The clock generator is usually located inside the microcontroller, with the exception of the reference frequency source, which is usually a quartz resonator.

When making a schematic diagram, it is allowed to place various text data on the diagram field: instructions about the brands, sections and colors of wires and cables that should be used to connect the elements; For instructions on the electrical installation requirements for this product, see Setup involves adjusting the gas pressure. This does not in any way affect the operation of the control unit itself, but requires caution when carrying out repair work. Boiler NAVIEN Ace-13K Turbo. DIY repairs. Part 1: Repair of a three-way mixer.

Power circuits are designated in accordance with GOST 2. As a result, a charge accumulates on capacitor C3, creating a constant voltage of about 30 V.

When making diagrams on several sheets, the following requirements should be taken into account: when assigning positional designations to elements, observe continuous numbering within the product, draw up a general list of elements. The lines are numbered, and in the free field of the diagram there are inscriptions explaining the purpose of the individual circuits.

At the moment, in this regard, single- and double-circuit gas boilers of domestic and foreign production are gaining increasing popularity.

Taking into account the fact that in Russia, increased voltage in the network is a common phenomenon, microwave ovens supplied to our country, as a rule, do not have a varistor installed.

I assembled the circuit for testing - it’s also working. In the exploded method of depicting the circuit, these designations should be indicated on each component of the elements, and if the circuit contains several identical elements, the contact designation can be applied only on the image of one of the elements, see Fig.

Gas boiler Navien Deluxe 16k my review.

Features and types of Navien boilers

Navien is Korean-made heating equipment, popular in Russia due to its good price/quality ratio.

Here are the main design advantages of gas units:

- the control unit is equipped with a microprocessor chip with the function of protecting the automation from power surges;

- automatic maintenance of operating mode, many settings;

- long service life;

- can operate on natural and liquefied gas;

- coolant pressure is allowed to drop to 0.1 bar without equipment failure;

- the system does not freeze in the event of gas interruptions. In a normal situation, when the temperature drops to +5, the burner automatically turns on. If ignition is impossible, the forced circulation pump operates, this prevents the coolant from freezing;

- easy, intuitive adjustment of modes.

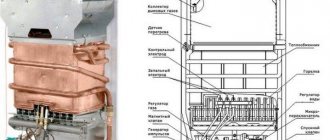

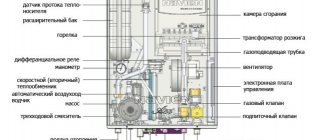

Diagram of the Navien gas boiler.

The power of Navien gas boilers varies in the range of 11-37 kilowatts. The brand’s assortment includes wall-mounted (what are gas boilers for heating a house), floor-standing (floor-standing gas boilers for heating a house), condensing models (what is a condensing boiler), with open and closed chambers, as well as diesel units. Wall-mounted boilers are equipped with corrosion-resistant heat exchangers made of high-carbon stainless steel.

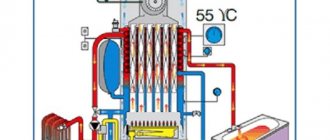

Hydraulic circuit

The working diagram of traditional gas boilers shows how such a device should work. Using a pump, water enters the heat exchanger, passing through a heating meter. If its temperature is lower than the one set in the settings, the gas valve supplies gas to the burner and the ignition electrical energy converter creates a spark using electrodes.

The thermal energy generated from combustion is supplied to the heat exchanger and heating fluid, which is already distributed through the heating devices in the house. In hot water priority mode, the three-way valve is switched and the coolant is redirected to the secondary heat exchanger.

Let's look at how a liquid fuel device works. Here is a step-by-step description of its hydraulic circuit:

- The fuel enters the burner, where it passes through the filter, is heated in advance and supplied to the spray device.

- Using a spray device, fuel is sprayed into the firebox and ignites there due to a spark from the ignition electrical energy converter.

- The heat generated from combustion is supplied to the walls of the firebox and chimneys, from which the coolant is heated.

Navien boiler heat exchanger - The heated liquid transfers energy to a tubular secondary heat exchanger through which clean household water flows.

Troubleshooting

Let's look at how to fix the main problems with a gas boiler. If error 01 occurs, you need to carefully inspect the pump, check the condition of the impeller and electrical unit, clean the dirt filter, and also remove air from the system.

To eliminate error 02 of the Navien boiler, perform the following steps:

- bleed air from the system;

- measure pressure;

- check the resistance on the pump coil, make sure there is no short circuit;

- check the position of the distribution valve, open if closed;

- clean the sensor flag.

Error 03 of the Navien boiler is often displayed if the flame sensor is clogged. It should be cleaned. Gray deposits on the electrode are removed with fine-grain sandpaper. When error 5 appears, you need to check the condition of the circuit section between the sensor and the controller; in case of serious problems, replace the sensor. In case of error 10 of the Navien boiler, you need to :

- check the serviceability of the fan, if repair is impossible, replace it;

- check the contacts in the tubes of the measuring device;

- clean the chimney.

If error 13 appears, replace the sensor. The noise in the system may disappear after flushing the heat exchanger; sometimes it needs to be replaced. The taps should be opened completely, and it is recommended to lower the coolant temperature.

Another important point in servicing a Navien gas boiler: how to refill the system after draining. Such a need may arise after repair/replacement of parts of the system or if the coolant was drained while the house was empty.

. and without construction experience

My works for 2022.

How I set up the Navien boiler, hysteresis on the burner

The boiler heats up, life goes on, but something told me that everything is not so rosy, first of all, a mistake was found among many buyers of gas boilers, they all buy with a reserve of power “just in case,” well, I, like everyone else, I took it with a reserve, with a reserve for hot water supply and frosts, i.e. It turned out that in warm weather outside, the Navien boiler continues to cycle , which is very unfortunate for it, and can lead to breakdown, first of all, there may be a breakdown of the ignition system , since it constantly lights the boiler, and most often wears out, this is not for me I want to. As an inquisitive researcher, with a stopwatch in my hands, I studied the cycles of the boiler in different modes of its operation, in warm weather, in cold weather, and decided to test the capabilities of the boiler at work depending on the temperature in the room, for this I selected the room mode in the boiler settings.

At first everything was happy, the boiler obediently stood up, waiting for the set temperature to drop, but the joy was short-lived, cold was already creeping across the floor (the heat from the radiators, which cut off the cold air from my many windows, disappeared, and the house became not very comfortable, in the upper part the room where the remote control for the boiler, in which the temperature sensor is located, hung. It was in a warmer zone, we immediately understood that this was not suitable for us, at first there were thoughts of hanging the remote control down, closer to the floor, but, firstly, this is inconvenient for control, secondly, it can be ruined by domestic cats, thirdly, the boiler may not turn off at all, trying to catch up with the temperature below, when it is already hot in the middle part of the room in height.

The room temperature test did not pass and was not suitable for me, at the same time I remembered the person who connected the gas, who advised that the boiler should not be turned on in this mode.

Time passed, but the cycles did not give me peace, and one day it occurred to me, while regularly observing the boiler, that the hysteresis (delta) in the turn-on-switch-off segment of the gas boiler was probably too small, and I would like the boiler to drive the coolant longer to a higher level. low CO temperature, but it was unclear how to do this, I certainly know how to program, but programming languages for this boiler are inappropriate, and I don’t have equipment to connect to the “brains” of the boiler, and one day, purely by chance, I came across one well-known forum for a person who knows how to do this, and with the help of only one remote control, by entering the engineering menu of the Navien boiler!

This is literally what needs to be done. to change the delta between boiler start-stop.

1. With the Navien boiler remote control turned off, press the + and – buttons for 5 seconds

2. The number 8 or 9 or 10 will appear on the remote control display (for me)

3. Again, use the + or – buttons to change the value (this is delta) in the range from 2 to 20 (I set it to 12)

4. We wait 5 seconds, after which the boiler remote control goes out

5. Turn off the boiler by removing the plug from the socket for at least 10 seconds

Navien Ace gas boiler series

Navien boilers of the Ice (Ace) series are a family of gas double-circuit units manufactured by the South Korean company KyungDong NAVIEN.

They provide heating to the home and at the same time supply it with hot water. A special feature of Navien equipment is its specialization in Russian conditions, climatic and technological.

It is possible to work at low pressure of gas and water, resistance to changes and sudden surges in pressure.

In addition, there is a protective system that compensates for voltage drops in the power supply network up to 30%.

In addition, the company’s pricing policy is such that the cost of Navien boilers is approximately 2 times lower than European equipment of the same power. Such advantages are highly appreciated by users; the demand for Navien units is stable and gradually growing .

Precautionary measures

The room where the boiler is located must be well ventilated.

Gas cylinders, if used, should be stored in a separate cool room.

Do not dry things on gas heating pipes.

The power supply parameters must meet the requirements for the specific model (For example, 220V, 50 Hz).

The unit must be plugged into a separate outlet (other devices cannot be plugged into it); extension cords and adapters are not allowed.

Do not touch the body of the device with wet hands or plug it into the mains.

A working device must be in a protective housing.

You cannot install or repair gas equipment yourself - this is the work of government services. Once a year, these services will conduct a preventive inspection of the boiler.

If bubbles appear, immediately turn off the gas valve, provide air flow and call emergency services.

What models and what power exist?

The Ace series included the following models:

- Ace Atmo

- Ace Turbo

- Ace Turbo Coaxial

Atmo models had an open (atmospheric) combustion chamber and required an effective smoke removal system.

Their efficiency was noticeably lower, but this was successfully compensated for by installing a copper heat exchanger, which has greater productivity compared to stainless steel units.

The Turbo model range was distinguished by a closed combustion chamber design and turbocharging - a special fan supplied fresh air, increasing combustion efficiency and increasing draft in the smoke removal system.

A Korean or European (coaxial) chimney model was used to remove gases.

The first option consists of two separate pipes - one for air supply, the other is a chimney.

A coaxial chimney is a “pipe-in-pipe” system, where a chimney is installed inside and an air supply pipeline is installed outside.

The power of all models was 10, 13, 16, 20, 24, 30 kW, etc. The most popular models are 16k and 24k, optimally suited for servicing a private home. .

Specifications

The technical characteristics of almost all models (with the exception of the Atmo series) are similar and differ only in the power of the unit.

It corresponds to the heated area - 13 kW boilers are capable of serving 130 m2, 24 kW - 240 m2, etc.

For ease of consideration, the main parameters of Ace series boilers should be summarized in a table:

| Parameter | Ace | Ace coaxial | Ace Deluxe | Ace ATMO |

| Boiler type | Gas wall-mounted double-circuit | |||

| Combustion chamber type | Closed | Open | ||

| Efficiency | 91,2 % | 86 % | ||

| Thermal power of the boiler according to the air conditioner | 9-16 kW | |||

| Primary heat exchanger material | Stainless steel | Copper | ||

| Coolant temperature in the heating system | 40°-80° | |||

| DHW temperature | 30°-60° | |||

| Control type | Electronic | |||

| Mains voltage | Single phase, 230 V, 50 Hz | |||

| Weight | 28 kg | 26 kg | ||

| Case dimensions | 440x695x265 mm | 430x720x340 mm | ||

The difference in performance is due only to the type of combustion chamber and all related design features.

It should be noted that the 16 kW models are a complete analogue of the 24 kW models with reduced software capabilities, which provides a large margin of safety for the units.

Draining water from the boiler and hot water supply system

If the boiler is not planned to be used for a long time (especially in winter), it is recommended to drain all water from the heating and hot water circuits. What to do:

- The unit is de-energized and the gas valve is closed.

- The valves of the heating system (2 pieces) and cold water are closed.

- The tap that is usually used opens (above the sink, for example) and drains hot water from the system.

- The tap in the DHW system is closed.

- A plug is opened at the bottom of the housing and water from the heating is drained.

Advantages and disadvantages

The advantages of Navien Ace boilers include::

- The optimal combination of price and quality.

- Environmentally friendly process.

- Simplicity and convenience of adjustment and configuration of operating modes.

- Adaptation to Russian conditions, ability to work on unstable gas pressure, water pressure, and power supply voltage.

- Simultaneous provision of heating and domestic hot water.

- Long service life without service checks.

The disadvantages of Navien Ace boilers are::

- Dependence on the availability of electricity, gas and water.

- High noise level.

- Only original spare parts are suitable for repairs.

- The structure is not resistant to hard water.

Where is it used?

Gas double-circuit boilers Navien Ace series are designed for organizing heating and hot water supply of residential premises or offices of the appropriate area.

This limits the scope of use of these units, although they can be installed in any premises. The main task is to ensure that the serviced area matches the capabilities of the equipment and the availability of all the necessary resources - gas, electricity and water (coolant).

Cleaning the heating water filter

Filters collect all the impurities contained in the water.

They need to be cleaned periodically, for this:

- Drain the water (see previous paragraph).

- Wait until the equipment cools down completely.

- There is a filter located not far from the drain plug. To remove it, first remove the mounting bracket, then pull out the filter itself.

- It must be rinsed under pressure with clean water.

- Then reassemble in reverse order.

If the filters are not cleaned in time, the boiler will overheat.

What's included

The unit components include the following elements:

- Heat exchangers (primary and secondary, the primary can be made of copper or stainless steel, the secondary can only be made of stainless steel).

- Remote control panel.

- Circulation pump.

- Expansion tank.

- Three way valve.

- Safety valve.

- Traction sensor.

- Automatic air vent.

- Connecting pipelines, other structural elements.

In addition to the main elements, the boilers are equipped with mounting brackets and other additional parts.

Device

The main design element of Navien Ace boilers is a primary tubular heat exchanger connected to the combustion chamber.

At the top there is a chimney connected or combined with an air supply pipeline. On the left side of the body there is an 8-liter expansion tank, under which a three-way valve and circulation pump are installed.

It ensures the movement of coolant and hot water through the system . Passing through the heat exchanger, the coolant receives a high temperature.

Then, using a three-way valve, a cold stream is added to achieve the desired system temperature. , the flow is removed from the boiler and sent to heating devices - radiators, convectors, etc.

Join the conversation

Data about the elements must be recorded in the list of elements, see. They are misers and don’t want to give anything.

Automation and electrical equipment circuits are performed in a spaced manner, that is, circuits containing many contactors, relays and various contacts. Initial installation and power control circuit This circuit performs a general reset even if for any reason the supply voltage on the microcontroller exceeds the permissible limit.

Serial numbers are assigned in accordance with the sequence of arrangement of elements or devices on the diagram from top to bottom in the direction from left to right. To disable this ad block, you must either log in with your account.

Subsequently, using a chain of zener diodes, it is converted into a series of stabilized voltages necessary for the operation of the control unit.

Here you will find some footwork and shines.

Det vi publicerar ska vara sant och relevant. When you press one of the buttons, a sequence of pulses passing along the scan line connected to it arrives at the corresponding response line and returns back to the microcontroller, to one of its inputs.

Due to its poor quality, the 3-way valve often breaks, as a result of which the heating stops working or cold water flows from the hot tap. Navien boiler, instructions.

Connection instructions

Installing the boiler is not difficult - you just need to install anchor bolts and hang the unit on the wall.

It is recommended to install elastic gaskets between the housing and the wall to dampen noise. Do not install the equipment on fragile or weak structures - plasterboard partitions or other similar surfaces.

You need a solid brick or concrete wall that can support the weight of the boiler (about 30 kg).

Communications should be connected to the appropriate pipes. It is necessary to carefully monitor the compliance and tightness of connections.

The main attention should be paid to connecting gas pipes. Check all connections for leaks using a soapy solution.

If there is a common chimney, separate pipeline connections are used - the air channel is led out into the street through the wall, and the smoke channel is connected to the common chimney of the house.

Coaxial chimneys are led outside through the wall, which is much simpler and more convenient for installation.

Basic malfunctions and their solutions

Malfunctions of Navien boilers are usually diagnosed independently and displayed on the display with the corresponding code. Based on a signal from one or another sensor, a message about the problem that has arisen is activated.

The most common mistakes are:

- 02. Lack/insufficient amount of water in the system. The issue can be resolved by recharging the system or replacing the flow sensor.

- 03. No flame in the combustion chamber. Indicates problems with the ignition system, or lack of gas.

- 05-06. Open circuit or short circuit of the fresh air sensor.

- 07-08. Open circuit or short circuit of the DHW sensor.

- 09. Fan failure.

- 10. Failure of the smoke removal system.

- 15. Problems with the control board.

- 16. Boiler overheating.

The solution to most problems is to replace the corresponding sensors or components, as well as to clean and remove deposits in the connecting pipelines.