More than one or two varieties of heating appliances have been invented, but the leadership position in terms of demand and sales level has long been firmly entrenched in gas boilers.

Both potential buyers and existing owners should have a good understanding of these units in order to be able to carry out feasible repairs and have a good understanding of the essence of preventative maintenance.

The reader is invited to study the structure of a gas boiler and become familiar with the purpose of all its components.

The principle of operation of a gas boiler

This equipment operates according to an extremely simple scheme. Natural gas is mixed with air to form a fuel-air mixture that is ignited. The flame and hot products of fuel combustion heat the contents of a special tank - a heat exchanger, which is connected to a heating system (CO) with a liquid coolant.

The latter constantly circulates through the system - either only due to convection (natural circulation), or also due to the operation of a special pump (forced circulation).

Installation of a wall-mounted double-circuit gas boiler

Flue gases, having given up part of their available energy to the coolant, are discharged outside through the chimney.

Along with conventional boilers, so-called condensing boilers are produced today. They “know how” to take more heat from the flue gases, so that they cool down to the condensation temperature of the water vapor they contain.

It is condensation that acts as the source of the main part of the additional heat (the processes of changing the state of aggregation are very energy-intensive). As a result, the efficiency of the installation increases to 97% - 98%.

Why install two boilers at once?

The role of the leader in the gas + electric combination is usually performed by a gas unit. This is logical, if only because of the lower cost of the fuel used in the supply. But the word “save” was mentioned above, and it is not clear what the cost reduction is.

The fact is that in many regions the electricity tariff is based on the day/night system. In some cases, it turns out, at least a little, but more economical than paying for gas. The difference is doubtful, but it can serve as an additional reason to add arguments for the double connective.

Installing an electric boiler in conjunction with a gas boiler can play a backup or additional role in the overall organization of heat supply. When choosing equipment power, you should focus specifically on the purpose of its use.

Of course, this is not such a compelling reason to immediately design a heating system with 2 boilers. The main advantages of the circuit are power amplification and uninterrupted operation. When choosing and installing a heat generator, you must clearly understand that any device and fuel supply are not eternal.

The power supply is turned off, the gas line may be blocked due to a leak, the voltage in the network will drop, or a simple breakdown of the unit itself will occur. In this case, you risk being left without heat and hot water during the cold season.

To ensure uninterrupted operation of heating equipment or increase the power of the system as a whole, it is possible to allow 2 boilers operating on different fuels to operate at once

This is called connecting an additional (to enhance power) or backup power source, depending on the purposes and situations that arise.

Classification of gas boilers

Such devices are divided into several groups according to the following characteristics:

By installation method

Two options are available:

- Wall-mounted: in this form they produce mainly boilers of low and medium power, intended for heating houses or apartments with a small area. The wall-mounted design is very convenient because the entire floor remains free for placing furniture or other equipment.

- Floor-standing. This type is typical for powerful models that have a lot of weight.

Diagram of a floor-standing gas boiler

To install boilers of the second type in the room, you will have to free up a fairly large space.

By functionality

Boilers are:

- Single-circuit. These are heaters in their purest form - their task is only to heat the coolant CO.

- Dual-circuit. They have a second heat exchanger connected to the water supply system and additionally perform the function of an instantaneous water heater.

Some models are equipped with a built-in boiler.

Double-circuit floor-standing gas boiler

By type of combustion chamber

There are also two options here:

- With open camera. The firebox communicates with the boiler room, from where air enters it (sucked in by natural draft).

- With a closed chamber (turbocharged). The firebox is isolated from the boiler room, air is sucked in from the street by a fan.

A safer option is the second, but it only works if electricity is available.

Advantages and disadvantages

Boilers with two circuits, like any other technological devices, have their advantages and disadvantages. Knowing them, it is easier to choose a unit for heating water and (convector) heating a house.

Double-circuit boilers have many advantages

The advantages of double-circuit floor-standing boilers are given below.

- The most important advantage of this unit is the ability to not only heat the house, but also provide it with hot water, which will be used for domestic needs.

- A wall-mounted gas boiler can separately perform the functions of a water heater and a heating device.

- It is possible to adjust the heating temperature of the liquid. On average, the boiler heats water to +30-40 degrees.

- The heating speed of the water is high - in order to wash, you can heat it (the water) in just a few minutes.

- Such units usually have a remote control system.

- Certain types of boilers can be modernized: it is possible to replace the burner, as well as convert the unit to a different type of fuel.

- The power of double-circuit floor-mounted installations is higher than that of wall-mounted ones.

- Floor-standing boilers are highly reliable compared to wall-mounted ones.

Heating water in a gas boiler

You should also know the disadvantages of double-circuit boilers.

- The secondary heat exchanger often becomes unusable, leaving the house without hot water.

- The double-circuit floor unit occupies a fairly large area. Its dimensions are approximately 80*50*80 cm, it weighs about 100 kg.

- Limited volumes of heated water - the boiler will not heat more water than it can. Therefore, if the consumption of hot water is high, then it is better to install a separate heater.

- Complex installation of equipment and the need to arrange a chimney that needs periodic cleaning.

- The floor-standing boiler makes noise during operation, so it is recommended to install it in the basement.

Floor-standing gas boiler Baxi Slim 2.300

In any case, purchasing one double-circuit floor-standing boiler is much cheaper than buying a separate single-circuit unit, and also a boiler for heating water. Also, the purchase of such a device is justified if the house is still under construction and the communications are not connected. Fortunately, the choice of models and types of floor-standing double-circuit boilers is quite large. You can read how to choose a solid fuel boiler for heating a private home in our article.

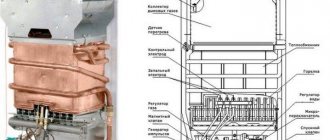

Basic elements of a gas boiler

Regardless of belonging to one group or another, gas boilers are basically designed the same and have the same set of main components:

- gas burner;

- heat exchanger;

- circulation pump (not available on all models);

- expansion tank;

- automation system.

Below you can take a closer look at each of the components.

Pump

Pump in a gas boiler

Serves to impart movement to the coolant. This device causes heating fluid to circulate from the heated primary heat exchanger to the radiators, heat them and move back to heat them. The pump usually has several speeds and is adjusted by a service engineer based on the size of your heating system.

Too high a pump speed can create additional noise and reduce the efficiency of the boiler. And too small will lead to uneven heating of the radiators. Therefore, for proper setup, it is very important to contact qualified service engineers.

Gas-burner

The burner's task is to mix the natural gas entering it with air, thereby preparing a fuel-air mixture. It is then distributed over several nozzles, where it burns.

Gas burners are:

There are a great variety of heating boilers on the market. Read on our website what are the advantages of the Beretta gas boiler over other manufacturers.

Read about the advantages of double-circuit heating boilers here.

Instructions for making a diesel burner are presented here.

Atmospheric

Air is sucked into the gas stream due to the low pressure present in it (according to Bernoulli's law, the pressure in a moving stream decreases in proportion to its speed).

Advantages:

- low cost;

- simplicity of design;

- silent operation.

But at the same time, the combustion chamber has to be made open, and the burner power is limited.

Operating principle of an atmospheric burner

Supercharged

A more complex structure into which air is pumped by a fan. With advantages and disadvantages, the picture is the opposite: the burner is expensive and noisy, but the combustion chamber is closed and there are no restrictions on power.

Boilers with forced-air burners and, accordingly, closed combustion chambers have another advantage: since the smoke is forced out, they can be equipped with a horizontal pipe that goes outside through the wall.

Usually a coaxial pipe is used, the cross-section of which is divided into two parts: combustion products are removed along the inner one, and air enters the firebox through the outer one.

In addition, gas burners are divided into the following types:

- Single-stage: they have a fixed heating output and operate in start-stop mode. They are cheap, but the elements of a boiler with such a burner operate under conditions of significant and sudden temperature changes, which is why their service life is reduced.

- Two-stage: can operate in two modes: with maximum power and with 40 percent. The intermediate stage ensures a smooth start of the burner and allows it to be turned off less often, so that ultimately the boiler operating mode becomes more gentle.

- Modulating: the most expensive burners, the heating output of which can be smoothly changed in the range from 10% to 100%. Instead of a “start-stop” mode, such a burner operates constantly at the required power, so that the boiler elements are not subject to thermal overload, and temperature changes are completely eliminated. The boiler, accordingly, lasts longer. In addition, the modulating burner optimizes fuel consumption, so that the heat generator becomes even more economical.

The burner is equipped with one of two types of ignition device:

- Piezo ignition: when starting the boiler, the user presses the piezo-mechanism button once, from the spark of which the pilot light or wick (pilot burner) lights up. Subsequently, the main burner lights up from the igniter.

- Electronic. The device generates a spark independently, without user intervention.

In the second case, the gas burner is ignited directly, so that a pilot light is not required (gas consumption is reduced).

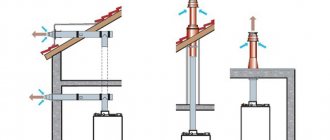

Chimney design

The chimney structure of a gas boiler is extremely important for the operation of the boiler, since it is thanks to it that combustion products are removed from the apparatus. True, it is a tube, and there are no special devices in it. However, they come in different types:

- Metal. They are sandwich panels made of lines of different diameters, made of stainless steel. The voids between them are usually filled with a basalt thermal insulation layer. They are highly reliable. They are multi-layered and have high heat-insulating properties. But they are assembled from a large number of parts, which is not entirely convenient.

- Ceramic. Simpler, but no less durable models. They even resist the effects of chemical substances. They are ceramic pipes wrapped in mineral wool. However, they require additional installation of condenser collectors.

- Coaxial chimney. Easy to use and looks great. Does not require installation of any additional devices. Condensation does not accumulate, which is also its advantage. And it is something like a pipe-within-a-pipe design. Can be used for closed type boilers (those that take air from the street. Open systems take air from the house). That is, air enters the boiler through the outer pipe, and exits through the inner pipe, being exhausted.

Coaxial chimney

Previously, a brick chimney was quite popular. But they are quite difficult to install, and they are quite bulky.

Heat exchanger

The durability of a heat exchanger depends on its material. Basically, users have to choose from two options:

Cast iron

The cast iron heat exchanger has thick walls, so it is durable and does not burn out.

In addition, it is little susceptible to corrosion.

Accordingly, this option is the most durable - it lasts about 25 years.

There are two disadvantages:

- fragility, and it can burst not only with a strong impact, but also with a sharp change in temperature;

- heavy weight.

The latter circumstance does not allow the use of cast iron heat exchangers in wall-mounted boilers.

Steel

A steel heat exchanger burns out relatively quickly (it has thin walls) and is highly susceptible to corrosion. In addition, it has weak points in the form of welds. As a result, the service life is only 15 years. But it is cheap, flexible and weighs little.

More durable are heat exchangers made of stainless, heat-resistant steel, which are installed in premium models.

Those buyers who cannot yet afford such a boiler can be advised to pay attention to steel heat exchangers with anti-corrosion protection in the form of a copper coating on the inside and special heat-resistant paint on the outside.

Installation of a double-circuit floor-standing boiler

Installation of a floor-standing boiler is carried out as follows.

Step 1. Select a location for installing the device. It is there that the floor and walls (especially in a wooden house) are sheathed with sheet iron and asbestos to protect the structure from fire.

Choosing a suitable location

Step 2. Install the cold water supply to the boiler.

Installation of cold water supply

Step 3. Next (using a laser level), the boiler is installed and secured to the floor using anchor bolts. At the same time, some distance remains between the walls and the boiler for installation of the water supply and gas pipeline systems.

Boiler installation

Step 4. A safety valve and a gas supply valve are mounted to the back of the boiler.

Safety valve and gas supply valve

Step 5. The return pipe tap is fixed at the bottom of the installation.

Return valve

Step 6. A pressure gauge, a safety valve, and an automatic air vent are installed on the safety valve - all together this will be a safety system.

Safety system

Step 7. An expansion tank is mounted on the wall next to the installation.

Expansion tank

Step 8. Using a level, install a circulation pump on the wall near the bottom of the unit.

Circulation pump

Step 9. A tap and filter are installed in front of the pump, the pump is connected by pipes to the installation in the lower part (return pipe tap).

Pump unit assembly

Connecting the pump unit

Step 10. The water supply is being installed. A shut-off valve is installed on the expander and connected to the water supply.

Water supply installation

Shut-off valve

Step 11. The supply pipe is brought closer to the wall, the pipeline is installed in the rooms.

Supply pipe connection

Supply and return

Step 12. The return pipeline is being installed. The figure shows what the boiler connection system looks like.

Pipeline installation

Boiler piping

Step 13. The pipes are installed up to the sink.

Installation of hot water supply before washing

Installation of pipes before washing

Step 14. Connect the battery using an angle tap.

Installation of an angle ball valve

Circulation pump and hydraulic group

A relatively small CO on the scale of a private home can function without a circulation pump, but its use provides a number of advantages:

- the diameter of the pipes can be reduced;

- During movement along the circuit, the coolant does not have time to cool down much, so the boiler operates in a gentle mode;

- it becomes possible to operate the heating system in low temperature mode.

The characteristics of the pump are linked to the power of the boiler, so the buyer can only focus on the manufacturer of this component. It is desirable that it be a well-known company with a decent reputation - Grundfos, Wilo, Vortex, etc.

It is important what the pipes for coolant and tap water inside the boiler are made of (if the boiler is double-circuit). The most preferable option is copper or good quality plastic.

Which harness to choose

The best option for implementation can rightfully be considered a simple piping scheme for a gas heating boiler. No extra equipment is required, and the design is as reliable as possible. This type of installation will be especially practical in small buildings, but if we are talking about large houses, then you cannot do without a circulation pump.

Many people know the fact that the simpler the design, the more reliable and durable it is, which is why most experts and consumers use a simplified algorithm of actions to implement the process of connecting a heating system.

Expansion tank

To prevent the coolant from making a gurgling sound, the heating system must be completely filled.

But at the same time, the possibility of free expansion of the working environment when heated must be provided. This is why an expansion tank is installed.

The boilers are equipped with membrane-type tanks that do not communicate with the atmosphere (closed). Such a tank is divided by an elastic membrane into two parts, one of which is connected to the heating system, and the other contains air at a certain pressure.

The volume of the first part should be approximately 10% of the volume of the total coolant in CO. In the second part, you need to maintain a pressure 0.2 atm less than that observed in the CO when the circulation pump is running.

Boilers dependent and independent of electricity

Floor-standing boilers can be either dependent on the electrical network or operating autonomously from it. The first type includes almost all modern installations, especially those with closed combustion chambers. The burner starts up as a result of exposure to electricity. Boilers, the operation of which does not depend on the availability of electricity, are started manually and have a piezo ignition system.

The second option is more economical, and in areas where there are power outages, it is better to install a non-volatile boiler.

It is advisable to install floor-standing boilers on a small pedestal

Automation systems

Modern gas boilers are equipped with two types of automation:

Working

Controls the operation of the boiler (controls power or switches it on/off) in order to maintain the temperature of the coolant or air in the room at a user-specified level (depending on where the temperature sensor is installed).

The most “advanced” is weather-dependent automation, which takes into account the outside temperature and therefore adjusts the boiler operating mode in a more timely manner.

At the same time, the system controller constantly “learns”, remembering how the temperature in the room changes at certain boiler heating outputs and outside temperatures.

Do you know what a heating distribution comb is and what it is used for? Read more about this in the article.

You will find recommendations for making a burner for a biofireplace with your own hands in this material.

Security automation

Consists of an electromagnetic valve at the gas inlet to the burner and sensors connected to it:

- traction;

- coolant overheating;

- flame on the burner.

If the boiler has an igniter, then a thermocouple is also connected to the valve, which blocks it when the igniter goes out.

Other sensors block the gas supply in case of emergency situations - deterioration of draft, overheating of the coolant or extinguishment of the flame on the main burner.

Best Pipes for the Job

The use of polypropylene pipes is quite common; if they are welded correctly, the pipeline will be monolithic. But when the coolant temperature increases from 80 degrees, such pipes become fragile and vulnerable to mechanical damage. Such components are only suitable for systems with low temperature indicators; the basis should be an automated unit.

Metal-plastic specimens, in contrast to polypropylene pipes connected to the heating boiler, withstand high temperatures much more effectively, the indicator reaches 95 degrees. For most systems, such figures are enough, but it would not be superfluous to install protection against excessive heating of the coolant.

The only drawback will be the narrowing at the junction of the fittings, whose design does not allow maintaining primary permeability after assembly. Connections must be constantly checked; there have been cases when the bypass and joints leaked over time. This design option is most suitable for heating in which water is the coolant.

Dual fuel heating boilers

The scheme in which gas and firewood are used to heat the coolant is considered the most popular and convenient, as it works with an open heating system. If you want to install a closed system, then it is recommended to install an additional circuit for the heating system in the tank of a universal boiler.

Manufacturers of heating boilers produce several types of dual-fuel combination boilers:

- gas with liquid fuel;

- gas with solid fuel;

- solid fuel with electricity.

Solid fuel boiler and electricity

A combination boiler runs on only one type of solid fuel. The water in the circuit begins to heat up when the loaded raw material burns. As soon as the fuel burns out, the thermostat activates and the electric heaters turn off, and the water begins to cool. As a result of a decrease in temperature, the heating element automatically turns on to heat the water. The heating and cooling process is cyclical, so the house is constantly maintained at a comfortable temperature.

heating systems

To summarize, it can be noted that to reduce the cost of heating a private home and ensure uninterrupted and stable operation of the heating system, installing a dual-fuel boiler is the best and proven option.

Operating rules

During operation of an open-type gas boiler, it is necessary to ensure a sufficient air supply in order to ensure complete combustion of gas.

Otherwise, the efficiency of the unit will be low, and the volume of unburned gas will be large, with possible release into the room. In closed fireboxes, it is also important to monitor the sufficiency of air and the functionality of the blower fan.

Basic rules for the safe operation of a heating boiler operating on gas fuel if there is a gas smell:

- immediately turn off the gas valve to the burner device;

- open windows for ventilation;

- in closed-type boilers, forced ventilation is turned on in the chimney system of the gas boiler;

- do not use electrical switches and matches;

- immediately turn off the open flame;

- report an emergency to the gas service.

Autonomous heating is gaining popularity; for many homeowners it has become as necessary in the cold season as an air conditioning system in the summer - an affordable level of comfort in residential premises that ensures normal life activities.

The main function in this is performed by modern boiler installations - technologically advanced, innovative units capable of solving multi-level thermal problems.

Types of solid fuel boilers

These devices differ in the types of fuel used, the number of fireboxes and combustion chambers, the method of fuel supply, and the material from which they are made. There are several types of solid fuel boilers.

Continuous combustion heaters

They are made of cast iron or steel, contain one or two fireboxes, run only on coal and wood, the operating cycle is 4–6 hours, the fuel is supplied manually. The control circuit for such equipment is mainly mechanical, the boiler temperature is 60–70 degrees, the difference between the flow and return is 20 degrees.

Power consumption is from 7 to 50 kW, and efficiency is 80–90%.

Long burning devices

Steel single-fuel units - the firebox is located on top, which ensures longer burning of one load (wood for more than 24 hours, coal for up to 144 hours) and uniform heating of the coolant.

Works on firewood and its derivatives (briquettes, sawdust, shavings, etc.), as well as on coal. Boiler temperature 70–80 degrees, power up to 50 kW, efficiency – 90–95%. Fuel is supplied manually.

Pyrolysis solid fuel

They are made of steel and have two chambers connected by a nozzle. The technology is that the main fuel (dry firewood with a moisture content of no more than 25%), burning in the first chamber, releases flammable wood gas, which ignites in the second chamber.

The operating cycle if a buffer tank is connected is possible from 6 hours to a day, the operating temperature of the boiler is from 70 to 95 degrees, power consumption is up to 120 kW, efficiency is 90–95%.

Pellet

Steel units operate on granules (pellets) made from wood waste - sawdust, shavings, etc. If there are removable grates, it is possible to use coal and firewood.

The achieved temperature is 70–80 degrees, power up to 400 kW, operating cycle from 24 to 144 hours.

The fuel supply circuit in such boilers can be automated and controlled electronically. This type of equipment is used for heating large areas.