The geyser is very popular among owners of apartments and private houses. Of course, the device does an excellent job of providing residents with hot water, does not require complex maintenance, and the cost of fuel used is minimal. But the water heater also has one serious drawback - a gas leak can lead to an explosion, destruction of the house and death. Therefore, it is extremely important to identify a breakdown in a timely manner and know how to check the draft in a gas water heater at home.

Each element of the device must work flawlessly, any problems must be corrected immediately, and failed parts must be immediately replaced. Regular checks of the system are carried out by gas service specialists, but you can periodically inspect some elements on which the safety of people living in the house depends on yourself.

We will try to figure out how to test the design, in particular, check the draft of the water heater, at home. In the article we will also consider effective ways to combat the lack of draft in the smoke duct.

Gas boiler chimney

Types of exhaust pipes Parameters of chimney pipes Installation standards for chimneys of gas-fired water heaters and boilers Specifics of certain types of gas-type heating devices Installation process of an exhaust pipe Specifications of installation inside chimney pipes Rules for the external process of installing exhaust pipes Small details of installing chimney pipes for gas-type heating devices

The operation of a gas boiler or water heater in an apartment is inevitably associated with the formation of toxic combustion products, which must certainly be removed from the house. For this purpose, a hood is installed on the equipment, ensuring its safe and effective use during the period of operation.

The service life of the exhaust pipe in most cases is determined by the accuracy of the calculations made, the excellent choice of materials for it and the accuracy of the installation technique.

Thrust calculation

So, draft calculation is the calculation of the cross-section of a chimney for a gas boiler, fireplace, stove or other heating equipment. How to calculate the cross section? To do this you need to define:

- the volume of gas that will pass through the chimney in 1 hour;

- cross-sectional area of the chimney;

- section diameter.

Calculation of gas volume

To calculate the volume of gas passing through the smoke channel, the following formula is used:

V = B x V1 x (1 + T/273) /3600, where

B – mass of fuel burned per 1 hour of operation of heating equipment;

V1 – correction factor, which depends on the type of fuel used for heating;

T – gas temperature determined at the exit from the chimney.

Indicators V1 and T can be obtained from the table available in GOST 2127 - 47.

Table from GOST for determining calculation parameters

Calculation of cross-sectional area

After determining the volume of gases passing through the smoke channel, you can calculate the cross-sectional size of the pipe:

S = V/W, where

V – volume calculated earlier;

W is the speed of passage of gases through the smoke channel (this value is constant and equal to 2 m/s).

Diameter determination

The next step is to directly determine the diameter of the chimney. The following formula is used for this:

D = √4 * S/ π, where

S – cross-sectional area of the smoke exhaust channel;

π is a constant equal to 3.14.

Example

For example, let’s carry out the calculation using the specified formulas with the following parameters:

- 10 kg of wood is burned every hour in the stove installed in the bathhouse;

- the temperature of the gases at the outlet of the pipe is 130ºС.

Let's calculate the volume of gases:

V = 10x10x(1+130/273)/3600 = 0.041 (m³/hour)

Let's determine the cross-section of the smoke exhaust pipe:

S = 0.041/02 = 0.0205 (m²)

Let's find the most suitable pipe diameter according to the given parameters:

D = √ 4 * 0.0205 / 3.14 = 0.162 (m)

This means that for the stove used in the example, it is enough to install a chimney with a diameter of 165 - 170 mm.

How to make calculations and install a chimney yourself, watch the video.

Types of exhaust pipes

Exhaust pipes for gas-fired dispensers or boilers are made of the following material:

- made of aluminum;

- stainless steel types 316L, 316, 310S, 304;

- made of steel with a fire-resistant enamel coating.

A noticeable disadvantage of pipes made of metal is condensation, which appears due to differences in temperatures inside and outside the lumen of the product. This can be avoided by insulating the pipes with heat-resistant materials for thermal insulation.

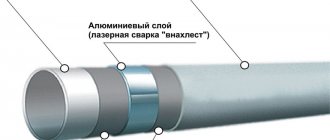

Pipes with an internal heat insulator are also produced, which are distinguished by their reliability and long service life. Another type of pipe products used for smoke exhaust are coaxial pipes, which consist of external and internal pipeline structures: the first is used to remove exhaust gases outside, the second is used to supply air to gas equipment.

On the other hand, pipes for gas-fired dispensers and boilers can be smooth or wavy. The use of corrugated pipes is the most functional option, making it possible to do without additional elements for profiles and transitions. Such pipes have very high strength, reliability and other cost-effective technical features. characteristics.

Methods for checking a chimney

To mitigate the potential risks of using faulty equipment, it is important to monitor the presence of traction. The following verification methods are offered:

- visual folk methods. A sheet of thin, lightweight paper (toilet paper will do) placed close to the chimney will indicate the presence and intensity of draft. This indicator increases the more the paper is deflected by the wind. The same information can be obtained from smoke - a lighted rolled-up sheet or cigarette is brought to the channel;

- using an anemometer. This device is also called a wind meter; it is used to determine the speed of movement of gases. Modern variations can accurately show the value of thrust; this information will help to make a reasonable conclusion about the timeliness and feasibility of starting the heating system and gas equipment. The only drawback of the technique is the high cost of high-quality measuring instruments;

- mechanical way to find blockages. One of the most common problems with the removal of smoke streams is the formation of a blockage in the pipes. In such conditions, a metal ball will be a convenient device; it is tied with a rope and lowered down from the top point of the canal. If the bundle descends unhindered to the end of the chimney, it means that it does not need cleaning; difficult gas removal may be caused by insufficient width or length of the pipe.

You can check the draft in the chimney with a sheet of paper

If the design of the structure allows, blockages can be identified through visual inspection.

Parameters of chimney pipes

Diameter of chimney pipe for geyser

or boiler is installed, based on the power of the device and the amount of gaseous, liquid and solid substances emitted (read: “Types of exhaust pipes for a gas heating boiler, installation rules and insulation”). The required pipe dimensions are also influenced by the height of the installed chimney and the ambient temperature in the external environment.

In many cases, with the typical power of the devices, the diameter of the exhaust pipe for a gas water heater

in the apartment it is 11-13 centimeters.

As for the height of the installed pipe, it first of all depends on the type of gas device and its power. In particular, for gas water heaters, the height of the pipe above the roof level should be at least several meters.

Operating principle of the sensor

A gas boiler works by burning blue fuel.

Naturally, combustion products are released. If they get into the room, this is fraught with severe poisoning of all residents of the house, even death. Therefore, the design of the column provides for connection to a chimney, through which all harmful substances are discharged to the street. Naturally, for high-quality exhaust, the ventilation shaft must have perfect draft. But it happens that some kind of violation occurs - for example, the chimney may become clogged with debris or soot. If in such a situation the boiler stubbornly continues to burn fuel, then the combustion products will inevitably go into the house.

To prevent this, the design of the gas boiler includes an element such as a chimney draft sensor. It is located in the place between the ventilation duct and the equipment housing. The type of sensor depends on the type of boiler:

- in a boiler with an open combustion chamber, the protective sensor is a metal plate to which a contact is connected. This plate is the indicator that monitors the temperature increase. The fact is that normally released gases are usually heated to 120–140 degrees. If the outflow is disrupted and they begin to accumulate, then this value increases. The metal from which the plate is made reacts to this situation and expands. The contact attached to the element moves and closes the valve responsible for the gas supply. Thus, the combustion process stops, and at the same time the entry of a new portion of harmful substances is prevented;

- in a boiler with a closed combustion chamber, products are removed through a coaxial channel, and a fan is used. The sensor in this case is a pneumatic relay with a membrane. It reacts not to temperature, but to flow speed. While it is within acceptable limits, the membrane is bent and the contacts are in the closed position. When the flow rate becomes weaker than necessary, the membrane straightens, the contacts open, and this leads to the gas supply valve closing.

As you can see, if the draft sensor is triggered, turning off the gas water heater, this means some kind of malfunction in the operation of the equipment. For example it could be:

- initially poor quality traction. This is the first and main reason why the sensor may be triggered. As a rule, this phenomenon is associated with improper installation of the exhaust structure. If combustion products are poorly drawn out, then this poses a danger to all living things in the house;

- reverse thrust. This phenomenon occurs when an air lock forms in the chimney. Gases, which normally should move to the very top of the pipe and then exit, cannot overcome this obstacle and return back, filling the room. The reverse draft effect can occur if the chimney insulation is very poorly done. Temperature differences lead to the formation of air pockets;

- chimney blockage. Inexperienced owners may think that the pipe going to the roof simply cannot become clogged with anything. In fact, there are many factors that lead to the formation of a blockage. The first of these is birds. They can make nests on the pipe, which then fall down. And the birds themselves often manage to get stuck in the chimney and then die there. In addition to birds, you should also take into account the possibility of ingress, for example, of leaves, as well as soot deposits on the inner walls of the pipe. If the chimney is clogged, the draft intensity becomes too low, and there is only one way out - cleaning;

- strong wind. If the pipe is not positioned correctly, gusts can enter it and blow out the burner. Naturally, in such cases the sensor cuts off the fuel supply. To avoid such a danger, it is necessary to purchase and install a stabilizer.

Installation standards for chimneys of gas-fired dispensers and boilers

The ventilation system installed in a wall or partition must be insulated with fire-resistant material. Each heating device must be equipped with an individual chimney pipe.

It is not uncommon for cases when, as an exception, two devices can be connected to one exhaust pipe, in particular:

- Two heating gas boilers located on the same floor.

- Two gas water heaters, in case the gaseous, liquid and solid substances in them will be at a distance of more than 75 centimeters from each other, and enter the chimney at different levels.

When installing the hood, the following conditions must be met:

- Materials used during installation must be non-flammable.

- Sealing of connecting zones should be done with heat-resistant compounds.

- No more than three bends should be used in the chimney structure.

- The integrity of the pipes must be maintained.

Plus, during the installation of the geyser

The plane of the wall on which it will be located should be insulated to prevent condensation from occurring. It is also important to emphasize that under no circumstances should grilles be installed on the ventilation holes in the walls or the lumen of chimneys.

Ways to recover and increase traction

The reasons for decreased traction are usually understandable and easily eliminated:

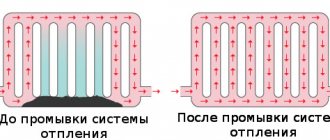

- Chimney blockage . This can occur due to soot formation or the ingress of dust and dirt from outside. Regular cleaning of the chimney, even under the most favorable operating conditions, is the norm. This can be done, for example, with a metal brush on a long wire. The walls of the chimney must be as clean as possible and have a smooth surface.

- Insufficient thermal insulation of the chimney . If insulation is insufficient, most of the chimney is cooled, as a result of which there is no longer a significant temperature difference necessary for sufficient vacuum.

- Errors in chimney design . Most often, its height is insufficient; it should be at least 5 m. There are also height standards relative to the roof ridge (see photo below). Weak draft is also possible if the chimney diameter is insufficient, there are an excessive number of bends, or leaks.

Specifics of certain types of gas-type heating devices

Quite a few types of gas-fired dispensers and boilers have closed combustion circuits, which makes it necessary to use coaxial chimneys for them, which ensure effective air circulation (for more details: “How to install a coaxial pipe for a gas boiler - basic installation rules”).

There are devices for heating a room with a forced gas exhaust system, in which air circulation is carried out using a fan.

The fan turns on automatically simultaneously with the gas heating device. With such a system arrangement, the probability of penetration of toxic gaseous, liquid and solid substances into the room space is almost zero.

Exhaust pipe installation process

When installing a geyser

Strict compliance with safety regulations is extremely important. The device is located higher on the wall - this makes the gas-powered device more secure, especially from children. If steel pipes are used in the installation, then along with them it is necessary to use L-shaped adapters for the exhaust system and ventilation duct. The distances between system elements must be measured, and pipes and adapters must be selected accordingly. If the exhaust pipe is suspended, it is necessary to avoid its sagging.

Terms of use

Any gas-using installation is a priori considered a source of increased danger, and instantaneous gas heaters are no exception. For this reason, they are subject to all rules for handling household gas equipment. So, if you smell gas in the room, then:

- immediately turn off the valve installed in front of the equipment;

- open the windows for ventilation;

- do not use electrical appliances, do not turn on (or turn off) the lights, do not smoke;

- call the gas service.

Typically, the rules for using a gas water heater are set out in the operating instructions that come with it. We will present them again, since compliance with these rules is the key to the safety of all people living in a house or apartment. This is especially true for those homeowners in whose homes chimney-type water heaters are installed:

- Only a specialized organization that has the appropriate permits has the right to install and connect the device. The basis for performing work is considered to be design documentation approved by the fuel supplier;

- It is prohibited to start the heating device when there is no draft in the chimney;

- do not turn on or adjust the column without reading the operating instructions;

- it is necessary to ensure a flow of fresh air into the room where the unit is located;

- changes to the design are not allowed;

- While the heater is operating, avoid touching the front panel near the inspection slot and open parts of the chimney pipe.

Now let’s talk about how to extend the life of your water heater. The heat exchanger is one of the most expensive elements of the installation, on the surface of which scale forms when the hot surface comes into contact with running water. Based on this, using the column correctly means protecting the heat exchanger from scale in all available ways.

You should not set the maximum heating temperature; in most devices it is 70 ºС, and the minimum is 30 ºС. For example, the instructions for the Russian-made NEVALUX unit states that the optimal operating temperature is 45-50 ºС. In this case, it is recommended to limit the flow through the column using a special control valve. The goal is simple: to reduce sudden pressure changes in the device when opening taps of various consumers.

Specifications for installation inside chimney pipes

The installation of chimney structures in the middle of houses and premises has the following characteristic features and specifics:

- It is necessary to prepare areas for pipes in the roof and walls.

- The assembly of chimney structures is very complex, as well as repair work if necessary.

- The possibility of toxic gases, liquids and solids entering the living space is relatively high.

- Detailed compliance with fire regulations and provision of good protection for wooden elements and products is necessary.

First of all, markings are applied, and then, in accordance with it, holes of appropriate sizes are cut out in the wall structures and roof. After which the chimney structure is assembled, starting from the gas-type device.

The pipes are fixed to the wall surface using spider fasteners and clamps. The flow passing through the roof is protected using sheet metal. The joining areas are insulated using heat-resistant sealant and insulation material. The outer part of the pipe should end with a cone-shaped tip.

What threatens the lack of normal vacuum in the furnace?

Modern, even the simplest gas heating equipment does not allow combustion with reverse draft or its complete absence. However, with insufficient, poor draft, not all boiler models interrupt combustion, and this is fraught with:

- the spread of natural gas throughout the room due to its under-combustion due to lack of oxygen. In this case, there is always a characteristic smell of gas;

- the entry of toxic combustion products into the room, sometimes, especially in small quantities, they are not noticeable by smell;

- increased soot formation, which leads to accelerated clogging of the chimney, heat exchanger and combustion chamber of the boiler.

Rules for the external process of installing exhaust pipes

The exhaust pipe for a gas boiler can be routed from the outside of the residential property. This installation option is much simpler than the previous one and is safer during operation.

First, a mark is made on the wall surface where the pipe exits and a hole of the required size is cut. In this case, the gap between the wall surface and the boiler should not be more than 25 centimeters. A pipe section is brought out through this hole, the second end of which is attached to the boiler section of the pipe. Further, its subsequent parts are gradually connected to the outer end of the pipe. The vertical part of the structure is assembled through a rotating elbow.

Metal surfaces are treated with anti-corrosion compounds. The joints are sealed using specialized heat-resistant compounds. The section on the outside of the pipe requires thermal insulation along its entire length.

To fix the pipe on the surface of the walls, holders are mounted every 1-2 meters. Fastening to them is done using clamps.

Small details for installing chimney pipes for gas-type heating devices

It must not be forgotten that chimneys for gas-fired dispensers and boilers, along with the removal of gaseous combustion products, provide the operational efficiency of these devices, and also prevent gas leaks from gas pipeline structures, the release of carbon monoxide, etc. Therefore, compliance with the standards and installation rules for these structures have a very high priority.

It is advisable to install exhaust structures for gas-powered dispensers using coaxial pipes. They are easier to insulate and provide excellent air flow. Also, such pipes are distinguished by their very high operational safety.

It is permitted to connect any gas-type device with periodic operation to the chimney duct of another heating device, provided that the conditions for their simultaneous operation are provided. Of course, the cross-section of the chimney pipe must be sufficient to remove exhaust gases from any of these devices.

In general, professional installation of exhaust equipment is possible only if all technical conditions are implemented, taking into account both the properties of the residential structure and the parameters of the heating device itself, as well as other significant details and conditions of the installation work being carried out. Given the serious nature of the installation process, all technical actions should be carried out only by professional craftsmen with sufficient experience in this field.

Troubleshooting Methods

If you have identified problems with traction, then, of course, they need to be eliminated as quickly as possible.

The choice of means to combat poor or reverse draft depends on the reasons that led to the abnormal operation of the chimney.

Pipe cleaning

One of the common methods of improving traction is cleaning the pipe. Fuel, burning in a stove, releases various substances that settle on the inner surface of the chimney. Soot sticks well to pipes if they are uneven or bent.

When carrying out work, do not forget about safety measures

How to clean a chimney so that there is good draft?

First of all, acting purely mechanically. The chimney channels can be made wider, getting rid of plaque, in the following ways:

After preparing about one bucket of potatoes, peel and cut them. Potato peelings will also work. Throw a little into the firebox and wait. When burned, potatoes will release starch, which will become a means that can soften carbon deposits. Soft pieces of soot will fall off on their own, but firmly stuck ones will have to be removed mechanically. Firewood from aspen. Heat the stove with two or three logs. They will heat up the chimney pipes very much and help get rid of carbon deposits.

But this method requires special care, since the likelihood of a fire will be very high (soot may ignite). Rock salt

This method is more suitable for prevention. Salt added at the time of combustion improves the condition of the chimney pipes. Pipe brush. A heavy weight is attached to a brush suspended on a steel rope and lowered into the chimney openings. By lowering and raising this structure, you can force soot formations to fly off the walls of the pipes and fall into the furnace. These fragments are then removed from the firebox.

the likelihood of a fire will be very high (soot may ignite). Rock salt. This method is more suitable for prevention. Salt added at the time of combustion improves the condition of the chimney pipes. Pipe brush. A heavy weight is attached to a brush suspended on a steel rope and lowered into the chimney openings. By lowering and raising this structure, you can force soot formations to fly off the walls of the pipes and fall into the furnace. These fragments are then removed from the firebox.

The second group of anti-particulate measures is based on the use of chemicals. The most popular chemicals for cleaning chimneys are “Log-chimney sweep”, “Komichek”. Chemicals are added to the coals formed during the heating of a stove or fireplace according to the instructions and the heating continues. After all the fuel has burned out, it is advisable to leave the coals, since they continue to “work” in terms of cleaning the chimney (at least, that’s what the manufacturers advise).

When used correctly, chemicals will not cause harm to your home.

Do not believe the spiteful critics who talk about the obligatory combustion of soot when using the chemical method. This method does not pose any danger, since the beneficial effect occurs due to chemical reactions, and not due to the ultra-high combustion temperatures of the reagent.

Special mention should be made of the observance of safety measures when carrying out all work related to the chimney. Do not fix chimney problems in windy weather! Try to use safety devices when working at height!

Troubleshooting structural problems

If certain features of the chimney design are identified that negatively affect the draft force, adjustments should be made to eliminate them. These actions include:

- dismantling several separate pipes and installing a single chimney channel;

- adding roof pipes to the required height;

- insulation of chimney elements, etc.

Ventilation arrangement

In some cases, traction may improve if drafts are avoided in the house or bathhouse. You can help with draft problems by installing ventilation devices on windows.

If there is no desired effect after all the methods described above, you should adopt modern devices to improve draft in the chimney.

Installation of devices

To improve the operation of the chimney, it is best to use special devices that allow you to regulate and control the draft. Such devices can be bought in a store or made with your own hands.

How to improve draft in the chimney of a gas water heater?

How to improve draft in the chimney of a gas

Khrushchev type on the fifth floor?

In the otherwise called “Khrushchev buildings” that you write about there are chimney columns, so to speak, “from birth” of the house, there is no hot water there, during house construction two shafts are laid, one for the columns, the other for ventilation, there are columns in any apartment.

If you have a house like this, then you need to start looking for the “missing” draft by cleaning this very shaft.

The cleaning is done by specialists from the gas office, it’s unusual why your draft is bad, they should come to such houses with an inspection every six months. Call them.

If you have a personal water heater with a hood that is not included in the house design, then you will need to look for the problem of poor draft step by step.

A very common cause of poor draft is an erroneously installed chimney exhaust pipe, the exhaust pipe should be without unnecessary turns and turns; no need to use 90-degree angles, try to get by with forty-fifths; if the exhaust pipe is corrugated, then there is no need to allow pointed bends during installation) , the more angles, the worse the traction

. This problem needs to be removed.

The exhaust pipe must be of the same diameter, without different narrowings.

It may be necessary to remove the exhaust system and clean it inside, there may be fumes there.

The second reason is that the pipe diameter of the hood is not good (you need to familiarize yourself with the parameters of your column, the power of the columns is different, then choose an exhaust system with the necessary parameters), you probably have it very large, the larger the diameter, the worse the draft .

The third popular reason is poor tightness of the hood; you need to check it and, if necessary, remove the problem.

The material used to make the hood also plays a very important role; you need to purchase a high-quality exhaust system.

If your exhaust pipe goes to the roof of the house (you are writing about the fifth and last floor), then the outlet pipe should be at least a meter higher than the roof level, this is the most decisive moment for traction, the traction force depends on the height of the outlet pipe.

As you can see, work to improve traction is a large complex of works.

Increased traction

If checking the chimney draft showed its complete absence or small value. You can also use a device such as a chimney draft stabilizer or turbine. True, their use is limited only to gas boilers. Too high a temperature of the exhaust gases at the outlet of the pipe will contribute to improper operation of the device or its failure.

If we talk about stoves or fireplaces, then in order for the chimney to work correctly during not very good weather conditions. Special tips - wings - are installed on the pipe. This device rotates freely so that its back is always facing the wind. This position prevents wind or rain from entering directly into the chimney.

Special fans can also be used. Such devices have a built-in electric motor. Their operating principle is as follows. Basically, they work from the wind; during strong gusts, the fan rotates, increasing the release of exhaust gases from the pipe; if the wind flows are not strong enough, then the electric motor turns on, which forces the fan to work forcibly and all harmful substances also end up on the street.

A small disclaimer: do not immediately after reading the article run to the store and buy a new device. Before you are going to install it, you should make calculations. And based on the results obtained, it will be clear whether this device can be installed on your chimney.

If there is no draft in the chimney, it will be useful to check the operation of the dampers. For stoves and fireplaces, this is a kind of regulator of the exhaust gas removal force.

How it works

In the middle of the column there are two main elements: an atmospheric burner and a heat exchanger, which looks like a long, narrow pipe, in most cases made of copper, rolled into a snake or spiral. Cool water flows from the water meter to the coil, heats up over the burner and leaves the device in a hot state.

Of course, everything is not very simple, because the safe and productive operation of the device is ensured by a number of main components, for example:

- ignition device or ignition wick;

- water-gas unit;

- solenoid valve with a set of sensors.

The ignition device often looks like a pilot burner: a small tongue of flame that burns regularly. With the electronic version of this unit, just before turning on the column, a spark appears, which ignites the ignition wick. This is a much modern version, it even allows you to achieve certain gas savings.

To produce a spark, a piezoelectric element is often used, which can also be started manually. In models of past years, such conveniences are not provided: the ignition wick is lit with an ordinary match. In order for the gas to turn on automatically, a water-gas unit is required when starting water. It consists of a membrane fabric, which is mounted in the water metering unit, and a valve in the gas path.

When the tap is opened, water begins to move, the membrane fabric changes position under the influence of the flow and transmits a signal to the valve. It opens and releases a stream of gas to the burner, which ignites. When the water is turned off, the membrane fabric returns to its initial position, the valve closes the gas flow, and the burner goes out.

Thanks to the water-gas unit, you don’t have to manually open the gas every time you turn on the water. The solenoid valve also changes the gas supply in accordance with the readings of various sensors that detect the presence of flame, draft, unsafe overheating, etc.

This node is needed to increase the security of the system. Sensors react to system interruptions, and the valve closes the gas supply if major problems arise in the operation of the device. In addition to the sensors, a thermocouple is connected to the valve. Such an element reacts to the presence or absence of a pilot burner flame. If there is no fire, the gas entering the column will not ignite, but will accumulate, which is too dangerous.

Troubleshooting instructions

There are various reasons for backdraft in a gas boiler. They have varying degrees of complexity, some will require large expenses to eliminate. These include the following problems:

- The design features of the chimney have a serious impact on the formation of draft. Therefore, if there are any defects in the system, they will definitely show themselves. There may be areas that are too narrow, incorrect pipe placement, or incorrect cross-section calculations. All this will require replacing the chimney, which is a rather complicated undertaking.

- There may be a blockage inside the pipe. In this case, you will need to clean it. This is a labor-intensive task, however, less complicated than replacing the entire system.

- The reason may be too tall trees or the presence of high-rise buildings around. In this case, it will also be necessary to redo the chimney, taking into account such an environment.

- The ventilation system also influences the formation of draft. If errors were made during its design, these communications will have to be redone to fix the problem.

And also the reason for poor traction may be less complex. Usually such situations arise suddenly, when everything was fine before, and then the cravings worsen for a couple of days, after which everything returns to normal again. As a rule, a similar phenomenon can be observed when the weather changes, if it becomes cooler. The situation may arise if the oven has not been used for some time. This occurs due to cold air masses that have accumulated in the chimney. The problem can be solved by continuing heating. After some time, it will be possible to break through the layer of cold air, and the draft will return to normal. You can use a special stabilizer device that provides a secondary air supply.

If the draft problem is related to the ventilation system, some actions may be required to restore normal air exchange in the room:

- Installing additional supply valves on walls and windows will provide additional air flow.

- A special device for forced air intake from the street can be placed on the windows.

- The easiest option is to open the window or door a little.

If there is poor draft, the source of the problem may actually be ventilation. If opening a window or door helps, then the problem is in the ventilation system. It may be possible to limit ourselves to only installing additional supply valves. If this does not help, then more complex and costly repairs will be required.

The most important for draft are the characteristics of the chimney pipe. Therefore, it is necessary to arrange everything correctly at the design stage, so as not to encounter problems later. The optimal height of the structure is 5-6 meters, this is enough to provide good traction, but not too strong.

Traditional brick structures perform well as a material, but metal heats up and cools down too quickly. And it is also necessary to ensure that the cross-sectional area of the pipe corresponds to the dimensions of the furnace. It is strictly forbidden to arrange the chimney so that there are sections of different diameters on it, since this contributes to the accumulation of soot and blockages, which invariably leads to problems with draft. Careful planning during the construction phase will avoid problems in the future.

Reasons for column fading

Any of the nodes described above can cause column attenuation. The flame goes out if the security system detects a violation of the normal operating mode. To start the device, it will be necessary to determine and remove the cause of such a violation. Here is a fairly popular version of acceptable problems:

- draft in the chimney ;

- the main burner has gone out;

- there is an unsafe temperature increase in the water in the heat exchanger;

- some parts are worn out and require replacement.

If the column does not produce a flame, you must first make sure that its operating conditions have not been violated and check the terms of the manufacturer’s warranty. The relevant information is contained in the product data sheet and instructions for its use.

If there is no draft in the chimney

Checking traction is the most common way to determine the condition of the device. You just need to bring a strip of thin paper or the flame of a lighter, match, etc. to the viewing hole of the column. However, if there is even a slight suspicion of a gas leak, it is better to avoid using open fire.

If the paper or flame is pulled inward, everything is fine, traction

There is.

The absence of changes in their position indicates a lack of traction, and a deviation back indicates that reverse traction

. To be sure of the causes of the problem, you need to disconnect the column and check the draft in the same way only in the chimney. After which it will be clear whether there are any breakdowns in the chimney duct or in the middle of the column too.

When the chimney structure is in order, the “culprit” for the lack of draft is the heat exchanger, or more precisely, the soot particles that clog it and interfere with normal air exchange. It is necessary to remove the casing with a protective function from the column and clean the heat exchanger with a stiff brush.

If the chimney is dirty, all that remains is to simply clean it and reconnect it with the device. If there is no good response, make sure that the chimney structure is assembled correctly from suitable materials. Sometimes the basis for the lack of traction can be errors during the installation process of a given section of the system.

Often problems of this type appear for external reasons, such as lack of normal ventilation of the room. PVC windows and a tightly closed door almost seal the room in which the speaker . There is no influx of fresh air flows, so there is no movement in the chimney channel. It doesn’t hurt to check the ventilation system in the entire apartment or house.

Make sure there is plenty of clean air entering the space. If you can’t really organize ventilation, you can install a supply valve. Then you should make sure that air flows not only enter the house, but also move freely throughout all rooms. To do this, install ventilation grilles on the doors or create a small gap at the bottom.

Why does the burner go out regularly?

The absence of a pilot burner flame is detected by a sensor, after which the gas supply is immediately shut off. This situation may occur if a small light was knocked down by a large gust of wind. There is no need to create a draft in the room during work, especially if it is very windy outside.

Strong air currents can penetrate not only through doors and windows, but also through the chimney duct. The result may be the same - the burner goes out, the automation closes the gas flow. To resume normal operation of the device, you need to turn off the column, check the condition of the pilot burner (a flame should appear here), and turn on the device again.

Causes of water overheating

This occurs when the pressure of the water flow that passes through the heat exchanger decreases, but the heating intensity remains unchanged. In some cases, water even boils, which is dangerous for the integrity of the device. The pressure decreases when cold water is opened to dilute the flow to the optimal temperature, and cool water displaces hot water. It is better to adjust the heating using the column settings.

The second reason for the appearance of this phenomenon is limescale deposits that have collected in the middle of the narrow pipe of the heat exchanger. To resume normal pressure, you need to systematically descale the device and also make sure that the water is not excessively hot. For domestic needs, it is enough to warm the water to 45-50 degrees.

This mode helps reduce the formation of solid sediment. If the water in the system is excessively hard, and you have to constantly clean the heat exchanger, it makes sense to think about installing a specialized filter that will remove salt from the flow. The heat exchanger is cleaned using the necessary products or household chemicals: soda, vinegar, etc.

You will have to remove the casing with a protective function from the column, and also close off the gas and water. Then the heat exchanger is disconnected from the water metering unit and disassembled. A cleaning compound is poured inside the coil pipe and left for some time. After which the heat exchanger is washed, put in place and the column is reassembled.

Sometimes the mesh filter installed at the entrance of water from the tap into the heat exchanger becomes clogged with contaminants. It also needs to be cleaned. To remove ordinary contaminants, it is very easy to wash the mesh in water, but sometimes it is necessary to use chemicals. If damage is found on the filter, it is best to change it immediately.

What other problems are possible?

The lack of normal water pressure in the system and without overheating can lead to the valve blocking the gas flow and the burner going out. In this situation, it is necessary to check the condition of the water supply system; perhaps you just need to install a circular pump. Even when purchasing a speaker, you should be curious about the very low pressure values for a particular model.

Lack of timely maintenance does not improve the situation at all. If the column provides electric ignition, it is performed using batteries. Worn power parts need to be replaced, and the problem will be solved. And when a piezoelectric element with a turbine is used to produce a spark, it will not start if the water pressure is not strong; this moment will need to be provided for.

The absence of a pilot burner flame often occurs when the pilot wick becomes dirty. Gas simply does not flow in the required quantity to light the burner. The ignition wick must be cleaned with a metal wire so that the column

started to work. It is better to carry out cleaning in advance, without waiting until the hole becomes clogged. The blockages are collected in stages.

If the flame has noticeably shrunk, it’s time to check the condition of the ignition wick. Another symptom of this problem is a popping sound that is heard when the burner is turned on. A weak flame is not able to immediately ignite the gas entering the device. It gradually accumulates and ignites with a pop resembling a small explosion.

As mentioned earlier, there is a membrane fabric in the water-gas unit. This is a polymer component that, with regular contact with water, gradually loses its plasticity. Sometimes cracks even appear on it, limescale deposits, etc. The membrane fabric stops responding to the water flow, and as a result, gas does not flow to the burner. It is worth disassembling the water-gas unit, removing the worn-out component and replacing it with a new membrane fabric.

If upon inspection it turns out that the contamination is not very large, and the component remains elastic, you can simply wash the membrane fabric and install it in its old place. In the newest models with a huge amount of electronics, the control board may burn out, after which the column

, of course, it won't light up.

The reason for this problem is the low level of quality of the electrical supply, for which foreign devices are not designed. Moreover, many electronically controlled models should not be turned off at night, but must be turned on regularly. To get rid of the problem of voltage surges in the network, you can use a stabilizer.

Top reasons for lack of traction

It is necessary to determine the time frame for the occurrence of the malfunction. Separately, it is worth considering cases when the chimney is new and during a test run the fact of reverse draft is revealed. Let us consider the reasons separately and in detail.

Reason 1. Incorrect chimney.

Proper chimney design is important for good air movement. If there is no draft when checking a new heating structure, then the reason is one or a combination of errors:

- The pipe diameter is too small and does not correspond to the installed capacity of the heating system being served.

- The chimney design has 90 degree turns. The maximum allowable rotation angle is 45 degrees. For ideal operation, the entire chimney must be extended along a strict vertical axis. However, such a design is not always possible; then tees and reducers are used. For a 90 degree rotation angle in the chimney, it is necessary to add 1 meter of pipe length. For a rotation angle of 45 degrees you need to add 0.5 meters.

- The presence of horizontal sections of the chimney. The total length of horizontal sections should not exceed 1 meter.

- Irregular pipe shape. The pipe must have a round cross-section. In the corners of the square pipe, a turbulence of the air flow occurs, which clogs the chimney. Square sections have chimneys made of brick; for their normal functioning, stainless steel pipes must be installed inside. Stainless steel pipes are easy to install, airtight, and their smooth surface prevents the accumulation of soot.

- The blower is not long enough, which does not provide the required oxygen flow.

- The chimney consists of pipes of different diameters; in places where there is a difference in size, favorable conditions are created for the accumulation of soot and soot.

- Insufficient tightness of pipe joints.

- No cap over the chimney. The cap protects against exposure to precipitation and objects that can clog the chimney (snow, dead birds).

- Incorrect pipe placement. The pipe should rise above the flat roof by at least 0.5 meters. The distance between the ridge and the pipe should be 1 meter. The total length of the sleeves must be at least 5 meters.

- Insufficient chimney insulation. The part of the pipe located outside the heated room must undergo insulation. Insulation will prevent gases from settling in the form of condensation on the inner surface of the pipe.

Reason 2. Ventilation

For proper operation of the heating system, proper ventilation must be established in rooms with approved combustion equipment. Often because of this there is no draft in the chimney. Reasons for lack of sufficient traction:

- Constantly open windows in the furnace room. Especially when the windows are located above the firebox.

- A strong draft, aerodynamic forces can change the direction of air movement.

- Insufficient fresh air required for combustion.

Reason 3. Exposure to natural factors.

The reasons for the lack of chimney draft can be:

- Rain, snow, hail, creating a pressure difference. Exposure to high street pressure leads to combustion products settling in the chimney, reducing the useful volume of the chimney.

- The crown of a tree obstructs free access to air masses.

- A tall building nearby reflects the smoke coming out of the chimney.

- Using raw wood as a raw material.

- The canopy is too low above the pipe.

Distinctive problems for individual models

Even speakers from trusted companies can break down over a period of time for a variety of reasons. During operation, the owners of the devices noticed problems that very often appear in certain models. For example, the weak point of the Junkers WR 13-P device manufactured by Bosch is the thermocouple.

Two to three years after the start of operation, it ceases to respond well to heating from the pilot burner. As a result, the flame of the pilot wick regularly goes out, and over a period of time it simply stops lighting well. Sometimes careful cleaning of the thermocouple with fine sandpaper helps, but when this method no longer has a good effect, the component will need to be replaced.

Displacement of the ignition wick tube, which in similar models is not secured very firmly, can also lead to similar problems. The pipe can be moved accidentally, even by simply touching it with a match during ignition. There is a gap between the gas tube nozzle and the burner through which air is supplied.

When displaced, this gap decreases, and the air needed for normal combustion becomes insufficient. The flame does not reach the thermocouple, it does not heat up, and gas does not flow to the key burner. If you resume the normal position of the tube, the column

will work properly again.

For Vector speakers, the oxidation of the contacts in the power supply is considered to be a distinctive problem. If this is the case, then replacing dead batteries with new parts will not give the desired result; a spark will not occur until the contacts are cleaned. Sometimes in such columns the microswitch rod on the water valve becomes sour.

After cleaning, normal operation of the device is restored in most cases. If a characteristic whistle occurs almost immediately after turning on the column, it is necessary to check the condition of the connections of the gas outlet tube; perhaps they need to be resealed.

In Neva brand dispensers, sometimes the rod gets jammed in the gas valve. As a result, such an element stops normal operation. To remove such a breakdown, you need to remove and disassemble the water-gas unit, and then move the rod with an ordinary screwdriver. If the part cannot be mechanically operated, the component must be completely replaced.

Water unit malfunction

Most often, geyser repairs are made due to a faulty water block. Its work is that, under the influence of liquid pressure, the membrane located inside it, arching, transmits movement to the rod, and it then moves the pusher of the gas unit. As a result, the spring valve opens and the electrical power supply to the control module is turned on. Therefore, if the water unit is faulty, the device will not start.

A broken water block can be determined by external signs.

- If you opened the water supply, and the rod pressing the switch plate remained motionless (shown in the figure with a blue arrow), this means that the membrane located inside the main component of the water unit - the “frog” - is damaged.

- Stem jamming may be due to sticking.

- There may be a leak in the place where the gas and water units are connected, or liquid leakage from under the control valve (shown by red arrows).

If you notice even one sign, the unit will need to be removed and repaired. The water unit can only be removed together with the gas module, since they are a single structure. You can do this in the following way:

- after you have made sure that the gas valve on the pipe is in the closed state, you can disconnect the supply hose (a);

- similarly, when the water supply is turned off, the nut on the water block pipe (b) is unscrewed;

- then, using a wrench, you need to unscrew the nut that connects the water block to the heat exchanger (c);

- disconnect the terminal block (d) on the conductors connecting the solenoid valve to the control module;

- wires (d) going to the switch are disconnected in the same way;

- using a screwdriver, you need to unscrew the 2 screws (e) attaching the pipe to the water-gas unit, through which fuel is supplied to the burner manifold;

- After unscrewing the fasteners, the entire assembly can be easily removed from the device.

Next, you will need to disassemble the gas-water module itself.

After removing the device, you need to separate the water unit. To do this, unscrew the 2 screws (indicated by arrows). It is not necessary to unscrew them completely. They use a clamp to secure the “frog” in the gas unit. The attachment of the “frog” to the latter may differ in different models, as, for example, in the Neva 3208 gas water heater.

This is what the gas module looks like with the water module disconnected.

Next, you will need to disassemble the “frog” itself by unscrewing 6 screws. They can stick and twist tightly or even be “licked off” with a screwdriver if you apply a lot of force. To prevent this from happening, you can first drop a special liquid WD-40 on them, after which they will easily unscrew and none of them will break.

After successfully unscrewing the screws, the module opens into two halves and you will see a rubber membrane.

The membrane must be carefully inspected, and if it is found that it has been stretched too much or there are tears on it, it must be replaced with a new one.

To get to the plate with the spring, you need to remove the membrane. If it is intact, you must do this carefully so as not to damage the ring with which it fits onto the pipe (indicated by the red arrow in the figure above). After removing the membrane you will see a plate with a spring.

To avoid having to disassemble the unit once again, inspect the oil seal

To do this, carefully remove the plate with the rod.

Take out the spring and you will see a plug with a cut for a screwdriver. There is an o-ring underneath

The plug must be unscrewed from time to time to lubricate and replace the rubber seal.

Having previously purchased a repair kit for the “frog”, replace the failed oil seal and membrane. When you install the oil seal back, do not forget to lubricate it with silicone grease, and also lubricate its location.

Assembling the water block of the geyser occurs in the reverse order. The plug must be tightened so that the rod passes through it without much effort. When you have completely assembled the “frog”, the repair of the water block can be considered complete.

Repairing a Neva 3208 gas water heater due to a faulty “frog” is similar and intuitive, although the internal appearance of the unit is slightly different. The Neva 4511 gas water heater can be disassembled in the same way, and repairing it yourself is quite feasible.

When a Chinese gas water heater is repaired, you are always surprised by the size of the water unit. It is quite small in size, and to disassemble the “frog” you only need to unscrew 4 screws.

Conclusions and necessary video on the topic

An overview of the reasons for the attenuation of the Gorenje speaker and how to eliminate them can be found here:

This video shows how to remove a similar breakdown for speaker :

Useful tips for cleaning and troubleshooting the JUNKERS column:

Column attenuation is a sign of internal failure or violation of the operating conditions of the device. It is necessary to correctly determine the cause of the problem, after which most of the described problems can be removed with your own hands. However, to solve major problems you will have to contact the warranty center.

2016.11.11 The plot of the Day program: Backdraft

What to do if the craving suddenly disappears?

This situation sometimes arises suddenly. More often in bad weather. Before dealing with the chimney system, you should assess the duration of the malfunction and the likelihood of carbon monoxide poisoning - ventilate the room by opening windows and doors. Then the reasons for stopping the hood should be assessed. It is better to make sure that the chimney is not blocked mechanically - there is no ice freezing on the tip, no soot has collapsed. Then begin to restore the operation of the equipment: open the damper, ignite the heating unit, build a strong fire in the stove or fireplace to warm up the walls of the chimney.

If movement through the chimney is not restored, you cannot leave the equipment turned on or the fire burning in the stove - you can be poisoned by carbon monoxide and carbon monoxide. Measures should be taken to clean the chimney and get rid of frozen ice and condensation (just not at night).