability;

- Ecowool is the next most popular insulation material if you have a cold floor in a private home. Ecowool is inexpensive, it is an environmentally friendly insulation, and has a high thermal insulation coefficient. But it quickly becomes saturated with condensate, so before laying the ecowool layer it is also necessary to install an additional waterproofing layer;

- Expanded polystyrene (PP) is a durable and warm insulator, retains moisture and noise, but has a low flammability group - G4. Combustion is accompanied by the release of harmful gases and substances, therefore PP is not recommended for residential buildings and premises;

- If the house has cold floors, then wood thermal insulation materials can help: multi-layer plywood, large sawdust or shavings, chipboard or fibreboard, laminate or parquet. Many people are interested in why laminate flooring is cold in an apartment, but there are objective reasons for this: laminate flooring does not have a low enough coefficient of thermal conductivity and moisture absorption. Therefore, it is recommended to lay the laminate on top of a higher-quality insulation layer;

- The lowest demand is for insulation materials such as glass wool, expanded clay and polystyrene foam. Each of these building materials has its own significant disadvantages, despite their low cost.

Therefore, if the house has cold floors, it is necessary to carefully study their technical and operational parameters before purchasing thermal insulation materials. If you don’t understand why there is a cold floor in a private house, take into account additional design characteristics - the area of the insulated room, the degree of insulation of window and door openings, features of the home interior, architecture and design, etc.

Types of insulation

Expanded polystyrene

Polystyrene sheets with grooves for insulating and leveling the floor

Expanded polystyrene, better known as polystyrene foam or its modified counterpart penoplex, has excellent thermal insulation properties, is lightweight and easy to use. There is also extruded polystyrene foam. Its difference from the usual one is that it is waterproof. If ordinary polystyrene foam can absorb a certain amount of liquid and become deformed due to temperature changes, then its more technologically advanced form is almost completely waterproof. The only disadvantage of polystyrene foam is its flammability.

Expanded clay

An example of different types of expanded clay used for insulation.

This bulk material has an attractive price and is universal. Can be used for dry floor screed or mixed with cement mortar. You can also use it to create a floating screed with your own hands.

Polystyrene concrete

Unlike expanded clay, polystyrene concrete requires a much smaller layer to create acceptable insulating properties. You can lay almost anything on it, including tiles. In addition, it has excellent sound insulation properties. You will learn more about this material from the video.

Mineral wool

Mineral wool, as well as glass wool, are some of the most popular insulation materials, which are made in the form of tiles or rolls. The advantages include thermal insulation properties, reasonable price and vapor absorption. The disadvantages are that the composition is hazardous to health. When installing it yourself, you should use respirators and avoid contact with exposed parts of the body. Therefore, mineral wool and glass wool need careful insulation to prevent dust from penetrating into the premises.

Cork

Cork is used as a backing for laminate flooring and as an insulating material.

Cork material is perhaps the most expensive on our list. It is environmentally friendly, durable and moisture resistant. It can be used even for fine finishing, because in addition to its insulating properties, it looks beautiful as a topcoat. Disadvantages include instability to cuts and other mechanical damage.

Ecowool

It is made on the basis of cellulose, which means it is environmentally friendly and not hazardous to health. It has high heat and sound insulation properties, but does not tolerate moisture. Therefore, it is used in areas where there is no risk of contact with moisture. For more information about the advantages and disadvantages of ecowool, watch the video

Penoizol

This is liquid polystyrene foam, all the advantages of which we talked about above. The advantageous difference between the liquid form of such material is its ability to penetrate into the most inconvenient places.

Warm floor

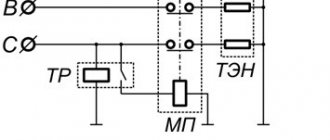

Installing an electric heated floor

The option of installing a heated floor is becoming increasingly popular. The only thing that puts me off is its cost. There are several variations:

- Water;

- Electric;

- Infrared.

Water heated floor, heats with the help of hot water communications under the subfloor. Electric underfloor heating is also installed and heats by converting electricity into heat. Infrared is the most modern, simplest option and can be installed with your own hands without the involvement of specialists. Thin underfloor heating elements are laid under the finishing flooring. Only this type of floor can be realized with your own hands, without special skills.

How to insulate a floor in a wooden house

In the table you will find not only a list of recommended insulation materials, but also their characteristics, advantages and disadvantages. The table will be useful to you if you have a cold floor in a private house; you don’t know what to do:

| Type of thermal insulation material | Advantages | Flaws |

| Mineral wool and ecowool | Naturalness, low thermal conductivity, high sound insulation, compactness (rolls or mats), light weight, easy installation, low cost | Low coefficient of moisture resistance, installation of an additional waterproofing layer, high fire hazard and low fire resistance |

| Fiberglass wool | Similar to mineral wool and ecowool. Contains glass fibers | It is necessary to use PPE - rubber gloves, safety glasses, a mask or respirator, clothing with closed sleeves and high shoes |

| Expanded polystyrene (PP) | Low thermal conductivity, high sound insulation and moisture resistance, light weight, easy installation, low price | Environmentally unsafe material, low flammability group (G4), toxicity when burning. Not recommended for use in residential areas |

| Expanded clay, wood shavings or sawdust | Natural, low thermal conductivity, does not allow street noise to pass through, simple and quick installation, low market value | When using expanded clay, wood shavings or sawdust, it is necessary to first equip forced and natural ventilation systems. Wood materials can become moldy and susceptible to fungal diseases |

If you have cold floors in a private house, what should you do? When laying thermal insulation salt, it is recommended to use multi-layer plywood, fiberboard and chipboard sheets, OSB and plasterboard. Sheet materials make it easier to cover bulk insulation without heat leakage. At the same time, a smooth surface is created that is prepared for laying the final decorative coating.

Expanded clay and wood bulk materials are recommended to be used only for insulating wooden floors due to the similarity of the structure of the materials and their ability to respond equally to changes in humidity and temperature in the room.

Installing additional heaters

If all measures for insulation and decoration do not bring the desired result, the “heavy artillery” comes into play, that is, a variety of additional radiators and convectors, of which there are a great variety today. If possible, the most obvious and practical solution would be to replace the old batteries with a new model that has greater heat dissipation, an attractive design and the ability to regulate temperature.

Decorative shelf-radiator, Vanixa

In addition to replacing stationary heating radiators, you can use additional options, for example, installing a flat convector. This convector is mounted on the wall and can operate continuously. Inside the convector there is a solid-cast heating element, which ensures silent operation and quick heating of the room to the desired temperature without changing air humidity.

Convectors are compact, which is very important, Galletti

One of the most progressive heating options today are infrared heaters and panels. Their fundamental difference from other models is that they ensure uniform circulation of warm air throughout the entire room, and not just near the radiator itself. This effect is achieved due to the fact that a quartz lamp in the form of a long tube is installed inside the metal case, while you can either equip the room with built-in infrared panels or connect a portable heater.

Compact infrared radiator-bedside table, Infrared

Compact and practical solution - infrared radiator on the ceiling, ATH Italia

If the lack of heat in the house is a temporary phenomenon, for example, before the start of the heating season, it is enough to acquire a compact electric fan or an oil radiator. They are mobile and relatively inexpensive, but they dry out the air, which has a negative impact on health, and consume quite a lot of electricity. It is better to have this option as an additional safety net in case of a sudden cold snap, and maintain a constant temperature in the room through other means.

Portable oil radiators in different sizes, S&P Italia

We briefly looked at different options for maintaining a comfortable temperature in the house during the winter. Of course, these decorative techniques are unlikely to replace high-quality repairs, but by combining our various tips, you will be able to make winter evenings much warmer and more comfortable for the whole family.

Insulating a cold wooden floor in an old house using traditional methods

Classic “warm floor” is an expensive system, both in terms of installation and operation. Complex piping, expensive equipment and fittings, and further payment of energy bills discourage homeowners from using this heating system. Therefore, in order to save money, if you have a cold floor in your apartment, you don’t know what to do, it is recommended to organize insulation of surfaces, both concrete and wooden. The main steps for insulating a wooden floor will be as follows:

- Slats or boards are fixed to the old base of the floor, cleaned of dirt and dust - they should be attached to the edge. The height of the frame will depend on the height of the ceiling - the sheathing will take a few centimeters from the total height of the room;

- A waterproofing lining is installed, and expanded clay is poured onto it. You can lay mineral wool, but not sawdust or shavings - these materials will quickly absorb moisture and mold will grow in them;

- The filled surface is covered with sheets of plywood, chipboard, OSB, plasterboard or board. The sheets must be coated with an antiseptic and moisture protection - there are special solutions and mixtures for this;

- Laminate, parquet, carpet and linoleum are laid on a plywood base. The boards are coated with varnish, mastic or decorative paint.

If a house is being built from scratch, then thermal insulation measures should be taken during the construction of the foundation and raising the walls of the building.

The quality of insulation depends on the design of the foundation. Thus, when constructing a pile foundation or MZLF, the thermal insulation system must be reinforced. Otherwise, you will never guess why the floor in a private house is cold. You can organize all stages of insulating the floor surface from any material yourself - without assistants or hired workers. Using step-by-step floor insulation technology, you will know exactly what to do if the house has a cold floor, what to do and what materials to use. And don’t forget that any insulation requires decorative finishing: linoleum, carpet, laminate or wear-resistant MDF will help make the floor beautiful and more durable.

Old wooden floors need to be stripped of paint. To do this, you can use special solutions or scraping.

Some subtleties

There are several points to consider when planning and installing thermal insulation:

- if there is a cold basement under the first floor, an important part of the floor insulation work will be the thermal insulation of the basement walls - a large amount of heat escapes through them into the cold ground;

- all wooden floor elements must be treated with an antiseptic;

- a mandatory element for thermal insulation materials is ventilation, it prevents condensation from settling and absorbing;

- steam and waterproofing - mandatory for any type of thermal insulation material;

- if a space of several centimeters is left between the layers of the subfloor and the finished floor, it should be insulated with a fine-mesh metal mesh - this will eliminate the possibility of rodents, which are very fond of many insulating materials, from entering the underground.

If thermal insulation work is carried out correctly, the floor will last as long as the basic structural elements of the house. All materials used for thermal insulation are durable under the right operating conditions and will not require replacement for many years. But if you are not confident in your abilities, it is better to postpone repairs and turn to professionals.

Recently I became the “lucky” owner of an outbuilding that simply stands on the ground. It's cold, the floor will have to be insulated in any case. Judging by the article, I can quite cope with some materials on my own, the algorithm of actions is clear to me. Now the problem is choosing a material for thermal insulation. I'm leaning towards either mineral wool or expanded clay. Anyone who has insulated with these materials, please tell me which is better.

Expanded clay, of course, will be much cheaper, but it needs to be spread in a much thicker layer than laying mineral wool. And expanded clay will still absorb moisture, you need to lay vapor and moisture insulation - cellophane. If you are laying mineral wool, then take one with a higher density - if you use a low density, it will “sit down” over time and stop performing its function. And of course, you also need to put cellophane under it. So, if space allows, use expanded clay and lay cellophane in two layers. It will be cheaper and not inferior to mineral wool.

Leave a comment (without registration): Cancel reply

How to insulate a concrete floor

Concrete floor slabs and a concrete layer on the floor surface in the house will serve as an excellent basis for installing a “warm floor” system. So that during the installation of the system you do not have questions: cold floors in the apartment, what to do and what steps to take, follow the diagram below for creating warm floors:

- Remove the old decorative coating - the concrete surface should be completely exposed and cleaned of dirt, dust and moisture. It is also necessary to eliminate cracks and chips in the concrete and make the concrete surface horizontal. To do this, you may have to pour a new thin layer of concrete mortar (10-30 mm);

- Draw up a diagram for laying the “warm floor” pipes, lay PVC pipes on the floor of the room, secure them;

- Connect the pipeline to the heat generator or storage boiler. If the heated floor is made on the basis of heating elements or infrared mats, then the kit should be accompanied by instructions from the manufacturer for installing the equipment. For electric heated floors, it is necessary to provide and install additional sockets, RCDs and distribution panels;

- The heating system based on liquid coolant must be protected by sheet materials: chipboard, OSB, plywood, gypsum fiber board or other materials with a flat, durable and smooth surface. The IF heating system or electrically conductive film is protected with a cement-sand mortar screed;

- Lay the finishing floor covering. For children's rooms and bedrooms, it is recommended to use soft materials that provide additional insulation of the floor. This can be a rug, carpet or other carpeting.

If the technology for insulating a concrete floor is followed, no one will have the unpleasant question of whether there is a cold floor in the house, what to do and how to insulate it correctly.

When installing electrical “warm floor” systems, in order to avoid mistakes, it is recommended to consult with specialized specialists and study the attached installation instructions.

Installation sequence

- The infrared film is laid out in planned areas and attached to the floor using a stapler or tape along transparent edges that do not have a built-in wire.

- Recesses are made in the wall. Place the cable going from the thermostat to the thermostat.

- The places on the film in the connection area are thickened; for them it is necessary to create technological recesses artificially.

- The starting point of installation is located on the opposite side from the power connection points. Leave a free space of 20 centimeters from the walls.

- Connect the copper ends to the thermostat using the cable and contact clamps included in the kit. Secure with pliers and isolate.

- The clamp is placed between the film and the wire. The IR strips are connected near the wall. When extending them, wires of the same color are connected to each other, followed by insulation, and additional fastening with tape.

- The cable is routed inside the corrugation. It is sealed with a film, protecting it from moisture.

- After completing installation, check the functionality of the entire structure using a portable sensor.

Useful video on installing electric floors

How to insulate the floor in an apartment on the first floor

A problem has arisen: there is a cold floor in the apartment, what should I do? Especially if the apartment is located on the ground floor? The presence of a damp basement and insufficient thermal insulation of the basement space complicates the solution of the problem, but does not eliminate it. There are special technologies for such cases - most often the problem occurs in houses on the secondary real estate market, in buildings of the old housing stock.

In “Stalin”, “Khrushchev” and “Brezhnev” buildings, basements were poorly insulated, if any measures were taken at all to arrange hydro- and thermal insulation of basement surfaces. Therefore, the basements in such houses were constantly damp, and water stood in many basements for years. In such conditions, the apartment on the first floor was doomed to constant dampness and cold floors. In addition, in old houses, finishing floor coverings were laid directly on concrete, which also did not increase the thermal insulation of the floors.

Thermal insulation or underfloor heating?

The best thermal insulation technologies in such situations are energetically active “warm floor” systems. That is, heating based on heat generation using electricity or heating the working fluid in the heating system. But this solution is the last option due to the high cost of materials and equipment. You can often get away with adding a layer of thermal insulation to improve the thermal performance of the floor surface.

Materials for floor insulation were listed above, but they do not answer the question “it’s cold in a private house, what to do.” The problem is solved comprehensively: the size of the cash injection, the type of premises and the house itself, living conditions, building materials in the apartment, the level of thermal insulation, etc. should be taken into account.

In “Stalin” and “Khrushchev” buildings, the floors were made of boards, so the most suitable insulation for such floors is mineral wool, and expanded clay is used as a loose heat insulator. Its use has additional advantages: saving the family budget and time. It is not recommended to use polystyrene foam and polystyrene foam - these materials are highly flammable and, when burned, release large volumes of toxic substances.

In Brezhnevkas, the floors were made using a concrete screed on the floor slabs. Concrete is a poor thermal insulation material, but 20th century technologies did not provide for insulation of a concrete floor. In some cases (houses of types P15-2, P-3/16, P-3/17) a layer of glass wool was laid on the concrete, which was then filled with a not too thick layer of cement. Over time, the glass wool was compacted, which was facilitated by constant loads on the thin cement screed. As a result, the cement cracked, the floor sagged, and the minimal insulation became even worse.

20% of heat losses in apartments are losses from a cold concrete floor.

In passage rooms (corridor, living room), the floor is insulated with polystyrene foam - this is permitted by SanPin requirements. For children's rooms and bedrooms, it is recommended to use bulk insulation - shavings, expanded clay, sawdust.

If the apartment on the ground floor has a cold floor, what should you do without the ability to carry out major repairs and insulate the concrete floor with several layers of thermal insulation?

Several simple solutions for insulating the floor of an apartment

Over many years of practice, builders have developed several complete solutions:

- Cover the floors with carpet or rugs. Such protection has a low thermal conductivity coefficient, and the best thermal insulation characteristics are found in woolen products;

- Lay linoleum on the floor on a jute, foam or felt base;

- Laminate flooring has its own requirements: it is recommended to lay a sheet of cork under the laminate layer, and after that you do not have to answer your family’s question: there is a cold floor in the apartment, what should I do?

Conclusions: installing a heated floor in an apartment most often does not require expensive heating systems and units. You can independently, subject to technology and recommendations, properly insulate any floors.

Choosing a method of insulation

Until now, a large number of varieties of insulation materials have been developed. To apply them best in a specific setting, it is important to become familiar with their strengths and weaknesses.

Expanded clay can be used as insulation

One of the methods of insulation, which has been used for quite a long time and does not lose its popularity, is the use of expanded clay. It is made from natural ingredients, and the manufacturing process involves firing a clay base. This material wins according to the following parameters:

- light weight;

- possibility to choose the size of granules;

- relatively low price;

- resistance to moisture (does not collapse under its influence);

- long service life;

- resistance to temperature changes;

- resistance to fire.

The disadvantages include:

- in some cases it is necessary to make a recess to ensure a sufficient layer;

- fragility;

- can draw in moisture, causing it to accumulate in the granules.

The next item on the list of materials that can be used for insulation purposes is polystyrene foam. Its strengths include:

- high level of thermal insulation (with the same thickness in comparison with other material, except penoplex, it will always surpass in performance);

- light weight;

- ease of fit and installation;

- inedible for parasites (although mice and rats cope well with it);

- does not absorb moisture;

- resistant to high temperatures (without direct exposure);

- no thermal expansion.

If you choose polystyrene foam, you need to consider:

- undesirable use in combination with wood flooring due to fire hazard;

- instability to chemical and physical influences;

- toxic when burned;

- When insulating with foam plastic, it is important to calculate everything correctly so that the dew point does not remain under the floor.

Many often have a choice between this material and mineral wool. To make it, broken glass, quartz, rock or slag can be used. If we talk about positive qualities, then these are:

- excellent sound and heat insulation;

- fire resistance (especially for stone wool);

- chemical resistance;

- good vapor permeability;

- high tensile strength (for some brands);

Some of the sad moments include:

- inconvenience of installing glass wool (it is necessary to use clothing that will prevent it from getting on the body, as well as glasses, gloves and a respirator);

- the possibility of compaction over time, which leads to the appearance of cold bridges;

- the appearance of unpleasant dust;

- Some types of this material absorb moisture well.

Penoplex is very similar in its characteristics to polystyrene foam. Has even greater thermal insulation. Can be used in any weather conditions. Also loved by rodents and afraid of high temperatures (if directly exposed). In some cases, insulation can be done using gypsum fiber. It is used in conjunction with dry screed. Filling cavities with polyurethane foam can be considered as a method. Under certain conditions, this can be done without removing the old floor.

Vermiculite is an excellent, durable material that is resistant to moisture, but its cost is quite high, so not everyone can afford it for floor insulation.

The ideal solution would be a combination of passive insulation with active underfloor heating. For the latter, a large number of types are available today, which include water-based and electric-based options.

Obvious causes of floor cooling and their elimination

The temperature condition of the floor depends on three factors:

- condition of the foundation or basement;

- quality of heat-insulating systems;

- condition of the floor base and finishing coating;

- temperature and humidity level.

Cold draft from the foundation

If the floor was laid in close proximity (without an air gap) to the foundation, and there is no thermal insulation layer between the floor and the base (or this layer is too thin), then the floor will always be cold - even in summer. In cold weather, when the ground freezes and the foundation partially freezes, this will be especially noticeable and very unpleasant. The problem cannot be solved using heaters alone. It is necessary to raise the floors, insulate the empty space between the foundation with floors, insulate the foundation itself or the walls, the ceiling and the floor in the basement.

Dampness under the floor

The underground is always damp if there is no hydro- and thermal insulation. But dampness is especially noticeable in spring and autumn. Waterproofing, which is installed before laying the heat-insulating layer, will save you from high humidity from the basement. As an additional measure, you can close the ventilation vents during the winter. Instead, it is recommended to make a ventilation grill above the ceiling and in the floor in the basement. If the basement floors are already wet, it is necessary to force them to dry, and then install insulation and ventilation.

Poor thermal insulation

Poor quality insulation or its absence is visible visually. The solution to the problem is laying high-quality insulation with preliminary calculations of the layer thickness and selection of optimal materials. At the same time, hydro- and vapor barrier layers are laid before attaching the insulation.

Gaps in the floor

A wooden floor will definitely become leaky over time, and cold air will penetrate through the cracks below, displacing warm currents. Along with the cold air, moisture will also enter the apartment. The cracks must be filled with putty, loose sheets of plywood or boards must be strengthened with self-tapping screws. It is recommended to lay new sheets of chipboard, OSB, gypsum fiber board or boards on top of the old plank floor.

Cold floor covering

If a thin decorative coating was laid on a cold floor, the floor will remain cold. This problem can be effectively solved by installing a “warm floor”. The layout and materials are selected for each living space separately. A thick layer of insulating materials is laid under the “warm floor” system so that the heat goes into the room rather than into the basement.

What to consider before

Determine Initial Conditions

Cold air always accumulates from below, and warm air rises upward, therefore, no matter how much you heat the house, if the floor remains cold, then it is almost impossible to achieve complete comfort. Before starting installation work, you need to analyze several points:

- What is the flooring made of? This could be a concrete screed on which the tiles are laid, perhaps it could be an edged board.

- If the floor is wooden. then whether there are any pests in it.

- Is mold visible in the corners and spreading from bottom to top?

- Does moisture accumulate under the coating?

- Is there space under the floor?

- Would it be critical if we had to raise the level even a little?

- Is there a basement downstairs? If not, what kind of covering is located under the floor.

- Does it bend when walking?

There may be a concrete screed under the floor

The answers to these questions will determine whether the old coating can be used or whether it must be dismantled with the need for additional disinfection and isolation measures.

Base primer

Polyurethane

The second name of the composition is epoxy primer, which has the ability to penetrate deeply into concrete. Apply the component to the screed with a roller. Work along the perimeter of the base with a brush. No spaces allowed. This type of primer is effective for adhesion to self-leveling floors (self-leveling), preventing the formation of fungus and moisture penetration.

Concrete contact

This is a composition of acrylic with quartz sand. Apply with roller and brush. After priming, a rough surface is formed on the base, ensuring tight contact with the subsequent layer. Acrylic in the composition makes the film resistant, preventing moisture from entering the concrete. After 4 hours, from the moment the composition is applied, the next stage of insulation begins.