Draft is a characteristic that displays the rate of air exchange in the boiler. The gas combustion process requires a continuous supply of air and removal of combustion products (carbon monoxide, carbon dioxide, soot and water evaporation) into the atmosphere.

Types of traction:

- natural;

When burning, the air rushes upward according to the laws of physics and has a high temperature. This ensures the removal of combustion products and the natural flow of air due to its vacuum at the combustion site.

Boilers with natural draft are simple in design, less noisy and do not require additional electricity consumption.

- forced.

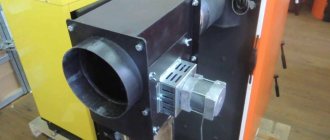

This type of draft is carried out due to the forced flow of air into the burner from a blowing device.

It is also controlled by an electronic control system.

Air is taken from the room or from the atmosphere. In the second case, a coxial pipe is often used.

Its design includes outer and inner pipes of different diameters. Through the outer pipe, air is sucked in for its forced supply, and through the inner pipe, carbon monoxide is released.

Boilers with forced draft and coxial tube necessarily have a sealed type of combustion chamber. Their advantages:

- safety, unlike an open combustion chamber;

- high boiler efficiency;

- does not consume oxygen in the room;

- For the boiler to operate, only one hole in the wall is required.

However, there are a number of disadvantages:

- complexity of the design, and, consequently, more complex maintenance and repair;

- noise due to the operation of the electric motor of the inflatable device;

- the need for continuous power supply.

Traction sensor

Definition

The autonomous operation of the gas boiler is carried out thanks to an electronic control system. It provides control using sensors, collecting technical indicators from different parts of the structure. If these indicators deviate from the norm, the control system changes the boiler operating mode or stops its operation.

A gas boiler draft sensor is a monitoring device that determines the presence and degree of draft in the chimney, and also transmits the corresponding signals to the electronic boiler control system.

It is the main device that protects the health and lives of people from the accumulation of carbon dioxide indoors.

What is it needed for

The main functions of the draft sensor are to determine the draft force and completeness of gas combustion, as well as ensure safety during operation of the gas boiler by sending a signal to the control system about insufficient draft.

If the process of removing carbon monoxide is disrupted, it accumulates in the room, which negatively affects human health, and, with a large volume of accumulated combustion products, poses a serious threat to human life.

The draft sensor detects and prevents incorrect operation of heating equipment.

Where is it located?

Installing a draft sensor in gas boilers is a prerequisite for their operation. This is approved by the relevant legislative act.

As a rule, the installation location of the sensor is the smoke hood or a section of the boiler body near the ventilation duct.

The draft sensor is not installed by the manufacturer directly into the flue or is separated from it by a special thermal insulating material. This type of installation eliminates overheating of the draft sensor due to direct contact with a hot surface.

The draft sensor, like the chimney, requires periodic inspection and cleaning.

Conclusions and useful video on the topic

The video discusses the structural details of the traction sensors, the location of these components and their operating principle:

If professional craftsmen are quite familiar with gas equipment, for the average user, troubleshooting a gas boiler is a “dark forest”. In addition, handling gas systems in the absence of appropriate knowledge is fraught with serious consequences.

Therefore, when there is a desire to independently replace or repair the same draft sensor or some other equipment of a gas water heater, you first need to at least study the system. But the best way to eliminate gas system defects is to contact specialists.

Would you like to supplement the above material with useful comments on the principle of operation of the traction sensor? Or would you like to share your sensor testing experience with other users? Write your remarks and comments in the block below, add unique photos of your own testing.

Device and principle of operation

The main principle of operation of a gas boiler draft sensor is the closing and opening of contacts.

It works according to the laws of physics, thereby controlling the temperature of the burned fuel. When the temperature indicator shifts into an unacceptable zone, the draft sensor transmits a corresponding signal to the electronic control unit of the boiler.

The type of sensor directly depends on the type and design of the gas boiler in which it is installed.

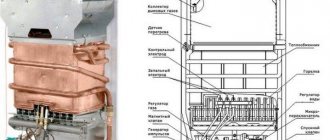

Boiler with natural draft and open combustion chamber

The main element is a plate consisting of two metals that have different deformation characteristics due to heating, as well as two contacts that are brought together and separated by these plates. As a rule, one of these plates is fixedly fixed to the sensor body, and the second is deformed due to thermal effects.

The sensor must match the fuel type. If the boiler operates on compressed natural gas, the sensor must operate in the temperature range from 95 to 950 °C, if on liquefied gas - from 75 to 1500 °C.

If the traction force becomes less, burnt gases accumulate. Due to this malfunction, the temperature of the measuring device increases. The bimetallic plate opens the contacts and the gas supply to the burner stops, that is, the boiler control unit performs an emergency shutdown.

Work will resume when the sensor cools down and its temperature drops within the appropriate range. This means that it also acts as a thermostat.

With forced draft and closed combustion chamber

In this case, the draft sensor has a pneumatic relay design with a very sensitive membrane. The blowing device creates strong draft and movement of burnt gases. Under their influence, the membrane is deformed and closes the sensor contacts. At this time, the control unit detects normal operation of the boiler with sufficient draft.

But, with insufficient traction, there is not enough force to displace the membrane and it returns to its original position. The contacts open and the heating device stops operating.

With condensing heating type

The sensors, as on boilers with natural draft, operate on the principle of deforming a bimetallic plate, but are set by the manufacturer to a lower temperature regime.

What does it look like and where is it located?

This is what the traction sensor of a turbocharged BAXI ECO Four looks like.

The exact location is always indicated in the instructions for the boiler. According to the gas safety rules PB 12-368-00, domestic heating boilers must be equipped with a draft sensor. The installation site, as a rule, is the smoke hood (located in the smoke extractor) or the free space between the ventilation duct and the unit body.

In atmospheric boilers, the draft sensor has a slightly different appearance.

It is worth paying attention that it cannot be attached closely to the surface of the flue. Paronite gaskets are used as a “separator”: this measure reduces the likelihood of contact heating, as well as creates a gap that will provide technical access to the flue opening and to the draft sensor.

When and why it works

There are a number of reasons why the draft in a gas boiler is disrupted and the sensor is triggered:

- improper design of heating equipment;

The reason that you first need to pay attention to. It implies an incorrect design of the chimney, the presence of bends, or poor-quality installation.

- chimney obstruction;

Gas boilers leave much less soot, unlike solid fuel boilers. Despite this, over a longer period of time, soot tends to accumulate in gas boilers, which is the reason for poor chimney permeability.

The next reason for a clogged chimney can be foreign objects, such as leaves, tree branches, and flying debris.

It is extremely rare for animals to get into the chimney. Often these are birds that make nests on the chimney during the non-heating period or during the absence of people and the boiler has not been working for a long time.

The chimney requires periodic inspection and, depending on the degree of contamination, mechanical cleaning.

- weather;

Moscow is a city of frequent changes in weather conditions.

The cause of shutdowns may be dense fog, heavy precipitation, or simply high humidity. This creates high atmospheric pressure, which is an obstacle to air exchange.

Strong winds also create high pressure in the atmosphere. It can harm natural draft and contribute to the reverse movement of combustion products (backdraft).

Bad weather conditions can only harm the operation of boilers with natural draft and an open combustion chamber.

It is advisable to install a protective cap on the chimney. Its name is traction stabilizer.

It prevents wind from blowing into the air duct and prevents the burner from extinguishing.

- airlock;

Smoke removal requires continuous movement of air masses. An air lock in the chimney can interfere with air exchange and cause combustion products to flow back.

An air lock occurs due to poor-quality thermal insulation of the chimney and a large temperature difference in its lower and upper parts. At the top it is usually cold, heavier and thicker.

- insufficient height and incorrect installation location of the chimney;

It depends on the distance of installation of the pipe from the highest point of the roof - the ridge of the roof. The ideal location is the middle of the roof side and the height above the ridge is about 50 cm.

- Unstable voltage level in the electrical circuit.

Power surges can negatively affect the operation of all electronic components of heating equipment.

If the sensor is triggered and the boiler is turned off, it is not recommended to force it to start again. This will damage the heating equipment and increase the danger to human health and life. In such cases, diagnostics, identification and elimination of the causes of the malfunction are necessary.

What to do if there is no traction

There are several reasons for the operation of protective devices of gas boiler equipment: an incorrectly installed exhaust gas removal system or sensor failure. So, why is there no draft in the chimney? To avoid malfunction or malfunction of the device and ensure normal exhaust from the boiler to the street, you need to correctly install the smoke removal system, guided by important criteria:

- you need to calculate the height of the chimney depending on the distance from the roof ridge to the chimney;

- It is advisable to place the chimney in the center of the roof so that the top point of the pipe rises above the ridge by more than 0.5 meters;

- install the boiler draft stabilizer in close proximity to the outlet pipe to avoid blowing out the flame in strong winds.

If the draft is insufficient, this will lead to an increase in the temperature of the gases in the boiler and blocking of the gas valve. During regular boiler maintenance, the gas removal system must be checked: the condition of the pipes, tightness, cleaning, operation of the boiler turbine.

How to check the draft in the chimney of a gas boiler? You can use an anemometer - a device that measures the speed of movement of gases, attach a sheet of thin paper, or use smoke from a cigarette. It is also necessary to visually inspect the chimney for mechanical blockages. If it becomes necessary to increase the temperature threshold for the draft sensor to operate, a specialist can adjust the required gap in the device. The device must be periodically cleaned from soot formed during fuel combustion, or due to incorrect gas and air supply to the burner.

Diagnostics

Before you check the draft sensor of a gas boiler, you should know: boilers equipped with an electronic control system independently diagnose the faulty unit and report an error.

However, if the model is not equipped with a control system, it is possible to independently check the condition of the boiler and identify a malfunction of the draft sensor based on the following signs:

- constant independent shutdown of the boiler during the operating cycle with normal combustion, no overheating and normal draft;

- no automatic restart after one cycle of operation (10–30 minutes).

- In order to perform independent diagnostics of the air exchange control system and identify its possible malfunction, you must:

- install a mirror to the location where the draft sensor is installed and start the boiler. There should be no traces of fogging on it;

- covering the damper in the chimney. If the smoke removal control system is working properly, the boiler will turn off on its own due to smoke accumulation and overheating;

- in case of automatic stop of the boiler operating in hot water supply mode and when the hot water tap is open. This is a sign of a faulty traction sensor.

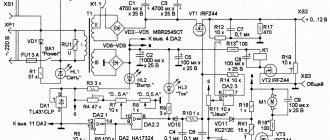

Design of a gas boiler pressure switch

The design of the pressure switch does not differ in pronounced mechanical or electrical complexity. However, the pressure switch device for a domestic gas boiler still has unique parts, for example, a sensitive membrane.

This element is connected to a microswitch that acts as a signal switch. To control the burner, a group of three contacts is usually used (control in normal mode or emergency mode). Essentially, one contact is "shared".

A widely used version of a differential relay designed to work in the design of many household gas boilers. It looks like a technically simple device, but significant in terms of functionality.

The normal operating mode of boiler equipment is accompanied by the operating state of the thermostatic membrane, in which the circuit remains closed through one configuration of boiler pressure switch contacts. If the operating mode of the equipment is disrupted (the smoke flow changes the characteristic), the position of the sensitive membrane changes accordingly.

In this condition, the working group of microswitch contacts is broken, while the second group (emergency switch), on the contrary, forms a conductive circuit. Through this circuit, power is supplied to the automatic locking system, as a result of which emergency control of the gas burner is activated, as well as the water circulation system.

Thanks to the presence of a pressure switch, the following can be effectively carried out:

- temperature control;

- smoke pressure monitoring;

- control of condensation formation.

All the noted functions radically affect the operation of water heating equipment, ensuring not only effective functionality, but also safe operation of the boiler.

Checking with a multimeter

This diagnosis requires some experience, knowledge of the electrical circuit of the boiler, as well as an understanding of how the draft sensor works in a gas boiler.

The reason for a malfunctioning air exchange control system, or if there are all signs of its malfunction, may be a violation of the integrity of the electrical wiring. In this case, the sensor may be working properly.

In this situation, it is necessary to inspect the wiring and connection points for integrity and absence of oxidation, as well as diagnostics with a multimeter. With its help, the electrical wiring is “ringed” and its faulty section is identified.

The tester can also diagnose an internal malfunction of the sensor itself. Normally, its resistance is 1–2 ohms. If the readings are 0 or infinity, the traction sensor is faulty.

The manufacturer does not recommend disassembling or repairing this device. The only way out is to replace it.

Ways to eliminate backdraft

You should pay attention to any, even the most minor, changes in the operation of the gas device. If the water heater makes strange noises or turns on with a bang, you should immediately contact a specialist.

Popping noises are most common in older speaker models. In modern flow columns such defects are extremely rare. Extraneous sounds occur due to accumulated gas in the heat exchanger, which can subsequently occupy the entire chimney.

In most cases, such a violation is provoked by a clogged chimney, a broken valve, or a deviation of the ignition wick.

In new water heater models, a malfunction can be caused by:

- defective spark plug;

- spent battery installed in the control module;

- faulty microswitch located in the water unit.

Having decided to carry out independent repair work, first of all, you need to check the intensity of traction using one of the methods listed above.

Further diagnostics will differ depending on the type of device - with an ignition wick or an automatic ignition system.

Column with automatic ignition system

In this type of water heater, the ignition device is controlled by an electronic module. The system with microswitches located on the fire and liquid regulators is considered one of the most reliable. Repairing a failed part can result in significant costs.

You can determine the severity of the failure as follows:

- Research batteries . Delayed ignition of the gas may be due to a low battery charge. In this case, it is enough to replace the power source with a new one.

- Check the functionality of the liquid pressure microregulator , designed to transmit signals to the control module. Its activity is associated with the supply of water when it is necessary to ignite the gas. Like other regulators, it can fail and issue incorrect commands. The problem can be determined using an ohmmeter and a multimeter. The worn element should be replaced with a new one.

- The appearance of uncharacteristic sounds can also be caused by deformation of the location of the device that ignites the gas . The malfunction is usually caused by a temperature difference. The part is secured using a screw; you should loosen it a little and correct the position of the spark plug. The gap should be 0.4-0.5 cm.

- Gas can also accumulate due to a faulty valve, which causes fluid flow to slow down . The small metal ball should move freely under the lid. If its movement is disturbed, you can try to move the valve from its place with a cable. If there is contamination, the channel should be cleaned. But it is not recommended to carry out such a procedure unless absolutely necessary.

Upon completion of the repair work, it is necessary to check the connections for leaks. You can enhance safety using rubber gaskets and special sealants.

Ignition wick water heaters

Flow-through geysers of the previous generation often emit characteristic pops when turned on. Such structures are considered not very convenient and often even unsafe; at the same time, much less money will be needed to repair them.

The accumulation of gas in an area not intended for this purpose can be caused by improper placement of the ignition wick. Failure to do so results in a reduced flame and an inability to reach the edge of the burner with the edge. The main reason for insufficient gas supplied to the wick is a clogged nozzle.

You can fix the problem yourself, but to do this you need to completely disassemble the device.

The first step is to turn off the water and gas supply.

The main part of water heaters has the same type of circuit, so the repair instructions will practically not differ:

- First you have to dismantle the protective casing of the water heater.

- Provide free access to the tee.

- Unscrew the fastening screws, and then remove the nuts securing the supply tubes and regulator.

- The tee must be carefully pulled out of the groove.

- Examine the lower pipe. A small screw with a through hole is the jet.

- The nozzle should be cleaned using a needle or wire.

- Upon completion of all work, you need to reassemble the water heater in the reverse order.

If the problem persists, you should contact a gas company specialist for help.

There are other reasons for the appearance of reverse thrust:

- Seasonal changes , in this case it is necessary to make sure that there are no errors when installing the chimney, and insulate the channels.

- An air lock inside the smoke channel can cause reverse draft in the chimney of a household gas water heater. To fix the problem, set fire to the newspaper inside the pipe.

- Forced exhaust in a room with a column causes a compensation process , air comes from the smoke duct. Metal-plastic windows only aggravate the problem; in some houses, air from the chimney begins to actively flow into the room.

We discussed more information about the causes of backdraft in a chimney in the next article.

The situation with air compensation can also be corrected using a check valve for the chimney of a gas water heater. You should also dismantle the fan and buy supply valves for metal-plastic windows.

Mechanical shut-off devices, known as a check valve or water heater damper, ensure that liquid and gas flow in only one direction.

Designed for turbocharged geysers. Their action is based on the opening of the exhaust hole when the column is operating and its closing after shutdown, which guarantees safe use.

How to disable

The instruction manual does not contain information on how to disable the draft sensor in a gas boiler. It does not recommend disabling this security system yourself. This can lead to negative consequences both for the device and for human health, since the activation of the sensor is a clear sign of danger.

Disabling the draft sensor is a direct violation of the safety rules established by the heating equipment manufacturer!

Carbon monoxide poisoning has the following symptoms:

- mild degree - headache, dizziness, chest pain, pounding in the temples, cough, lacrimation, nausea, vomiting, possible hallucinations, redness of the skin and mucous surface, rapid heartbeat, hypertension;

- moderate - tinnitus, drowsiness, paralysis;

- severe - loss of consciousness, convulsions, involuntary defecation or loss of urine, abnormal breathing rhythm, blue skin color, death.

The consequences of carbon monoxide poisoning can negatively affect a person’s future life activities.

At the same time, the boiler design allows for the possibility of turning off this system. To do this, it is necessary to disconnect the thermocouple breaker and the electrical wiring of the draft sensor from the solenoid valve, as well as from the electronic control unit of the boiler.

Thus, the control unit will continue to autonomously control the operation of the boiler, without taking into account the temperature of the burned gas and the force of its release into the atmosphere.

Design of a protection system in geysers (sensors)

- Flame sensor (combustion sensor) - is a thermocouple that heats up during the burning process of the burner, the pressure inside the sensor increases and is transferred to the gas supply valve, when the burner goes out, the sensor cools down and the gas supply valve closes. This sensor insures the gas water heater against gas leakage. Some models of geysers have a flame sensor installed, which is an ionization electrode; this sensor is installed directly in the burner flame and reacts to flame ions; if the flame disappears, the sensor will turn off the gas supply.

- Draft sensor - in the absence of draft, this sensor sends a signal to the fuel supply valve and the column goes out. If the sensor does not detect the presence of traction when turned on, the column will not turn on. The draft sensor protects the room from carbon monoxide in the event of faulty ventilation or a clogged chimney.

- Thermal relay (overheating sensor) – the sensor is installed on the heat exchanger and monitors the presence of overheating of the water; if the temperature rises above +85? C, the geyser turns off. Overheat protection is necessary to protect the heat exchanger from damage.

- Flow sensor - monitors the presence of water flow through the geyser when the water supply tap is closed, thanks to this sensor the column is turned off.

- Low water pressure sensor - this sensor prevents the geyser from turning on if there is no water pressure sufficient for its proper functioning.

- Pressure relief safety valve - in case of increased water pressure, the safety valve will protect the column pipes from rupture.

How to troubleshoot

If a fault is detected in the gas boiler draft sensor itself, it is replaced with a new one. If a break or fault in the electrical wiring was detected using the tester, the corresponding section of the wire must be replaced or repaired.

After performing the above steps, it is necessary to re-check the operation of the boiler and the draft sensor by forcing it.

It is important to note that during the operation of any type of boiler, its periodic maintenance is mandatory and recommended by the manufacturer. It includes checking the electronic control unit, control devices, as well as the mechanical parts of the boiler. In addition, the components of the boiler and chimney are cleaned from accumulated combustion products.

For this purpose, qualified workers with appropriate education and diagnostic equipment corresponding to the characteristics of a particular type of boiler are involved.

How to check the functioning of the device?

Diagnostics of the proper functioning of the pressure switch of gas equipment is a necessary and useful matter. As a rule, such a check is carried out by representatives of gas companies using special instruments.

The classic diagram for connecting a differential relay (pressostat) in the design of a domestic gas boiler: 1 – fan; 2 – manometric device; 3 – differential relay

However, the owner of the gas boiler himself can also perform a kind of “testing” with simple steps. Just keep in mind that such actions violate the rules for servicing gas equipment.

If, nevertheless, the owner decides to break the rules, it is enough to reduce the supply of network water supplied to the boiler, for example, by partially closing the shut-off network tap of the water supply.

As a result of a decrease in the mass of the water flow in the gas boiler system, the temperature and pressure of the flue gases inevitably begins to change. The fan increases the speed to create greater vacuum in the chamber.

Accordingly, according to the theory of operation of the pressure switch, this device is triggered, turning off the boiler due to insufficient vacuum through the supply line of silicone tubes. The device also operates in the opposite case, when the vacuum value exceeds the set value.

Construction of a gas boiler gas unit

The gas unit is connected by a rod to the water unit; the rod regulates the flow of gas to the burners, only during water flow, when the column is turned on. Gas enters the gas unit through an electromagnetic valve; it also houses a rotary knob for adjusting the power and ignition of the gas water heater. From the gas unit there are gas pipes to the ignition and main burner. The rotary power regulator releases gas to the ignition burner, and the rod connected to the water unit, when the water is turned on, opens the gas access valve to the main burner.

The design of a geyser is not too complicated, but if you are not a specialist, diagnosing a malfunction will not be easy, since gas water heaters, despite a similar device, have differences, and also, each malfunction has different nuances. If you doubt that you can safely fix a geyser malfunction, contact us. We employ experienced specialists who will quickly and with a guarantee repair your speaker.

You can call a gas technician 24 hours a day by calling 8 (812) 777-0-777, and we can find out our prices in the section of the website for the repair of geysers.

The device of the water unit (reducer) of the gas water heater

The water unit of the gas column is located in front of the heat exchanger and regulates the operation of the column depending on the water flow. The water assembly can be made of brass, plastic or polyamide. The water unit is responsible for turning on the column and its functioning when water is supplied to the hot tap. The flow of water affects the parts of the water unit - the membrane and the disk, they in turn affect the rod, which regulates the operation of the valve of the gas unit. When water flows through the water unit, the gas supply is turned on. Accordingly, when the water is turned off, the gas supply is turned off.

The water unit consists of:

- Base and cover.

- Diaphragm with a disk attached to the rod.

- Flow regulator.

- Venturi nozzles.

- Flow regulator.

- Temperature selector.

- Water purification filter.