Here you will learn:

Indirect heating boilers are actively used in everyday life as productive devices for convenient and safe preparation of hot water. Using heat from traditional heating pipes for power, they are economical. Connecting an indirect heating boiler is carried out using several schemes described in this review - we will consider both complex and simple schemes. At the same time, we’ll figure out how to make the electrical connection of this unit.

Indirect heating boiler design

Electric storage water heaters are gradually becoming more common sources of hot water, using a regular household electrical network for power. They are equipped with conventional heating elements responsible for heating water in the internal tanks. Electricity costs are not the highest, but not the lowest either - the larger the boiler, the higher the consumption. But in the world of water heaters, there is also a more economical technique.

Indirect heating boilers use heat extracted from heating systems to heat hot water. To do this, they are equipped with metal coils. Having a large area, they quickly heat the water to the temperature set on the panel. The temperature regime is maintained through built-in or connected automation.

The scheme for organizing a DHW circuit using capacious wall-mounted and floor-mounted indirectly heated boilers has the following advantages:

- Saving on electricity – in winter it will be noticeable;

- Fast preparation of hot water - “indirect” ones are characterized by high productivity;

- High reliability - many experts tend to use this particular scheme rather than double-circuit boilers.

The scheme is really simple and reliable, all that remains is to select and connect the indirect heating boiler to the heating system. Let's see how to connect.

Basic connection diagrams

In our review we will look at several of the most popular schemes for connecting indirect heating boilers to heating equipment. They differ in their degree of complexity, so you have to choose the best option.

Connection without regulation

This scheme is characterized by maximum simplicity, but is practically not used in hot water supply systems. Yes, we can safely connect an indirect heating boiler to a gas boiler without additional wiring. But you will have to somehow put up with the lack of ability to adjust the temperature to your liking. In fact, the temperature of the water in the tank with this connection scheme depends on the temperature of the coolant at the connection point.

Remember that the maximum water temperature in the tank of an indirectly heated boiler (water heater) is only a couple of degrees lower than the temperature in the heating circuit.

In some cases, the coolant (water) in heating systems warms up to high temperatures, up to +70-80 degrees. More impressive indicators are also recorded. Such powerful heating leads to the fact that the temperature of the water in water heaters jumps to similar levels. We open the tap, and our hands are scalded with almost boiling water. Agree that such a connection is not safe, even if you dilute the water with a mixer.

Thus, the connection diagram for an indirect heating boiler must necessarily contain regulatory elements. Temperature stability at the outlet will allow you to avoid problems with scalding your hands and other parts of the body. Moreover, most connection methods are relatively simple.

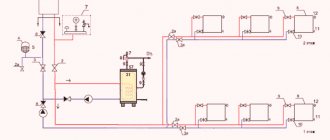

Connection with circulation pump

Connecting an indirect heating boiler to a single-circuit boiler using a low-noise “wet” type circulation pump is one of the simplest schemes. It uses the following nodes:

- Circulation pump – provides a forced supply of coolant into the inside of the water heater (into the tank);

- Thermostat for an indirect heating boiler - built-in or external;

- Check valve - prevents the reverse flow of coolant and stops circulation when the pump is turned off.

Let's take the simplest case, when the water heater already has automation. To carry out the installation, we will need an indirect heating boiler piping, which includes the following elements - a tap for quick disconnection from the heating network, a circulation pump, a check valve, a tap for shutting off the water supply, a check valve for the water supply.

We begin connection work - we install our indirect heating boiler in a given location (floor or wall mounting). Next, we lead the pipe to the heating system and connect through the tap. We install a circulation pump at the outlet of the water heater, and after it we install a check valve.

This method involves installing another “wet” type circulation pump into the home heating system.

Connection with three-way valve

A gas boiler with an indirect heating boiler is a simple and reliable combination for organizing a durable and productive hot water circuit. To connect a water heater, we can use one simple circuit using a three-way valve. It will play here approximately the same role as in a conventional double-circuit boiler - there it switches the movement of the coolant from the heating circuit to the secondary heat exchanger, in which the water is heated (when the tap is opened).

It works in a similar way here. To organize the connection, we will need a three-way valve, a low-power circulation pump and the indirect heating boiler itself. The circulation pump is common here; it circulates the coolant through the heating circuit and through the water heater. This process is controlled by a three-way valve connected to the thermostat. As soon as the temperature in the tank drops below normal, the valve switches and water heating in the DHW circuit begins.

Recirculation connection

Let’s assume that the indirect boiler is installed at a distance of 15 meters from the tap. In this case, if you open the tap, you will have to wait a while for hot water to flow from it. To implement the recirculation scheme, we find the farthest point of the hot water supply and, using a tee, connect another pipe, returning it back to the boiler. It turns out that we loop the system, install a special circulation pump for recirculation, for hot water supply, and after that hot water heated in the boiler will constantly circulate in our ring. Now, even at the farthest point, opening the tap, hot water will flow at the same second.

To minimize heat loss, all pipes through which hot water circulates from the boiler must be insulated with thermal insulation. Most boilers already have a special outlet for connecting the recirculation line. A special pump is installed on the line, designed specifically for DHW recirculation. Pumps that are used for heating are not suitable for this purpose. The pump is usually installed within one and a half meters from the boiler and connected with two taps. It is also recommended to install a strainer and a check valve. When connecting a pipe - recirculation line to the boiler itself, it is enough to install a quick connector. The tap does not need to be installed, since the tap is located on the pump itself. If the boiler does not have a special outlet for connecting the recirculation line, then we take a tee and install it at the cold water inlet, in front of the boiler.

The assembly of this connection unit occurs sequentially:

- ball valve with detachable connection towards the boiler;

- safety check valve;

- tee for connecting the expansion tank;

- tee for connecting the recirculation line;

- At the hot water outlet after the boiler, we install only a ball valve with a detachable connection towards the boiler.

With this piping scheme, if necessary, the expansion tank can be moved to the hot water outlet line from the boiler. Installation is made between the tap and the boiler. We connect the circulation pump with 2 ball valves with detachable connections. The detachable connections must be on the pump side. Also, do not forget to install a check valve. After installing this circuit, we get the same effect as with the boiler connection circuit, which has a special output for connecting the recirculation line.

Source

How to choose the right connection

An indirect heating boiler can even be connected to a double-circuit boiler, if this makes sense - for example, such a scheme will allow you to connect multiple water points and use them simultaneously. Here we select any available scheme. In the absence of heated floors and several heating circuits, the optimal solution would be to connect through a circulation pump or a three-way valve.

If you need to create a connection diagram for a solid fuel boiler that runs on wood, we recommend choosing the option shown in the picture below. Here the priority of the indirect heating boiler is used. The coolant for heating devices is taken from its outlet. This connection reduces the thermal load on the radiators and ensures a reliable supply of hot water.

Connection through hydraulic arrows and collectors is used if it is necessary to provide heat and hot water to a building of impressive size. For example, it could be a two- or three-story cottage. In this case, a powerful boiler is installed in the system, and distribution equipment is connected to it.

Electrical connection

During the warm season, the equipment is turned off, so you need to somehow solve the problem with hot water. To do this, we can shut off the heating circuit and leave only the indirect heating boiler running. But most often the practice is to simply connect the water heater to the electrical network - for this purpose, heating elements are installed here (in some models they are built-in initially). It is necessary to connect to the electrical network through circuit breakers.

Official BAXI Forum in Russia

- Unanswered topics

- Active topics

- Search

- Users

- our team

- Acknowledgments

- 07/19/2019 – The BAXI seminar book 3Q was published. 2019 (119 MB). Download

- 06/20/2019 – BAXI Energy voltage stabilizers are on sale.

- 04/16/2019 – Sales of BAXI Eco Nova boilers have started.

- 11/16/2018 – The BAXI 4Q seminar notebook was published. 2018 (8 MB). Download

Connecting pump thermostats and indirect heating boiler

Connecting pump thermostats and indirect heating boiler

Post by Roman13vs777 » Jan 27, 2015, 9:11 pm

Re: Connecting thermostats for pumps and an indirect heating boiler

Post by Bahus » Jan 27, 2015, 10:22 pm

Re: Connecting thermostats for pumps and an indirect heating boiler

Post by Guest » Jan 27, 2015, 11:41 pm

Re: Connecting thermostats for pumps and an indirect heating boiler

Post by BAXI-Ural » 28 Jan 2015, 08:34

Re: Connecting thermostats for pumps and an indirect heating boiler

Post by Bahus » Jan 28, 2015, 10:30 am

Re: Connecting thermostats for pumps and an indirect heating boiler

Post by Roman13vs777 » Jan 28, 2015, 9:05 pm

I suggest continuing to those who are interested and who are engaged in self-development (from the institute I have a passion as an engineer for technical puzzles). I reviewed the schemes, well, a lot of them, I especially liked the resource eurosantechnik.ru and the execution by Vitaly Luzhetsky, for anyone interested, here is the link

There is absolutely no time to draw or draw a diagram. I don’t want to post a photo of a diagram from a notebook in pencil. And why draw everything in the standard way: boiler-arrow-distribution manifold-supply to the circuit-pump-heat exchanger-return-manifold-arrow-boiler. To make the concept easier, I omitted all the taps, filters, and valves. Based on your feedback, I understand that your opinion is that it is better to let the system operate according to the VT temperature, but with so many zones the needle will not cool down.

The discussion boils down to narrowing down the questions: 1) Is it possible to connect a pump to the thermostat and a thermostat to the boiler at the same time? 2) How will the boiler react if a DHW priority sensor is connected to it? What will happen without a three-way valve. Or it's not possible at all. 3) “tuning” was written in quotation marks. "3.5. TECHNICAL NOTES: The AFR system improves the operating and combustion characteristics of the boiler." Does the “slingshot” also improve or is there no point?

The design and principle of operation of the boiler

An indirect exchange boiler (water heater) is a tank filled with water in which a heat exchanger is located. A coil or water jacket is usually used as a heat exchanger. The heat exchanger is connected to a heat source that transfers energy through a coolant.

The process of heating water in the boiler occurs as follows:

- First, coolant from the heating boiler is supplied to the heat exchanger;

- The walls of the heat exchanger are heated by the supplied energy;

- Heat is transferred from the walls to the water located in the tank;

- Heated water is taken by consumers as needed.

With this technology, there is an intermediate link between the water and the coolant, which ensures heat transfer - that’s why the device is called an indirect heating boiler.

The heating system with an indirect heating boiler is in close cooperation. Thus, the water in the boiler usually has a slightly lower temperature compared to the temperature of the coolant entering the heat exchanger - that is, the water in the tank can only be heated to the level that the boiler is capable of producing.

However, there is one way to bypass this limitation - all you need is to choose a combined boiler, which, in addition to the heat exchanger, also has a heating element. In such devices, the main source of heat is indirect heating, and the heating element increases the water temperature to the required level. The most effective combination of equipment, in which the water remains hot the longest, is a boiler with a heating element and a solid fuel boiler.

Some boiler models are equipped with additional heat exchangers - with a large tank volume this will significantly speed up the heating of the water. To ensure that the water remains heated for as long as possible, when choosing equipment you should give preference to devices with insulation.

Compatibility with heating equipment

Indirect heating boilers work without problems with any heating system that supplies hot water - as long as its power is sufficient. As noted above, solid fuel boilers that operate on all available types of fuel are an excellent option. However, devices running on gas, electricity or liquid fuel will also be quite effective.

The installation of the tank itself is not very complicated, but the connection diagram for an indirect heating boiler is no different in simplicity. When choosing a model with controls, there will be no special problems, but with simplified products you will have to tinker so that the boiler working in conjunction with them can work with both heating and water supply.

Principle of operation

Boilers are floor-mounted, wall-mounted, or combined with a heat exchanger and a built-in thermal heating element. Unlike heating element water heaters, where there is direct contact with the heater, indirect heating boilers most often have a built-in coil in the form of a stainless steel pipe. The principle of operation is to transfer heat from the coolant moving along the coil to the water with which the tank is filled.

Due to this operating scheme, water is heated much faster than with a conventional heating element, scale formation is minimized and the tank will require maintenance much less often.

In this article we will look at connection diagrams for an indirect heating boiler:

- to a wall-mounted gas boiler;

- to a floor-standing gas boiler;

- electric boiler;

- to a solid fuel boiler.

Types of indirect heating boilers

The classification of water heaters of the type under consideration is carried out according to one main feature - the presence or absence of built-in control:

- Boilers with built-in control . Such devices are connected to heating systems that use boilers that are not equipped with automation. Such boilers have a temperature sensor and their own automation unit, which regulates the supply of heated water to the heat exchanger. Connecting an indirect heating boiler with built-in control is simple - you just need to connect the supply and return pipes from the boiler to it, provide a supply of cold water and connect an output channel that allows you to distribute water to consumers.

- Boilers without built-in control . As a rule, this category of boilers usually works in conjunction with automated boilers. Piping a boiler of this type begins with installing a temperature sensor and connecting it to a suitable boiler input. Next, the boiler is connected according to one of the existing schemes. If necessary, such devices are connected to non-volatile boilers, but in this case it is necessary to use the appropriate wiring diagrams.

Boilers are also divided into types depending on their shape and installation method. As for the latter, there are two types of devices - wall-mounted (volume no more than 200 liters) and floor-mounted (volume up to 1500 liters). Both options can be in horizontal or vertical format. Wall-mounted boilers are mounted on brackets fixed with dowels.

The vast majority of water heaters are cylindrical in shape, and their outlet pipes are located on the back - this greatly simplifies the connection of an indirect heating boiler and does not spoil the decorative qualities of the structure. On the outside of the panel there is space for installing a temperature sensor or relay, and some models have the ability to connect a heating element.

Examples of popular connection diagrams for a single-circuit gas boiler with an indirect heating boiler

They are less often connected to free-standing boilers of similar volume. Using a thermostatic head with a built-in sensor, the water temperature for the boiler can be set no higher than the coolant temperature. Various boiler piping schemes There are several main ways of piping the device, which are: With two circular pumps Both pumps are designed for parallel operation. In normal mode, the top layer of water in the tank is used first, which is hotter.

We have already mentioned the three-way valve.

The heated water is used for household needs as needed. General requirements In order for the piping system of a single-circuit boiler with a boiler to work normally, without interruptions and emergency situations, the following requirements must be met: At the outlet of the boiler, an expansion tank with a volume of at least 10 percent of the boiler is installed.

The boiler is connected to an indirect heating boiler as follows: A three-way valve is installed near the circulation pump. Internal coating of the tank In cheap boilers, the internal coating of the tank is made of enamel or glass ceramics.

Of stainless steel. Many single-circuit gas boilers have a summer operating mode, which will allow you not to work on the heating system, but to provide heating for the indirect heating boiler. In both cases there are horizontal and vertical models. In this case, the boiler electronics know about the temperature of the water in the DHW system, and it decides where to direct its power: to heat water in the BKN or for heating.

The boiler is designed in such a way that when water is consumed, it is filled with a new portion, and the process continues. The water in the tank can be heated using connected solar heating systems or heat pumps. Remember to set the thermostat correctly!

How to avoid these shortcomings? They differ in their degree of complexity, so you have to choose the best option. That is, in this case, it is desirable to install wall-mounted models. Ideally, the bottom of the indirect water heater is located above the boiler and radiators. Indirect heating boiler device, operating principle and connection diagrams

Connection diagrams and features

The indirect connection can be carried out according to two basic schemes:

- In the first scheme, the water supply circuit will be a priority for the system;

- In the second scheme, water is heated in accordance with the operating mode of the heating equipment.

The first scheme of a heating system with an indirect heating boiler directs the entire volume of coolant to warm up the tank, which ensures very fast heating of water. When the water temperature reaches a set point, the coolant is redirected to the heating circuit.

The second scheme for piping an indirect heating boiler does not distinguish between heating and water supply, therefore only a certain part of the coolant is given to the latter. Accordingly, no drop in heat transfer from the radiators is observed, but the water in the boiler heats up much more slowly than in the previous case.

When installing an indirect type water heater, it would be better to give preference to the first scheme - it ensures an uninterrupted supply of hot water in the required volume. In this case, the heating efficiency will practically not deteriorate - to maintain the temperature regime, the coolant is removed from the heating circuit for about 5 minutes, and it will take about half an hour to fully heat the entire tank.

Of course, these figures are very approximate - the heating speed directly depends on the power of the boiler and the volume of the tank. One thing is for sure - if the power of the heating equipment exceeds the required level by at least a quarter, then it will take very little time to heat the water, and these costs will not affect the heating efficiency. In any case, before connecting the indirect heating tank to the boiler, you need to think through all aspects and calculate the efficiency of the future system.

Boiler piping rules

There are a number of general rules that must be followed when installing indirect heating boilers:

- So that all devices connected to the hot water supply can function normally, an expansion tank is supplied to the boiler output channel, the volume of which is equal to 10% of the total volume of the tank. The installed tank will compensate for thermal expansion in the plumbing system.

- Each branch of the system must be equipped with a ball valve, which will allow, if necessary, to turn off any device without turning off the entire water supply circuit.

- It is strongly recommended to equip supply pipes with check valves. These elements prevent water from flowing back into the boiler and thus ensure its safe use.

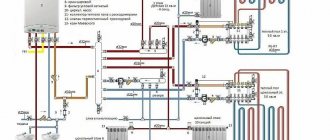

Connecting the hydraulic accumulator

Let's consider connecting a boiler according to a hot water supply scheme - how a wall-mounted gas boiler connected to a boiler heats the heat exchanger. Cold water, rising through the pipe, passes through a coarse filter and then goes along the wall, straight to the boiler. Before connecting the cold water pipe to the boiler, it is necessary to install a ball valve with a detachable connection, which should be directed towards the tank. Then you should install a safety check valve, the so-called two in one. After this, install a tee to connect the hydraulic accumulator (expansion tank), and only then connect the cold water pipe to the boiler.

When connecting cold water, you need to follow exactly the above sequence:

- ball valve;

- safety check valve;

- expansion tank;

- connection to the boiler.

It is advisable to do such piping exactly at the entrance, that is, next to the boiler. A safety check valve for a boiler, as a rule, comes complete with a water heating device. If it is not included in the kit or is lost, you must purchase it. You can buy a safety check valve in a ready-made version or separately, that is, a separate safety valve and a separate check valve and connect them together. Cold water after the ball valve must pass through the non-return valve, and then through the safety valve and go to the expanded tank.

Example of a safety valve for a boiler

Before you buy a safety check valve, you need to look at the boiler’s data sheet at what pressure it should operate. Thus, we supplied cold water to the boiler, since we tied everything up correctly. At the hot water outlet, we just need to install a ball valve with a detachable connection, which must be installed between the tap and the boiler. If necessary, an expansion tank for the boiler can be installed and at the hot water outlet, for this purpose, a tee is installed between the tap and the boiler and the expansion tank is connected. Tanks can be universal, for hot or cold water supply, or only for hot water supply. The main thing is that the water temperature is working - up to +70 degrees.

Expansion tanks used for heating are not suitable for hot water supply. Expansion tanks for hot water systems are selected depending on the capacity of the boiler. As a rule, no less than 10% of the total volume.

It is recommended to select hydraulic accumulators with a little reserve:

- for 150 liters – 18 liter tank;

- for 200 liters - 25 liter tank.

Connecting the boiler to a boiler with forced circulation of liquid

If a circulation pump is installed at the system supply, and there is a place near the boiler to install a boiler, then the best option would be to organize a separate circuit coming from the heating boiler. As a rule, such a heating scheme with an indirect heating boiler is used for wall-mounted boilers - in this case, a parallel connection of the water heater and the heating circuit is obtained.

Behind the circulation pump, you need to install a three-way valve for an indirect heating boiler, to which a temperature sensor installed on the tank is connected. The output of the three-way valve is connected to the boiler pipe so that the circuit can be connected to the heating. A tee is cut into the return pipe in the area before the boiler entrance, designed to draw water from the heat exchanger.

The workflow with this scheme looks like this:

- When the three-way valve receives data that the water temperature has dropped below the required level, the entire coolant is redirected to the boiler;

- The water in the boiler is heated by the coolant that gets into it;

- When the water temperature reaches a predetermined upper level, the three-way valve switches again and the coolant again enters the heating system.

Types of thermostats

Of the many types of thermostats, the three most common are:

- core. The oldest among all thermostats presented to the buyer today. It is a tube that, when heated, expands and puts pressure on the switch, and when cooled, it contracts and turns off the heater. This type has a significant drawback. To maintain a constant water level in the boiler, cold water is constantly supplied to it, replacing the hot water that is drained. The thermostat is located too close to the place through which water enters the tank, because of this it is constantly cooled, as a result of which there is constant heating, and the device works almost without stopping;

- capillary thermostat. A thin tube with liquid extends from the regulator, which changes the structure when the water is heated, due to which the automatic shutdown was triggered (the liquid in the capsule expands and presses on the membrane, which opens the contacts). Accordingly, the reverse process occurred when the water was cooled, giving a command to turn on the heater;

- electronic. Another modern type of protective thermostat, along with the capillary one. For better functioning, this type of thermostat interacts with a safety valve (relay), which allows you to turn off the system when the tank is empty. From a security point of view, this is definitely the best option.

Scheme with two circulation pumps

If the system is already equipped with a circulation pump, then the boiler piping circuit may include another pump, which will be located exactly on the pipeline on which the tank is located. The location of the pump relative to the boiler itself does not matter - it can be installed both on the supply and on the return.

There is no three-way valve in this diagram - the indirect heating boiler is connected using tees. To regulate the supply of coolant to the boiler, pumps are used, the activity of which is controlled by a temperature sensor - at low temperatures, the circulation pump for the indirect heating boiler starts, and after heating, the second pump begins to operate, ensuring the circulation of liquid in the heating system.

Connecting the boiler to a non-volatile boiler

When used with non-volatile heating equipment, the boiler must be provided with priority supply of coolant. The easiest way to achieve this goal is to install the tank above the level of the radiators - which is why wall-mounted models are usually used in such situations. The optimal location of a wall-mounted boiler assumes that its lower part is located at least slightly above the level of the boiler and heating devices.

Of course, such a water heater piping can also work with floor-standing devices, but heating of the water will be slow and incomplete. At the bottom of the tank, the water will not be able to warm up completely (its temperature will be at the same level as the temperature of the liquid in the return pipeline), so the total volume of hot water will be reduced.

Coolant circulation in non-volatile systems occurs naturally. To increase the efficiency of the system, you can embed a circulation pump into it, and if electricity is available, the water will be constantly heated. If desired, you can do without a pump - for normal supply of coolant to the water heater, the supply pipes to it must have an increased diameter compared to the heating circuit pipes.

A thermostatic head equipped with a sensor is installed in the section of the heating pipeline behind the branch. This thermostat allows you to set the desired temperature. The supply of coolant is regulated by a thermostat, which opens and closes depending on the temperature of the water in the tank.

Storage water heaters

What does a storage boiler consist of?

- the heater body itself (made of metal, plastic, or a combination);

- thermal insulation (due to which heated water remains warm for a long time);

- a water container covered with waterproof material - enamel, stainless steel, etc.;

- magnesium anode, which protects the tank from corrosion (if the anode is replaced in a timely manner, the tank will last much longer);

- heating element, abbreviated as heating element (directly that part of the boiler that heats up; for inexperienced buyers, it can be noted that in appearance it resembles the spiral of a boiler);

- thermostat (responsible for controlling the water heating temperature);

- safety valve (protects against excess pressure inside the tank, releasing air if there is excess).

Boiler temperature sensor for gas boiler Clas System

The thermostat in a water heater is one of the most important components, since it not only controls the heating and cooling of water, but is also responsible for safety when using boilers, turning off the thermostat if excessive steam formation occurs when the water in the boiler overheats.

In many sources it is called not just a “thermostat”, but a protective thermostat, and it fully lives up to its name, helping to regulate temperature and pressure, which allows you to avoid many unpleasant or even dangerous consequences.

Scheme with coolant recirculation

If there are additional consumers in the system (for example, a device for drying towels), you need to arrange it so that they all receive hot water. For this, a recirculation loop is used, in which water is constantly circulated throughout the entire circuit by a pump. Connecting an indirect heating boiler with recirculation has an important advantage, which is that heated water constantly flows from the tap, and no time is wasted on cold water draining.

The disadvantage is that when the coolant is recirculated, the cost of heating the water in the boiler increases. The thing is that the liquid constantly circulates around the ring and cools, so the boiler spends much more resources on constantly heating it. In addition, the temperature reduction is enhanced by mixing different layers of liquid.

Arranging a recirculation system can be done in several ways. The simplest of them is to choose a water heater that has a built-in recirculation circuit, implemented in the form of additional pipes. Of course, an indirect heating boiler with recirculation is much more expensive than conventional models. Another option is to combine all consumers into one circuit using tees.

Conclusion

The connection of a single-circuit boiler with an indirect heating boiler is carried out according to different schemes, each of which allows you to solve a certain number of problems. In order for the hot water supply to work efficiently and without interruptions, you need to think in advance about its design features and nuances that may arise during operation.

Checking the Thermostat

Taras Kalenyuk

auto RU

Even the best quality water heaters sometimes break down. If this happens before the expiration of the warranty period, you should contact a specialized service center. If the warranty has already expired, it is better to entrust the diagnosis and repair to a professional. But if you have certain skills and the necessary equipment, it is possible to independently diagnose the thermostat. What will you need for this? First, a multimeter (combined electrical measuring instrument).

Before removing the spare part from the water heater, you must:

- completely de-energize it;

- shut off the cold water pipe;

- drain the water from the tank.

Next, you need to disconnect the thermostat sensor and “ring” it using a multimeter. If the circuit is working properly, we proceed to checking the automation. To do this, you need to dip the thermostat sensor in a simple pan of water. We are waiting for heating to the desired temperature and, if the automation is working properly, you will hear a click, and the multimeter will show that a pair of thermostat terminals is open.

If the thermostat still turns out to be faulty, you need to purchase a similar one to replace it. To do this, you must present the technical passport to the seller so that he can select the appropriate model.

We recommend to buy