In private homes, the main source of heat is a heating boiler. In order to control the heating process of the equipment, a temperature sensor is needed for the heating boiler. It is on its normal operation that both the comfort throughout the house and the safety of the heating equipment largely depend.

Traction regulator functions

The main task will become clear if you look at the name of the device.

If you do not regulate the temperature of the coolant (water jacket), it will simply boil. Without an automatic regulator, you will either have to constantly add liquid or manually control the flow of air entering the firebox. The traction regulator greatly simplifies the life of private home owners. In addition to control, it performs two more useful functions:

- setting and maintaining the maximum permissible water temperature without boiling (up to 90° C; this is especially true in autumn or early spring);

- fuel economy (when the damper is closed, the intensity (speed) of firewood combustion decreases (albeit due to a decrease in boiler efficiency)).

Installing a draft regulator on a solid fuel boiler involves certain costs. To save money, some use a safety valve for similar purposes. For some reason it is considered an analogue of a regulator.

The solution is not the most rational, since after only 3-4 operations (turning off the boiler if there is a risk of overheating and reactivating it if there is excessive cooling), the accessory begins to leak.

What is an overheat sensor?

In addition to the draft sensor, there is also an overheat sensor. It is a device that protects water heated by the boiler from boiling, which occurs when the temperature rises above 100 degrees Celsius.

Temperature sensors for the boiler are one of the auxiliary automation elements for controlling the heating system, allowing you to determine the temperature of the environment

When triggered, such a device turns off the boiler. The overheat sensor only works properly if installed correctly. An increase in water temperature without this device would threaten the failure of the gas boiler.

The overheating sensor monitors the temperature increase in the heating circuit. It is installed at the outlet of the heating circuit heat exchanger. When the critical temperature is reached, it opens the contacts and turns off the boiler.

Reasons for triggering the overheating sensor:

- Such a device can work if the water in the column heats up too much;

- If the sensor contact is poor;

- Due to its malfunction;

- If the sensor has poor contact with the pipe.

In order to make the heating sensor more sensitive, heat-conducting paste is used. When overheating, the sensor blocks the operation of the boiler. Modern devices are able to indicate a fault code on the display.

Where can I buy

Electronics for heating boilers are available for purchase in specialized stores in your city. But there is another option that has recently received significant improvements. You no longer need to wait a long time for a parcel from China: the AliExpress online store now offers the opportunity to ship from transshipment warehouses located in various countries. For example, when ordering, you can specify the “Delivery from the Russian Federation” option.

Follow the links and choose:

| Thermostat for gas boiler with Wi-Fi and remote control, 3A | Smart Wi-Fi thermostat Tuya for boiler | Smart Wi-Fi Touch Thermostat, Wireless |

| Digital LCD Thermometer with Water Temperature Gauge | Thermostat for gas boiler TUYA, wireless | Intelligent Thermostat, Temperature Controller |

Functionality check

If problems are observed in the operation of the boiler, the sensor may need to be replaced. For example, if the burner is regularly turned off, but no problems are observed in the combustion gas exhaust system. You also need to check the operation of the device when it periodically turns off after 20-30 minutes.

To check the serviceability of the boiler sensor, you need to consider 3 methods:

- Attach a regular mirror near the device. If the sensor is operating normally, then the surface of the mirror should not be covered with condensation.

- A simple way to check by partially blocking the chimney. A working sensor will promptly give a signal and the equipment will turn off.

- If a double-circuit boiler is used as heating equipment, then to check the device you can switch it to DHW mode, without heat supply. Then open the tap to a powerful stream of water. Here the situation is the opposite - turning off the sensor will be a sign of its problematic operation.

There are many manufacturers of traction sensors. Among them are such market leaders as Junkers, KAPE, Sitgroup, Eurosit. Some boiler manufacturers (Baxi, Danko) produce devices for their heating equipment. It is necessary to select the correct sensors for the equipment that is used (gas water heaters, wall-mounted or floor-standing boilers)

It is important to periodically check the serviceability of the boiler draft sensor

Prices

| Manufacturer (intended for manufacturer's boilers) | price, rub. |

| Specialized | |

| BAXI | 1 400 |

| Protherm S010075 for boilers Panther, Cheetah, Skat | 2 550 |

| Ariston | 2 100 |

| Ferroli | 1 100 |

| Universal | |

| Shuft ATF2-NTC10K | 2 100-2 250 |

| Gira 130200 | 2 280-2 900 |

Principle of operation

If we talk about the operating principle of this type of equipment, it must promptly send a signal to the valve, which will allow the gas supply to the burner to be shut off. The sensor reacts if there is a disturbance in the flow of combustion products in the correct and natural direction, that is, from the boiler towards the street through the chimney. If the sensor does not work in this situation, then the smoke generated from the flame, which consists of dangerous gases and water vapor, as well as soot, begins to enter the house where the boiler is located and can cause harm to health, or even lead to the death of a person.

If we talk about how it works, then everything is very simple. As already noted, everything is based on the ordinary laws of physics.

Essentially, these are bimetallic relays operating in two modes:

- inclusion;

- shutdown.

Inside such a thermal relay there is a strip of metal, the main task of which is to respond to temperature changes. Such a device is usually adjusted to a certain temperature. Its indicator will depend on the category of fuel used. If we are talking about natural gas, the temperature range will be from 75 to 950 degrees Celsius. If we are talking about liquefied gas, then the spread will occur in the range of 70-1500 degrees Celsius.

You can talk about the principle of operation in a little more detail using the example of how the sensor works on a gas boiler. If the device, analyzing the information, concludes that the draft inside the boiler deviates significantly from the norm and the heating of the gas smoke begins to increase, then the device immediately begins to block and it is almost instantly turned off.

In different categories of devices, sensors can monitor different parameters. For example, in models with an open combustion chamber, a special thermostat controls the draft and temperature of gases escaping to the street. And if we are talking about a model with a closed combustion chamber, then in this case the sensor monitors the air pressure that is blown out by the turbine.

It should be noted that the role of this type of controller is very difficult to overestimate in terms of security. For example, if we talk about turbocharged models where a closed combustion chamber is installed, then combustion products are removed using a turbine fan. The controller is usually made as a pneumatic relay. Operation is controlled using a membrane. If the pressure becomes weaker, then the contact simply opens, which causes the gas supply valve to close.

It should be said that the traction sensor can work in the following cases:

- accumulation of debris in the chimney;

- incorrect installation of the device;

- when installing a fan in a boiler where there is forced draft;

- if the dimensions of the chimney shaft are smaller than the calculated ones or it was installed incorrectly.

Is it possible to disable

When installing the sensor and using gas equipment, you can often observe periodic shutdowns in operation. In this case, you may want to turn off the traction device completely. However, there is no need to rush.

Draft sensor for gas boiler AOGV and AKGV

There are several reasons for this:

- Firstly, a sensor disconnection may indicate poor traction performance. Weak intensity of movement of smoke gases leads to overturning of the draft in boiler equipment. Harmful fumes will enter the house in large quantities.

- Secondly, the problem may be backdraft. An air lock forms. The exhaust gases of the smoke move to a certain point in the chimney and then fall back. This occurs due to poor heating of the pipe and poor thermal insulation.

Of course, theoretically it is possible to disable the sensor, but this entails great danger. If an emergency suddenly arises, there will be no protection. Therefore, it is not recommended to operate a gas unit without such a controller.

Main reasons for triggering

There are a number of main reasons why the controller may work, regardless of the type of combustion chamber installed in the gas installation.

You should not absolutely rely on the sensor's performance. Therefore, if possible, it is better to foresee negative scenarios in advance and eliminate the cause of their occurrence.

Gusty wind

To prevent a gust of wind from extinguishing the burner, experts recommend installing a stabilizer. It is mounted at the outlet pipe.

Incorrect installation

If errors were made in calculations or installation during installation. Carry out control measurements and check the correct installation of the boiler and chimney. The height of the outlet is calculated depending on the location of the pipe from the ridge. Experts recommend placing it in the center of the roof. The head is placed 50 cm above the ridge.

Disabling the fan

Turning off the fan stops the supply ventilation, and carbon monoxide is not discharged to the street. In this case, the reason for stopping the operation of the ventilation system is identified.

Experts recommend performing a seasonal preventive inspection of the heating device in the fall and spring. Operating the boiler without a thermostat is not recommended.

Poor quality traction

Poor quality traction is the main reason why the control sensor may work. This problem may arise due to improper design of the boiler and exhaust system. For example, poor-quality draft can be caused by a chimney with incorrectly calculated dimensions, if we are talking about a boiler with natural exhaust of combustion products, or a fan that does not operate at the required power, if it is a boiler with forced draft.

It is also worth checking the integrity of the output system. If the parts of the pipe are poorly connected to each other, the magnitude of the traction force will change.

Backdraft

Reverse traction force is a type of poor-quality traction. It is formed if a so-called air lock appears in the outlet system. If it is present, the gases that should exit through the outlet system to the street return back to the gas installation due to the fact that they cannot overcome the air lock.

This problem may arise due to poor thermal insulation (tightness) of the exhaust system pipes. As soon as the tightness of the pipe is broken, a temperature difference is formed, which provokes the appearance of an air lock.

Chimney blockage

A change in draft can also occur due to a clogged chimney. If its outlet is poorly protected from external influences, then, for example, foliage can get into it. But even good protection of the outlet does not guarantee its cleanliness. Birds can build a nest in a warm place and thereby affect the draft. But even the absence of birds does not guarantee good traction, because the output system can become contaminated with its own soot.

There is only one way out of the situation - regularly clean the chimney not only to eliminate problems, but also to prevent their occurrence.

Strong wind

If the outlet pipe is located in such a way that wind can blow into it, then you should prepare for the fact that this will affect the operation of the boiler. A gust of wind entering the pipe can overcome the resistance of the combustion products coming out towards them and blow out the burner.

If the controller does not work in such a situation, then the fuel will continue to flow uncontrollably into the boiler, but will not burn in it. To prevent such a development of the situation, you need to buy a stabilizer and install it in place of the outlet pipe.

Signs that replacement is needed

The sensor is an integral part of the gas system. Despite its high reliability, it may become unusable after a long period of use. It will need to be replaced sooner or later. What will happen if this is not done is described above.

The following signs may indicate the need to replace the controller:

- The installation is permanently switched off unless there is a fault in the output system.

- The heat generator operates at intervals of 20-30 minutes, after which it is deactivated and reactivated only after complete cooling.

If one of these signs appears, you should either call a repair service or check the sensor for serviceability yourself.

The operation of the gas boiler sensor in the heating system can be checked using one of the methods described below:

- It is necessary to install a mirror near the sensor mounting location. And if the boiler is in an active state and the glass surface fogs up, it means the sensor is faulty;

- If you close the damper of the exhaust system halfway, the boiler in operating mode should immediately turn off, since the traction force will be insufficient. If this does not happen, the sensor does not work correctly and needs to be replaced.

There is another, less accurate, but still quite effective way to check the health of the sensor. It is necessary to switch the boiler to hot water supply mode and open the water at full power. If in this case the heat generator turns off, then with a high degree of probability the sensor does not work. The accuracy of the verification method is 95%.

The boiler may turn off even if the controller is working properly. The issue may be a malfunction of other devices inside the boiler.

To solve any problem that arises, you must contact gas service specialists and under no circumstances try to fix the problem yourself.

Increased traction

If checking the chimney draft showed its complete absence or small value. You can also use a device such as a chimney draft stabilizer or turbine. True, their use is limited only to gas boilers. Too high a temperature of the exhaust gases at the outlet of the pipe will contribute to improper operation of the device or its failure.

If we talk about stoves or fireplaces, then in order for the chimney to work correctly during not very good weather conditions. Special tips - wings - are installed on the pipe. This device rotates freely so that its back is always facing the wind. This position prevents wind or rain from entering directly into the chimney.

Special fans can also be used. Such devices have a built-in electric motor. Their operating principle is as follows. Basically, they work from the wind; during strong gusts, the fan rotates, increasing the release of exhaust gases from the pipe; if the wind flows are not strong enough, then the electric motor turns on, which forces the fan to work forcibly and all harmful substances also end up on the street.

A small disclaimer: do not immediately after reading the article run to the store and buy a new device. Before you are going to install it, you should make calculations. And based on the results obtained, it will be clear whether this device can be installed on your chimney.

If there is no draft in the chimney, it will be useful to check the operation of the dampers. For stoves and fireplaces, this is a kind of regulator of the exhaust gas removal force.

Traction sensor

Definition

The autonomous operation of the gas boiler is carried out thanks to an electronic control system. It provides control using sensors, collecting technical indicators from different parts of the structure. If these indicators deviate from the norm, the control system changes the boiler operating mode or stops its operation.

A gas boiler draft sensor is a monitoring device that determines the presence and degree of draft in the chimney, and also transmits the corresponding signals to the electronic boiler control system.

It is the main device that protects the health and lives of people from the accumulation of carbon dioxide indoors.

What is it needed for

The main functions of the draft sensor are to determine the draft force and completeness of gas combustion, as well as ensure safety during operation of the gas boiler by sending a signal to the control system about insufficient draft.

If the process of removing carbon monoxide is disrupted, it accumulates in the room, which negatively affects human health, and, with a large volume of accumulated combustion products, poses a serious threat to human life.

The draft sensor detects and prevents incorrect operation of heating equipment.

Where is it located?

Installing a draft sensor in gas boilers is a prerequisite for their operation. This is approved by the relevant legislative act.

As a rule, the installation location of the sensor is the smoke hood or a section of the boiler body near the ventilation duct.

The draft sensor is not installed by the manufacturer directly into the flue or is separated from it by a special thermal insulating material. This type of installation eliminates overheating of the draft sensor due to direct contact with a hot surface.

The draft sensor, like the chimney, requires periodic inspection and cleaning.

Purpose and principle of operation

The flawless functioning of 4th generation HBO sensors ensures the stability of equipment performance. Strict control of temperature parameters minimizes the likelihood of hazardous situations that may arise as a result of increasing temperature values above the limit values.

The 4th generation HBO temperature sensor operates in conjunction with pressure sensors. This principle of collecting and transmitting information is necessary to ensure reliable and economical operation of gas-powered internal combustion engines.

These devices are installed in the following LPG units:

- directly in the reducer to control the gas temperature in the evaporator;

- in front of the reducer to analyze the pressure level in the gas tank.

Thanks to this conglomerate, the system can determine the amount of remaining fuel in the gas tank. A smart electronic control unit transmits this information to the control panel.

The information collected by the LPG gas temperature sensor allows the ECU to adjust economical fuel injection. If these steps are violated, you can not count on the correct functioning of gas equipment. This eliminates the possibility of cold gas entering the heated gearbox and maintains the temperature balance necessary for smooth operation of the machine.

Features of the use of the most common thermocouples

Technical characteristics depend directly on the materials from which they are made.

Type J (Iron Constantan Thermocouple)

- It is not recommended to use below 0°C, because Moisture condensation on the iron terminal leads to the formation of rust.

- The most suitable type for rarefied atmospheres.

- The maximum temperature of use is 500°C, because Above this temperature, rapid oxidation of the leads occurs. Both terminals are quickly destroyed in a sulfur atmosphere.

- The readings increase after thermal aging.

- Low cost is also an advantage.

Type E (chromel-constantan thermocouple)

- The advantage is high sensitivity.

- Thermoelectric homogeneity of electrode materials.

- Suitable for use at low temperatures.

Type T (copper-constantan thermocouple)

- Can be used below 0°C.

- Can be used in atmospheres with slight excess or deficiency of oxygen.

- Use at temperatures above 400°C is not recommended.

- Not sensitive to high humidity.

- Both leads can be annealed to remove materials causing thermoelectric inhomogeneity.

Type K (chromel-alumel thermocouple)

- Widely used in various areas from -100°C to +1000°C (recommended limit depending on the diameter of the thermoelectrode).

- In the range from 200 to 500°C, a hysteresis effect occurs, i.e., readings during heating and cooling may differ. Sometimes the difference reaches 5°C.

- Used in a neutral atmosphere or an atmosphere with excess oxygen.

- After thermal aging, the readings decrease.

- It is not recommended to use in a rarefied atmosphere, because... chromium can be released from the Ni-Cr terminal (so-called migration), and the thermocouple changes the thermoelectric force and shows a low temperature.

- A sulfur atmosphere is harmful to a thermocouple because affects both electrodes.

Type K thermocouple.

Type N (nicrosil-nisil thermocouple)

- This is a relatively new type of thermocouple, developed from the K-type thermocouple. The K-type thermocouple can be easily contaminated by impurities at high temperatures. By fusing both electrodes with silicon, the thermocouple can be precontaminated and thus reduce the risk of further contamination during operation.

- Recommended operating temperature up to 1200°C (depending on wire diameter).

- Short-term operation is possible at 1250°C.

- High stability at temperatures from 200 to 500°C (significantly less hysteresis than for a type K thermocouple).

- Considered to be the most accurate base metal thermocouple.

General Tips for Selecting Base Metal Thermocouples

- Application temperature below zero – type E, T

- Room temperatures for use – type K, E, T

- Application temperature up to 300°C – type K

- Application temperature from 300 to 600°C – type N

- Application temperature above 600°C – type K or N

Precious metal thermocouples

Recommended maximum operating temperature 1350°C. Short-term use is possible at 1600°C. It becomes contaminated at temperatures above 900°C with hydrogen, carbon, and metallic impurities of copper and iron. When the iron content in the platinum electrode is 0.1%, TEMF changes by more than 1 mV (100°C) at 1200°C and 1.5 mV (160°C) at 1600°C. The same picture is observed with copper contamination. Thus, thermocouples should not be reinforced with steel tube, or the electrodes should be insulated from the tube with gas-tight ceramics. Can be used in oxidizing atmosphere. At temperatures above 1000°C, the thermocouple may become contaminated with silicon, which is present in some types of protective ceramic materials

It is important to use ceramic tubes consisting of high purity aluminum oxide. It is not recommended to use below 400°C, since the thermoelectric force in this region is small and extremely nonlinear.

Precious metal thermocouples

The properties are the same as those of type S thermocouples.

It will be interesting What is a short circuit

Type B (platinum-platinum-rhodium)

Recommended maximum operating temperature is 1500°C (depending on wire diameter). Short-term use is possible up to 1750°C. Can be contaminated at temperatures above 900°C by hydrogen, silicon, copper and iron vapor, but the effect is less than for S and R thermocouples. At temperatures above 1000°C the thermocouple can be contaminated by silicon, which is present in some types of protective ceramic materials

It is important to use ceramic tubes consisting of high purity aluminum oxide. Can be used in oxidizing environments. Application is not recommended at temperatures below 600°C, where the emf is very small and nonlinear. Summary table of thermocouple types

Summary table of thermocouple types.

Measurement error

The correctness of temperature readings obtained using a thermocouple depends on the material of the contact group, as well as external factors. The latter include pressure, background radiation or other reasons that can affect the physical and chemical properties of the metals from which the contacts are made.

consists of the following components:

- random error caused by the manufacturing features of the thermocouple;

- error caused by a violation of the temperature regime of the “cold” contact;

- error caused by external interference;

- error of control equipment.

How to use the equipment?

Without violating the operating rules, you can significantly extend the service life of gas appliances:

• Do not turn on the boiler with a broken burner or a clogged chimney.

• The chassis must be grounded.

• When using antifreeze as a coolant instead of water, you need to purchase only a certified product. Containing ethylene glycol is prohibited.

• Water should not heat above 95 degrees.

• When installing the device near a wall that is covered with a fire-hazardous material, it is necessary to make a gasket made of steel or asbestos.

• The device may only be turned on after the system has been filled with water/antifreeze.

• Clean your chimney and filters annually. Make sure all connections are tight.

Flame ionization sensor

The flame ionization sensor is another device that ensures safe operation of the boiler. This device monitors the presence of a flame. If during operation the sensor detects the absence of fire, it can turn off the boiler.

The presence of a flame is monitored either using an ionization electrode or a photosensor

The operating principle of such a device is based on the formation of ions and electrons during combustion of a flame. Ions, attracted to the ionization electrode, cause the formation of an ionic current. This device is connected to a combustion control sensor.

When the sensor check detects the formation of a sufficient number of ions, the gas boiler operates normally. If the ion level decreases, the sensor blocks the operation of the device.

In certain places, pressure gauges are connected to the igniter air path. The ionization electrode itself is mounted on the igniter body through a special bushing and connected to the output of the igniter automatic.

Repair

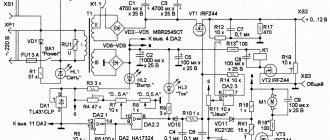

Self-repair of damaged boiler automation is not only unpleasant, but most often almost hopeless, since boiler passports are not written for these purposes. And without an exact knowledge of the circuit and all the intricacies of the automatic system design, it is better for a common person (not an electronics engineer) not to even start. Of course, I will not be opening America if I say that the best solution would be to initially buy a boiler with reliable automation from a reputable manufacturer, so you risk running into trouble less.

To control pumps, stations and other water supply devices, it is necessary to use special devices. A differential water pressure switch for the pump allows you to automatically turn off or turn on the pump when the pressure in the system changes.

Types of gas boiler draft sensor

There are two types of gas boilers. The first is boilers with natural draft, and the second is equipment with forced draft. Each type needs its own type of equipment.

The closed combustion chamber, with the help of blowing devices, detects the forced draft equipment, which contains a sensor, the so-called pneumatic relay. The device controls the operation of the fan and the exhaust rate of combustion gases. Structurally, the device consists of a membrane that bends during normal draft under the pressure of flue gases. As soon as the gas pressure drops below normal, the membrane reduces deflection and the contacts open and the gas valve closes. Sensors ensure normal operation of the heating device. The device is a fundamental element of boiler protection, because with low draft, the process of re-drafting flue gases is possible and combustion products leave the boiler not towards the street, but go into the room.

Placements

Naturally, the sensor must be placed in the zone of influence of the heater. Therefore, they are distinguished by the method of placement:

- overhead - installed with tight contact directly on the heated surface;

- submersible - placed inside the coolant;

- room - the room temperature is controlled;

- external - the state of the external environment outside the house is measured. They have a waterproof body.

Reasons for the operation of a gas boiler draft sensor

There are many reasons that can trigger the device. Among the main reasons leading to the disabling of the column, it is worth highlighting:

- Poor quality traction. Often the problem arises due to improper installation of the exhaust structure. Poor extraction of combustion products can cause poisoning of people living in a residential area.

- Backdraft, which occurs due to the formation of an air plug in the chimney area, which does not allow decay products to escape out. Quite often, a sharp change in temperature conditions leads to the formation of air jams.

- Blockage in the chimney area. Homeowners lacking experience believe that the pipe does not clog. But it is not so. Birds looking for a place to build a nest often choose a chimney. When a bird builds a nest, it can fall into a pipe, get stuck there and die. In addition to birds, clogs can be caused by leaves and soot deposits on the inner walls of the chimney. When it occurs, the intensity of traction decreases. The only solution to the problem is cleaning.

- Strong gusts of wind. If the pipe is positioned incorrectly, wind gets into it and blows out the burner. Triggering of the sensor causes the fuel supply to be cut off.

- Incorrect installation of equipment. An incorrect calculation of the dimensions of the chimney often provokes the burner to go out. It is recommended to measure the height of the chimney depending on how far the pipes are from the roof ridge. The head should be 60-70 cm higher than the ridge.

Before you start replacing the draft sensor, it is important to familiarize yourself with the design of the gas water heater

Is it possible to disable

With a constant shutdown, many may think about completely dismantling it by short-circuiting the terminals instead of the sensor. But doing this is contraindicated under any circumstances. If the device turns off, this primarily indicates unsatisfactory traction performance.

The unstable movement of flue gases in the boiler leads to draft reversals, which leads to the entry of harmful gases into the room and a burning smell begins to be felt. A shutdown can also be caused by reverse draft: an air lock appears in the chimney pipe, and the gases flow back.

How does a draft sensor work in a gas boiler?

Traction sensors can have different structures. It depends on what type of boiler they are installed in.

The function of the draft sensor is to generate a signal when the draft indicators in the boiler deteriorate

At the moment there are two types of gas boilers. The first is a boiler with natural draft, the second is with forced draft.

Types of sensors in different types of boilers:

If you have a boiler with natural draft, then you might have noticed that the combustion chamber is open. The draft in such devices is achieved using the correct dimensions of the chimney. Draft sensors in boilers with an open combustion chamber are made on the basis of a biometallic element

This device is a metal plate on which a contact is attached. It is installed in the gas path of the boiler and responds to temperature changes. With good draft, the temperature in the boiler remains quite low and the plate does not react in any way. If the draft becomes too low, the temperature inside the boiler will rise and the metal of the sensor will begin to expand. Having reached a certain temperature, the contact will release and the gas valve will close. When the cause of the breakdown is eliminated, the gas valve will return to its normal position. Those who have forced draft boilers should have noticed that the combustion chamber in them is of a closed type. The draft in such boilers is created by the operation of a fan. Such devices have a traction sensor installed in the form of a pneumatic relay. It monitors both the operation of the fan and the speed of combustion products. Such a sensor is made in the form of a membrane that bends under the influence of flue gases that arise during normal draft. If the flow becomes too weak, the membrane stops bending, the contacts open and the gas valve closes.

Draft sensors in boilers with an open combustion chamber are made on the basis of a biometallic element. This device is a metal plate on which a contact is attached. It is installed in the gas path of the boiler and responds to temperature changes. With good draft, the temperature in the boiler remains quite low and the plate does not react in any way. If the draft becomes too low, the temperature inside the boiler will rise and the metal of the sensor will begin to expand. Having reached a certain temperature, the contact will release and the gas valve will close. When the cause of the breakdown is eliminated, the gas valve will return to its normal position. Those who have forced draft boilers should have noticed that the combustion chamber in them is of a closed type. The draft in such boilers is created by the operation of a fan. Such devices have a traction sensor installed in the form of a pneumatic relay. It monitors both the operation of the fan and the speed of combustion products. Such a sensor is made in the form of a membrane that bends under the influence of flue gases that arise during normal draft. If the flow becomes too weak, the membrane stops bending, the contacts open and the gas valve closes.

Draft sensors ensure normal operation of the boiler. In natural combustion boilers, if there is insufficient draft, symptoms of reverse draft may be observed. With this problem, combustion products do not go out into the street through the chimney, but return back into the apartment.

There are a number of reasons why a traction sensor may trip. By eliminating them, you will ensure normal operation of the boiler.

What can cause the traction sensor to work:

- Due to a clogged chimney;

- If the dimensions of the chimney are incorrectly calculated or installed incorrectly.

- If the gas boiler itself was installed incorrectly;

- When a fan was installed in a forced draft boiler.

When the sensor is triggered, you must urgently find and eliminate the cause of the failure. However, do not try to forcefully close the contacts; this not only can lead to failure of the device, but is also dangerous for your life.

The gas sensor protects the boiler from damage. For better analysis, you can purchase an air gas analyzer; it will immediately report the problem, which will allow you to quickly fix it.

Overheating of the boiler threatens combustion products entering the room. Which can have a negative impact on the health of you and your loved ones.

Diagnosis of problems and ways to solve them

If your gas water heater equipped with an automatic security system does not work, you need to make sure that the problem lies in the operation of one of the sensors:

- If your draft sensor goes off, you will most likely smell burning or gas in the room at that moment. To make sure that the problem is indeed incorrect draft, place your palm or a piece of paper near the chimney. If the draft is disrupted and air flows from the chimney into the room, then the solution to the problem often lies in calling a stove technician who will clean the chimney of soot and combustion products deposited in it.

- The overheating sensor will work in your geyser if the cause of an excessive increase in temperature is contamination of the heat exchanger. You need to proceed as follows: open the windows and doors, wait until the room is cleaned with fresh air and the boiler has cooled down, then contact a qualified specialist.

- If you have an ionization sensor installed, it may make it impossible to ignite the igniter due to the fact that the igniter nozzles are clogged with soot, and the safe ignition time programmed in the flame detector will expire. The solution in this situation is to clean the nozzles at the igniter and try to ignite again. If it is unsuccessful, you should contact a qualified technician.

From the author: hello, friends! A geyser is a rather complex structure consisting of many elements. Each of them plays an important role in the operation of the device. If some of these elements break down, the problem is immediately visible and does not require any testing. But how can I check the draft sensor for a gas water heater? And what is this part even needed for? This is exactly what will be discussed in today's article.

In general, a gas water heater is an excellent heating device. No wonder it is the most popular among owners of both apartments and private houses. The boiler is highly efficient, does not require too much maintenance, and the fuel used usually costs literally pennies.

The only drawback of this equipment is the possible danger of its operation in the event of any malfunction. Everyone knows that a gas leak, for example, can have dire consequences, including an explosion, destruction of a house and death. Therefore, each element of the column must work perfectly, any problem must be corrected immediately, and a part that is absolutely faulty must be replaced.

Therefore, it is extremely important to detect a breakdown in a timely manner. To do this, regular checks of the system are carried out, and, as a rule, they are performed by gas service specialists. But you yourself can periodically inspect some elements on which the safety of the people living in the house depends

One of these parts of the design is the traction sensor

But you yourself can periodically inspect some elements on which the safety of the people living in the house depends. One such part of the design is the traction sensor.