Please help me with the following problem. We recently replaced an old Soviet boiler with a 12 kW Conord boiler produced in Rostov-Don. They started heating, and there was a problem with the smell in the room, i.e. the boiler turns on and off, the system heats up, but after 2-3 hours a certain smell and a suffocating atmosphere appears, all this is accompanied by poor health, headache, etc. Chimney increased to 120 mm (according to the output of the boiler), the height is 5.8 m, while the norm according to the instructions is 5 m, there seems to be a draft when holding a lit match. There is a suspicion of incomplete combustion. The service technician reduced the gas supply, only the heating time of the system changed. According to him, the boiler is working properly. Tell me what to check? Or give up and replace it with something else while there is time before the cold weather. The flame is blue at the bottom and yellowish-reddish at the top. Until we turned down the gas, it burned well with a hum. Automation Honeywell, I can’t say more precisely now. Model KSC-GV. The fact is that the master believes that everything is in order with the device and is not going to do anything else. But at the same time, it is still very difficult to breathe (today they extended the chimney additionally by about +1 m), the effect is minimal, i.e. the draft is somewhat better, but the gas pollution remains.

The boiler must not be used until the fault is corrected! Most likely there is a problem with the smoke exhaust. It is possible that when installing a new pipe, some cracks were formed through which fumes escape into the room. Take out the burner and light something smoky in the firebox, but not poisonous like sulfur. See if there is smoke coming into the room from where. Do it as a team, not alone. Ask local fire departments who inspect chimneys to see if they have a special compound for the color of the smoke. It is possible that the new pipe is inserted too far into the chimney and almost touches the chimney wall. But there are still gaps somewhere in the room, maybe the pipe is hanging out at the outlet of the boiler? In general, do not use the device until the cause is eliminated. The pipes must be inserted into each other along the gas flow at least 50 mm. Everything should be tight, only the unit itself may have a hole for the traction sensor.

The gas boiler Conord KSC-G-12N with Honeywell automation (V9500 (V5475) is in operation. It has been working for about 3 years, but from time to time there are problems with igniting the pilot/main burner. Actually, I have two questions: 1) How to set up the automation ? I searched, but couldn’t find current advice on setting up the automation. 2) How to disassemble and clean the boiler? For 3 years it has never been cleaned. The reason is banal, I don’t know how to take it apart and I’m afraid of damaging something. Maybe someone will give instructions for disassembly or some sensible advice.

Malfunction of the Conord boiler with Honeywell automation. Model KSC-GV-10. The device is new. Gas turned on. The pilot burner ignites when the plastic button is pressed. When released it goes out. Doesn't turn counterclockwise. It rotates clockwise by a very small degree. The copper coil gets hot.

I would start by checking the voltage on a heated, disconnected thermocouple. If it is less than the minimum, about 20 microvolts, then the igniter flame may be blown or, more likely, the igniter nozzle or tube is clogged. Then I would clean all possible automation contacts, as well as electrical contacts.

Conord floor heating boiler with Honeywell automation (gas valve V8620). The device heats up to approximately temp. 65-70 degrees, I determine it from the pipe that comes out of the boiler, and then the main burner and pilot are turned off, and until the temperature drops to 50 degrees, the main burner will start and go out after 3-5 minutes, blowing out the pilot.

Perhaps the overheating sensor is faulty and not only that.

Malfunction of the Conord KS-20 boiler. It was turned off for the summer. In connection with the upcoming onset of cold weather, I decided to test the water and discovered that the liquid temperature indicator had fallen out. How and when it fell out is a mystery, shrouded in darkness (no one admits it). I called a gas mechanic, but he will only come on the weekend. Therefore, the question is whether it is possible to turn on the device with such an indicator, at least in the evening for an hour or two.

Yes, you won't see the temperature. And in the future, replace it. Take out the old one and insert the new one. There is no need to drain the water.

Incorrect operation of the burner (automation AGU-T-M 23). Gas floor-standing boiler Conord. Tell me how to properly repair it. The problem is this: It regulates and turns off the gas supply very poorly. That is, it probably doesn’t regulate at all. The sensor with antifreeze built into the boiler should heat up and, expanding the antifreeze, blow out the rubber membrane, and the membrane should shut off the supply. I repaired this thing 2-3 years ago - I completely removed the sensor with a copper tube, with a block tap and put everything in the freezer, then unscrewed it, tapped it to keep it from airing and added a couple of cubes of antifreeze. Now it doesn't help. If you turn off the electricity, the boiler will boil, even if the tap block is barely open. Maybe there needs to be a membrane replaced or a fluid or I don’t know what.

The steps are as follows: Turn off the gas. (In general, it is advisable to do everything on a cooled thermal cylinder). Unscrew the 2 bolts on the thermostat and remove the thermostat rod. Inspect the rod, it is plastic, as a rule, it is crushed with excessive force (if it is crushed, then replace it). If the rod is intact, then change the 2 rubber rings on it and lubricate it with grease. Do not skimp on the grease on the rings and do not forget to lubricate the inside of the thermostat glass. Before installation, pull out the aluminum ring (there are usually 2 of them on the cotter pin between the rod and the thermostat cover) and unscrew the rod all the way up. Pull up the lower part (brass, where the membrane with antifreeze is). After this, insert the rod into the glass and tighten the 2 bolts. Before lighting, be sure to tighten the handle, but do not over-tighten it. Check if everything works as it should.

Heating boilers Conord

Rostovsky has a rich history and equally rich experience. Initially, the company was engaged in the repair of road equipment, but in the early 70s it was reoriented to the production of heating equipment.

At the same time, the name “Conord” appeared, which is an abbreviation for the words “Heating Boilers, Non-Standard Equipment, Rostov-on-Don.” The newly born plant began its activities with the production of the DON-16 boiler, famous throughout the USSR.

Heating equipment “Conord”

Today it is a modern enterprise, the technical equipment of which does not in any way remind of its advanced age. The production lines are equipped with the latest high-precision laser machines, imported presses and robots, which allow us to quickly and efficiently produce reliable and affordable devices. The main part of the range consists of gas water heaters, as well as heating boilers - gas, solid fuel and combined.

The range of boilers is quite diverse. First of all, the products differ in the gas burner device used (for short, they call it automatic). Three varieties are available.

Automation AGU-T-M (Russia)

- is cheap;

- does not require power supply (a bimetallic plate is used as a temperature sensor);

- does not impose special requirements on operating conditions and is inexpensive to repair (replacing the bimetallic plate - the only “weak link” - costs only 50 rubles).

This type of automation is quite common in our country and its use is not limited to the Conord brand. You can also see it in such Russian boilers as Mimax and some others.

There is no ignition system in the AGU-T-M, so the boiler has to be started using a lighter or a match.

Automation Euro SIT (Italy)

A boiler with such automation will be more expensive, but it simplifies setting the operating mode and ensures a higher level of safety. It contains:

- igniter with safety device (thermocouple);

- sectional burner with Polidoro tubes;

- gas valve SIT;

- temperature sensor;

- traction sensor

Unlike AGU-T-M, this automation reacts not only to gas shutdown, but also to deterioration of draft in the chimney.

The coolant temperature is set using a thermostat and is maintained automatically by a gas valve.

A piezoelectric spark gap is used to ignite the boiler.

Honeywell (USA)

The automation is of the same type as Euro SIT, only other materials are used for the manufacture of some elements.

An economy mode function has been added, to enter which the ignition knob must be turned all the way.

Conord boilers are also divided into single-circuit and double-circuit.

The former are intended for connection only to the heating system, the latter can additionally perform the function of an instantaneous gas water heater.

Unlike many other boilers with two circuits, Conord does not turn off the heating while using hot water. The 2nd circuit heat exchanger is heated by the smoke pipes. But still, the amount of heat supplied to the heating circuit decreases at this time.

Reviews of Conord boilers

Usually, studying reviews helps to get a fairly clear idea of the quality of the product, but in the case of Conord equipment, everything is different: there are messages with diametrically opposite meanings, so it won’t take long for a potential buyer to get confused. In general, we can say this: the boiler is of fairly high quality, but there may be problems with individual copies.

For one of the users, the temperature sensor on a KSC-G-16 boiler did not work well from the very beginning, and after 6 months of operation it began to fade for no apparent reason. At the same time, it was not possible to light the burner again immediately.

There are complaints about a large amount of soot settling on the heat exchanger. However, the issue here is not the unit, but poor traction. One of the users who encountered this problem, on the advice of a specialist, installed a chimney of a smaller diameter and corrugation, after which cleaning from plaque began to be required much less frequently.

Some users report difficulties when trying to adjust the coolant temperature. In one case, for example, the working environment could not be heated above 60 degrees. The problem was solved only by interfering with the boiler design: the technician who came on call removed the thermal cylinder connected to the capillary valve halfway and secured it in this position.

To be fair, we draw the potential buyer’s attention to the large number of positive ratings. It is reported that the Conord actually operates successfully at low gas pressure and also withstands extreme operating conditions. Thus, a case is described when a KCh-G-16 unit, due to an error in setting up the automation, overheated greatly, but this incident did not entail any particularly serious consequences.

Another advantage is that energy-dependent automation, unlike imported boilers, can be connected to the electrical network without a stabilizer.

Usually, when a gas boiler breaks down, the equipment gives a signal indicating a malfunction. The Ferroli boiler displays faults using LEDs. Let's look at how to diagnose errors using these signals and look at the types of breakdowns and their elimination.

The main heating schemes for private houses are presented in this review. As well as alternative heating methods.

Gas boilers CONORD with steel heat exchanger

More comfort, warmth.

Less worries and gas consumption.

Perfect lines – elegant design.

Boiler efficiency is 90%. The thermal insulation used eliminates heat loss.

The innovative design of the smoke collector and the location of the draft sensor on it guarantees that the gas supply is turned off in the absence of draft, and also allows you to maintain stable operation of the boiler in the event of a short-term reverse draft.

The service life of the gas boiler is 15 years.

Presentable and convenient

Original design, compactness with low noise level, the ability to use the secondary circuit of the boiler in the summer when the heating system is turned off.

The use of Italian SIT automation ensures stability of the set temperature and operation at low gas pressure

The cladding parts are made of modern material with triple protection: a layer of zinc, polymer paint and a protective synthetic film. The boiler design facilitates installation and maintenance.

Works great at low gas pressure of 0.6 kPa - 46% of the nominal 1.3 kPa. The cylindrical heat exchanger is made of cold-rolled metal, which allows the boiler to be used in a closed heating system.

Ideal value for money

Tested and certified in accordance with Russian standards

Advantages and disadvantages

The advantages of Conord gas boilers include:

- High quality assembly and manufacturing of components and parts.

- Boiler efficiency exceeds 90%.

- The non-volatile design allows the units to be used in any room or area.

- The service life of boilers is at least 15 years.

- Capable of operating at low gas pressure.

- The manufacturer's warranty on Conord boilers is 3 years.

- The price of the units is noticeably lower than that of other manufacturers.

The disadvantages of the units should be considered:

- The dimensions of the boilers are quite large and require a certain amount of space for installation and maintenance.

- The use of natural draft places increased demands on the design of the chimney and the creation of conditions for high-quality smoke removal.

Gas boiler Conord - technical characteristics and features

The thickness of the steel sheets used to make the Conord boiler firebox is 3 mm. The material has a fire-resistant powder coating, thanks to which the service life of the boiler, as the manufacturer assures, is 15 years.

The warranty is valid for 3 years.

The efficiency of boilers of this brand is 90%.

Such a high indicator was achieved due to the installation of turbulators in smoke pipes.

The connections to the pipelines are located on the rear panel of the heat generator.

Their diameters are 50 mm or 2 inches (heating circuit connection) and 15 mm or ½ inch (for the DHW line).

The lowest-power model provides heat generation of 8 kW. The oldest representative of the line has a power of 30 kW. Intermediate values: 10, 12, 16, 20 and 25 kW.

The diameter of the chimney depends on the power of the device. For boilers with a heat output of up to 12 kW inclusive, it is 115 mm, for more powerful ones - 150 mm.

Heat generators of this brand have built-in expansion tanks with a volume of 8.5 liters. The maximum permissible coolant pressure is 6 atm.

An important feature of Conord boilers is the ability to operate at a gas pressure in the main line of only 0.6 kPa (usually the pressure in the distribution gas pipeline is maintained at 1.3 kPa)

Specifications

Let's look at the technical characteristics of Conord gas boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Installation method | Floor |

| Feature Set | Heating and hot water supply |

| Efficiency | 90 % |

| Unit power range | 8-50 kW |

| Combustion chamber design | Open (atmospheric type) |

| Fuel type | Natural gas |

| Heat exchanger material | Stainless steel 3 mm, cast iron |

| Energy consumption | Absent |

| Service life declared by the manufacturer | At least 15 years |

| Guarantee period | 3 years |

Quality Policy:

The main goals of the team of LLC “Plant CONORD” in the field of quality:

|

The strategy for achieving the goals is:

|

| The management of Zavod CONORD LLC takes responsibility for the implementation of the declared quality policy, effectiveness and continuous improvement of the quality management system to demonstrate its commitment to the principles of total quality management in the production of heating equipment |

Gas boilers "Conord" and their description

As already mentioned, all boilers under the Conord brand are floor-standing, and they are quite large; their outer casing is equipped with a special protective enamel. They also have the following descriptive characteristics:

- the boiler is made of steel 3 mm thick;

- The efficiency of the unit is 90 percent;

- energy independence;

- affordable price;

- good customer reviews.

Gas units of the Conord brand include several modifications, in particular, with and without hot water preparation. In addition, the unit can be equipped with thermo-hydraulic type automatics or SIT automatics. In the first case, the boiler is classified as non-volatile. The supply and shutdown of fuel in this design is controlled by a thermostat. Then, when the temperature next to it reaches the set parameter, gas stops flowing to the main burner and this way the desired temperature regime can be maintained.

These devices are well adapted to the conditions of both cold and moderate winters; they are able to maintain any given temperature, provided the power is correctly calculated. Thanks to the high-quality installation of the burner, excellent boiler productivity is achieved, an optimal gas-air mixture and thermal insulation are created, thanks to which a huge amount of heat is spent on heating the coolant.

Of course, boilers of this brand are safe and have several levels of protection:

- a smoke exhaust sensor that is triggered in the absence of draft and turns off the gas supply to the burner. It also does not allow you to turn it off when short-term reverse draft occurs during intense gusts of wind;

- the presence of a flame on the main burner is monitored. If it is not there, then there is no gas supply;

- possibility of temperature control in the heating circuit. Heating of the coolant stops when the maximum temperature value is reached.

Conord boilers are adapted to operate in conditions of low fuel pressure. Different models may be marked KSts-G-10S or KSts-GV-12. It has this meaning:

- K-boiler;

- C - made of steel;

- C – the firebox has a cylindrical shape;

- G - gas;

- GW – gas with hot water supply function.

Subsequent numbers in the marking indicate its maximum power level. To calculate the required power when purchasing a boiler depending on the room, take 1 kW per 10 square meters, provided the ceiling height is within 2.5 meters and the average level of heat loss.

How to serve

Maintenance of Conord boilers consists of maintaining the cleanliness of the body, timely removal of soot or ash from the burner and performing other necessary procedures.

Most of the work is performed by the owner of the unit, but for some activities it is necessary to invite a specialist from a warranty or service organization. This must be done annually, or as urgently necessary - in case of problems or breakdown of the boiler.

Attempts at self-repair can cause permanent failure, so you should entrust complex operations to professionals.

Any attempt to independently interfere with the boiler design will be regarded as termination of the warranty agreement at the initiative of the owner.

Floor steel models Conord

Let us immediately note that all boilers of this brand are produced in a floor-standing version. “Steel” boilers are those whose heat exchanger is made of steel. It is easy to find such a device in a catalog or price list by the marking, which begins with the letters “KS” (steel boiler).

For example, it is the steel heat exchanger that is installed in the boiler of the KSC-G-16 brand.

Here the letter “C” denotes the cylindrical shape of the heat exchanger, “G” is the type of fuel (gas), and the number “16” is the power in kilowatts.

The presence of the letter “B” in the marking (for example, KSC-GV-20) means that the boiler is 2-circuit.

Boilers with a steel heat exchanger are lighter and heat up quickly. However, they are less reliable and not as durable as cast iron. A significant disadvantage of steel is its susceptibility to corrosion.

Review: Floor-standing single-circuit gas boiler Conord KSts-G-12N - Reliable and economical!

Advantages:

Inexpensive, works properly, economical, 3 year warranty

Flaws:

there are small ones

Gas heating has its pros and cons. On the one hand, living in an apartment, you don’t have to bother with boilers, installing them somewhere, periodically cleaning them, lighting them, etc. You wait until the heat is turned on, and that’s it. But on the other hand, they don’t always turn it on when you want. And you have to freeze without heating in the fall and spring, and sometimes, on the contrary, die from the heat. This is a huge advantage of gas heating - when you need it, you turn it on, when you don’t need it, you turn it off. We live in a private house, and we, in fact, don’t have to choose: if you want heat, install a boiler. So we installed the Conord KSts-G-12N when the previous one gave up its life.

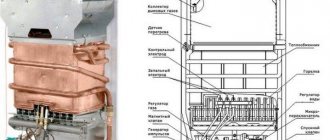

Some technical data: overall dimensions 412/342/786, weight about 40 kg. Designed for 120 square meters (we have 100, we took it with a small margin). The efficiency is stated to be at least 90%, but how to check this? Gas consumption at nominal heating output is indicated at 1.35 cubic meters per hour. The boiler is steel, white, covered with heat-resistant powder enamel. All the “stuffing” is behind the door:

As you can see in the photo, the top cover is loose - this is not a defect in the boiler, it was after a preventive inspection and cleaning that the gas workers (!) installed it incorrectly, we didn’t notice right away, but we didn’t want to disassemble, remove the pipe and redo it ourselves, so we decided to leave it until next time . This boiler model is single-circuit; we use a gas water heater to heat water. The boiler is non-volatile, but our heating is with a circulation pump, i.e. when the power goes out, the pump does not work, the boiler overheats and automatically turns off. Fortunately, this rarely happens. There is one inconvenience during the initial ignition - you need to hold the button pressed for a while, your finger gets tired)

The instructions are the same for several models, for me personally it is not very clear, but still boilers should be installed and maintained by specialists, or at least technically competent people, this is not about me:

The boiler does not, of course, have all sorts of useful and pleasant functions such as programmable switching on at a certain time and the like, like its more expensive counterparts. But the manufacturer gave a 3-year warranty, and the promised service life is at least 15 years. The boiler was installed in the summer of 2010 and survived 2 winters. It was not very warm at home only in the most severe frosts of 30 degrees. In general, everything is fine so far, only this spring, however, it unexpectedly began to smoke, I had to urgently clean it (I confess, it was cleaned for the first time, although it needs to be at least once a year). It is more economical compared to the previous boiler, heating a 2-storey house with an area of 100 sq. m., an average of 500 cubic meters per month is consumed (naturally, more in winter, much less in summer, but I’m used to paying one amount all year round, it’s more convenient for me). PS Unfortunately, we have to add a fly in the ointment to the previous positive impression. Today it suddenly started smoking again, 9 months have passed since the previous cleaning. So, during cleaning, specialists removed one of the turbulators and discovered that it had burned out in one place. After less than 3 years of work.

Use time: 2 years

Cost: 9600 rub.

Year of manufacture/purchase:2010

General impression

.

Reliable and economical!

Solved: Conord boiler does not regulate water temperature

Gas burner device AGU-T-M, I ignite it, bring the temperature to, for example, 70 degrees, turn the regulator clockwise until the combustion starts to decrease, but the burner continues to burn at 80 and at 90, and so on until the water boils, if you turn it a little counterclockwise, the burner goes out and won't turn on until it reaches room temperature. Those. no automatic regulation. I disassembled the block tap (if I call it correctly), there was dried grease in it, washed it, lubricated it with graphite, but it didn’t help, it looks like the temperature sensor is faulty. Who is “in the know”, tell me, is there a possibility of checking it?, Repairing it? What's in it? Kerosene? If anyone has it, please share the drawing of this automation unit.

- 18 Sep 2011

Malfunctions of gas boilers Repair of gas boilers Diagnostics of gas boilers Diagrams and instructions Brands and models of boilers Popular topics

Malfunctions

This block is for those who first came to the pages of our site. Our forum discusses various malfunctions that occur in gas boilers and water heaters. The most common manifestations of defects are the following:

- won't turn on

- gas burner goes out

- does not gain temperature

- does not execute control commands

- low flame

- whistling and noise in the boiler

- cold water in the system

- circulation pump problem

Repair of gas boilers and water heaters

Please note that gas equipment repairs and heating installations must be performed by professional, certified workers. The forum contains topics designed for masters in this field. Unskilled repairs can have very serious consequences. The forum addresses the following issues:

- Diagnostics

- Troubleshooting

- Repair methods

- Search for spare parts

- Service

- Installation and configuration

Diagnostics of gas boilers

As a rule, most modern gas boilers have an internal diagnostic system that independently detects any malfunction and displays its code on a digital display. Since each model has its own codes, they are not listed here, but in the corresponding forum topics

From the error codes, the technician identifies the most likely cause of the failure. However, some defects are not detected by the processor (controller) in error codes; they require detailed manual measurements or adjustment of equipment components. Based on the diagnostic results, you may need:

- Replacing individual components

- Replacing the board assembly

- Replacement of units

- Setting up nodes

Where can I download the gas boiler diagram?

Beginning repairmen often look for circuit diagrams, wiring diagrams, user and service manuals. On the website they are posted in specially designated sections and are available for downloading by guests, or after creating an account:

What brands are considered?

The forum covers almost all used brands of boilers. A large database of faults, methods for diagnosing and eliminating them has been compiled. Here are a few links:

Popular Topics

During the renovation process, craftsmen have interesting topics to discuss. Let's list just a few:

Gas water heating device

The use of Italian SIT automation ensures stability of the set temperature and operation at low gas pressure.

Possibility of installing a circulation pump and operating the AOGV in a closed heating system. The cylindrical heat exchanger is made of high quality steel and can withstand high pressure.

3 years warranty

Simple installation without reworking the heating system or replacing the design. Complete match of all connecting dimensions for this model

| Connecting thread of the gas supply fitting | ½» |

| Efficiency for exhaust gases on gas fuel | at least 85-90% |

| Operating water pressure in the apparatus | 100+20 kPa (1.0+0.2 kg/cm²) 0.12 (1.2) |

| Water temperature in the apparatus | 50—90 °C |

| Internal dimensions of the chimney | ø 112.6 mm |

| Nominal gas pressure | 1274 Pa (130 mm water column) |

| Exhaust gas composition: | - no more than 119 mg/m³ carbon monoxide CO - no more than 240 mg/m³ nitrogen oxide NO |

| Discharge behind the device | — minimum 5 Pa — maximum 25 Pa |

The power calculation does not include the power consumed by the hot water circuit. All parameters indicated in the table correspond to the operation of the device at rated heat output and established thermal equilibrium.

The prices presented on the website are not a public offer and may differ at points of sale.

comparison table

| vendor code | Power | Heated area | Average flow, m3/hour | Weight, kg | Dimensions, mm | Factory price including VAT, rub. |

| AOGV-11.6-3 | 11.60 | 116 | 0,74 | 41,1 | 411/304/936 | 17600 ₽ |

| AOGV-11.6-1 | 11.60 | 116 | 0,74 | 38,2 | 380/327/953 | 17600 ₽ |

| AOGVK-11.6-1 | 11.00 | 116 | 0,74 | 39,2 | 406/327/953 | 20100 ₽ |

| AKGV-11.6-3 | 11.60 | 116 | 0,74 | 42,1 | 413/304/936 | 20100 ₽ |

| AOGV-17.4-1 | 17.40 | 174 | 0,94 | 56 | 466/396/958 | 20900 ₽ |

| AOGV-17.4-3 | 17.40 | 174 | 2 | 56,2 | 495/368/936 | 20900 ₽ |

| AOGV-23.2-3-2 | 23.00 | 232 | 1,48 | 76 | 580/475/1120 | 24000 ₽ |

| AOGVK-17.4-1 | 17.40 | 174 | 0,94 | 60 | 495/396/958 | 25400 ₽ |

| AKGV-17.4-3 | 17.40 | 174 | 0,94 | 57,2 | 495/368/936 | 25400 ₽ |

| AOGV-29-3-2 | 29.00 | 290 | 1,48 | 76 | 580/475/1120 | 26400 ₽ |

Main types of Conord boilers

The manufacturer produces heating equipment with two types of heat exchangers: steel and cast iron.

All gas storage tanks from the Rostov company are floor-standing only. When purchasing wall-mounted units, it is recommended to choose other brands.

Steel

Steel heat exchangers will give the buyer the following advantages:

- High heat transfer rate, which any heating boiler has.

- Less specific gravity.

- A more ductile material compared to cast iron.

Interesting! Low resistance to damage and corrosion processes is the main drawback, which for some will be significant. Therefore, many people prefer cast iron analogues. Manufacturers add durable coatings, but they are not capable of providing 100% protection.

Cast iron

Immunity to corrosion along with high thermal conductivity are the main positive aspects of the products. They have much fewer disadvantages, these are:

fragility. Almost all buyers will notice it. During transportation and installation, the likelihood of damage is highest. Therefore, such stages of work are trusted only to specialists.

When the device is delivered home, it is important to check its functionality in advance. Even microcracks can lead to serious damage. Less strength when compared to steel. Less flexibility and ductility

Although this does not prevent you from igniting the fuel for further operation.

Peculiarities

To make sure that this product is of the best quality, you can read various reviews about these products that users leave about them

Consumers are drawn to the fact that heating devices from Conord have a long service life, a decent degree of reliability and excellent efficiency. The full period of this guarantee is 15 years.

Externally, these units are distinguished by a rather strict design. Models with two circuits can be used in hot water systems during the warm season of the year and will not be dependent on heating. Gas products from Conord are launched using piezo ignition, and the technical characteristics reflect their excellent functionality.

All devices from Conord are divided into:

- Models where there is no system for supplying the consumer with heated water. They have built-in Italian automation and are extremely in demand.

- Heating devices that can only give warmth to your home. Their automatic elements use the principle of thermohydraulics.

- Boilers that not only provide home heating, but also heat water for domestic needs. They have built-in automation from Italy from SIT.

- Models that are capable of heating rooms and calmly warming liquid for various purposes. Thermohydraulic automation makes these tasks more simplified.

Installation rules, how to turn on a floor-standing boiler correctly

It is recommended to trust the installation, configuration and commissioning of the Conord floor-standing gas boiler to specialists from certified service centers. Only in this case can you count on the validity of the warranty period. After installation of the equipment, a corresponding entry must be made in the technical data sheet of the product.

Every year, specialists from the service center carry out a technical inspection of the boiler, which is also noted in the passport. The warranty does not apply to products whose passport does not contain these marks.

When installing a gas boiler, the following must be taken into account:

- The equipment cannot be installed on a combustible floor; it is necessary to make a backing made of fire-resistant material. The size of the substrate must exceed the dimensions of the boiler by 0.5 meters on each side.

- For normal circulation of the working medium in the system, the lower pipe of the boiler should be mounted below the heating radiators.

- The Conord gas boiler for heating a private home can be connected to pipes made of any material. However, when connecting by welding, it is recommended to make several threaded joints for possible troubleshooting.

- The riser must be strictly vertical, the deviation should not exceed 3 mm per 3 linear meters of pipe.

- According to the technical characteristics of Conord gas boilers, for free air removal, the slope of the horizontal sections should be 1 cm per linear meter.

- Branches to radiators of the heating system must be installed with a slope of at least 1 cm per linear meter.

- A shut-off valve must be installed at the coil outlet.

- The chimney for the boiler is installed in the load-bearing walls of the house.

- Sections of the chimney located in unheated rooms must be insulated.

- The diameter of the chimney should be slightly larger than the diameter of the outlet pipe. This ensures stable operation of the equipment and sufficient traction.

- It is not recommended to make chimneys with protrusions; it is best to place straight sections vertically.

- In any case, the equipment and supplied elements must comply with fire safety requirements and regulatory standards.

- Installation of a gas boiler is carried out only after agreement with special authorities.

Product line

There are practically no wall-mounted boiler models in the brand’s line, so for a home heating system, consumers often purchase a Conord gas floor-standing boiler, which can be equipped with additional options. Floor-standing boiler models are produced in four series. The manufacturer makes all boilers from durable high-quality steel. To increase the stability of the boiler, its surface is treated with heat-resistant powder, which protects the device from high temperatures and loads.

Consumers who are interested in such a device as the Conord gas boiler, instructions for use are supplied by the manufacturer, should analyze devices from the following series:

- KSC-G-S;

- KSC-G-N;

- KSts-GV-S;

- KSts-GV-N.

Series KSts-G-S

In this series you can find a good single-circuit heating boiler, which is equipped with a functional gas supply regulator. Italian automation, which controls the operation of a domestic boiler, guarantees its safety, reliability and efficiency in the heating system of a house or apartment. Devices from this series can be adapted for heating buildings with an area of 80 to 300 sq.m., but for this you need to choose the right boiler in terms of power.

In order for boilers to meet the requirements of the heating scheme, it is important to pay attention to other parameters. Thus, the operating pressure of devices from the KSts-G-S series ranges from 0.2 to 1.9 bar, the minimum heating temperature of the coolant is 60 degrees, and the maximum is 90 degrees

Series KSts-G-N

More functional boilers can be purchased under the marking KSts-G-N. They are equipped with a unique cylindrical heat exchanger, which is made of high-quality cold-rolled steel. This solution allowed manufacturers to achieve the most efficient performance and ensure the ability to quickly and uniformly heat the coolant circulating in the circuit. This series includes single-circuit models that can be used to heat houses with an area of 100 to 300 sq.m.

Due to increased reliability, KSts-G-N boilers can operate in difficult conditions - they are designed for use in systems with operating pressures reaching 5 Bar. To optimize the heating process, excellent thermo-hydraulic automation is installed on the boilers. Since this series of products is more functional and versatile, the cost of boilers in it is somewhat more expensive - the minimum price of a basic device starts from 16 thousand rubles.

Series KSts-GV-S

An inexpensive double-circuit gas boiler Conord, reviews about which you should definitely read before purchasing, can be found under the marking KSts-GV-S. Models from this series are equipped with an additional circuit to provide hot water supply in the house. They operate under the control of Italian SIT automation and are designed to heat houses with an area of 120 to 300 sq.m.

Having studied reviews of the Conord gas boiler, purchasing a double-circuit unit, the owner solves two problems at once and equips his home with an appliance that will help heat the rooms and provide the necessary supply of hot water for household needs. The boilers are quite versatile - they can be used in almost any circuit.

Series KSts-GV-N

Among the products united under the marking KSts-GV-N, you can choose a good double-circuit gas boiler Conord, the technical characteristics of which are represented by the unique shape of the smoke collector and the presence of thermo-hydraulic automation.

KSts-GV-N boilers have a unique emergency protection system.

These models are the safest and most reliable. They are equipped with detectors that stop the gas supply if there is a threat of explosion. Also, the boiler can independently stabilize the operating process when it detects short-term reverse draft. The power of devices in this series ranges from 12 to 30 kW. You can read how to choose a gas boiler for your apartment here.

The Russian company has earned itself a good and strong reputation in the market through the production of reliable heating equipment. Among consumers, Conord gas boilers, reviews of which are mostly positive, are in consistently high demand.

In the manufacturer’s line, you can choose a boiler for almost any heating system - after all, the power of various models ranges from 8 to 30 kW. By correctly selecting a boiler from the brand’s product range, the owner can make it the basic element of the heating system of an apartment, country house or large private mansion.

Briefly about the operating instructions and setup

The operation of Conord gas boilers is not particularly difficult, since the units have a durable and reliable design and are resistant to loads and external influences.

However, to improve working conditions, several simple procedures should be performed:

- Install a strainer in the gas line to prevent fine metal dust and scale from entering the burner.

- Use water softeners or filters. This is especially important for residents of regions with hard water.

- On the return line of the heating system, it is necessary to install a filter that retains scale, slag and other debris that is present in the system. This will protect the heat exchanger from clogging and increase the service life of the boiler.