If there is no central heating in a country house or cottage, the ideal solution for heating the home is a wood-electricity combination boiler. On the heating equipment market, about 70% of all models of heat generators designed for heating private homes are multi-fuel devices.

Combined devices are an excellent guarantee that with the onset of cold weather, the most comfortable temperature in the house will always be maintained, even if there are interruptions in the supply of one type of fuel. In addition, the necessary supply of firewood for the winter can be created in advance, and the availability of electricity in homes is not always stable, especially in bad weather.

Features of combined heating boilers

Today, dozens of domestic and foreign companies are engaged in the development and production of combined heat generators. Combined wood-electric heating boilers, the price of which can vary depending on the power and manufacturer, are steadily in demand.

First of all, this is due to the competitive advantages of this type of equipment, including:

- relative simplicity of design;

- use of available fuels;

- possibility of integration into heating systems of both closed and open types;

- compatibility with various switching devices and units;

- maintaining the set temperature of the system for a long time in automatic mode;

- availability and interchangeability of standard electric heating elements;

- low cost;

- high service life.

Like any type of heating equipment, electric wood heat generators have a number of disadvantages:

- the need to allocate a special room for installation of equipment with a ventilation and smoke exhaust system;

- low power of the electrical component for domestic boilers powered by a single-phase network;

- large weight, which determines the possibility of only floor installation, sometimes requiring reinforcement of the base;

- dependence on energy supply;

- heat loss through the chimney when electric heaters are turned on, which reduces the overall efficiency by 2-5%.

Flaws

Like any heating systems, combined designs have a number of disadvantages:

- To install the boiler you will need a separate dedicated room. You should also find and equip a place where the fuel will be stored;

- Cast iron is usually used to make heating units. It has significant weight. Before carrying out installation work, it is sometimes necessary to pour a concrete pad. It will strengthen the foundation structure;

- There are no models that can be mounted on a wall. Installation is carried out only on the floor;

- The devices have a complex design. As a result, the cost of installation work and maintenance increases;

- electric heating elements have low power;

- the price of combined devices is higher than the cost of conventional boilers.

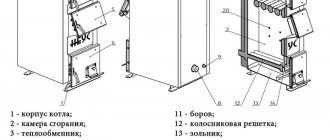

Electric wood boiler design

Multifuel heat generators use a combination of elements capable of converting energy received from various sources into heat. Electric wood-burning units are practically no different in design from conventional boilers that burn wood and coal.

Structurally they consist of:

- a housing, inside of which there is a water jacket or a heat exchanger of a heat- or water-tube type;

- combustion chamber with air supply and smoke exhaust system;

- ash chamber for accumulation and removal of solid combustion products;

- A heating element (tubular electric heater) or a block of heating elements;

- control equipment.

Depending on the chosen method of controlling the air supply to maintain combustion, heat generators operating on solid fuels can be equipped with either a mechanical draft regulator or an electric boost fan.

Principle of operation

The operation of a combined wood-electricity heat generator is based on the principle of automatic or manual switching from solid fuel to electricity. At the moment when the firewood placed in the combustion chamber burns out, electric heaters come into operation, maintaining the temperature of the coolant within the specified limits. Turning on and off a heating element or a block of heating elements is carried out by a switching device when it receives a signal from a temperature sensor installed in the heating circuit.

Benefits of use

The presence of an electrical component in a solid fuel boiler can significantly increase the reliability of the entire heating system and the ease of use.

A relatively small complication of the design of the combined unit during operation allows:

- maintain a comfortable temperature when heating the house both during the day and at night;

- avoid defrosting the heating circuit of a country house, cottage or cottage in the event of a long departure;

- use electricity during periods of absence of firewood or coal as a backup heat source.

Advantages of the model

The advantages of combined heating in such heating systems are obvious. The model completely protects its owner from problems with electricity - you can always use gas or wood. In the absence of gas or wood fuel, the boiler can operate on electricity.

Construction of electric-wood boilers

A combi boiler has the following advantages:

- Versatility - heating is possible without resources;

- The boiler can quickly switch between operating modes;

- Boilers are able to maintain the required temperature at any time of the year;

- Easy to use and install;

- Reliability and durability of heating equipment;

- The ability to adjust the temperature in real time even when gas or wood is used;

Thus, combined boilers are qualitatively different from their closest relatives - heating devices that use only a strictly fixed resource, in particular gas. Design features

Components of a combi boiler

When switching to electricity, the heating of the house is carried out using heating elements. Practice has shown that with low-power operation, a combination boiler is capable of maintaining the minimum temperature in the house using electricity for several days.

c4407dd4b174d081ddb5620b6aca3d77.jpe

0b48952ce157a65ab42578d048ad28a8.jpeTypes of boilers

One of the main parameters by which combined heat generators are classified is the types of fuel used.

This is usually reflected in the marking, which consists of several letters meaning:

- T - solid fuel (wood, coal, pellets, peat, etc.);

- G - gas;

- E - electricity;

- F - liquid fuels (fuel oil, kerosene, used engine oil, diesel fuel, etc.).

For example. the combination of the letters “TG” in the name of the heat generator means that it can operate on solid fuel and gas, and the design will use a design with two combustion chambers. If necessary, you can buy a multi-fuel unit, the name of which contains four letters “TGEZH”. Such heat generators are the most versatile devices, however, the complexity of the design and high price do not have the best effect on their prevalence among consumers.

The most optimal solutions for private homes remain devices using two types of fuel.

Gas/electric combination

Electric gas equipment is usually used in gasified areas where interruptions in the supply of pipeline gas occur. Considering that the cost of electricity is approximately three times higher than the cost of gas, in combined units of this type gas is used as the main source of heat, and electricity as a backup. Compared to solid fuel heaters, gas-electric heaters are more compact and are often mounted on the walls of residential premises, significantly saving space.

Wood/gas combination

Wood-gas heat generators are represented quite widely on the heating equipment market. They are popular in gasified areas with harsh climates, where the use of two types of fuel during an extended period of cold weather can reduce overall heating costs.

Prices for combined boilers ZOTA

combi boilers ZOTA

There are two types of solid fuel-gas installations:

- Units that use gas as the main fuel and wood as an alternative fuel. To switch from one type of fuel to another, a small upgrade is required.

- Universal heat generators in which the gas turns on automatically when the wood burns out.

This type of equipment usually has two combustion chambers with a common chimney. Grate bars are installed in one chamber, and a gas burner is installed in the other.

Wood/electricity combination

In those regions where the cost of firewood is low and there are no gas mains, combined wood-electricity installations remain the most preferred and in demand. Two sources of thermal energy not only minimize heating costs, but also increase the overall stability of the system. The heating circuit is inertial. Constantly maintaining the required coolant temperature by electric heaters reduces the consumption of firewood for heating it when igniting, which makes it possible to use less wood.

Multi-fuel installations

The prevalence of multi-fuel installations in private homes is hampered by two main factors: high price and difficulty of maintenance. The use of fuel with different physical properties in one unit requires the installation of a larger number of burners, pumps, nozzles and other elements. This leads to more complex control automation and a decrease in overall reliability.

For private households, a maximum of three fuel combinations are usually used, including wood, gas and electricity. Combinations such as pellets/liquid fuel/gas are very rare.

How to achieve joint operation of electric and solid fuel units

If you are faced with a choice of which individual heating option to give preference to - a solid fuel boiler, an autonomous electric unit or a combination of these two devices, the latter option has advantages. To install the circuit, you will need a connection diagram for both units, similar to a gas-solid fuel heating system. Properly done equipment piping is a guarantee of the efficiency and safety of operation of this equipment.

The proposed video describes in detail how and in what way to connect solid fuel heating devices together with electric heating elements

What you need to pay attention to during installation:

- both devices must have a reasonable power ratio, the coal or wood heating device is the main source of heat, so its power must be twice the power of the electric boiler;

- both units are connected in parallel, which makes the operation of one independent from the other;

- the solid fuel unit is the main one and is connected to the large circuit, while the electric boiler is responsible for the temperature in the small circuit;

- the main heating unit is equipped with a three-way valve;

- to save energy resources and ensure heating safety, installation of a heat accumulator is mandatory;

- each heating device is set to a certain heating temperature - for solid fuel equipment the operating temperature should be 60-70 0C, while on an electric unit the temperature value is set to 40-50 0C, since due to the presence of a heat accumulator, the water for heating will cool more slowly, and the electric boiler will start with a time delay.

Heat exchanger material

Since the thermal efficiency of a heat generator is decisive for the entire heating system, manufacturers use materials with high thermal conductivity to manufacture heat exchangers. Typically this is steel and cast iron for solid fuel installations, and copper and aluminum for gas installations. In modern combined units, especially those with a dual-circuit layout, heat exchangers made of cast iron, steel or non-ferrous metals or their alloys can be used simultaneously.

Prices for Kentatsu combi boilers

Kentatsu combi boilers

Criteria for choosing a wood/electricity boiler

When choosing reliable heating equipment, it is not enough to be guided only by the availability of a certain amount of money and personal preferences. The main thing in this complex matter is the technical parameters that ensure the efficiency of the entire system.

When choosing a boiler, be sure to take into account:

- thermal power and area of heated premises;

- type of fuel intended for use;

- possibility of connection to gas mains and electrical networks;

- the presence of special premises for the installation of equipment, equipped with ventilation and a system for removing combustion products;

- type of heating circuit (open or closed);

- the need for coordination with licensing technical authorities.

The ideal option before purchasing any type of heat generator would be to develop a project with an accurate professional calculation of all system parameters. Errors at this stage can lead not only to the fact that the already assembled system will not provide the necessary heat, but also to its complete failure.

What should you pay attention to?

When selecting a model, you need to take into account several rules, failure to comply with which will lead to an error. As a result, the boiler may not be suitable for a particular home; for example, it may not be powerful enough and the room will be cold. For example, a device using wood or gas is dependent on the pressure in the main line, and when it decreases, it can give off noticeably less heat.

In addition to power, the technical specifications usually indicate the area of the house for which it is designed. The calculations are made by professionals and are quite accurate. You can use various tables found on the Internet

Particular attention should be paid to power when choosing the most universal options, such as a wood-gas-electricity device

It is worth considering a possible decrease in gas pressure in the line. This can significantly reduce the heating output. If there is no “reserve”, you will also have to use additional heaters powered by electricity. There is no point in heating with such characteristics; you will have to modernize it and incur additional costs.

The next stage is to determine the purpose of the combined boiler for heating. It can be purchased both as the main source of heat and for additional heating of running water, i.e. immediately choose the combined option.

Such a boiler is more profitable than a separate boiler, because wood or gas is already consumed for heating, and a separate water heater is usually powered by electricity. Wood heating often allows you to gain in the speed of reaching the desired temperature.

Installation nuances

The operation of home heating equipment is associated with a significant risk to health and life, therefore manufacturers and regulatory authorities have developed clear rules for its installation, use and maintenance. They are set out in the technical documentation attached to each unit and SNiP (Building Norms and Regulations) standards.

Their strict observance eliminates the possibility of a fire in the home, a gas explosion, and poisoning by combustion products.

Premises requirements

The ideal option for installing the entire complex of equipment is to organize a special room - a boiler room.

This takes into account:

- size of ventilation holes;

- area and volume of the room;

- distance from the protruding parts of the boiler to the walls;

- the presence and size of windows and doors;

- type and power of ventilation;

- presence and nature of electrical wiring and lighting.

If for solid fuel units the presence of a separate room is mandatory, then, for example, for gas-electric boilers with closed combustion chambers, installation in kitchens is allowed. In this case, a coaxial chimney is installed to ensure combustion of gas and removal of its combustion products.

Chimney installation conditions

When purchasing combined heating units, be sure to check that the hole for the chimney matches the dimensions of the chimney pipe. Depending on the model, the gas exhaust hole can be either rectangular or round. If these parameters do not correspond, it will be impossible to install the chimney properly or the installation of additional transition elements will be required.

In cases where the installation of heating equipment requires forced ventilation, you should ensure that the supply duct is larger in area than the chimney duct.

Prices for combined boilers Teplodar

combined boilers Teplodar

Requirements and rules for connecting to the electrical network

In the furnace of small private houses and cottages, electrical equipment is usually installed, consuming from 1 to 5 kW and operating from a single-phase network. In this case, the connection of electric heaters or heating element blocks occurs without significant alteration of the house's power supply system. For more powerful equipment, 380 V power cables are laid.

Lighting in boiler rooms and furnaces should ensure comfortable maintenance of all systems at any time of the day. The SNiP standards in the section “Natural and artificial lighting” discuss in detail the requirements and rules for its technical arrangement.

Popular manufacturers and their offers

There are quite a few companies that produce solid fuel boilers, among them there are several of the most popular. Our rating of the best boilers of 2022.

Buderus Logano

Price: 100,000 -109,000 rubles.

| Advantages | Flaws |

| High quality design, manufacturer's warranty up to 20 years | High price |

| Reliable automation | |

| Ease of installation |

Stropuva

This Baltic brand has been known in Russia since 2008, Stropuva units are reliable and have an impressive fuel chamber volume, they can work on one load for up to 5 days, if coal is used, for firewood this limit is limited to 30 hours.

Price: 52,000 – 65,000 rubles.

| Advantages | Flaws |

| High efficiency, minimum 90% | Heavy weight of the unit |

| Economical consumption | Lack of built-in automation |

Protherm

The Czech company Protherm has been present on the Russian market since 2011, during which time the company's products have gained wide popularity due to such qualities as reliability, ease of installation and maintenance, as well as the energy independence of heating devices of this brand.

Price: 52,000 – 60,000 rubles.

| Advantages | Flaws |

| Not expensive | Manual ignition |

| Efficiency up to 90% | Small firebox |

| Built-in automation |

Zota

Who, if not the Siberians, knows what cold is? The Krasnoyarsk enterprise Zota is known for its combined models of boilers. The versatility of the equipment allows you to use different types of fuel - gas, wood, coal or diesel fuel; with such a set of options it is impossible to be left without heat, even in hard-to-reach areas.

Price: 34,000 – 40,000 rubles.

| Advantages | Flaws |

| Built-in automation | Low efficiency, 70% |

| Low price | |

| Built-in electric heater |

Teplodar

A characteristic name for the products of a Russian company, which fully justifies it. Teplodar boilers are distinguished by their versatility; it is always possible to replace wood or coal with pellets or gas; this does not require replacing the unit; it is enough to install the appropriate burner. This brand produces many different models, both expensive and budget.

Price: 30,000 – 90,000 rubles.

| Advantages | Flaws |

| Large selection of models by type and fuel | Additional equipment must be purchased separately |

| Built-in heating element |

Teplodar Kupper

This product from the Teplodar plant allows the owner not to think about problems with purchasing fuel - any will do. The unique design of the Kupper brand is the basis for the efficient operation of the equipment; its efficiency is one of the highest among analogues.

Cooper Pro

Another successful development of the Teplodar company is long-burning boilers Kupper Pro, the entire line of this series has an efficient heat exchanger and a water-cooled grate, the units are equipped with an additional door, there are now three of them on the front side.

Don

Another Russian representative on the market of solid fuel boilers, Don heat generators are produced in Rostov. They have earned their popularity due to their versatility and reliability; the manufacturer uses high-quality boiler steel for production.

Siberia

The NMK plant from Novosibirsk specializes in the production of inexpensive budget models, but despite the reasonable price, Siberia brand units are very efficient, high efficiency is ensured by a grate made of pipes and beams at the flue gas outlet, also filled with coolant.

In conclusion, a few video reviews

Indeed, solid fuel equipment can be installed without worrying about poor infrastructure or distance from large populated areas. You can always choose a model that will provide heat and hot water to residential or industrial premises in the most unfavorable conditions.

Cost of combination boilers of different types

The cost of combined units depends on many factors, including:

- brand awareness;

- boiler power;

- number of types of fuel used;

- equipment.

Standard boilers operating on two types of fuel remain the most affordable today.

Universal equipment using 3 or more types of fuel is the most expensive due to the complexity of the design. The wider the functionality, the more elements are involved to implement it.

The excessive costs of expensive multi-fuel models are not always justified, and during operation it turns out that many functions are simply not used. Simple and reliable equipment with a combination of wood and electricity in most cases copes perfectly with the tasks of heating private houses. Find out which is better stone wool or mineral wool at the link.