Previously, draft and blower fans were used only in industrial boiler installations. The first ones are placed inside the chimney channel and create a vacuum, the second ones pump air into the firebox. Gradually, the units migrated to the domestic sphere - manufacturers began to equip heaters with a closed combustion chamber with turbines. The idea was picked up by home craftsmen, because a smoke exhauster for a boiler helps solve the problem of poor draft in the chimney pipe. Let's figure out whether forced exhaust of combustion products is always necessary.

Making a smoke exhauster with your own hands

If you wish, you can assemble such a device yourself from scrap materials.

We only need an electric motor. Everything else can be made independently, although it is better to purchase a factory-made impeller, even if it is used. Tool you may need:

- Bulgarian;

- Welding machine or inverter;

- Drill, plumbing tool, hammer;

- Ruler, caliper.

The easiest way to manufacture is an exhaust fan, which will be installed inside the pipe. To do this, you will need a small electric motor with a power of up to 1 kW and a suitable impeller with blades. It is mounted on the motor shaft, and its housing is equipped with fasteners for placement in the pipe

When connecting the wiring and first start-up, pay attention to where the air flow will go

A self-made smoke exhauster for a solid fuel boiler can be seen in the following video.

A design with a volute and a centrifugal fan will be more complicated. The procedure for its manufacture is as follows:

- For a ready-made turbine, we select a piece of pipe with a diameter 2-3 centimeters larger. Cut it to the size of the fan plus 3-5 mm;

- We cut a hole on the side for the outlet pipe, and weld a lid to one of the ends with a hole in the center for the chimney from the boiler. The incoming flow will be perpendicular to the outgoing one; with this scheme, the electric motor is located horizontally;

- The most critical stage is the installation of the shaft and fan. For accuracy, you can use bushings for centering and pressing the bearing. When the engine is turned on, beating and vibration are unacceptable.

- We weld or screw the back cover and install the engine on the stand. We connect air ducts and electrical wiring.

How to properly install a smoke exhauster on a fuel boiler

Here are some tips:

- If there is a separate room for the boiler, then the hood is mounted in it for ease of maintenance;

- It is advisable to place powerful chimneys outside the house due to the loud noise during operation;

- The electric motor is protected by a separate circuit breaker, and its control is conveniently transferred to the general heating system control panel;

- There must be free access to the smoke exhauster for cleaning.

Cost of installation of a smoke exhauster

For homemade products, the price is determined by the cost of the electric motor and impeller. The cost of a three-phase electric motor with a power of 0.18 kW starts from 1950 rubles, the simplest blade impellers - from 350 rubles. Add to this the purchase of wires and small accessories. There will be benefits if you can get a used engine.

A ready-made smoke exhauster costs a little more. So, for a device with a capacity of 2000 m3 per hour you will have to pay from 14,000 rubles for an unknown manufacturer to 23,500 for a smoke exhauster from the Wirbel company. Simple blade units cost inexpensively 6-8 thousand rubles. If the installation of a smoke exhauster on a solid fuel boiler is carried out by a specialist, then for the work and turnkey connection you will have to pay up to the cost of the pump itself, depending on the complexity.

Prices: summary table

| Model | Power | Weight, kg | Cost, rub. |

| WPA 120, Poland, M+M | 83 W, for boilers up to 60 kW | 2,1 | 4 800 |

| NWS-100, Poland | 80 W, for boilers up to 50 kW | 2,0 | 4 620 |

| DP-120, Poland, KG Elektronik | 90 W, for boilers up to 60 kW. | 2,1 | 5 660 |

| RR 152-3030 LH, Poland, M+M, developer – Germany, EBM. | 44 W, for boilers up to 30 kW | 1,0 | 6 000 |

When should you buy a smoke exhauster?

Heating equipment has its own fans, which are needed due to the high resistance of the heat exchanger - the gas changes the direction of its path in the flame tubes. A fan is installed to remove heat from combustion products and increase the efficiency of the heating device.

The forced exhaust that comes with the boiler is configured for combustion in this equipment and is controlled from the remote control. If a fan is installed on a device without a computer, then their operation will not be synchronized.

To coordinate the work, you need to buy automation or set the speed yourself.

In what cases is a smoke exhauster necessary to improve operation and simplify boiler maintenance:

- if there are problems with draft, when the wind blows, air pockets appear, there are many turns in the chimney, the diameter narrows;

- smoke from the boiler enters the room when the door is opened;

- the chimney is low or the top of the chimney is in the area of wind pressure, covered by another building or ridge;

- there are cracks in the brick pipe through which smoke escapes.

It is useless to buy a smoke exhauster if there is no air flow from outside. Immediately after installation, the wings will discharge the air a little, but then they will simply knead it in place.

Air supply is the key to proper operation of the heating installation.

Some solid fuel boilers may release smoke through the loading door when it is open. The same phenomenon can be seen in three-pass heating systems in fire tube heat exchangers with high resistance.

There is only one solution - install a smoke exhauster with automatic control or normalize the draft.

There is also a disadvantage to installing forced ventilation. If a chimney hood is not installed, the device cannot be turned off, otherwise carbon monoxide will accumulate in the room.

This is dangerous in the event of an unexpected power outage.

Therefore, forced ventilation is not forever; it should not replace natural draft, but only help in cases where something interferes with it. Therefore, if there are difficulties, the causes of interruptions in traction should be eliminated.

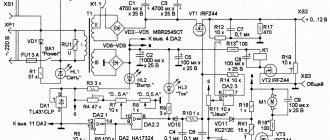

How to connect it to the mains voltage.

The smoke exhauster is connected through a thermostat, which controls the temperature of the coolant leaving the boiler and periodically turns on the smoke exhauster when the coolant temperature drops, and then turns it off when the set temperature is reached.

The smoke exhauster can be connected through the standard boiler control unit when replacing the blower fan with a smoke exhauster, if their powers are the same.

If the power of the smoke exhauster is greater, then the electrician must connect it through a contactor of the appropriate power. If such a unit is not available, you must purchase a device that is available from our company.

Connecting the electric motor.

The power cable must be connected using cable lugs only. Use cable lugs of the appropriate cross-section to prevent overheating of the cable connection to the winding terminals. The cable to the terminal box must be connected without tension, and the contact connections must be securely tightened.

Motor protection.

Each electric motor must be protected against overload and short circuit. The settings of the protection devices must correspond to the operating mode of the electric motor, as well as its characteristics.

Short circuit protection is carried out using fuses or circuit breakers (the second option is more preferable, as it eliminates the occurrence of a “phase loss” mode). When choosing an automatic machine, it is necessary to take into account that the starting current of an asynchronous electric motor with a short-circuited winding is 5–7 times higher than the rated one.

Thermal protection must be time-delayed and can be achieved using a thermal relay.

If the engine has built-in temperature sensors, they must be connected.

Attention! Short circuit protection must be implemented in any case, regardless of whether there is built-in temperature protection or not.

Electric motor maintenance.

1. Checking the degree of contamination of the outer surface.

As well as the fan and engine protective casing. If the housing is dirty, remove the dirt using a rag or soft brush. Use compressed air to remove dust or chips from the surface of the engine, as well as from the ventilation unit.

2. Checking the temperature of the bearing units and motor housing.

3. Checking the vibration level of electric motor components.

If you have the appropriate measuring instruments, perform vibration diagnostics of the engine bearing units to determine their technical condition and make a decision on repairs.

4. Check the degree of wear of the shaft seals.

While the engine is stopped.

5. Checking the motor insulation resistance.

While the engine is stopped.

6. Check the tightness of all bolted connections.

Including the connection of the power cable and motor terminals (first make sure that there is no voltage applied to the motor).

7. Visual external inspection of bearing units.

Make sure there are no grease leaks.

Types of smoke exhausters

All these devices can be classified into groups according to several criteria:

- The first type of smoke exhauster is smoke exhauster D. In the design of this chimney, the impeller is located directly on the shaft of the propulsion motor. This device belongs to the group of small-sized structures.

- The second type of draft machines is the DN smoke exhauster. In this case, the impeller is also mounted on the motor shaft, however, despite this similarity, the structures of chimneys of the DN group are considered to be of higher quality, since the power of its drive will be much greater than that of chimneys of the first type.

The following three types of chimneys are combined into one large group of fire chimneys:

- DPE chimney (fire electric smoke exhauster). This device has one important advantage: the DPE smoke exhaust engine runs on electricity and is portable. The type of engine can also vary: it can be centrifugal, axial turbocharged, centrifugal mobile or axial turbocharged mobile.

- The second type of chimneys are DPM smoke exhausters. These devices for the furnace have a portable motor engine; it can also be of different designs, namely: a centrifugal fire engine or an axial turbocharged fire engine.

- The third type of draft machines are devices for trailed-type furnaces (DP smoke exhausters). These furnace units have several main characteristics, now we will list them: productivity;

- pressure (pressure).

During operation of trailed-type draft machines for furnaces, the main limitations of the machines are:

- The manufacturer indicates the value that is the maximum permissible temperature for all gases. This value must not be exceeded when using the oven.

- The manufacturer also indicates the maximum permitted level of dust, dirt and other solid substances.

Good draft is the result of correct calculation and installation of the chimney

When asked which chimney is better for a coal boiler, and which for a diesel boiler, etc., the correct answer will always be different. Because a chimney made for a wood-burning stove may be completely unsuitable for a gas boiler, for example. And there may be several reasons for this. At the same time, few people are able to install a new capital chimney to replace an ineffective one. That is why existing chimney pipes have to be improved in one way or another. Often, an improvement involves installing a smoke exhauster for a new domestic boiler.

Everywhere the chimney for a solid fuel boiler is made of solid brick. If it has sufficient height and cross-section, then it always has excellent traction and no air movement amplifiers are required. But there are also exceptions. For example, a brick chimney for a stationary solid fuel boiler cannot be brought to the required height. As a rule, a chimney for a solid fuel boiler is simply made by hand, but it does not always cope with its function perfectly. And it often happens that additional draft needs to be provided using smoke exhausters for household solid fuel boilers, purchased or made by yourself.

What and how to lay out a chimney so that it effectively copes with smoke removal is the topic of a separate large article, and now we will not touch on it. A solid brick chimney is good for a solid fuel boiler or stove, but without additional inserts it cannot be used for modern boilers using other types of fuel. For example, a smoke exhauster for a boiler may be needed if the chimney installation was done incorrectly from the very beginning.

How to properly make a connection to the chimney for a conventional solid fuel boiler? Highly qualified specialists know about this, but they are also mistaken, not noticing some local detail in time. A good smoke exhauster for a solid fuel boiler or any other can eliminate all errors in the design and construction of boilers and chimneys. Especially if the chimney for the boiler is not brick, but metal.

This is a whole science - installing a chimney for a solid fuel boiler. What can we say about more complex options for heating devices. Therefore, errors occur quite often; even simple brick laying is rarely ideal. Compliance with all technical standards for aerodynamics is another task! How to make a chimney if a brick boiler is connected to it? Will your own chimney for a solid fuel boiler be efficient enough? Such questions often cannot be answered in advance.

What benefits does the introduction of a traction fan give?

In reality, these technical solutions are far from new. Traction and blowing machines have long been used in industrial thermal power plants. Indeed, with large volumes of fuel burned, the efficiency of this process plays a huge role. We can say that smoke exhausters for household solid fuel boilers migrated there from industrial equipment relatively recently, this is due to a massive increase in demand for this type of heaters. The use of a draft fan in solid fuel boilers provides the following advantages:

- Increasing the efficiency of the unit as a whole thanks to controlled fuel combustion.

- More precise regulation of coolant temperature by regulating combustion intensity.

- Possibility of stable operation of the heating installation in conditions where there is poor chimney draft.

- Preventing smoke from entering the furnace room when opening any firebox door.

Unlike blowing machines, smoke exhausters for domestic boilers are located not at the beginning of the gas-air duct, but at its end, immediately in front of the chimney pipe. They are a fan, the working part of which is protected from high temperatures (up to 250ºС) and small volatile inclusions contained in combustion products.

The purpose of traction machines is similar to blast machines, the difference is that the former provide a vacuum in the furnace; it is required for the normal functioning of any solid fuel unit and is about 16-25 Pa for various modifications. Blower fans create increased pressure in the firebox, and a vacuum should be created by the chimney for a solid fuel boiler. For various reasons, this is not always possible, and installing a new pipe to discharge combustion products can be very expensive.

Why install a smoke exhauster?

The correct and durable service of the heating device, its efficiency and the normal microclimate in the room depend on a high-quality chimney and good draft. Complete exhaust gas removal, that is, an effective smoke removal system, ensures complete combustion of fuel and maximum efficiency. All technical nuances of the design and construction of chimneys are aimed at obtaining excellent draft. It must be sustainable and sufficient.

And traction occurs when there is a temperature difference. According to the laws of physics, the hot air from the firebox rushes upward, taking with it the smoke and soot that are formed during combustion. In modern wood-burning boilers, the mode can vary from sub-zero temperatures to plus 350 degrees. And at the same time there should always be excellent air movement in them. Natural traction in such conditions may not be enough. This is how separate draft amplifiers, or smoke exhausters, were invented. They acquired particular importance with the advent of modern high-efficiency boilers, which are more capricious and demanding.

The main reason for installing a smoke exhauster is that the horizontal section of the transition from the boiler to the chimney is too long. Most often this happens due to thick walls. One and a half meters of horizontal section is bad for any boiler or stove. Smoke does not like to travel through horizontal channels, and in the case of high-efficiency boilers (such as pyrolysis boilers, for example), this situation can lead to an almost complete absence of draft.

Why do you need a three-way valve?

The main purpose of a three-way valve.

In relation to a solid fuel boiler, its function is to maintain a high temperature of the boiler to reduce the condensation of resins on its inner surface. This ensures the required temperature of the coolant used for heating by mixing hot boiler water with low-temperature water supplied back from the consumer...

Read the article...

Homemade designs

You can make smoke exhausters for boilers with your own hands. This will save you money on buying a factory hood. To fold such a machine yourself, you only need to purchase an electric motor. The remaining components can be made from available materials.

Hood from scrap materials

The set of tools required for work consists of:

- Bulgarians;

- welding machine;

- drills;

- metalworking tools;

- hammer;

- rulers;

- caliper.

Work begins with the manufacture of an exhaust fan. The impeller, matched to the size of the exhaust pipe, is secured to the motor shaft. The engine, using fasteners equipped on its body, is placed in the pipe.

After connecting the motor to the wiring, during the first test run it is necessary to check the direction of the air flow and, if necessary, adjust the operation of the rotor.

The pipe for placing the turbine is selected with a diameter 2-3 cm wider. Its length should extend beyond the fan by 3-5 mm. One end of the pipe is welded with a lid, a hole is made in the center for the chimney, and another one is equipped on the side, to which the outlet pipe is attached.

During operation, the fan should not cause increased vibration of the hood body. To prevent this from happening, it is installed using bushings to center the bearings.

The hood assembly is completed by welding the back cover to the pipe and attaching the motor to the stand. After connecting the air ducts and electrical wiring to the unit, it is ready for use.

Intermediate option

This option for assembling a drawing machine does not require special alignment of the impeller, which is a rather delicate and complex job for a non-professional. A factory-assembled mechanism is usually already centered and only requires checking during trial operation.

Sources

- https://teplo.guru/kotly/tverdotoplivnye/dyimosos.html

- https://aquagroup.ru/articles/dymososy-dlya-kotlov.html

- https://kaminguru.com/dymohod/dymosos-dlja-kotla.html

- https://trubanet.ru/truby-dlya-otopleniya/prinuditelnaia-vytiazhka-dlia-dymohoda.html

- https://teplospec.com/tverdotoplivnoe-otoplenie/kak-vybrat-dymosos-dlya-tverdotoplivnogo-kotla-vidy-razlichiya.html

- https://otivent.com/dymosos-dlja-tverdotoplivnogo-kotla

- https://1poclimaty.ru/montazh/dymosos-svoimi-rukami.html

- https://klimatlab.com/otoplenie/tverdtoplivo/dymosos-dlya-tverdotoplivnogo-kotla-svoimi-rukami.html

- https://teplofan.ru/sistemy-otopleniya/komplektuyushhie/dymosos

Step-by-step instruction

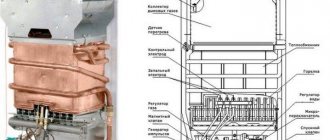

Scheme of a single-suction smoke exhauster.

To begin with, it is worth preparing the material according to the appropriate dimensions. All of them must be prepared in advance according to the drawing. It's worth starting with a snail. By the way, it is quite difficult to do it yourself, so the unit can either be ordered or taken from an old engine. The main thing is that its dimensions are optimal and can provide the required performance for air removal. A steel mesh will be attached to the snail. It is installed using a metal ring that presses it to the body. According to the size, it is necessary to drill holes both in the snail itself and in the metal ring. Next you need to prepare the engine for installation. It will be bolted to the volute. Here you will have to try to drill several holes in the metal case. 6 pieces will be enough.

The motor itself will be powered by single-phase voltage. No one should have any problems connecting here. As a rule, such a unit has an output in the form of a cable, which will be connected to the outlet. Some models can be equipped with three-phase units. In this case, you will have to connect the electricity cable yourself. Typically, the cable consists of four cores. Three of them are phases, and the fourth is grounding. Here, too, no one should have any problems with the connection.

As for attaching the engine to the frame, you need to prepare the technological holes in advance. Moreover, they must correspond to the size that is installed on the engine. In the metal plate that will act as the frame, it is necessary to drill using a drill. This is done extremely simply. By the way, it is better to start the assembly itself with the engine.

Schematic diagram of the smoke exhaust unit.

When all the parts are prepared, you can begin assembling the smoke exhauster. Everything is done extremely simply. First you need to secure the engine to the frame. This is done using a bolted connection. For more reliable fastening, the nut and bolt should be tightened using open-end wrenches. When everything is ready, you can start assembling the snail. Here you should perform a set of primitive actions. To begin with, a mesh and a metal plate are attached to the front. It will press the mesh against the surface of the cochlea. Here it is best to use a collapsible bolted connection. All bolts are tightened using a wrench. For assembly, first a mesh is placed on the snail, and then a metal sheet is put on. This is what is tightened with bolts. When this stage of work is completed, you can begin further installation. It will consist of installing an impeller on the motor shaft. There must be a rigid fastening here. Otherwise, the wheel may simply not sit in its rightful place or spin out of alignment with the shaft.

To fit it, it is best to use a keyed connection. To do this, a recess must be provided in the shaft. The same size hole should be on the wheel. Now you can connect the parts into a single whole. All that remains is to insert the wheel into the volute and mount it together with the engine directly to it. It is better to do this using a bolted connection. As noted earlier, to create better rigidity, fastening should be done using open-end wrenches. Now we can state the fact that the work is almost complete. All that remains is to connect three-phase voltage to the motor.

This is done extremely simply.

Device of a “cold” smoke exhauster.

Here you can see several bolts, or rather, there will only be three of them here. Each of them serves to connect a phase. A protective ground is installed on a separate bolt. Without closing the lid, you need to test the unit to determine the correct direction of rotation. If it turns in the wrong direction, then you just need to switch two phases, that is, swap two wires. Now you can safely close the lid.

Next, the tightness of all connections is checked.

After all, it is very important that dirty exhaust air does not escape back into the room. If necessary, a special sealant can be used to eliminate cracks

Fortunately, no one should have any problems buying it. All cracks and holes are sealed with sealant. Only after this can you make a test run to test the smoke exhauster in action.

If you bring your hand to it, air should be drawn in. If this is the case, then everything should work normally, and accordingly, you can put the device into operation.

Choosing a smoke exhauster

Forced air supply depends on the type of boiler. For efficient operation of the heating device, the smoke exhauster must fully meet the nominal requirements and, in its technical parameters, correspond to the characteristics of the boiler.

If it is powerful, then a centrifugal traction machine capable of creating high pressure should be chosen as an air blower. Boilers that have average power can be equipped with flow-through smoke exhausters so that they additionally supply air to the firebox. If the boiler is low-power, a fan installed at the outlet is used.

The type of solid fuel used plays a big role in choosing a smoke exhauster. Firewood burns out much faster than coal. For a boiler in which wood material will burn in the firebox, you can limit yourself to a flow-through smoke exhauster or a fan.

If the boiler is fired with coal, the draft must be stronger so that all the fuel can burn out. After coal, combustion products are formed in greater quantities than after firewood. To effectively remove them into the chimney by force, the smoke exhaust device must be powerful enough.

The use of smoke exhausters of any type allows you to fully realize the functions of the heating device, avoid smoke and organize a sufficient air supply to the boiler furnace. In this case, the fuel completely burns out, releasing volatile products and ash outside the room.

We recommend reading our other articles

- White interior doors in the apartment

- The main reasons for iPhone repair

- Biotal - a high-quality solution for wastewater treatment

- Dupont Typar geotextiles for different uses

Features of using smoke exhausters

When choosing a traction smoke exhauster, you need to calculate the cross-section of the exhaust pipe and the power of the exhaust unit. Unlike pressure units, they are more versatile and efficient, they allow you to add firewood while the boiler is operating, and prevent combustion products from entering the room.

Forced exhaust of combustion products will help make your stay in the room safe and reduce the risk of carbon monoxide poisoning to a minimum.

The use of smoke exhausters for pellet burners or boilers running on sawdust or peat is the only possible way to organize the heating process. Under normal conditions they burn poorly.

Advantages of using a chimney hood:

- Improving the efficiency of heating devices, firewood burns with virtually no residue;

- Eliminates the accumulation of smoke in rooms, eliminates unpleasant odors;

- Exhaust gases do not flow back into the room when the firebox door is open;

- Reduce deposits on the walls of chimneys due to the filtration and separation system.

They have practically no disadvantages. If no errors were made during installation, the service life of the smoke exhauster in the chimney is comparable to the service life of the boiler itself. In this case, regular maintenance must be carried out.

Varieties

There are two types of fireplace fans. A smoke exhauster with a vertical outlet is standard when installed in homes. This variety can withstand temperatures above 210 degrees. Its power is sufficient to provide normal traction. This fan is equipped with several modes. This feature allows you to significantly save electrical energy consumption. So, for example, in order for the fireplace to work normally, it is enough to use the smoke exhauster at full power only until the cold air is completely removed, then it needs to be switched to saving mode.

More powerful is the horizontal fan outlet in the smoke exhauster for the fireplace. Such a device draws out the fumes after a strong fire, and then is able to function as usual. In this case, no additional maintenance is required. Due to the special design, soot and soot do not clog the system for a long time. It is noted that such a fan works properly at any time of the year, even in the coldest weather. Often, for the sake of convenience, or following some other goals, people do not install a large chimney system, but prefer home-made smoke exhausters for fireplaces.

Which chimney is better for a solid fuel boiler?

A nuance: the operation of the smoke exhauster in a factory-installed boiler is coordinated with the combustion process and is controlled by an electronic unit. When installing a fan unit on a “brainless” heater, such consistency is excluded; you need to buy an automation unit or adjust the speed manually.

We list the situations when a smoke exhauster will help improve the operation and maintenance of a solid fuel heat generator:

- problems with draft - blowing by the wind, air pockets in the gas duct, many turns, narrowing of the diameter;

- due to the design features, the boiler smokes into the room when the door is opened;

- the height of the chimney is insufficient or the cut of the pipe fell into the wind support zone behind the ridge of the roof or another building;

- Cracks have appeared in the brick pipe, from which smoke is leaking.

It is better to operate the V. G. Kholmov mine heat generator with a traction fan

Some wood boiler designs (for example, shaft type) tend to emit smoke through an open loading hatch. A similar picture is observed in heat generators with a three-pass fire-tube heat exchanger of high resistance. The solution to the problem is to install a traction or blowing machine controlled by a controller.

Strengthening natural draft with the help of a smoke exhauster also has a downside. If, after warming up the pipe, natural exhaust has not been restored, the unit cannot be turned off - you may get burned. Now imagine that in the middle of the night the power supply goes out and the fan stops. While the chain thermostat closes the damper, smoke will fill the boiler room.

When the traction turbine is integrated into the heat generator by the manufacturer, such questions do not arise. Adding an exhaust fan to a conventional direct combustion boiler is another matter. You need to understand that in this case, the smoke exhauster solves only 1 problem - creating a vacuum in the firebox and increasing draft. There are a number of negative points here:

- Without an electronic control unit, performance will have to be adjusted manually. Automatic maintenance of coolant temperature is excluded.

- When air is supplied through the open ash chamber door, the fan will force the boiler to operate at maximum. Setting up a long burn mode will not be easy.

- In the event of an emergency stop of the impeller, fuel combustion will not stop, since gases pass freely through the volute or the body of the smoke exhauster. Air enters the firebox, increasing the likelihood of overheating.

- The impeller and internal surfaces of the unit become covered with soot, which must be removed. The rate of sticking depends on the moisture content and resin content of the wood.

Blowing machines always work in conjunction with a controller, so the problems listed above do not exist:

- the blower changes performance and turns off at the command of the control unit, the coolant heats up to the set temperature;

- during the combustion process, the ash pan door is hermetically closed, air is supplied through a separate channel;

- when there is a power outage, the air channel is automatically closed by a gravity damper;

- the impeller blades do not come into contact with hot smoke and soot.

The installation complexity of the units is approximately the same. Installation of the discharge volute involves cutting out an opening in the ash pan door, and the smoke exhauster involves disassembling or cutting out the pipe. It is easier to install a roof hood, but you will have to pull a long cable.

Device Application

It is important to synchronize the operation of the boiler and fan during operation. Installing a smoke exhauster on a boiler without a control and automation unit is excluded, so you will have to buy and install all the electronics entirely anew

Such fans are indispensable when the following situations arise:

- heavy smoke in the room due to opening the firebox door, which may be facilitated by the design of the boiler;

- holes and cracks form in the brick chimney, so smoke is sucked through them;

- problems with draft - complex chimney design, strong winds and other problems;

- insufficient chimney height.

How to install a smoke exhauster

Increasing draft using a smoke exhauster also has a downside. If, after operating the fan for a certain time, the natural pressure does not increase, then you cannot turn off the smoke exhauster, since a possible consequence may be carbon monoxide suffocation. If the electricity goes out at night, smoke will enter the room, and this cannot be avoided. While the chain thermostat closes the damper, the entire boiler room will be in smoke

In this regard, it is very important to do good natural traction to avoid such cases.

Sources

- https://teplofan.ru/sistemy-otopleniya/komplektuyushhie/ventilyator-kotla

- https://RSVgroup.ru/ventilyatsiya/dutevoj-ventilyator-dlya-kotla.html

- https://oventilyacii.ru/kondicionirovanie/kak-sdelat-dymosos.html

- https://svoimi-rykami.ru/stroitelstvo-doma/pechi_i_mangaly/ventilyator-dlya-kotla-svoimi-rukami.html

- https://klimatlab.com/otoplenie/tverdtoplivo/dymosos-dlya-tverdotoplivnogo-kotla-svoimi-rukami.html

Types of boilers according to operating principle

Burning wood or coal in the combustion chamber can occur using various methods. The use of one method or another divides solid fuel equipment into several categories.

Classic

This method is popular in the manufacture of low-power household boilers. Due to the simplicity of the design, craftsmen who independently manufacture a heating unit often resort to using this technique. The smooth surfaces of the internal cavities make it easy to maintain and clean the internal surface from ash and soot.

Long burning

The main disadvantage of using a solid fuel boiler is the need to frequently add firewood to the firebox. To increase the time interval between downloads, various technologies have been developed. One such method is called long-burning.

A feature of this method is the gradual layer-by-layer combustion of a large amount of stored fuel. Slowing down the combustion process is achieved by changing the directions of the flow of hot air masses in the internal part of the heat exchanger. Depending on the number of oncoming flows, long-burning units are:

- two-way;

- three-way;

- multi-pass.

Heat exchangers with a large number of strokes are used in high-power industrial boilers from 100 kW. Long-burning household equipment is made with a two- or three-pass water jacket.

Solid fuel mine-type units are widely used in everyday life. The design feature of which is that the blower is located in the upper part, and the chimney originates at the bottom. Such boilers have one heat exchanger stroke from top to bottom. Combustion occurs in a direction unusual for the laws of physics, due to the opposite direction of thrust. The big disadvantage of such equipment is the constant need to clean the smoke outlet pipe located in the lower part of the housing. Due to the unusual direction of the work process, wood burning occurs very slowly.

In addition to long-burning boilers that use natural draft in a slow mode to increase the time intervals between fuel loadings, there are units with forced regulation of air flows using fans. The complexity of selecting equipment, and subsequently controlling the movement of hot air flows, makes boilers with forced movement of exhaust gases not very popular.

Pyrolysis

To slow down combustion in pyrolysis units, reverse draft is often used, similar to that created in a shaft-type unit. Or they use special smoke exhausters that regulate the movement of combustion products inside the heat exchanger. Air is supplied to the second combustion chamber for combustion of secondary gas. The internal cavity of such equipment has high aerodynamic resistance, which allows the fuel not to flare up in the first chamber. The working process in the second compartment burns all harmful gases, the formation of which is typical for normal combustion.

The double combustion process increases the efficiency of the solid fuel unit. The use of less wood or coal compared to conventional boilers makes the consumer think about the possibility of using such technology to heat their own home.

On pellets

Expensive equipment includes long-burning equipment that uses granular fuel as a resource. The complexity of the design is due to the presence of a hopper for loading and a mechanism for feeding pellets into the firebox. The amount of time (up to 7 days) of autonomous operation of the unit depends on the size of the loading container; it has the shape of a truncated cone, where there is a hole for connecting to a screw or other type of mechanism that portions the briquettes into the firebox, as needed.

The operation of all components and mechanisms of such a unit is controlled automatically. Modern models are even equipped with a mechanism for cleaning the ash pan from ash. The only thing the consumer needs to do is load the bunker and light the pellets. Similar designs are used when using wood chips, coal briquettes and other types of bulk fuel.

The use of different combustion and loading methods deprives solid fuel boilers of the need for frequent loading, while significantly increasing the cost. A large selection of heating equipment allows the consumer to correctly assess their own needs and make an informed choice.

Pyrolysis

The specificity of the operation of pyrolysis boilers for water heating using solid fuel is the use of gas in their operation. It is a product of wood decomposition under conditions of high temperature and lack of oxygen. The design includes two chambers separated by a grate. The upper compartment is intended for burning fuel, and the lower one is for afterburning the resulting gas. First, the fuel enters the upper chamber. After it ignites, the fan turns on.

Upon reaching temperatures of +250 degrees, the process of charring the wood and releasing gas begins. To supply it to the lower chamber, ceramic nozzles are provided. There, gas and air are mixed, which is accompanied by reheating of the ignited fuel mixture in the first compartment. In limited supply mode, the wood gradually decomposes and gasifies. This process is called pyrolysis.

Solid fuel pyrolysis home heating systems have the following characteristics:

- Efficiency up to 90%.

- Good operating time on one fuel fill is up to 10 hours.

- Expensive.

- Energy dependence.

- Requirement to use full downloads.

- The need for high-quality drying of firewood.

How does forced draft work and how does it work?

Factory fans have several permanent elements:

- Impeller with blades made of heat-resistant material.

- Plate with fasteners.

- Electric motor with a power of 20−50 W.

- Cable connector.

- Remote Control.

- Temperature sensor with flask and capillary tube, emergency thermostat.

- Network connection wire.

The smoke exhauster is attached to the box at the back of the boiler near the pipe where the smoke comes out. The flask is immersed in the water jacket sleeve, the remote control is removed separately.

Forced ventilation draws hot gases into the chimney. The whole process goes like this:

- Firewood is loaded into the boiler and set on fire.

- The loading compartment door closes and the flap opens. The hood is turned on from the remote control and its power is adjusted.

- When the entire system warms up, the impeller rotation speed is reduced. When the draft is established, the ventilation can be turned off.

- If the smoke exhauster heats up to 100°C or more, the fan automatically turns off.

The performance of the smoke exhaust system is set based on the amount of fuel, heating of the chimney and combustion mode. The main purpose of forced ventilation is to prevent smoke from entering the room and to prevent it from accumulating inside the boiler.

You cannot set a higher number of revolutions than is necessary for operation, otherwise the heat will escape. If you need to add fuel, you should first speed up the rotation of the fan.

Design and operating principle

The smoke exhauster is designed for the forced removal of solid fuel combustion products due to the vacuum created by the device in the combustion chamber.

The smoke exhauster has the following design:

- Electric motor. An asynchronous model is preferable.

- An impeller consisting of two plates.

- A metal snail casing in which air currents circulate.

In addition, the smoke exhaust device contains such elements as pipes, a drive shaft, an additional impeller, a damper, a dust seal, a cyclone, a chimney and a hopper. Structural elements may differ slightly depending on the model of a particular smoke exhauster. They are usually enclosed in a metal frame.

The principle of operation of a blower type smoke exhauster is the forced injection of flowing air. When the impeller begins to rotate, the air tends to the center, then is thrown away from it and fed into the firebox. Here it creates a vacuum, which contributes to the formation of a continuous air flow. The blades in the device create a turbulence in the air directed in the direction of rotation of the fan rotor. Thus, the smoke exhauster creates a constant “suction” of oxygen into the firebox and simultaneous exhaust of combustion products.

Device

The smoke exhauster is a simple device in terms of design. It consists of several nodes, each of which has its own purpose.

- Frame.

- Suction pipe or suction pocket of the smoke exhauster.

- Guide apparatus. There is right and left rotation, which is determined by the direction of the fan blades.

- Working wheel.

- Frame.

- Electric motor.

The body is made in the form of a “snail”, which provides the required swirl of air entering the unit. Made of heat-resistant steel, covered with thermal insulation.

The guide apparatus of the smoke exhauster is located on the suction pipe and allows air pressure to be regulated using a rotating mechanism that combines the fan blades. Each blade is curved, which allows the air flow to rotate in the same direction in which the rotor rotates. Using a rotating mechanism, you can block the lumen of the pipe to one degree or another.

The smoke exhauster impeller is the unit on which the fan blades are located. They are attached to it by welding or rivets. A rarefied atmosphere is created in the central part of the wheel as it rotates. For this reason, incoming air is drawn in here. Small-sized devices such as smoke exhausters for fireplaces work in a similar way.

The wheel docking unit can be located on the motor shaft or intermediate shaft, depending on the design of the unit. If this is dust collection equipment, the device includes special filters with absorbents. All fire-fighting units are equipped in this way. Ash collectors can be included in the design of boiler room equipment. The design of the smoke exhauster determines its purpose.

The impeller may have holes necessary to fix the blades in a given position. Balancing can be done manually or by an electrical actuator. You can distinguish the direction of rotation of the fan blades if you look at the unit from the side of its electric motor. The axial guide apparatus of the smoke exhauster ensures rotation of the blades, regardless of their number and direction of slope, at an angle from 0 to 90°.

A blower fan and a smoke exhauster have a similar design, but differ in purpose. Devices of the first type provide air injection into the boiler furnace. The latter are designed to remove fuel combustion products and release them into the atmosphere outside the boiler room.

Fans and smoke exhausters of boiler installations have the same operating principle; they can be left- or right-handed, with forward and reverse draft. These machines are designed for long-term trouble-free operation in a temperature range from 0 °C to +250 °C. Smoke exhausters are marked as “D” and “DN”, fans - as “VDN”. The latter are produced with the impeller mounted on the electric motor shaft.

Repair of smoke exhausters and fans is carried out by persons who have undergone appropriate certification and instruction in the safety precautions for operating electrical appliances.

Homemade unit

For those who don’t mind spending money on a purchased smoke exhauster, there is an excellent alternative - you can make it yourself! Compared to purchased ones, such a unit costs mere pennies. A homemade smoke exhauster is usually made from a 230 mm worn diamond disk to which the blades are welded. The engine can be purchased at a flea market, for example, a motor from a two-speed washing machine. This simple device provides up to 3000 revolutions in spin mode. You don’t even have to connect it through a step-down transformer, but you can immediately (or later) make a power regulator. Without much overload, such a homemade device can work perfectly for several years.

Self-made smoke exhauster in the shape of a snail

A properly installed smoke exhauster, despite the fact that it is installed inside metal pipes, is practically inaudible during operation; it is even quieter than a blower fan. In this case, the “wind” speed reaches 150 meters inside the chimney. To check the operation of the device, there must be an inspection hatch at the bottom, so that at any time you can see how the device will work when the loading door in the boiler is opened.