Today we will talk to you about induction heating. Many are trying to present induction boilers as something innovative that will supposedly save us money and ensure the existence of our heating system. But what really?

In fact, induction boilers are units that are very expensive, bulky, inconvenient to use and not endowed with a sufficient number of properties and qualities that are necessary for the normal operation of a modern electric heating boiler.

Those people who invent these boilers and try to sell them to you do not tell the consumer anything about these aspects of their products, but only highlight positive qualities. Here we will display all the pros and cons of induction heating at home

What do induction heating manufacturers say?

Most often, manufacturers compare induction heating boilers with traditional ones, and traditional ones make up 99% of all electric boilers on the market.

Boilers are always compared according to this scheme: the imaginary shortcomings of heating element boilers and the positive qualities of induction heating at home are highlighted.

For example, the following indicators:

- Quite a lot of heating elements;

- That supposedly one or even several heating elements can fail;

- It is argued that the boiler may lose its working ability;

- They pay special attention to scale, which can appear as deposits directly on the very surface of the heating elements;

- The complexity and bulkiness of the design is due to the fairly large number of electrical contacts;

- The creators of induction boilers claim that their boilers last longer due to the fact that they can soften water;

- An absolutely unfounded and unfounded statement that periodic replacement of gaskets, heating elements and risters is required.

Working principle

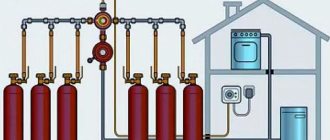

A common example of this is a coil that is wound on a dielectric pipe. A steel core must be installed in the middle. An electric coil will warm the pyron.

All that remains is to connect it to the main line with the heat carrier, and such an “induction boiler” will begin to supply heat.

Hotmer induction boiler design

Electromechanical boilers are perfect for heating a private home. The boiler operates by using a coil based on the principle of an induction cooker. The inductive coil produces a magnetic field.

Heat moves from the heater to the liquid heat carrier through a labyrinth of iron tubes without leakage.

The strength of the current acts to change the strength of the magnetic field in the device. This is how the house is heated.

After placing a core in the middle of the coil, Foucault eddy currents appear, which affect the electrical resistance of the metal. There is a temperature increase on the surface of the tube system.

Criticism of incorrect heating boilers

They indicate that in a high-quality induction heating boiler there are no heating elements. Of course, this is not true, because without a heating element we would have nothing to heat the water with, that is, it is always present in any boiler!

In the vast majority of installed electric boilers, the heating element does not fail for almost the entire service life of the boiler.

If the heating element does fail, we can easily change it, since it is under a flange or on a thread. If suddenly an induction heating unit breaks down for no reason, then it is almost impossible to replace it.

Now about scale . It exists in a kettle, but in home heating systems it does not exist, because there the water does not boil at all, and deposits are always and everywhere present, in any system: on gas, diesel, wood, electric, heating element, electronic, induction boilers. It doesn't matter what kind of boiler it is. Sediment will always be present as it is sediment that is always present in the water. This is not a disadvantage or an advantage, but a given.

About electrical contacts. Manufacturers write that there are no electrical contacts in an induction heating boiler. But in fact, electrical contacts are always and everywhere. And if we talk about heating element boilers, then electrical contacts, stone terminals. have been absent there for many years. There are electrical contacts located under screw connections that do not require tightening, and there are spring clamps that are also not worth servicing.

Regarding the service life of the heating element and the figures justifying this life. It is not clear where these figures come from and how they are confirmed. In addition, here the authors confuse water supply and heating systems. There are not as many impurities in the heating system as there are in the water supply system. Softening the water of the heating system carrier is not required.

It should be noted that in an induction heating boiler, replacing components is practically impossible at all, because everything is in a sealed flask and it needs to be cut in order to get something out of there.

Loosening contacts

Terminal contacts in heating element models, most of them, can be in temperature difference mode.

Heating at maximum load, and cooling when switched off. And this imposes obligations for their revision and tightening.

And in induction, there are supposedly no electrical contacts. In fact, they are always and everywhere, including induction ones.

But as for the former, in recent years specimens with high-quality screw clamps have begun to be produced.

Or there may be screw connections with a locking washer, which do not require maintenance, or spring clamps, which also go without control and revision for years.

In fact, these are just made-up benefits.

Revealing the main myth of induction heating

Lately they have stopped saying that the efficiency of induction heating is 2-3 times higher than the efficiency of a heating element boiler. But supporters of the induction boiler claim that a heating element boiler quickly loses its properties and goes out of use because scale grows on it!

They say that during the year the power of a heating element boiler decreases by 15-20%. Is it really?

Yes, heating element deposits are indeed present, but you should never confuse the heating system and the water supply system. For example, scale actually forms in the water supply, just as it forms in the kettle that we see in the kitchen every morning. This never interferes with our work; we know, and there is no doubt, that water boils in a kettle in any case.

On the contrary, in the heating system we know, impurities rarely enter the water. The deposit layer is very thin and does not pose any significant obstacle to heat transfer.

If energy leaves the network somewhere, it does not completely disappear anywhere. It turns into absolute heat and the coolant heats up, which, in turn, heats up with exactly the same efficiency as it was heated before and as it will always heat up. If it were not so, then the heating element would be torn apart by excess energy.

As soon as scale appears, heat exchange occurs at a higher temperature. There can be no talk of any reduction in efficiency, no matter what the temperature in the heating element.

Decrease in electric boiler efficiency

Another argument for comparison is that an induction boiler does not lose its original power during operation. But with heating element, due to scale formation, this happens as a matter of course.

Even sometimes calculations are given, according to which, within just one year, the power of a heating element decreases by 15-20%. This means that its efficiency also decreases.

Let's look at this in more detail.

Almost any electric boiler has an efficiency exceeding 98%. And even boilers operating at ultra-high frequency currents from 25 kHz and above, what can they change for you? Add an extra one and a half percent, but at the same time jump the price by 100%?!

As for deposits on the heating element element, they are indeed present.

In water supply systems in direct heating boilers, a certain “scale” is deposited on the working element. It actually gradually prevents the water from heating up quickly.

What happens where there is no constant supply of impurities? A small layer of deposits may settle on the heating element, however:

- this layer is not thick enough

- it does not in any way interfere with heat transfer

For example, let’s assume that on a clean surface of the heating element, heat transfer occurs at t=60 degrees. As soon as this surface becomes contaminated with deposits, heat exchange will not disappear anywhere, but will begin to occur at high degrees, say 75-80C. And accordingly, the boiler in no way loses its original efficiency.

That is, in fact, both on a clean heating element and on a dirty one, the same amount of energy is transferred, only at different temperatures.

Cost and maintenance of induction heating boilers

Induction heating boilers cost 2 times more than heating element boilers. Despite the fact that they are qualitatively lower, as we saw from a critical analysis of their so-called “advantages”.

They also weigh 2 times more than heating element boilers, have large bulky dimensions, and all the electronic filling is located outside. While in heating element boilers it is hidden in the boiler itself. And here there is an additional box, which sometimes there is no place to place it, especially when we are talking about a very small boiler room.

In induction boilers there is no automatic power selection, that is, only the heating element boiler can choose for itself at what power it needs to operate at the moment.

With induction heating at home there will always be power surges and overload, but in heating element boilers the relay operates very quietly. And you can only notice it as quiet clicks when you are next to a working boiler.

Induction boilers also completely lack thermal protection for overheating and freezing, which is available in heating element boilers.

Induction heating boilers do not have low water pressure sensors. There is no error indication that allows you to accurately determine the malfunction that caused it to stop (the corresponding indicator will blink on the display of the heating element boiler).

But the most important thing that induction boilers do not have is the ability to connect a boiler!

Varieties

The general classification is the same as for other heat-generating units - by power, power (single- or three-phase) and so on. The fundamental difference between induction heating systems is in the design of the electrical part. There are two modifications.

The primary winding of the induction heater is supplied with industrial voltage (220/50) from the boiler power supply. Secondary - a closed circuit through which fluid circulates. It is also part of the heat exchanger, where the heating fluid of the heating system is heated. Not only water, but also antifreeze can be used as such. The current quite quickly increases the temperature of the circuit, so the efficiency of all boilers in this category is very high.

- VIN

The models are called vortex models (hence the abbreviation). The main difference from the previous group is in nutrition. The converted, high-frequency energy is supplied to the primary winding. The EMF intensity is enhanced by Foucault currents. This is also facilitated by the specific manufacturing of the heat exchanger and boiler body. Ferromagnetic alloys are used for their production. Constant “magnetization reversal” initiates rapid heating of the material, which is why such boilers are somewhat more efficient than the SAV version. However, their price is higher due to the perfection of the design.

Brief overview of models

1. "Geyser".

A good boiler for heating a private home. The second class of electrical safety does not require the installation of protective grounding. Large selection both in terms of boiler power (4.5 - 250 kW) and installation specifications. If a storage tank is provided in the heating system circuit, modification “E” is installed. In other cases (with a heat exchanger) – boilers of category “B”. The difficulty of connecting the units is noted as a disadvantage. Only low-power induction electric boilers operate from a 220/50 network. All other models require 380/3f. How relevant is this for a private home? Although, judging by the reviews of the owners, Geyser is reliable, stable in operation and there are no complaints about this brand of boilers.

2. "Miratron".

Such boilers are aimed at heating residential buildings (up to 300 - 350 m2). The power range (kW) is from 8.5 to 32. This is enough for most homes. Owners give the most positive reviews about Miratron brand boilers, which is understandable. Firstly, they operate almost silently. Secondly, they do not require constant monitoring. Thirdly, efficiency is achieved by stepwise power switching. At the initial stage of operation of the induction boiler, it accelerates at high speed, and then switches to optimal mode. Fourthly, the design feature ensures that a private house will not be left without heating in any case. And this is probably one of the most important advantages of Miratron. Boilers of this brand are equipped with several induction heaters, which provides not only the possibility of stepwise switching, but also emergency backup.

3. "Edison".

The range of models is large - from small domestic boilers to industrial installations. There is a limitation in use - only for closed contours. Guaranteed efficiency – 98%.

4. Induction-type electric boilers from Alternative Energy LLC (St. Petersburg).

All units are designed for heating private houses. Boiler power (kW) - from 3 to 75. Second class of energy safety, the ability to connect to any heating circuit - the main system, “warm floor” and so on. A modern automation scheme increases the cost of production - from 29,890 rubles (3 kW). But there is also a significant advantage - the compactness of the equipment. Judging by the reviews, this is what attracts buyers.

To buy or not to buy an induction heating boiler?

Of course, you yourself must decide for yourself which boiler you should buy: a high-quality heating element or a more bulky, less efficient and expensive induction boiler.

But you must take into account the following: an induction boiler is not a unit for heating systems, especially if they are individual and do not require large capacities. Of course, it is impossible to do without induction heating in some industrial areas of technical production, but this applies to production tasks.

Still, there is no reason to drag a complex, heavy and expensive unit into your home. You can get by with a more elegant solution - a heating element boiler.

Manufacturers of induction heating boilers deliberately provide incomplete information about their products, which misleads those who make a choice in favor of one boiler or another. The important thing here is to tell the truth and show your product from all angles so that people know what they are buying.

Replacing the heating element

The service life of heating elements depends on the quality of the coolant.

As “comparators” assure, this is only 1000 hours of work, if you do not take action and soften hard water. Well, if they softened it, then about 5000. When using this data, the heating and water supply systems are confused.

In closed heating systems there are not as many impurities as in water supply. In most cases, water softening is simply not required here.

This may only apply to domestic hot water or central heating. There, the boiler room operator is unable to track water leaks.

If we are talking purely about your home, where everything is assembled and connected without leaks or holes, then no constant water preparation is required. Of course, the water will contain some elements, but once they are poured into the heating system, they will react once or more; they will have nowhere to come from.

Induction ones supposedly have low operating costs due to the very rare replacement of components. In fact, this is in high-quality PETN samples; the elements change extremely rarely, as mentioned above.

But if you need to change something in the induction room, you will think twice before doing it. Everything there is sealed in a sealed flask and you can’t get inside without physically cutting it.

Expert review of an induction heating boiler

One of the leading Russian experts in the field of installation and maintenance of boilers in Russia, Vladimir Sukhorukov, in one of his programs on YouTube “Induction boiler - a big misunderstanding,” released on December 12, 2022, thoroughly and in detail proved that induction heating boilers are inferior to traditional heating element boilers .

Vladimir Sukhorukov did not find a single reason for using an induction boiler in a boiler room. Moreover, he strongly advises under no circumstances to buy induction boilers when there are high-quality heating element boilers that work stably and smoothly.

Perhaps you need to listen to the advice of an expert.