An electric boiler is an advantageous alternative to solid fuel or gas appliances. It has increased efficiency, does not make noise during operation, and does not require a separate room or special permission for installation. Electric boilers for heating a private house at 380 V belong to the category of powerful three-phase devices and are divided into several types. Before purchasing and installing such a boiler, it is useful to study its pros and cons, operating and installation rules, as well as available connection options.

What are the advantages of a 380 volt electric heating boiler?

Electric boilers for home heating are a reasonable alternative to solid fuel and gas units.

Such heating devices have high efficiency, are silent in operation, and do not require a separate room or additional permits for installation. Depending on the rated power, electric boilers are divided into two types: single-phase (power 1–10 kW) and three-phase (power 12 kW and above). Today we will get acquainted with more powerful devices that require connection to a voltage of 380 volts.

User manual

Each manufacturer has its own technical solutions, and therefore, before using the device, you must read the instructions. However, there are a few general rules. For example, before each time you turn on the device, you must check the condition of the equipment to make sure there are no mechanical damages. The coolant must not leak.

It is important to monitor the condition of the electrical network. If it is determined that the grounding is damaged, it is necessary to de-energize the device and call a technician to repair the problem.

Installation of equipment and repair work must be carried out by a specialist. This is due to safety regulations and is considered a condition of warranty service.

Depending on the features of the model, periodic flushing of the boiler may be required. The temperature must be monitored during operation of the device.

Types of electric boilers

Depending on the method of transferring thermal energy to the coolant, electric boilers are divided into three types:

All these heating units are produced in two versions: 220 and 380 volts.

Heating boilers

These electric boilers for home heating are the most popular. The principle of their operation is as follows:

- The tubular element heats the water circulating in the closed system.

- Circulation ensures fast and uniform heating of the entire system.

- The number of heating elements required depends on the power of the device and can vary from 1 to 6 heating elements.

Such boilers are equipped with a reliable automation system that allows you to monitor and regulate the temperature of the coolant. The advantages of heating elements heating units are:

- Simplicity and reliability of design.

- Easy to install.

- Cheap design.

- The ability to use almost any liquid as a coolant.

- These 380 volt boilers have a modern design and fit well into any interior.

Induction boilers

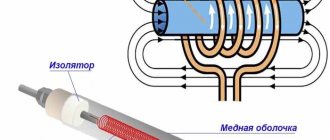

The principle of electromagnetic induction has long been successfully used for heating residential premises. This boiler has the following device:

- A metal core is inserted into a cylindrical body (usually a piece of pipe), on which a coil is wound.

- When voltage is applied to the coil and winding, vortex flows arise, as a result of which the pipe through which the coolant circulates heats up and transfers heat to the water.

- The water circulation must be constant so that the coil and core do not overheat.

This electric heating system has the following advantages:

- High efficiency, reaching 98%.

- This 380 volt boiler is not susceptible to scale formation.

- Increased safety - no heating elements.

- Small dimensions and low weight ensure easy and quick installation of induction boilers.

Advice! Induction electric boilers can do without a circulation pump. But this does not apply to a large heating system of a two-story house.

Electrode systems

In its operation, the 380 volt electrode boiler uses specially prepared water. Preparing the coolant involves dissolving a certain amount of salts in it to give the required density. The general operating principle of electrode heating devices is as follows:

- Two electrodes are inserted into a pipe of suitable diameter.

- Due to the potential difference and frequent polarity changes, the ions begin to move chaotically. This way the coolant heats up quickly.

- Due to the rapid heating of the coolant, powerful convection currents are created, allowing you to quickly warm up a large volume without the use of a circulation pump.

The electrode boiler has obvious advantages, including:

- Small sizes.

- Fast ramp up to rated power.

- Compact and simple design.

- No emergency situation, even if water leaks from the heating system.

Advice! Electrode boilers require a special approach to grounding equipment. Not only the boiler itself is connected to the ground loop, but also the heating system of the house, especially metal radiators.

The most popular models of electric boilers 380 V

“Rusnit REKO-18P” (18 kW) is suitable for heating large rooms. The unit has 3 power levels in increments of 6, 12, 18 kW. It is possible to customize parameters to suit the characteristics of the house.

The model belongs to the category of heating element boilers. Moreover, this is a new generation of equipment, in which all design details have been thought out, and due to semiconductors for switching heating elements, the service life of the device has been increased. The unit is characterized by silent operation and the risk of radio interference is reduced.

“Evan EXPERT 9 12335” is a universal model, connects to a 220 V and 380 V network. The electric boiler is a mini-boiler room: equipped with a built-in circulation pump and an expansion tank. The power of the device is 9 kW. If heat loss is not taken into account, the device is used to heat a house with an area of up to 90 sq.m.

Kospel 12 kW EKCO.A-12 combines compactness and good power ratings - 12 kW. The model of the Polish brand is installed in country houses, small warehouses and trade pavilions. The advantages include high operational safety, long service life and ease of installation.

For small rooms, the Zerten SE-7.5 electric boiler is suitable. This is a device that operates from a 220/380 V network, that is, it is universal. With a power of 7.5 kW, the device is suitable for rooms up to 70 sq.m. Its advantages: a corrosion-resistant heating element made of stainless steel and a convenient control and temperature control system.

When choosing, you need to take into account the power of the equipment, pay attention to the presence of additional functions, etc. If in doubt, it is better to trust a specialist or at least first read the manufacturer’s instructions and study the main characteristics of the device.

Rules for installation and operation of electric boilers

When connecting an electric boiler, you must follow certain rules, which we will now examine in more detail.

Electrical connection

When connecting an electric boiler, it is necessary to correctly calculate the cross-section of the power cable. The safety of the entire heating system depends on this indicator.

It is worth noting that 380 volt electric boilers are quite powerful, so the cable must be appropriate. To calculate the wire cross-section, a formula is used, according to which no more than 8 A of current should fall per 1 mm2 of cable cross-section.

According to this formula, in order to connect a 10 kW heating unit to a voltage of 380 volts, it is necessary to make the following calculations: 10000/380/8. The result shows that each conductor of the cable must have a cross-section of at least 3.3 mm.

Advice! When choosing a cable cross-section, fractional values should only be rounded up!

Connection to the heating system

All electric boilers are connected to the heating system according to a similar scheme:

- For connection, plastic pipes or jumpers made of dielectric material are used.

- The circulation pump must be installed on the return pipe.

- A safety group must be installed on the hot coolant supply pipe (no further than 50 cm from the boiler).

- If the heating system uses a small circuit, then it is necessary to install shut-off valves after it.

- An open-type expansion tank is installed at the highest point of the pipe system without the use of shut-off devices. A closed expansion tank is installed near the boiler, up to the shut-off valves.

During operation of a 380-volt electric boiler, it is necessary to monitor the serviceability of the electrical wiring and prevent coolant leaks.

Advice! When operating electrical heating equipment, special attention should be paid to the serviceability of the grounding conductor. In case of damage, you should immediately turn off the power to the boiler and restore the grounding.

In conclusion, I would like to note that 380 volt electric boilers perform excellently during long-term operation. Due to their greater power, they are less likely to operate at their maximum capacity, which has a positive effect on their service life. Installing such a boiler is an excellent solution to solve the problem of heating a large house.

Installation Rules

Installation of the device should be entrusted to a specialist. It is especially important to correctly calculate the cross-section of the power cable - the safe operation of the heating system depends on this.

380V electric boilers are high powered and the wire must be sized to withstand the corresponding loads. There is also a general formula, according to which per 1 sq.mm of cable cross-section there is a current strength of no more than 8 A. Rounding in calculations should be done upward.

Connecting the boiler to the heating system complies with existing rules for energy-dependent units. For connection, plastic elements and parts made of dielectric material are used, and the circulation pump is installed on the return pipe.

Electric boiler: single-phase or three-phase?

Despite the expansion of diesel and gas boilers, electric boilers are considered in demand for heating houses with a relatively small area. Indeed, if the heating area is no more than 80-100 sq.m., why buy expensive heating equipment?

To heat medium-sized private houses, we recommend buying a small single-phase electric boiler that connects to a standard 220 V electrical outlet. The boiler will immediately begin to function - first, using a heating element, heat the coolant (water), which will then begin to release the accumulated heat to the heating radiators. The principle of its operation is practically no different from any heating device; no special permission is required.

For houses with a larger heating area, it is recommended to install a three-phase electric boiler, which will require an additional third phase to operate. The power of these boilers is more than 10 kW and they require an additional third wire from the beam. But on the plus side there is a constant supply of electrical energy through the wires. There is no need to install a separate gas pipe and install a step-down station, as is customary when installing gas boilers. You also won’t have to buy large fuel tanks, as is common with diesel versions of boilers. The savings are significant.

Types of three-phase heaters

The three-phase boiler is characterized by increased productivity, quiet operation and compact size.

Homemade induction heater

Most often used for heat and hot water supply systems in country houses. Double-circuit models are especially popular. It is recommended to install in combination with other heaters.

Available in two types:

- Electrode. The advantage of such a boiler is the high heating rate of the coolant.

- Induction. This is the most innovative type. Provides low specific energy consumption. The disadvantages include the large mass and relatively high price of the equipment. Such units are not produced with high power. To expand it, the method of cascading installation of three heaters at once is used, in which each boiler is connected to a separate phase.

Boilers with heating elements are also produced, but their popularity in private households is declining. Heating elements have to be cleaned and replaced frequently.

Advantages and disadvantages of electric boilers

Electric boilers are completely silent in operation, they do not dry out the air, are inexpensive and can be installed instantly. If you need to heat your house quickly and with minimal financial costs, then choose a trouble-free version of an electric boiler.

The latest versions of electric boilers may have an additional expansion tank in which the hot water needed for domestic needs will be accumulated. Using a circulation pump, water will be supplied to the bathroom and kitchen taps.

But keep in mind that electricity is not cheap these days. To minimize electricity costs (in Russia, heating a house with electricity costs more than 100 Euros per house), it is recommended to install an additional two-tariff electronic electricity meter. In this case, the house will be heated at maximum power using an electric boiler at night, and during the day, when energy is more expensive, the boiler will only work to maintain the set temperature.

If power outages often occur in your city or town, it is better to use an electric boiler in conjunction with a solid fuel one.

Choosing a boiler

Is it important for you to know all the pros and cons?

Then we will discuss the pros and cons of electric boilers. They are safe - there are no open flames or flammable fuels in the house. The work does not pollute the house, there is no ash, smoke or dust. They do not produce harmful emissions into the environment. Residents do not care about fuel supplies. They can be in shutdown mode for a long time, this is important for seasonal residences or for frequent long-term departures of the owners. In terms of size, they do not require much space. There are plenty to choose from both in terms of tasks and design. The main disadvantage is the cost of energy. Infrequently used for heating large houses. We'll tell you how to save below.

| Electric boiler |

Do you like consistency?

Then the first thing you need to do is find out how much power the power supply line will provide. Boiler power starts at 3.5 kW. If the voltage of the provided network is 220 V (single-phase), then you can connect a boiler with 7 to 12 kW of power. This power is enough for apartments. For more powerful devices, for example, in a private house, a three-phase network with a voltage of 380 V is needed. If you connect a powerful boiler to a single-phase network, a short circuit and fire are possible.

| Cable cross-section |

It is equally important to choose the correct cable cross-section:

| Boiler power | Cable cross-section of single-phase electric boilers | Cable sections of three-phase electric boilers |

| 4 kW | 4 mm² | |

| 6 kW | 6 mm² | |

| 10 kW | 10 mm² | |

| 12 kW | 16 mm² | 2.5 mm² |

| 16 kW | 4 mm² | |

| 22 kW | 6 mm² | |

| 27 kW | 10 mm² | |

| 30 kW | 16 mm² |

Floor or wall?

Floor-standing boilers operate at high power (40-60 kW). They are chosen for private houses from 500-600 m² or more. Cons: increased electricity consumption, take up a lot of space in the house. They are placed in the kitchen or bathroom. Usually a separate room is allocated. They work silently. A dedicated 380 V line is required.

| Floor-standing electric boiler |

Wall-mounted boilers are purchased for cottages, apartments and houses up to 500 m². Sometimes they are used as auxiliary equipment when the main one fails. They save energy, have a compact size, and are placed in the kitchen, hallway, or any other convenient place. They are not always available with a hot water circuit. You need to pay attention to this if the task is not only to heat the house, but also to heat water.

| Wall-mounted electric boiler |

Do you want to understand what you are paying for?

Then take into account the different methods of heating the coolant in boilers. There are three types: heating elements, electrode and induction.

If you want to save money, choose a heating element boiler . The heater in such a boiler consists of tubular elements with a spiral inside. The heating element itself is mounted in a heat exchanger, which is filled with water (or other coolant). For safety and long-term operation, shut-off and control valves are built into the body. Heating element boilers are time-tested and affordable. You can fill in any type of coolant. It has a simple structure and is easy to repair. The disadvantages of such a boiler include plaque, which builds up on the heating element over time. Clean it yourself, otherwise the efficiency of the boiler drops. This can be avoided if you provide a high-quality coolant - soft or distilled water. The spiral in the heating element is also subject to burnout and can be replaced.

| New electric boiler |

An electrode boiler converts electricity into heat through ion exchange. Water with salts dissolved in it turns into an electrolyte. It flows between two electrodes and is heated through an alternating electrical voltage. Such boilers are compact, simple in design, safe and inexpensive. No need for a large tank or pump for circulation. The main disadvantage is that you need to monitor the quality of the coolant: the water must correspond to the resistivity values. If the quality does not match, the efficiency decreases, and the boiler may stop working altogether. You will also have to change the electrodes, because... they dissolve in water during use. A particularly reliable grounding system is made for electrode boilers.

| Electrode boiler |

A coil (inductor) is located inside the induction boiler It, like an antenna, creates a magnetic field with high voltage. The metal core inside the coil heats up quickly. It gives off heat to the liquid. This can be water or ethylene glycol. Such boilers are not expensive to operate. They are fireproof, have no moving mechanisms, so they will last a long time. No need for a separate room for installation. Efficiency is 99%. Almost do not suffer from scale. The disadvantages of induction boilers include the fact that they are quite heavy and bulky. Such boilers are more expensive than other electric ones.

| Induction boiler |

When choosing one of the three options, you need to understand what goal you are pursuing. If your goal is to save money, take a proven and reliable heating element mechanism. But be prepared for possible scale that needs to be cleaned. If possible, it is better to purchase a more expensive but effective induction boiler. It is also good for combination, for example, with underfloor heating. In tandem, they warm up the house in a few minutes.

Do you want to know for sure that you will get the desired result?

| Boiler power calculation |

Even knowing that the boiler operates with an efficiency close to 100%, you should not rely on the fact that the house will be guaranteed to be heated. Therefore, you need to calculate the boiler power. It is calculated individually for each house, and this is due to different degrees of insulation. Approximate power is calculated as 1 kW for every 10 m². Let’s say for a house of 120 m² you will need a 12 kW boiler. This is the lower limit of the required power. For a more accurate calculation, this figure is multiplied by the climate coefficient and 10-15% of possible heat loss is added. The climatic coefficient for the Moscow region and Moscow is 1.2-1.5.

You can find out more about calculating boiler power here.

Do you want to save on electricity?

| Save on electricity |

To do this, choose models with automatic power levels, where a thermostat is built into the boiler. When the coolant reaches the set temperature, the thermostat blocks the heater power circuit. Boilers with a microprocessor can save up to 30% energy. If there is an external boiler sensor, then when the air in the room warms up to the desired temperature, the equipment switches to economy mode.

You can also buy a two-tariff meter and use night heating when the price per kW is less than the daily tariff. It’s cold outside at night and the house is heated at this time. And during the day, if everyone is absent, the heating is turned off.

Radiators warm up better if the boiler is placed at the lowest point of the heating system. It is better to provide for this at the design stage of the heating system.

If you add a “warm floor” solution to the main heating system, the heat consumption will be optimized, the house will become warmer without additional energy costs.

Do you want to understand the package?

There are options in the maximum assembly. This means that everything necessary will already be built in: an expansion tank, a pump for coolant circulation, automation. And the boiler works like a mini boiler room. This option is suitable for those who value time and do not want to purchase and install additional devices themselves.

An option with a minimum configuration can only be afforded by people who understand the intricacies of choosing additional equipment and are able to assemble it all into a single system. You will have to buy a separate tank, pump, safety unit and shut-off valves.

The maximum configuration may come out cheaper if you add up all the costs of the second option.

Device

The single-phase (three-phase) electric heating boiler consists of the following main parts:

- A tank with heating elements built into it (they are also called heating elements), which acts as a heat exchanger (details about: Heating boilers);

- Unit for adjusting and controlling the boiler.

The kit may also include:

- Pump for regulating the circulation of heated liquid;

- Expansion tank with a valve as a fuse;

- Filter.

Connection to the heating system

Network connection diagram

To connect a three-phase boiler you need to follow a special diagram. It is better to entrust this process to a specialist who must understand heating devices and know the principles of operation of sensors, pumps and other elements. The connection diagram for electric boilers to the heating system consists of several standard steps. To avoid possible problems, you need to follow the basic rules:

- To secure the elements of the unit, you need to use plastic pipes or jumpers made of dielectric material.

- The circulation pump is installed on the pipe for return flow.

- A safety group is placed on the pipe for supplying the heated coolant.

- When using a small circuit, shut-off valves must be installed after it.

An open expansion tank should be installed at the highest point of the system without the need to use shut-off devices. Closed tanks are placed not far from the device to the shut-off valves.

Distinctive features

A single-phase electric boiler operates from a network with a voltage of 220V, and a three-phase one - 380V. But if the power of the device exceeds 12 kW, then in most cases, you will have a three-phase electric boiler.

Manufacturing boilers with multi-stage operating modes makes it possible to reduce energy costs depending on weather conditions. Therefore, almost all boilers with a power exceeding 6 kW are equipped with power regulators. Moreover, the higher the power of the boilers, the wider the possibility of adjustment (2 or 3 stages).

Theory

What is a heating element in an electric boiler? From the point of view of electrical engineering, this is an active resistance that generates heat when an electric current passes through it.

In appearance, a single heating element looks like a bent or curled tube. Spirals can be of very different shapes, but the connection principle is the same; a single heating element has two contacts for connection.

When connecting a single heating element to the supply voltage, we simply need to connect its terminals to the power supply. If the heating element is designed for 220 Volts, then we connect it to the phase and working zero. If the heating element is 380 Volt, then connect the heating element to two phases.

But this is a single heating element, which we can see in an electric kettle, but not in an electric boiler. The heating element of a heating boiler is three single heating elements mounted on a single platform (flange) with contacts located on it.

The most common boiler heating element consists of three single heating elements mounted on a common flange. On the flange there are 6 (six) contacts of the electric heating element of the boiler for connection. There are boilers with a large number of single heating elements, for example, like this:

What should you pay attention to when choosing a boiler?

- When choosing a heating system in favor of an electric one, you should make sure that the electrical line connected to the house can handle the load. It is easy to calculate it knowing the power of the planned system. Don't forget to take into account that in addition to heating, there will be a lot of household appliances running in the house, which also need Kilowatts.

- You should also make sure that the power supply system is stable. Frequent power outages, due to which a three-phase (single-phase) electric heating boiler turns off, can cause it to fail prematurely.

- And finally, calculate the cost of electricity that you will spend on heating and compare it with your financial capabilities. Perhaps the boiler itself and its installation will not cost much, but monthly bills can make you despondent...

Safety regulations

Installation of an electric boiler must be carried out in compliance with safety rules:

- Before starting work, make sure that the electrical supply is turned off.

- It is prohibited to install an electric heating boiler in close proximity to a water supply or water source.

- The recommended distances between the unit body and building structures should be observed.

- Make sure that the electrical wiring parameters correspond to the power of the boiler (connecting a powerful unit to a 220 V household network can cause overload and short circuit).

- The boiler must be connected to a grounding circuit.

- Installation of an electric boiler is permitted on a wall made of non-combustible material. If the wall structures are made of wood or other material prone to fire, non-combustible sheathing made of basalt cardboard and sheet metal is mounted on the wall.

- Power cables must not be laid under heating circuit or water supply pipes. If this cannot be avoided, use special sealed housings made of metal or plastic to protect the cable from possible moisture ingress.

- When installing a heating boiler with your own hands, the heating circuit pipelines that are connected to it should be securely attached to the wall so that they do not add load to the body of the unit.

Installation of a residual current device

Subtleties of choice

Circumstances that you should pay attention to before making your final choice of heating boiler:

The power of the selected boiler should provide heating of the room, depending on its size.

The boiler power calculator will help you calculate the exact data, because you will have to take into account many factors:

- the region in which the house is located and its climatic conditions;

- the material from which a private house is built, the degree of its insulation; and so on.

Approximate results are easy to find out. Calculate 1 kW of power per 10 m² of room area. It is necessary to take into account all utility rooms, corridors, hallways, etc. Thus, if the area of the room planned for heating is 120 m², then it is obvious that the boiler power must be at least 12 kW.

The cost of a kilowatt of electricity in your region

The structure of the boiler you have chosen, its functionality, such as the ability to adjust depending on the ambient temperature.

Product completeness

It is advisable that your option be equipped with a pump and filter, and a safety valve. Such a three-phase electric heating boiler will serve much more reliably and efficiently.

Equipment

It's better to choose the maximum one.

Purchasing a boiler that is initially equipped with everything necessary will ultimately cost less than purchasing an inexpensive model and equipping it with separate units. Here we mean that part of the boiler “piping” that can be installed inside its body: a circulation pump, an expansion tank, a fine coolant filter and a safety valve that protects the system from critical excess pressure. Of course, their presence increases the cost of the unit. But: these devices will still have to be purchased and installed - without them, normal operation of the heating system is simply impossible. This means that you will also need to pay for installation services for additional equipment.

If we consider electric boilers for heating a private house at 380V, they have high power. To choose a three-phase model, you need to know the manufacturers and be able to evaluate the design. The devices differ in their operating principles, and product reviews play an important role.

Installation features

No matter how good a craftsman you consider yourself, however, if you do not have a special education in electrical engineering, it is better to entrust the work to a master. (see Installation of an electric boiler: how and why). Let single-phase electric boilers for heating your home be installed by a specialist. You won't spend a lot of money, but in return you will receive quality guarantees.

An advantageous advantage is the connection of special programmers to the heating system, which automatically regulate the temperature, therefore saving the owner’s money!

Boiler heating element connection diagrams

Option 1. Connection diagram to a single-phase network

Typically, three single heating elements in such a design are placed so that the contacts from different heating elements are located opposite each other.

To connect a heating element to 220 Volts, you need to connect three contacts from different single spirals with a jumper and connect them to the working zero.

The three remaining contacts also need to be connected and connected to the working phase. This will ensure that all heating elements are turned on simultaneously for heating when power is applied.

However, the connection is not made directly this way, and for every second contact the heating element is connected to a phase after its own machine or, what is done more often, it is connected from its own control line (automation).

Option 2. Three-phase connection

If we look at the heating elements for boilers sold, we will see that almost all of them are labeled as 220/380 Volt heating elements.

If you have this version of the heating element, and you have the opportunity to connect to a three-phase power supply of 220 Volts or 380 Volts, then you need to use connection diagrams called “star” and “delta”.

According to the “star” circuit of 220 Volts, three phases, you need to connect the three contacts of single heating elements with a perm and connect them to the working zero. Apply to the second free contacts via a phase wire. Each single heating element will operate from 220 Volts, independently of each other.

According to the “triangle” circuit of 380 Volts, you need to connect contacts 1-6, 2-3, 4-5 with jumpers, for single heating elements 1-2.3-4.5-6 and supply phase wires to them. Each single heating element will operate at 380 Volts, independently of each other.