Most country property owners use natural gas for heating. But this energy carrier is an explosive substance, posing a threat to residents and the building itself. Before equipping gas boiler rooms, you need to familiarize yourself with the official requirements. This guarantees safety when using gas-powered equipment.

Gas workers will not issue permits if the installation is carried out with violations.

We recommend reading: Documents required when connecting gas

Rules and regulations for the installation of boilers operating on gas fuel

Such boilers are installed according to a design that reflects all safety standards, determines the installation location and fire-safe distances to the structural elements of the building.

Before the start of construction and installation work, the design documentation is agreed upon with the relevant regulatory agencies, which also check it for compliance with state standards.

Installation of the boiler is carried out only by a specialized organization that has a license to carry out such work. After completion of installation work, the boiler is put into operation by a commission consisting of representatives of the customer, the design organization of the installation company, city gas, architecture, capital construction, SES and the fire department. Thus, the owner must also know the requirements for the location of gas boiler equipment in order to correctly prepare technical specifications for the design.

Wall-mounted

Boiler diagram on the wall

Requirements for rooms where it is planned to install a wall-mounted heating unit are primarily aimed at protecting building structures from fire. In this option, the owner will have to pay special attention to the wall on which they plan to mount the device; it must be able to withstand the weight of the structure and be fire resistant.

Basic room requirements for wall-mounted units:

- The volume of the room for a gas boiler is over 7.51 m3.

- The presence of powerful natural ventilation; the room should have a window unit with a window and a door with an opening for air intake - 0.02 m2.

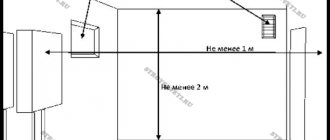

- Maximum distances to the building enclosing elements: floor - 80 cm, ceiling - 45 cm, walls on the sides - 20 cm, from the body to the rear wall - 40 mm, from the front of the unit to the door - 100 cm.

- The placement wall is covered with fire-resistant material made of steel sheet with a thickness of more than 3 mm.

- Thermally insulate the adjacent side surfaces of walls and furniture.

Floor-standing

For these models, more attention needs to be paid to the floor structure, since such structures are heavy, and heat losses from the body mainly flow to the flooring underneath.

Therefore, in the area of the boiler unit, a base is made of non-combustible material, with reinforcement capable of supporting the entire structure of the heating system, with a boiler and an indirect heating boiler.

Room standards for installing a gas boiler with floor installation:

- Free access to the working elements of the boiler unit.

- The minimum area for placing one unit is at least 4 m2, while no more than 2 devices are allowed in the room.

- The height of the room is 2.20 m.

- Supply and exhaust ventilation, windows at the rate of 0.3 m2 per 10.0 m3 of room volume, door with an opening of 0.8 m.

- The gap between the door and the front of the unit is 1 m.

- The walls and floor are made of non-combustible materials.

Basic requirements for premises for placing gas boilers

The fire safety of the room is ensured due to the fire resistance of the walls and floor, as well as reliable triple natural air circulation.

The minimum volumes of premises depend on the thermal power of the units:

- Up to 30.0 kW - 7.5 m3;

- from 30.0 to 60.0 kW - 13.5 m3;

- over 60 kW - 15 m3.

For units with a power of more than 60 kW, for each additional kW, 0.2 m3 of volume is added, for example, for a gas boiler with a power of 150 kW, the volume of the furnace room should be equal to:

150-60 = 90 x 0.2 + 15 = 33 m2.

To the kitchen

This room today is most suitable for installing gas boilers, especially the wall-mounted version. Many users try to close the boiler from public view, so they install it either in a special box or cover it with a decorative panel.

The boiler in the kitchen can also be beautifully placed

In order for the gas service not to impose a ban on such an installation, you need to know and follow the rules for placing boilers in the kitchen.

According to the main parameters: ceiling height, minimum area and the presence of triple air circulation, the requirements for kitchens are similar to other furnace rooms.

There are also some peculiarities, given that the kitchen may have other gas-using equipment, for example, a gas stove and a water heater, their number is limited to no more than 2, so the owner will have to choose what to leave.

To the apartment

Installing a gas heating boiler in an apartment is much more difficult, especially in a multi-storey building with access to central heating. The owner needs to be very motivated to obtain permission from the local administration for such an installation.

Next, you will need to obtain specifications from all engineering services: city gas, heating network and house balance holder. Next, according to the general scheme, the project is carried out, approved by the architectural department of the local administration, and the boiler is installed by a specialized organization.

The rules allow the installation of boilers in multi-apartment residential buildings no higher than 3 floors and a power of up to 30 kW. In kitchens integrated into the living room, the installation of closed-type units is allowed.

All these actions will become impossible if the premises for installing a gas boiler in the apartment do not meet the general requirements. The most difficult thing will be to make a through hole in the wall to connect the chimney.

To a private house

In a private home, there are more opportunities for the safe installation of gas heating equipment. In accordance with current regulations, gas equipment may only be located in rooms with good natural ventilation.

They can be located:

- On the 1st floor.

- In basements or basements.

- In the attic.

- In the kitchen units up to 35 kW.

- Thermal power up to 150 kW - on any floor, in an individual building.

- Thermal power from 150 to 350 kW - in extensions.

To the boiler room

A boiler room attached or equipped inside a house is built from fire-resistant building materials. The interior finishing is also heat-resistant.

A gas boiler room must have:

- Custom foundation and concrete floor covered with ceramic tiles.

- Adjacent to a blank solid wall of an object.

- Be at a distance of 1 m from the window and door.

- Have natural ventilation with three air changes per hour.

- Have an opening window with a glazing area of 0.03 m2 per 1 m3 of combustion volume.

- The ceiling height is more than 2.2 meters.

- Have a separate power supply with devices: sockets, switches, automatic machines.

- For power below 30 kW, the volume of the combustion chamber must be more than 7.5 m3, and for 30-60 kW - more than 13.5 m3.

- Air intake for the gas combustion process must be carried out through a coaxial chimney, a window, and ventilation holes.

Room standards for a boiler unit with an open combustion chamber

Such a boiler must be installed in a separate room that complies with SNIP standards. Installation in bathrooms and toilets is prohibited.

Special requirements for these modifications of boilers are due to the fact that they take combustion air directly from rooms that should not be residential.

Therefore, in addition to the general requirements for installing boilers, the following are added:

- The need for a separate furnace door with access to the street.

- Air intake must not be carried out from internal rooms.

- Exhaust ventilation and flue ducts must comply with the parameters specified by the manufacturer in the technical documentation for the boiler and its installation design.

Room standards for a boiler with a closed firebox

The regulatory requirements for installing a gas unit with a closed firebox are not so demanding. This is due to the reliable smoke exhaust system of these modifications.

Scheme with a closed firebox

In them, exhaust boiler gases are removed from a closed combustion space into a coaxial pipe. Through it, directly from the street, a forced supply of fresh air is performed to ensure complete combustion of the fuel.

In this regard, modifications of boilers with a power of up to 60 kW can be installed in any non-residential premises that meet the following requirements:

- The height of the room is not lower than 2.2 m;

- total volume - over 7.5 m3;

- reliable supply ventilation;

- walls and floors made of durable fire-hazardous materials.

Heating options for a country house with gas

To implement the process, special equipment is often used; the boiler may have an open chamber, in which case air from the room is drawn into it to burn natural fuel.

Combustion products exit through chimneys, but some of their residues will be in the living room, which I would advise to equip with forced ventilation. The positive side of this equipment and the coolant for the heating system of a country house can be safely considered natural draft; electricity is not required for good functioning.

A boiler with a closed chamber is considered no less effective; the working tank does not communicate with the air in the room. But due to the lack of draft, a special drive is required that will pump up the flow to remove combustion products into the chimney; such equipment often depends on the power supply.

Gas heating options

Gas can be supplied to the consumer in two types:

- Using a centralized highway.

- By refueling storage containers located indoors or on the territory of the building (cylinders or gas tanks).

In the first option, the pressure in the system is monitored by a distribution device that works with the main line and the consumer pipeline. After which the fuel is supplied to the heat generator, which ensures autonomous gas heating of the country house. In the second type of natural resource supply, a special reducer is installed, which is responsible for equalizing the gas supply between the container and the combustion point.

Warmth for a country house. Heating with gas holder

Heat for a country house using a gas tank. Installing such massive equipment will require quite a bit of expense in the first stages of installing heating in a country house; over time, the device will begin to pay for itself, because gas is considered the most economical.

Gas tanks are great for areas where the natural fuel supply line is not installed or is far away, I have seen this quite often in the suburbs. Do not forget about the mandatory equipment of such equipment, this includes:

- Emergency pressure relief valve.

- Gearbox.

- Refill valve.

- Tap for removing condensate from the tank.

- Pressure gauge and fuel level sensor.

Sales of used gas tanks are quite common, I do not recommend purchasing such equipment, because often only the outer walls are restored, and the internal components are 50% damaged by rust. It is equally important before installing the device to think about the access of special vehicles to refuel the tank; this nuance is best decided at the stage of planning the location of the device.

Heating with liquefied gas

I would like to note that without proper insulation and antifreeze for the heating system of a country house, the method of using liquefied gas cylinders will be unprofitable. It will be expensive to use this alternative type of equipment supply if the building area exceeds 200 square meters. m.

Small residential properties up to 70 sq.m. m. can be serviced quite productively with one 50-liter cylinder; taking into account the weather outside, it will last from 2 to 7 days. Therefore, you must have several containers for replacement, so as not to subsequently experience interruptions in heating the house.

Requirements for the chimney device

The safety of a gas boiler is directly related to the correct installation of the smoke ventilation system, which must exhaust all exhaust gases into the atmosphere.

The following requirements apply to chimney installation:

- The chimney should not have more than 3 turns.

- The diameter of the flue must match the size specified by the boiler manufacturer.

- The edge of the pipe is placed 500 mm above the roof ridge.

- The hole for the passage of the chimney through the building structures of the task is made larger than the diameter of the pipe, the gaps between them are filled with fireproof material, especially in the area of wooden nodes.

- The smoke exhaust system must have a condensate drain at the bottom of the pipe and a deflector at the top.

Installation of new boiler equipment

condensation equipment

Sometimes the phrase replace (change) the boiler hides a whole complex of works: moving gas pipes, supplying power cables and even arranging a drain for disposal of acid condensate.

Using a new boiler with old heating requires the installation of filter devices on the return pipe. It is desirable that they include flushing of the mesh without disconnecting from the system or a quick-change filter cartridge. The transfer of gravity heating to a closed mode requires the installation of an automatic air valve (AVV) and a membrane-type expansion tank.

The relevant organizations complete the procedure for replacing the boiler by submitting the facility to the gas supervision authorities. In addition, a mandatory stage is the implementation of commissioning activities. The system is filled with coolant, the functionality of the unit is tested, and the draft in the chimney is checked. The power of the equipment is adapted to the heated area.

It is better to entrust the replacement of gas equipment to professional teams. High-quality installation is the key to a long MTBF of a new unit.

Features of energy supply

The power supply of a gas boiler unit must be of two types: a separate power line from the subscriber panel and an emergency power supply, from batteries or a backup line. In addition, the boiler room power supply circuit must fulfill the following conditions:

- Mandatory installation of a boiler grounding system.

- Connecting the unit through a voltage stabilizer or uninterruptible power supply.

- The socket for the heating device must be located nearby in order to connect directly.

- The use of carriers is not permitted.

Fire safety

The combustion area must be kept clean, and there must be sufficient artificial lighting inside the room to provide good illumination for work and public areas. Storage of any flammable materials in such premises is prohibited. When pipes freeze, they can only be heated with steam or hot water. The use of open flame is prohibited.

Special requirements are imposed on the operation and maintenance of smoke ventilation systems; they must be checked and cleaned periodically:

- Every year in August – cleaning of smoke channels from soot contaminants and checking draft.

- Quarterly - cleaning of brick chimneys.

- The integrity of the ventilation ducts is inspected annually.

The entrance doors of the furnace room must open outwards. Windows - must have easily removable packages. At the entrance of the gas pipeline in the combustion chamber, a protective electromagnetic valve, a fire alarm and indoor gas sensors are installed.

Documentation of the change of thermal installation

The paperwork, dictated by the possible scale of damage in the event of unauthorized replacement of equipment without complying with regulatory rules, provides for the collection and provision of the following documents:

- Imported equipment will require a certificate confirming compliance with domestic safety standards. For double-circuit models, it is additionally necessary to have a sanitary and hygienic certificate, which concerns hot water for domestic needs. As a rule, retail chains provide this package along with a warranty card.

- An inspection report with a positive conclusion about the suitability of smoke and ventilation ducts.

- A report on the results of connecting the boiler to engineering systems, as well as a report on hidden work when laying a coaxial chimney through the wall.

- Warranty service agreement concluded for at least 1 year with a service organization.

- The cornerstone of the documentation is the project with the changes made. A necessary condition for a new boiler to be considered legal.

Please note: the owner collects documents independently or delegates this process to a specialized installation organization, which is reflected in the overall price.

Choosing a location for a gas boiler

The choice of such a location can be carried out by a specialized organization during the development of a gas boiler installation project. The owner must only agree with the design organization on the preferred location from the possible options:

- In the kitchen;

- in the basement or attic;

- in non-residential premises, for example, in a garage and workshop;

- in an extension to a residential building.

Thus, simply taking and placing a gas boiler in the house will not work. It will be necessary to fulfill all the numerous requirements of the boiler installation project, SNIP, gas, fire and sanitary safety regulations.

Only then will the owner of such a heating device be able to obtain permission to operate it.

How to make remote control of the heating of a country house with your own hands

The best option would be a GSM socket; I consider this modern device to be the easiest to install to control the heating system yourself. The unit has a built-in temperature sensor, and a maximum load of 4 kW is enough for small country houses.

All radiators must be connected in series, then the device is inserted into a regular socket, the smart heating temperature sensor is able to independently turn off the created system after heating the room to a given temperature, and the owner can do this from any gadget.