When deciding on the organization of heat supply, the correct choice of equipment occupies a central place. The heat generator is the center of any heating system, and the productivity of the entire heating circuit as a whole depends on the efficiency of its operation. The heating equipment market offers a lot of different solutions.

Solid fuel boilers still remain in demand and popular, largely due to the possibility of modification. Installing heating elements (tubular electric heaters) is a fairly simple and relatively cheap way to transform a solid fuel boiler into a combined device that produces heat using electricity. A solid fuel boiler with heating elements is essentially a unit in which there is the possibility of alternative or joint use of the main types of fuel and electricity.

Operating principle of a heating boiler

The operating principle of a heating boiler is quite simple.

The heat generator connected to the electrical network starts the electric heater, and the heating elements begin to warm up the water automatically. It is better to set the coolant temperature on the control panel 10-12°C below the operating temperature. While heating the coolant, you can load fuel into the chamber located at the bottom of the device. During the combustion process, the heat released heats the heat exchanger to a certain temperature. As soon as the temperature of the heat exchanger reaches the limit level, the heating elements are automatically turned off and subsequently the water is heated only by firewood.

Operation of a combi boiler

The heated liquid enters the heating system through the riser, releasing heat through radiators installed in the rooms. When the fuel supply in the chamber is completely burned and there is no new loading, the water will gradually begin to cool.

The sensor of the electrical unit will react to the set minimum limit temperature value and give a command to start the water heaters. They will maintain the water temperature in the system at the required level until the next firewood is added.

Acting as the embodiment of the latest engineering solutions, they successfully cope with the task, increasing the efficiency of the heating process.

The equipment can operate smoothly without human intervention. And even in unforeseen situations when solid fuel fails, the process is not interrupted: the automation switches the operating mode. Then the coolant in the system will begin to heat up with electric heating elements.

Combination heating boiler design

Universal combined heating systems are good because even with irregular operation of the boiler they are able to maintain the boundary temperature in the system, thereby preventing freezing of water in the pipes.

The principle of operation of the boiler using electricity and solid fuel

In low-rise construction, the most common type of combined heat generators are devices for which firewood, coal, peat or pellets are the main source, and electricity is the backup source of heat. The principle of operation is quite simple. If the solid fuel runs out or burns out in the firebox, the heating element (pipe electric heater) comes into operation, heating the coolant to the optimal temperature. The control control unit is usually responsible for the timely switching on and off of heating elements.

What you need to know when choosing a universal boiler

With all its versatility, one type of fuel should be the main one, and the boiler should be selected according to the type of main fuel. When purchasing an imported boiler, please note that the nameplate indicates the rated power, and not the maximum, as for Russian ones. Sellers usually also name the maximum power. For each type of fuel, a universal boiler will have different power.

Some examples of combination boilers.

Single-circuit universal boiler Zota Dymok KOTV-20M (Russia)

The boiler is designed to operate in water heating systems for residential and industrial premises.

Main characteristics:

- fuel wood/electricity;

- power 20 kW;

- circuit 1;

- type of installation: floor;

- heating area 140 sq. m;

- heat exchanger steel;

- Efficiency 70%;

- chimney 150 mm;

- weight 108 kg;

- dimensions 750x400x705 mm.

The cost of the boiler is 25,000 rubles.

According to reviews, inexpensive and reliable. Ideal for a country house and small production. The main advantages are simplicity, reliability and low price.

The photo shows the universal boiler Zota Dymok KOTV-20M

Single-circuit universal boiler Protherm Bizon 30 NL (Slovakia)

- gas and diesel power 27.1 kW;

- fuel - natural and liquefied gas, diesel fuel and fuel oil;

- open camera;

- heat exchanger cast iron;

- number of sections – 2;

- connecting a DHW boiler is possible;

- chimney diameter 150 mm;

- weight 121 kg;

- dimensions 870x450x385 mm.

The cost of the boiler is 41,300 rubles.

Reviews about the unit are positive. Buyers like the efficiency of the boiler. Heats up quickly and holds heat well. Some customers note difficulties in selecting a burner for this model.

The photo shows the universal boiler Protherm Bizon 30 NL

Combination boiler Ferroli Atlas 32 (Italy)

Designed to heat water below its boiling point at atmospheric pressure. Digital interface, microprocessor. Frost protection, remote control, room thermostat.

Characteristics:

- fuel natural gas, diesel fuel;

- gas power 30 kW;

- diesel power 30 kW;

- heat exchanger cast iron;

- combustion chamber is open;

- connecting a hot water boiler;

- chimney 100 mm;

- weight 127 kg;

- dimensions 850x500x400 mm.

Cost 54,100 rubles.

According to customer reviews, the boiler is very efficient. Fuel consumption is low, water heats up quickly. Excellent design, modern management and control system. Disadvantage: high cost.

The photo shows the universal boiler Ferroli Atlas 32

Electric heating

System Features

In the absence of access to the central gas supply line, owners of cottages and summer houses are increasingly choosing to heat their private homes using electricity. In this case, of course, the cost of operating the system is quite high, but in the absence of alternatives, the use of electric boilers is the only possible heating option.

Heating using an electric boiler

What is included in the electric heating system at home?

- The peripheral part is practically no different from any other design - radiators are responsible for maintaining the temperature in the rooms, to which heated water is supplied through pipes.

- Water is heated in a special device - an electric boiler. The boiler is a reservoir, inside of which tubular heating elements are installed - heating elements. When the current is connected, the heating element heats up, transferring heat to the liquid in the tank.

Note! An alternative to heating elements are electrode boilers, which are direct-acting devices. The coolant is heated by the passage of electric current through it.

- The operation of the boiler heating elements is regulated by the control unit. As soon as the liquid reaches the required temperature, the heating element turns off, thereby saving energy.

- Heated water from the tank enters the system and is carried through pipes to the radiators. To ensure efficient water circulation, special circulation pumps are installed. They help the coolant overcome hydraulic resistance and guarantee quick and uniform heating of the entire heated area.

Advantages and disadvantages

Using an electric boiler has a number of advantages:

- Installing such a boiler is much easier and cheaper than a gas boiler. And the costs of installation work are incomparable: if necessary, you can do everything yourself.

- Electric boilers are convenient and safe to use, so they are an ideal option if it is not you who live in a country house, but your elderly parents.

- When heating a house with electricity, no harmful substances are formed, so this heating method can be considered completely environmentally friendly.

As for the disadvantages, first of all, this is the high price of electricity, as well as the dependence of your comfort on the presence of voltage in the network. In regions where power outages are not uncommon, it is better to have at least one alternative heating source, for example, a fireplace.

What should you pay attention to?

When selecting a model, you need to take into account several rules, failure to comply with which will lead to an error. As a result, the boiler may not be suitable for a particular home; for example, it may not be powerful enough and the room will be cold. For example, a device using wood or gas is dependent on the pressure in the main line, and when it decreases, it can give off noticeably less heat.

In addition to power, the technical specifications usually indicate the area of the house for which it is designed. The calculations are made by professionals and are quite accurate. You can use various tables found on the Internet

Particular attention should be paid to power when choosing the most universal options, such as a wood-gas-electricity device

It is worth considering a possible decrease in gas pressure in the line. This can significantly reduce the heating output. If there is no “reserve”, you will also have to use additional heaters powered by electricity. There is no point in heating with such characteristics; you will have to modernize it and incur additional costs.

The next stage is to determine the purpose of the combined boiler for heating. It can be purchased both as the main source of heat and for additional heating of running water, i.e. immediately choose the combined option.

Such a boiler is more profitable than a separate boiler, because wood or gas is already consumed for heating, and a separate water heater is usually powered by electricity. Wood heating often allows you to gain in the speed of reaching the desired temperature.

How to choose the right boiler

To achieve the required temperature parameters, a building or room needs equipment that can provide them. The list of all elements of the heating system of even a small house contains tens and hundreds of items. The main thing on this list is a heat generator of a certain power. When choosing a unit based on power, you should maintain a balance. Low-power equipment will not be able to sufficiently heat the room; too powerful equipment will lead to excessive consumption of fuel or failure of the entire system.

The thermal power of any household heating device is indicated by the manufacturer in kilowatts. Ideally, it is better to entrust the calculation, selection and installation of the entire heating complex to specialists. Preliminary parameters can be set independently, taking into account that 1 kW of heat generator power is enough to heat 10 m2 of room area with average insulation and a ceiling height of 2.5 m.

Flaws

Like any heating systems, combined designs have a number of disadvantages:

- To install the boiler you will need a separate dedicated room. You should also find and equip a place where the fuel will be stored;

- Cast iron is usually used to make heating units. It has significant weight. Before carrying out installation work, it is sometimes necessary to pour a concrete pad. It will strengthen the foundation structure;

- There are no models that can be mounted on a wall. Installation is carried out only on the floor;

- The devices have a complex design. As a result, the cost of installation work and maintenance increases;

- electric heating elements have low power;

- the price of combined devices is higher than the cost of conventional boilers.

What is more profitable - a separate electric boiler or a built-in heating element?

According to many experts, a separate electric water heater is better, since it only heats the system coolant, excluding heating the boiler water jacket. True, in some models, built-in heating elements are installed in the upper part of the heat generator housing, which completely solves the problem. In this case, the advantages of a multi-fuel device are obvious.

Operation of universal boilers

Before installing a long-burning combination boiler, you should take into account that such equipment is heavy and requires a fairly strong foundation. Another equally important point is the purchase and installation of a chimney sufficient to provide boiler draft

It is also necessary to pay attention to cleaning the ash pan. The degree of contamination will depend on the type of fuel and the intensity of the boiler operation. The boiler room is an important point that you should not forget about when purchasing universal boilers

The chimney should be purchased with non-flammable thermal insulation to prevent fire upon contact with the heated surface of the pipes. Next, it is necessary to place a steel sheet in front of the boiler firebox to protect the floor from possible sparks or burning particles. Also, do not forget about fuel delivery and loading; some boilers need to be loaded every 4 hours. The moisture content of firewood should not exceed 20%

The boiler room is an important point that you should not forget about when purchasing universal boilers. The chimney should be purchased with non-flammable thermal insulation to prevent fire upon contact with the heated surface of the pipes. Next, it is necessary to place a steel sheet in front of the boiler firebox to protect the floor from possible sparks or burning particles. Also, do not forget about fuel delivery and loading; some boilers need to be loaded every 4 hours. The moisture content of firewood should not exceed 20%.

Heating with wood

Wood boilers and stoves

As an alternative to the method of heating a country house described above, there are various devices that burn wood - solid fuel boilers (with or without a water circuit) and various stoves. The difference between them is as follows:

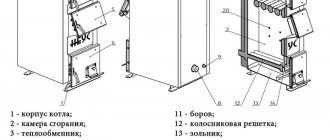

Wood boiler diagram

- A wood-burning boiler uses the energy released during the combustion of wood or pressed sawdust pellets to heat the water in the container. Water flows through pipes to the heating radiators and ensures the maintenance of the microclimate in the room.

- In the furnace, just like in the boiler, wood is burned. But in this case it is not the water that is heated, but the air, which transfers the heat.

Photo - wood stove

Today, solid fuel heating systems are quite popular, the reason for which is the obvious advantages of their operation.

Advantages and disadvantages of wood-burning installations

The advantages of wood heating are as follows:

- In many regions of Russia, the cost of wood fuel is significantly lower than its other varieties, so heating a country house with wood is quite profitable.

- This heating method does not depend on the presence of gas in the pipelines or on the network voltage. In any situation, you can always load fuel into the stove or boiler and provide heat to the house.

- Although the environmental friendliness of wood heating is lower than that of electric heating, when burning wood, significantly fewer harmful substances are released into the air than when burning natural gas or petroleum products.

Fuel needs to be stored somewhere!

This system also has disadvantages:

- The operation of a wood-burning boiler must be monitored by constantly adding fuel.

Note! This disadvantage can be minimized by installing a stove with automatic supply of firewood or by installing a heat storage tank. This way fuel can be added no more than once a day.

- Solid fuel requires a lot of storage space.

Construction and operation of gas-wood boilers

A universal gas-wood boiler for home heating, available in three different modifications, differing in design and functionality.

- Module with the possibility of conversion to gas.

- A boiler that has two combustion chambers at once, separately for wood and gas.

- Heat generator with built-in electric heating element.

Combined boilers of mixed type, for gas and wood, have built-in automation that fully automates the combustion process. After the wood burns in the firebox, the module automatically switches to gas or electricity. For domestic hot water, the water is heated by an electric heating element.

Simultaneous installation of a wood and gas boiler in one system requires significant financial costs. The purchase and installation of universal equipment reduces costs by 30-40%.

Bi-fuel wood-gas boilers

Combined gas-wood boilers are widely used in domestic settings. The design includes the following components:

- Combustion chamber - made of steel or cast iron. One or two fireboxes are installed in the design. A modification with two combustion chambers is more convenient. A gas burner is installed in the lower firebox. In the upper chamber there are grates for burning wood.

- Heating and hot water circuits - manufacturers produce models designed exclusively for heating (with the possibility of subsequent connection to an indirect heating boiler), as well as for producing hot water and heating rooms. The latter are equipped with two circuits. DHW is heated using a flow method.

Heating of water for domestic hot water, depending on the performance of the boiler heater, reaches 700 l/hour. There are modifications with built-in storage capacity for 40-120 liters of water.

Electric-gas-wood boilers

Combined heating boilers, gas, wood and electricity, have a device reminiscent of what dual-fuel units use. The main difference is the installed electric heating element. The operating principle of combined boilers, gas, wood, electricity, is as follows:

- The main type of fuel is firewood. After the wood is burned, the gas burner turns on automatically. The heating process continues without stopping.

- The heating element is used to maintain a minimum temperature of the coolant after the gas and firewood have run out. Operation in antifreeze mode is allowed. An electric heating element maintains a minimum temperature in the heating system, preventing the water circuit from freezing.

Some universal heating boilers - gas, wood, electricity - use the principle of gas generation in their operation, which increases the battery life to 6-12 hours, from one load of logs.

Choosing the type of heating in a private household

Since installation restrictions in an individual house are minimized (you can generally build a separate boiler room next to the living space), there remains a relatively free choice of energy source.

What can be used for heating in the private sector?

- First of all, solid fuel. This can be coal, firewood, or fuel briquettes (essentially the same firewood). We will leave such exotic products as cow dung for areas where it is “found” in abundance.

- Gas in our country is quite a profitable option. Unless, of course, it exists in a specific locality.

- Electricity is valuable because it is available almost everywhere. With the possible exception of territory remote from civilization (there is no gas there).

When choosing fuel for a boiler, the first thing to consider is the cost per unit of heated area for a specific region. If logging is developed around you, the choice is made in favor of firewood.

If there is a coal mine nearby, firewood is needed only for kindling. Gas is almost always chosen immediately after connecting the house to blue fuel. Today there is practically no alternative (in terms of heat cost). Of course, we are talking about central gas supply; liquefied fuel in cylinders is unprofitable for heating.

Electricity is available almost everywhere (you just need to worry about the technical conditions in advance to provide the necessary power).

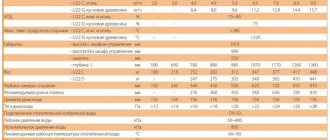

So, let’s assume that the technical capabilities of supplying any fuel are present. We will make an approximate calculation of the monthly heating costs of a cottage with an area of 200 m².

Important: Energy prices may differ for different regions, so the figures are approximate. The table below only shows the relative dependence of the cost of heat on the material.

Let's say you analyzed all possible costs, including delivery costs, and made a decision in favor of one type of fuel or another. We bought a boiler, integrated it into the heating system of your home, and entered into an agreement for the supply of fuel.

A year passes, and the forest in which firewood was collected was recognized as a specially protected natural area. Firewood must be transported 100–200 km.

An accident occurred at a nearby coal mine and it was closed. Coal has become more expensive than firewood.

A nuclear power plant was built nearby; the cost of electricity for the surrounding villages became so favorable that it was even more expensive to heat with natural gas.

How to protect yourself from such economic risks?

Types of boilers

One of the main parameters by which combined heat generators are classified is the types of fuel used.

This is usually reflected in the marking, which consists of several letters meaning:

- T - solid fuel (wood, coal, pellets, peat, etc.);

- G - gas;

- E - electricity;

- F - liquid fuels (fuel oil, kerosene, used engine oil, diesel fuel, etc.).

For example. the combination of the letters “TG” in the name of the heat generator means that it can operate on solid fuel and gas, and the design will use a design with two combustion chambers. If necessary, you can buy a multi-fuel unit, the name of which contains four letters “TGEZH”. Such heat generators are the most versatile devices, however, the complexity of the design and high price do not have the best effect on their prevalence among consumers.

The most optimal solutions for private homes remain devices using two types of fuel.

Gas/electric combination

Electric gas equipment is usually used in gasified areas where interruptions in the supply of pipeline gas occur. Considering that the cost of electricity is approximately three times higher than the cost of gas, in combined units of this type gas is used as the main source of heat, and electricity as a backup. Compared to solid fuel heaters, gas-electric heaters are more compact and are often mounted on the walls of residential premises, significantly saving space.

Wood/gas combination

Wood-gas heat generators are represented quite widely on the heating equipment market. They are popular in gasified areas with harsh climates, where the use of two types of fuel during an extended period of cold weather can reduce overall heating costs.

Prices for combined boilers ZOTA

combi boilers ZOTA

There are two types of solid fuel-gas installations:

- Units that use gas as the main fuel and wood as an alternative fuel. To switch from one type of fuel to another, a small upgrade is required.

- Universal heat generators in which the gas turns on automatically when the wood burns out.

This type of equipment usually has two combustion chambers with a common chimney. Grate bars are installed in one chamber, and a gas burner is installed in the other.

Wood/electricity combination

In those regions where the cost of firewood is low and there are no gas mains, combined wood-electricity installations remain the most preferred and in demand. Two sources of thermal energy not only minimize heating costs, but also increase the overall stability of the system. The heating circuit is inertial. Constantly maintaining the required coolant temperature by electric heaters reduces the consumption of firewood for heating it when igniting, which makes it possible to use less wood.

Multi-fuel installations

The prevalence of multi-fuel installations in private homes is hampered by two main factors: high price and difficulty of maintenance. The use of fuel with different physical properties in one unit requires the installation of a larger number of burners, pumps, nozzles and other elements. This leads to more complex control automation and a decrease in overall reliability.

For private households, a maximum of three fuel combinations are usually used, including wood, gas and electricity. Combinations such as pellets/liquid fuel/gas are very rare.

Advantages and disadvantages of solid fuel units with electric heating elements

An ordinary wood- or coal-fired boiler installed in your home or dacha is fine. There is only one disadvantage that the owners have to keep silent about. The problem is the constant need to feed the heating unit with fuel. Electric heating elements installed in the boiler can radically improve the current situation by taking on part of the work in an endless process. With such devices, you do not have to regularly visit the boiler room and monitor the fuel combustion process.

Important! You should not count on full heating of a residential building and provision of hot water with electric heating elements running. Electricity in this case is a temporary source of thermal energy. Allowing long interruptions in the operation of the main part of the boiler means facing the fact of high costs for consumed electricity.

*

What benefits do you get by installing a combined solid fuel boiler at home:

- autonomous operation of the entire home heating system;

- increased time interval between loading fuel into the combustion chamber;

- protection of the water heating system from defrosting at low temperatures.

As for technological advantages, solid fuel units equipped with electric heating devices have the following capabilities:

- no condensation formation on the internal walls of the combustion chamber due to the constant heating of the heat exchanger by electric heating elements;

- with constant maintenance of the required coolant temperature, there is no need to install a spare circuit and install a thermal mixing valve;

- Due to the operation of electrical appliances, the efficiency of a solid fuel heating boiler increases to 95%.

Versatility is the main advantage of this technology, but such advantages also have a downside. The combination of both types of heating elements in one device leads to a significant increase in the cost of the model. Compared to traditional solid fuel units, such boilers are much more expensive. However, if you want peace of mind and comfort, price will not be a deterrent.

The second aspect that may scare consumers away from such boiler equipment is the manufacturability of the device. The large inertia of the heating boiler is characteristic of both the solid fuel unit and its electrical part. The low power of electric heating elements is the main factor preventing your choice. As a rule, with a basic power of 50 kW or more, electric heaters produce only 6-24 kW. As a rule, the total power of electric thermal heaters is no more than 1/3 of the maximum power of a solid fuel boiler.

Note: Boilers equipped with more powerful electric heating devices are more expensive, and the energy consumption in this case will be significant. Such combination boilers are easy to use, but are not at all cost-effective as a heat source for a heating system.

Installation nuances

The operation of home heating equipment is associated with a significant risk to health and life, therefore manufacturers and regulatory authorities have developed clear rules for its installation, use and maintenance. They are set out in the technical documentation attached to each unit and SNiP (Building Norms and Regulations) standards.

Their strict observance eliminates the possibility of a fire in the home, a gas explosion, and poisoning by combustion products.

Premises requirements

The ideal option for installing the entire complex of equipment is to organize a special room - a boiler room.

This takes into account:

- size of ventilation holes;

- area and volume of the room;

- distance from the protruding parts of the boiler to the walls;

- the presence and size of windows and doors;

- type and power of ventilation;

- presence and nature of electrical wiring and lighting.

If for solid fuel units the presence of a separate room is mandatory, then, for example, for gas-electric boilers with closed combustion chambers, installation in kitchens is allowed. In this case, a coaxial chimney is installed to ensure combustion of gas and removal of its combustion products.

Chimney installation conditions

When purchasing combined heating units, be sure to check that the hole for the chimney matches the dimensions of the chimney pipe. Depending on the model, the gas exhaust hole can be either rectangular or round. If these parameters do not correspond, it will be impossible to install the chimney properly or the installation of additional transition elements will be required.

In cases where the installation of heating equipment requires forced ventilation, you should ensure that the supply duct is larger in area than the chimney duct.

Prices for combined boilers Teplodar

combined boilers Teplodar

Requirements and rules for connecting to the electrical network

In the furnace of small private houses and cottages, electrical equipment is usually installed, consuming from 1 to 5 kW and operating from a single-phase network. In this case, the connection of electric heaters or heating element blocks occurs without significant alteration of the house's power supply system. For more powerful equipment, 380 V power cables are laid.

Lighting in boiler rooms and furnaces should ensure comfortable maintenance of all systems at any time of the day. The SNiP standards in the section “Natural and artificial lighting” discuss in detail the requirements and rules for its technical arrangement.

Criterias of choice

When choosing heating equipment, any consumer is guided by its ability to heat the home and utility or technical rooms as efficiently as possible. The main indicator of any heat generator is its power. As a rule, the required power is calculated through complex calculations, taking into account the heated area of the premises, the characteristics of wall and roof materials, the number of door and window openings and dozens of other parameters.

A simplified calculation is made based on the area and volume of the premises. In the most simplified form, it is generally accepted that 1 kW of the declared boiler power is enough to effectively heat 10 m² of room area. In practice, for a house with an area of 150 m², a 15 kW boiler will be sufficient. Ideally, a heat generator with parameters higher than the calculated ones by 10-15% is selected.

When choosing, you should also consider:

- materials for manufacturing the housing and heat exchangers;

- linear dimensions of the boiler;

- possibility of connecting electrical equipment and characteristics of the electrical network;

- location of connection points for pipes and shut-off valves;

- features and shape of the gas outlet;

- the need for arrangement and power of supply ventilation;

- price and brand authority.

Application of combi boilers

Today, such devices are universal and at the same time economical devices for autonomous heating at home. Their main trump card is that they are not tied to one type of fuel. If such a boiler runs on electricity, then during a sudden power outage you can light the wood stove to keep the house warm and vice versa.

Buying a combination boiler solves several problems

- If there is no main gas pipeline in the village where the house is built, then it is possible to use two alternative types of energy at once - solid fuel and electricity.

- If a country house is connected to a weak power supply line, a combination boiler is almost an ideal option - you won’t have to freeze if you need to turn on another powerful electrical appliance for a long time.

- Eliminates cooling of the house when using solid fuel. Such a unit, connected to water heating, helps maintain a constant temperature in the system: if the fuel burns out, the boiler will automatically smoothly switch to heating through the heating element. This is especially convenient at night: you don’t have to get up and add wood to the stove’s firebox.

When a conventional boiler cools down, it must be lit immediately so as not to lose heat Source iobogrev.ru

Combined heating: installation and installation requirements

Combination boilers, due to the use of different types of fuel, require compliance with greater installation parameters than products operating on a single energy carrier. Thus, for the safe operation of units of the “electricity - firewood” type, the following conditions must be met.

Premises requirements

- Firstly, the room must be decorated with non-combustible materials that are unable to spread fire.

- Secondly, it is prohibited to install any non-hermetic electrical equipment (IP below 44) in wet rooms - showers, bathrooms.

- Thirdly, the room must be equipped with high-quality supply and exhaust ventilation, preferably forced. This will provide an influx of oxygen-saturated outdoor air, which, in turn, will facilitate complete combustion of the fuel.

- And fourthly, before installing heavy heating equipment, the mass of which is several centners, it is necessary to consider strengthening the floor surface.

Chimney requirements

Since from time to time the heater has to be operated on solid fuel, a chimney must be installed.

The main condition for a high-quality chimney pipe is the absence of holes, cracks, holes in it, the tight connection of all joints and the presence of good draft , which is ensured by installing the chimney in such a way that its upper part protrudes above the roof level at a distance of no less than half a meter.

Also, the chimney must be reliably insulated in order to prevent the occurrence of condensation, which can lead to the formation of ice plugs inside the pipe.

Electrical requirements

The electrical network for connecting the heating elements of the combined boiler must correspond to the configuration and power of the heating equipment:

- When power consumption is up to three to four kilowatts, single-phase heaters are usually used, and when this indicator exceeds the 5-kilowatt mark, the units are equipped with three-phase heating elements.

- The cross-section of the electrical wiring must correspond to the maximum current consumption of the device.

- The automatic protection of boiler equipment is selected in a similar way: by current - in accordance with the cross-section of the supply wiring. That is, the nearest higher standard value from the range of automatic protection is selected than the maximum power of the boiler, but less than what the electrical wiring can withstand.

- It is also recommended to connect the unit through a differential relay (residual current device), which is triggered at a leakage current of 30 milliamps.

- First you need to thoroughly clean the heating circuit with a special product or install a new system.

- Install ball valves on the incoming and outgoing pipes.

- Install the chimney pipe in accordance with the rules of safe operation.

- Connect the chimney to the boiler pipe and carefully treat it with heat-resistant sealant.

- Connect the heating system to the unit.

- We check the presence of draft and tight closure of all doors in the boiler.

- We install a panel with automatic protection near the unit and connect it to the power supply.

- Using a flexible three- or five-core cable, we connect the terminals of the boiler box to the machines. Don't forget to connect the ground wire.

- In the case of a single-phase version, the device can be equipped with a Euro plug and connected to a three-pole socket.

In the video you can see how the Retra 3M solid fuel boiler is connected to electricity:

Advantages and disadvantages

It should be said that this category of devices has its disadvantages and advantages, which you should definitely pay attention to. If we talk about the advantages that such a combined boiler has, we should name:

If we talk about the advantages that such a combined boiler has, we should name:

- Long service life. If a boiler of this type is operated correctly, it will be able to perform its functions efficiently for at least 20 years.

- Autonomy. There is no point in monitoring the operation of such a boiler, since the automation installed in it will perfectly control its activity. Especially when it comes to working from a power outlet. Heating using heating elements is limited to the uninterrupted transmission of electrical energy.

- Smart design. Heat is distributed as efficiently and intelligently as possible, and energy losses will be very low, which makes these boilers an excellent and efficient solution.

- Economical. Electricity today is one of the most accessible types of energy, as is wood. As a solid fuel alternative, you can use coal or briquettes or pellets. In general, if we talk about efficiency, this boiler simply has no equal.

- Versatility. Such solutions are universal, because you can use any of the 2 types of fuel if desired.

But with all these advantages, combined solutions also have disadvantages. But any heating equipment has them, which is generally not surprising.

If we talk about the disadvantages, we should name:

- Large mass. Boilers that are made of cast iron weigh a couple of hundred kilograms, or even more. To install such a boiler, you must first make a concrete pad to strengthen the base of the floor. Due to the heavy weight of the device, there are no models that can be mounted on a wall. There are only solutions for floor mounting.

- Not a simple design. Combined options have a rather complex design, which leads to higher installation and maintenance costs.

- Low power of the electrical component. Typically, the power of electric heaters should not be greater than the power of the chamber where the firewood must be placed. The power of the firebox for firewood is usually from 6 to 25 kilowatts.

- Takes up a lot of space. As a rule, in order to install such a boiler, it is necessary to allocate a separate room for this - a boiler room, where fuel reserves should be stored.

Review of popular models and prices

The variety of boiler models operating on solid fuels is almost limitless. Some models differ from competitors not only in their low cost, but also in their excellent performance parameters that have stood the test of time.

Warmos-TT (Evan)

The Warmos-tt line of boilers is an example of high-quality and inexpensive heating equipment from a Russian manufacturer. The line includes devices with rated thermal power of 18 and 25 kW. Models whose names contain the letter “K” are equipped with a 2.1 kW heating element and a draft regulator. A distinctive feature of the devices is the presence of an exhaust gas afterburning system, which ensures more complete combustion of the fuel. The boiler body is made of sheet steel with external powder coating. If the operating rules are followed, the manufacturer guarantees the operation of the unit for 10 years.

The price of Warmos-tt models ranges from 29 to 30.5 thousand rubles, which is significantly lower than the cost of analogues from famous foreign brands. The advantages of the design include a spacious combustion chamber and the presence of a protective screen from flames.

Prices for WARMOS-TT

WARMOS-TT

Zota Mix and Dymok

The Zota Mix line of heat generators includes units with a power from 20 to 50 kW with heating elements from 3 to 9 kW. The main competitive advantage of Zota Mix boilers is the ability to use almost all types of solid fuel: from wood to brown coal. Boilers under the Zota brand are manufactured by the Krasnoyarsk Heating Equipment and Automation Plant. The popular “Dymok” boiler is also the creation of the company. Small in size and power, “Dymok” boilers with and without a hob have found their use in dachas and small houses. The popularity of products under the Zota brand was ensured by the low cost and ease of use of the equipment.

The dealer price for a Zota solid fuel boiler with a power of 31.5 kW is not critical for the common man and ranges from 33 to 35 thousand rubles. At the same time, the quality of the product is at the proper level, and the domestic manufacturer guarantees the availability of the necessary spare parts.

EKO-EL (Wirbel)

The most interesting technical solution that distinguishes the Wirbel boilers of the EKO-El series is the inclined hatch, which greatly facilitates the loading of firewood into the combustion chamber. The lineup includes 9 models with power from 14 to 80 kW. Models with the “EL” index are equipped with heating elements with a power from 6 to 24 kW. The efficiency of heat transfer in heat generators of this series is significantly increased due to the use of a water-filled grate.

The price for the lowest-power model Wirbel ECO-EL 14 is in the range of 77-78 thousand rubles, which fully corresponds to the thoughtfulness of all elements, the high quality of manufacturing and assembly materials.

Prices for EKO-EL

EKO-EL

What to look for when choosing a combination boiler for heating a private house

There are many factors to consider before choosing a combi boiler:

- single- or double-circuit - according to the configuration of the heating system of a private house;

- power - calculate based on the size of the home and its thermal insulation;

- take into account the economic component;

- the fuel used according to the availability of one or another type of energy carrier, both main and additional;

- the presence of a chimney depending on the structural characteristics of the building.

And these are not all the nuances that determine the model of a combined boiler. By contacting professional consultants, you can avoid unnecessary expenses, select the right model and ensure warmth and comfort in your home at any time of the year.

Which equipment is better to choose?

It is impossible to use a solid fuel boiler if there is no smoke removal system and space for storing energy. It makes no sense to install an electric unit if there are regular interruptions in the household network.

Solid fuel systems with manual loading mode cannot operate in a maintenance rhythm. When the energy carrier burns out, the boiler is deactivated, which leads to the cooling of the liquid circulating along the heating line.

If you are not constantly in the house, it is better to choose electrical equipment. This type of device must be installed even if there is no space for mounting a solid fuel unit.

To compensate for the disadvantages of one device with the advantages of the second, you can make a combined system consisting of both types of devices. However, the installation must be configured correctly.

How to choose a wood-electricity combi boiler

Combined heating boiler "wood-electricity"

When choosing a combined electric-wood boiler, you should pay attention to the following points:

- Correctly select its power, which should correspond to the area (volume) of the heated premises of the house, and also take into account the level of their thermal insulation, that is, heat losses. It is best to calculate the heat losses of the heated rooms of the house. As a last resort, you can focus on average values of 1.0-1.2 kW per 10 m2 of heated area.

- Type and cost of the boiler. This may be the cheapest option - a regular boiler with a small combustion chamber and short-term burning of wood, or a more expensive unit with pyrolysis combustion of fuel. The cost of the boiler also depends on the complexity of the design and the reliability of the manufacturer, as well as the quality of work and materials used in its manufacture. Here a lot depends on the availability of funds and everyone makes their own choice.

- The power of the heating element must be such that the electrical wiring in your home will “pull” or it will have to be redone.

- Heat exchanger material. The cast iron heat exchanger is more durable, resistant to corrosion and does not have welding seams. It is a prefabricated unit, the elements of which can be replaced, if necessary. But he is afraid of sudden changes in temperature and shocks. A steel “water jacket” is not afraid of changes and impacts, but it rusts and burns out faster.

- Some combined electric-wood boilers have a second heat exchanger (circuit) for domestic hot water. This is both a plus and a minus. On the one hand, simultaneously with heating, we also receive hot water into the water supply system. On the other hand, this requires additional boiler power. In addition, such a hot water system will only work during the heating season.

Methods for switching fuel types

Combined units in general are designed to solve several problems at once, so manufacturers try to make their devices as minimally independent as possible from human intervention in their operation. Moreover, the integration of each element of the heating system into a complex that is popular these days, called a “smart home,” requires a fairly serious level of automation. A specific feature of solid fuel equipment is the mandatory human participation, at least when loading and igniting fuel.

Manual

Any type of solid fuel is placed manually. The process of its ignition at the initial stage should almost always be controlled. When the firebox reaches operating mode, you can make a transition to an alternative type of fuel in advance. For heating elements, the corresponding circuit breaker is turned on, and for gas or liquid fuel, main taps are opened.

Auto

For example, if a pellet bunker or one stack of a pyrolysis unit allows generating heat for more than a day, all issues related to combustion control or switching to alternative types of fuel are taken over by automation. The homeowner or summer resident can only set the necessary parameters in the programmer or control unit. Executing mechanisms in the form of servos or electric valves, when power is supplied to them, at the right moment transfer the operation of thermal equipment to the appropriate type of fuel. For liquid fuel equipment, power is also supplied to the fuel priming pumps at the right time.

Construction of a wood-electricity combined boiler

Today, quite often, when creating a heating system in individual buildings, units that use two types of fuel are used. The appearance of the combined structure is very similar to the shape of a conventional heating device. Boilers for heating with wood and electricity contain additional heating elements built into the heat exchanger. But even if the electrical energy is completely turned off, the unit will operate on solid fuel alone. Thus, the reliability of the heater used increases many times over.

Basic operating elements

Combined devices that use wood and electricity for heating include the following structural elements:

- loading chamber (furnace). The duration of continuous operation depends on its size;

- The ash pan is used to regulate the oxygen supply. Ash collects in it;

- the special design of the burner makes it possible to work on solid fuel and electricity;

- The draft damper regulates the combustion intensity. It opens or closes using a chain drive device;

- the heat exchanger is designed to provide hot water supply;

- Using temperature sensors, the operation of heating elements is monitored during their continuous operation.

The boiler operation is adjusted automatically. Some models are equipped with hobs. They are usually located above the combustion chamber. You can cook food on them.

Single-circuit and double-circuit heating devices are produced. The first type of boilers can only be used for heating premises (this could be a cottage or a small individual building). The second type of heaters allows you to organize a hot water supply system.

Operating principle

Combined wood-electricity heating boilers have a fairly simple principle of operation. Using a heat generator powered from the electrical network, the electric heater is started. The coolant, in contact with electric heating elements, heats up. The operation of the system resembles the operation of a conventional boiler. The process is controlled using a special device. In manual mode, only wood is loaded into the combustion chamber.

While the water is heating up, wood is loaded into the combustion chamber and set on fire. It is located below. From it, thermal energy is transferred to the heat exchange structure. After the temperature of the coolant reaches a certain set level, the heating elements are turned off. Further heat generation is carried out only using solid fuel. The unit continues to operate on wood.

When the wood is completely burned, the heater turns on again. With its help, the temperature is maintained at the required level. A wood-electric combination boiler can operate using only wood or electric energy. But in most cases, the combination of two types of fuel allows the unit to operate more efficiently. This mode is very convenient at night. In the evening, firewood is placed in the firebox and the heating element is turned on at the required power.

If you plan to heat your house mainly with electricity, maintaining the system becomes quite simple. Using an automatic control device, the set temperature is set. It is supported by heating elements. When the electricity is turned off, firewood is placed in the combustion chamber and the heating structure continues to operate.

Advantages of a boiler operating on different types of fuel

We examined economic feasibility in the previous section. Indeed, the cost of heating with different types of fuel may change, and then all your calculations will be reduced to zero. Emergency safety is also important: when you have 300% fuel reserves, life is somehow calmer. The same applies to technology: let’s say the gas burner is out of order, and the repairman will come only in a week. We heat with wood or electricity.

But there are other advantages:

- Complete energy independence. There are times when the main energy source cannot be purchased. There are many reasons, including illegal ones. You will still be able to provide your home with heat.

- Any heating system (especially with liquid coolant) is quite inertial. While you melt the wood (coal) and the gas burner comes into operation, a lot of time will pass. If you enter the house after a long absence, you want instant warm-up. You can start the express mode from an electric heater, then switch to economical heating from gas or solid fuel.

- You can dismantle the gas burner for maintenance without disturbing the heating mode.

The best combined wood and electric models

The domestic market offers a wide range of heat generators from Russian and foreign manufacturers.

Teplodar Cooper Praktik-14

The compact single-circuit boiler “Kupper Praktik 14” is capable of serving a room with an area of 70-140 m². Designed for storing firewood up to 40 cm long and coal. After the fuel burns out, the temperature is maintained by a 6 kW electric heater. Manufacturer – Russia.

Teplodar Kupper Praktik-14 is a compact single-circuit boiler.

Teplodar Cooper PRO-22

A single-circuit device heats cottages with an area of 150-220 m². Operates on various solid fuels in long-term combustion mode. The logs burn out in 8 hours. Working pressure – 3 atm. Manufacturer – Russia.

Zota Topol M-14

The power of the device (14 kW) is designed to heat a house with an area of 100-140 m². The body is insulated with basalt cardboard. The main types of fuel are small firewood, coal, gas connection is possible. Device efficiency is 78%. Manufacturer – Russia.

If it is necessary to heat a larger area, the Topol M 20 boiler is suitable.

Zota Poplar M-14 is designed for 100-140 m².

Zota Mix 20

The steel water heating boiler “Zota Mix 20” with a power of 20 kW is suitable for heating cottages with an area of up to 200 m². Operates on different types of fuel, including connection to gas (additional equipment required). The pressure in the system is 3 atm, can withstand a short-term increase of up to 4 atm. Manufacturer – Russia.

Protherm Bison 40 NL

A solid fuel and electric boiler in one system is used for heating and water heating. Power – 43 kW. Material – cast iron. You can use fuel oil, diesel fuel, or gas as a fuel agent. The microclimate is maintained by a regulator. There is protection against freezing and overheating. Efficiency – 89%. Manufacturer – Slovenia.

Protherm Bison 40 NL is made of cast iron.

Kiturami KRM 30R

Double-circuit system with power up to 35 kW. Capable of heating a room of 350 m². Works on any type of solid fuel, as well as diesel and biofuel. Manufacturer – South Korea.

Karakan 16TPEV 3

Compact dual-circuit device with a hob for cooking. The power (16 kW) is designed to heat a home with an area of 160 m². The device is capable of operating on electricity most of the time (9 kW heating element). The pressure in the system is 3 atm. Efficiency – 75%. Manufacturer – Russia.

Karakan 16TPEV 3 is a dual-circuit device.

Universal water heaters

Today, many consumers prefer to use powerful multifunctional equipment for heating the room, so they install combined heating boilers in their homes. Such devices make it possible to use gas and electricity (or other combinations) as energy carriers.

These are technologically advanced units that have the ability to switch to another type of fuel with minimal modifications. Some models combine solid fuel components, while others combine solid fuel with liquid or gaseous fuel.

Internal organization

Combined devices for heating a private home have become especially popular due to their versatility, thanks to which any type of fuel can be used. This effect is due to the special design of the device:

- two chambers for different types of fuel (solid, gas, electricity);

- integrated heating element;

- several outputs for different heating circuits;

- inflatable burner.

Additional outlets for connecting the heating system make it possible to heat several rooms at the same time, and they also reduce the main length of the radiator pipes.

Advantages of the device

Universal models have the following advantages:

- operate simultaneously on different fuels;

- reliable;

- operate autonomously;

- can serve as a backup heating option;

- comfortable to use.

Autonomy

Experts note that combination boilers provide complete autonomy. So, you can use main and bottled gas for heating until the system is connected to the central gas supply.

The universal design will keep your home warm if the electricity goes out. Solid fuel units that have structural elements for switching to gas or liquid fuel reduce the complexity of their maintenance process.

If you run out of liquid fuel, you can use a combination boiler to heat your house with wood. If due to bad weather it is not possible to prepare firewood, then using built-in tubular electric heaters you can heat the cottage using electricity. This will prevent the system from defrosting and prevent the inhabitants of the house from freezing.

Requirements for the boiler room

The installation of a wood-burning electric boiler is carried out in a special room - a boiler room. It is subject to a number of safety requirements:

- The room is dry, well ventilated.

- The walls are made of non-combustible material.

- The floor is reinforced to support the weight of the unit and, if necessary, reinforced with a concrete screed.

- The distance between the wall and the heat generator is at least 300 m.

Flammable liquids and any combustible materials must not be stored in the boiler room.

The boiler room must be dry.