If in conventional storage water heaters the water temperature increases due to the operation of heating elements, then in boilers heating is carried out by circulating coolant in the system. That is, the liquid is heated in the boiler and supplied through pipes to a coil or other heat exchanger installed in the tank. At the same time, cold water enters the tank from the central line, which is subsequently heated by heat exchange through the walls of the coil. This system will allow you to forget forever about problems with the lack of hot water.

Indirect heating boiler tank size

The tank volume is selected in the same way as when choosing an electric storage boiler. The main factor is the number of active users, i.e. residents in an apartment or house.

For example, if such a boiler is needed only to provide the kitchen with hot water, then the best option would be to use a 30-liter tank. This is quite enough to wash the dishes or wash your face, if necessary.

In order for 1-2 people to take a shower, you need to use a tank with a volume of at least 50 liters, 60-80 liters would be optimal for two people.

If there are more active users, or you want to take a full bath, then you need to select a tank with a volume of 100 to 120 liters. This is enough to take a hot bath.

Instantaneous water heater power

As in the previous paragraph, here too everything is similar to an electric water heater. Initially, you need to find out the capabilities of the electrical network in your house or apartment, and then select the optimal value.

However, in addition to the power of the heater itself, the power of the connected boiler or central heating, which will heat the coolants, also plays a role. The temperature of the coolant in the heating system is also taken into account if a connection to central heating is used.

Electrical connection diagram

The combined version of the tank, equipped with a heating element, must be connected to the house electrical network, taking into account the transition to summer mode, in which the main coil will no longer receive heat from the boiler. We suggest using a universal circuit that includes a pump control module via a thermostat.

The colors of the wires shown in the figure correspond to the generally accepted classification: blue - neutral, brown - phase, yellow-green - ground, and so on

The circuit involves a second safety thermostat, which is activated when the sanitary water overheats. The indicator lamp signals that the heating element is turned on.

Construction type

There are several main types of structures that are in demand:

- Tubular type coil. This variety is further divided into 2 subspecies. One coil is used in standard format boilers, two coils are used in indirect heating boilers connected to boilers or central heating.

- System of connected tanks. This system involves placing tanks inside each other; they are of different diameters, and are usually made of stainless steel. Water is poured into the internal tank, which will need to be heated. Coolant is poured into the external tank, through which heating will occur.

Material

The material used in the manufacture of the tank is of great importance. Currently there are 3 varieties.

Enameled tank

It is very popular due to its availability and low cost.

- May contain silver ions, but they make sense as a disinfecting element only if the design involves the use of coils.

- Otherwise, they will be useless, since the inner surface of the enameled tank will not come into contact with sanitary water, which will be used for washing.

- This material is relatively protected from corrosion, but it can still occur.

Welding seams are the most vulnerable, since they, as a rule, are not treated with a special compound, so the spread of rust often begins from them.

Stainless steel

This option is more reliable compared to the previous one, but it is more expensive and weighs a little more. However, it is also in high demand.

- It is perfectly protected from corrosion, which allows you to completely protect the structure from rust.

- Welding seams, as a rule, are also not processed, as in the previous version, so special attention is required for them.

Titanium coating

The most expensive material used to make a water heater tank. It is much better than stainless steel, stronger and more resistant to high temperatures. Otherwise the characteristics are very similar.

If you decide to use an enameled tank, you should pay attention to the presence of a magnesium anode; it will protect the surface from rust.

Top 7 rating according to KP

Thermex Combi Inox IRP 150 V (RUB 37,650)

Thermex Combi Inox IRP 150 V. Photo: market.yandex

The Thermex Combi Inox series of boilers (in addition to this unit with a volume of 150 liters, but also includes models with a 200 and 280-liter tank) attracts the attention of buyers for several reasons. First of all, this is a combined heating method - the ability to work from an indirect heat exchanger (power 24 kW) and from a heating element (maximum electrical power 6 kW). The internal tank and coil are made of stainless steel.

This model has the usual cylindrical shape and a white body. Mounted on the floor, without the possibility of wall mounting. The water connection is made on the side.

The maximum permissible operating pressure is up to 7 atmospheres. It is also worth noting that the control type of this device is mechanical, unlike many competitors. It differs from electronics in its simplicity and reliability.

Combined heating method, adjustable electric heater power - 2, 4 and 6 kW, safety valve, thermostat, warranty period for the internal tank - 6 years

General warranty only 1 year, high cost

show more

Drazice OKC 125 NTR (RUB 23,100)

Drazice OKC 125 NTR. Photo: market.yandex

Reliable and unpretentious, this representative of the Czech manufacturer is able to solve your problems with the lack of hot water, which, unfortunately, often arises in many cities. The tank capacity is 113 liters, which is more than enough for a family of 2-3 people.

This water heater is directly connected to the heating boiler circuit. And thanks to a special system of tubes through which the coolant circulates, you can heat water to a temperature of 80 degrees in just 17 minutes.

Fast heating, relatively low cost, large tank

It operates at a pressure no higher than 6 atm, which makes it necessary to monitor this indicator with centralized heating; installation of an auxiliary heating element is not provided

show more

Protherm FE 200/6 BM (RUB 38,700)

Protherm FE 200/6 BM.

Photo: market.yandex This spacious model with a 184-liter tank is compatible with many types of boilers. A titanium anode will reduce the formation of corrosion stains and scale inside the tank, and the lower location of the tubular heat exchanger will ensure rapid heating of the water. A spacious tank will provide hot water to a family of 4-5 people.

An additional protection system will eliminate the consequences of overheating, and a thermal insulation system using a polyurethane “coat” will keep the water warm for a long time.

Capacious tank, antibacterial coating of the tank, sensor regulating water temperature

Relatively high price, installation of an auxiliary heating element is not provided

show more

Baxi Premier Plus-150 (RUB 41,600)

Baxi Premier Plus-150.

Photo: market.yandex Despite the rather high cost, this device is one of the recognized leaders on the market. To a greater extent, this status is achieved due to the quality and reliability of components and assembly, which are guaranteed by the manufacturer.

The internal tank with a volume of 150 liters is made of stainless steel. The additional heat-insulating layer is made of foamed polyurethane, which allows for maximum reduction of heat loss. And to ensure fast and smooth heating, the device features “coil-in-coil” technology.

Another advantage is the possibility of both wall and floor installation.

Universal installation, fast heating, high quality

Relatively high price

show more

Gorenje GBK 150 ORLNB6 (RUB 22,500)

Gorenje GBK 150 ORLNB6.

Photo: market.yandex This device will delight you with its high efficiency and excellent quality, which are guaranteed by the popular Slovenian brand. In addition, the device also stands out for its wide functionality.

Thus, the equipment uses two “dry” electric heaters of 1000 W each as additional heating sources. A large magnesium anode will help cope with corrosion.

It is worth saying that the system is equipped with frost protection, so the boiler can be installed even in an unheated room. At the same time, the heater is equipped with an electronic control system, making it quite quick and convenient to configure.

The main advantage of this model is the innovative antibacterial system. If there is no heating of more than 65 degrees for 120 minutes, the device will automatically heat the water to reduce the number of microorganisms in it.

Relatively low price, high-quality thermal insulation, anti-freeze system, electronic control, spacious tank

Only a vertical installation option is available; it operates at a pressure no higher than 6 atm, which makes it necessary to monitor this indicator with centralized heating

show more

Gorenje GBK–80 ORRNB6 (RUB 19,650)

Gorenje GBK–80 ORRNB6.

Photo: market.yandex Due to the tank volume of 80 liters, which is less than most analogues, the device is very compact. The tank capacity is enough to provide warm water to a small family of 2-3 people. Moreover, the device has two water points, so it can be used for the kitchen and bathroom at the same time.

The electronic control system will allow you to accurately adjust the required temperature to which heating will occur. In total, the temperature range is from 20 to 75 degrees. For an additional heating system, the equipment design provides two heating elements of a “dry” arrangement.

It is also worth noting that this model is very safe and is protected from corrosion, overheating and switching on without water. In addition, there is a reliable system of antibacterial protection and anti-freeze, which allows you to install the equipment in an unheated room, for example, in a country house.

Relatively low price, safety, electronic control, several water points, compact dimensions, anti-freeze system

Operates at a pressure no higher than 6 atm, which makes it necessary to monitor this indicator with centralized heating, small tank volume

show more

Hajdu AQ IND150FC (RUB 20,690)

Hajdu AQ IND150FC.

Photo: market.yandex This water heater is in demand among buyers due to its affordable price and fairly wide functionality. The device is equipped with several water collection points. In addition, it is possible to install an electric heater with a power of 2 or 3 kW.

The inside of the tank is covered with glass enamel, which protects the steel from corrosion for a long time. The heat exchanger itself is made of ordinary steel with protective enamel. At the same time, thermal insulation made of polyurethane foam and a polymer paint layer on the outer surface allow the water to remain hot for a long time. Among the disadvantages, it can be noted that the device has a heating limit of up to 65 degrees and a small heat exchanger area - 0.81 sq.m.

Relatively low price, high-quality thermal insulation, the ability to install an additional electric heater, several water collection points

Heating limitation 65 degrees, small heat exchanger area

show more

Operating pressure

This parameter can be viewed in the technical documentation of the boiler. As a rule, the pressure can vary from 6 to 11 bar, depending on the type and power.

The dimensions of indirect heating boilers also affect the overall power and operating pressure, but are not the fundamental factor.

- Working pressure is very important if the boiler is installed in an apartment.

- This is due to the fact that domestic central heating sometimes allows voltage surges, which can have a very detrimental effect on the equipment.

- Safety valves, in turn, do not provide 100% protection against such pressure surges.

The best option would be to install a reducer at the inlet, which will control the pressure, preventing pressure drops from affecting the equipment.

- The presence of a heating element will also not be superfluous. The thing is that sometimes the heating can be turned off, in which case the heating boiler will not be able to function.

- In case of heating failure, it is recommended to purchase a combined model, which has an electric or gas modification.

- When the heating is turned off, the boiler will switch to using heating elements.

Connecting the “indirect” with the boiler

First of all, the unit must be installed on the floor or securely attached to a solid wall made of brick or concrete. If the partition is built from porous materials (foam block, aerated concrete), it is better to refrain from wall mounting. When installing on the floor, maintain a distance of 50 cm from the nearest structure - clearance is necessary for servicing the boiler.

Important. Before mounting the wall-mounted horizontal boiler model, carefully read the instructions. Usually the device is hung in such a way that the cold water pipe is at the bottom. If the tank is turned upside down, the coil and heating element will be in the upper zone, which is unacceptable.

Recommended technological distances from the floor boiler to the nearest walls

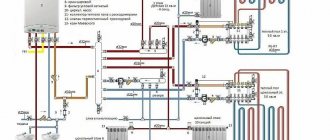

Connecting the boiler to a solid fuel or gas boiler that is not equipped with an electronic control unit is carried out according to the diagram below.

Let us list the main elements of the boiler circuit and indicate their functions:

- an automatic air vent is installed at the top point of the supply line and discharges air bubbles accumulating in the pipeline;

- the circulation pump ensures the flow of coolant through the loading circuit and the coil;

- a thermostat with an immersion sensor stops the pump when the set temperature inside the tank is reached;

- the check valve eliminates the occurrence of stray flow from the main line into the boiler heat exchanger;

- The diagram does not conventionally show cut-off valves with American connections, intended for disconnecting and servicing the device.

When starting the boiler “cold”, it is better to stop the boiler circulation pump until the heat generator warms up

Comment. For normal operation of the loading circuit, a 25-40 pump (pressure - 0.4 Bar) is enough. The element can be installed on the return or supply line - there is no big difference. The installation manual for DRAZICE water heaters provides a piping diagram where the pumping unit is located on the supply side.

Likewise, the heater is connected to more complex systems with multiple boilers and heating circuits. The only condition: the boiler must receive the hottest coolant, so it cuts into the main line first, and is connected directly to the distribution comb of the hydraulic arrow, without a three-way valve. An example is shown in the tying diagram using the primary/secondary ring method.

The general diagram does not show the check valve and boiler thermostat

When it is necessary to connect a tank-in-tank boiler, the manufacturer recommends using an expansion tank and a safety group connected to the coolant outlet. Rationale: when expanding the internal hot water tank, the volume of the water jacket decreases, the liquid has nowhere to go. The equipment and fittings used are shown in the figure.

When connecting tank-in-tank water heaters, the manufacturer recommends installing an expansion tank on the side of the heating system

The easiest way is to connect an indirect heating boiler to wall-mounted boilers, which have a special fitting. The remaining heat generators, equipped with electronics, are connected to the water heater through a three-way electric changeover valve controlled by the boiler controller. The algorithm is like this:

- When the temperature in the tank decreases, the thermostat signals the boiler control unit.

- The controller gives a command to the three-way valve, which transfers all the coolant to loading the hot water tank. Circulation through the coil is ensured by the built-in boiler pump.

- Upon reaching the set temperature, the electronics receives a signal from the boiler temperature sensor and moves the three-way valve to its original position. The coolant goes back into the heating network.

An important nuance. The above-described scheme is also used when connecting the storage device to a double-circuit gas boiler. It is unacceptable to connect the “indirect” to the hot water supply line of the heat generator.

The connection of the solar collector to the second boiler coil is shown in the following diagram. The solar system is a complete closed circuit with its own expansion tank, pump and safety group. Here you cannot do without a separate unit that controls the operation of the collector using signals from two temperature sensors.

Heating of water from the solar collector must be controlled by a separate electronic unit

Benefits and recommendations

The pros and cons of indirect heating boilers vary from person to person. However, it is worth noting the general reduction in the cost of hot water supply after installing such a boiler.

However, it requires the installation of an additional reducer to prevent pressure surges in the heating system.

It is recommended to foresee this possibility in advance and take it into account at the initial stage.

About manufacturers

Boilers are a fairly narrow-profile product, known in detail only to professionals in their field. We offer you a table with a brief description of well-known companies whose products deserve attention due to their high quality.

Table No. 1. Manufacturers

| Manufacturer | Description |

| Gorenje | A world-famous company from Slovenia. Founded in 1950. Specialization – household appliances. Almost all of its products are export-oriented. |

| Protherm | A company whose main office is in the Czech Republic. Founded in 1992. Since the same year, it has been producing water heating and heating equipment. |

| De Dietrich | French group of companies. Founded in 1864. Mainly produces equipment for heating systems and more. |

| Vaillant | It is Germany's leading manufacturer of heating equipment. Formed in 1874. The company is known for the fact that today people assemble robots and instruments. |

| Drazice | A company from the Czech Republic, which is known for its reliable water heaters. Founded in 1956. Its products meet all the standards and requirements of EU countries. |

| Baxi | An Italian company that has been making high-quality heating and water heating equipment for more than half a century. The company was formed in 1866. |

The best manufacturers offer only high-quality devices