Combined boilers with wood and electricity are standard solid fuel boilers with a built-in heating element that heats up the coolant after the fuel has burned out or in autonomous mode. The power of the heating element unit in such boilers is small, usually 3-6 kW, which allows the use of electricity as the main energy only in small private houses with an area of 40-60 m2.

In terms of cost, models with a built-in heating element unit are practically no different from classic solid fuel boilers, they have only a slightly modified design, they are still reliable, the heating elements themselves last 5-7 years or more, and their replacement does not require special skills or serious financial costs.

What are wood-electricity combination boilers?

Mixed-type boilers operating on solid fuel and electricity are always a floor-mounted design, the dimensions corresponding to conventional solid fuel models. Without the use of heating elements (tubular electric heaters), these are ordinary solid fuel boilers that burn not only wood, but also coal, pellets, peat, coke, and anthracite. Piping, installation and connection of universal boilers is carried out similarly to single-fuel boilers.

Cooper Praktik model.

Why are they needed and how are they used?

Heating with electricity is the most expensive. However, if you use it as a backup heat source in a solid fuel boiler, you can get more benefits than might seem at first glance:

- maintaining a comfortable temperature level after burning out solid fuel for a longer period, for example, until the morning if the load burned out at midnight;

- smoothing out the cyclicity of solid fuel boilers, when at the peak of combustion excessive heat output is achieved, and between loads it is greatly reduced. As a result, it is difficult to maintain a constant comfortable temperature level in the house;

- the possibility of faster heating of the coolant while simultaneously using firewood and electricity;

- serious savings in boiler room space, since the installation of two separate single-fuel boilers requires at least 6 m2 of free space.

Unlike gas-wood models, solid fuel and electric boilers are more justified and practically do not differ in cost from conventional solid fuel analogues.

However, if there are financial opportunities, and the space in the boiler room is not limited, we recommend installing two separate boilers, which can be connected in parallel (if the system is with natural circulation) or in series (if a closed heating system with forced circulation of coolant is planned). There are several reasons for this:

- the functionality of a separate electric boiler is much higher, especially when using a room thermostat;

- the block of heating elements reduces the volume of the combustion chamber by an average of 5-15 liters, which affects the burning time of one load;

- The efficiency of heating elements when operating after burning out the load decreases by several percent (from the standard 99%) due to the presence of constant draft in the firebox. In addition, the water jacket in which tubular electric heaters are placed is usually not separated by a layer of thermal insulation, which adds heat loss through the heat exchanger (when the heating unit of even budget electric boilers has a layer of thermal insulation).

Boilers with a burning duration of one load of fuel up to 7 days

Design and principle of operation

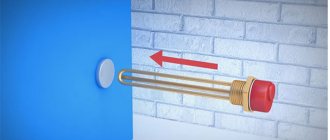

Boilers with a built-in heating element have exactly the same design as their classic solid fuel counterparts, with the exception of the space allocated in the water jacket for a block of heating elements, which often means a reduction in the volume of the combustion chamber. The block of tubular electric heaters is removable, the heating part is placed directly in the heat exchanger, and the contacts are brought out through a hole in the wall of the boiler body.

Even 6 kW units operate from a single-phase power supply and are controlled from the boiler, automatically or using a separate control panel, as in the Zota and Teplodar Kupper models.

The operating algorithm is simple:

- When fired with wood or coal, the boiler works like any other solid fuel stove. The draft and temperature levels are maintained by a mechanical thermostat.

- After combustion of the fuel load, the temperature of the coolant drops and, when a critical point is reached, the temperature sensor sends a signal to the heating element block.

- If, while heating the heating elements, a new portion of solid fuel is loaded, the temperature of the coolant will rise and the heating elements will turn off.

This is what a ready-made replacement kit looks like (PU, heating element and wiring) for Zota boilers.

How to achieve joint operation of electric and solid fuel units

*

If you are faced with a choice of which individual heating option to give preference to - a solid fuel boiler, an autonomous electric unit or a combination of these two devices, the latter option has advantages. To install the circuit, you will need a connection diagram for both units, similar to a gas-solid fuel heating system. Properly done equipment piping is a guarantee of the efficiency and safety of operation of this equipment.

The proposed video describes in detail how and in what way to connect solid fuel heating devices together with electric heating elements

What you need to pay attention to during installation:

- both devices must have a reasonable power ratio, the coal or wood heating device is the main source of heat, so its power must be twice the power of the electric boiler;

- both units are connected in parallel, which makes the operation of one independent from the other;

- the solid fuel unit is the main one and is connected to the large circuit, while the electric boiler is responsible for the temperature in the small circuit;

- the main heating unit is equipped with a three-way valve;

- to save energy resources and ensure heating safety, installation of a heat accumulator is mandatory;

- each heating device is set to a certain heating temperature - for solid fuel equipment the operating temperature should be 60-70 0C, while on an electric unit the temperature value is set to 40-50 0C, since due to the presence of a heat accumulator, the water for heating will cool more slowly, and the electric boiler will start with a time delay.

Reviews of universal solid fuel boilers with built-in heating elements: advantages and disadvantages

| Advantages | Flaws |

| Only 10-15% higher cost, which makes the purchase of a combined model more profitable from a financial point of view | Quite simple functionality, lack of advanced automation |

| Partial elimination of the main drawback of TT boilers - the need for constant reloading. According to reviews from owners of even fairly large houses with an area of 150-200 m2, the power of heating elements is enough to maintain a temperature of 17-19°C until the morning. | In universal boilers for wood and electricity, only steel heat exchangers that are susceptible to corrosion are used. There are currently no cast iron models. |

| Saving space in the boiler room | Lower efficiency of heating elements |

| Possibility of using two sources of thermal energy at any time | Typically smaller firebox volume |

| Availability of dual-circuit models | Limited choice of models; foreign manufacturers are almost completely absent from the market |

| Possibility of using electricity for heating only at night at reduced rates (you need an electric meter that differentiates consumption by time zones) | The heating element block has low power and, despite the fact that it can work autonomously, is intended only to maintain temperature, and not to provide full heating |

How to choose a combi boiler

The choice of heating boilers for wood and electricity is limited, since they are all very similar floor-mounted designs with a steel heat exchanger. When choosing, you should pay attention only to:

- Number of circuits . Single-circuit models are used only for heating. Double-circuit systems also heat water in the DHW circuit, the sanitary water of which does not mix with technical water in the heating circuit. Double-circuit models are 10-30% more expensive, but this is still the cheapest way to organize hot water supply.

- Burnt fuel . Typically, such boilers are designed to burn not only wood, but also coal, peat, pellets - this information is always indicated in the product description or operating instructions. However, there are exclusively dual-fuel models (wood-burning with built-in electric heaters) that are not designed to burn coal.

- Operating pressure . Due to the steel heat exchanger, many models are characterized by a maximum permissible operating pressure of only 1 bar. This means that they can only be used in an open heating system with natural circulation, since in closed systems the operating pressure is usually within 1.5-2 bar.

- Efficiency . Despite the fact that this is an efficiency indicator, in this case it can be paid attention only as a last resort, since it very much depends on the quality of the fuel. The 75% declared by the manufacturer can turn into 60 or even 50% when using too damp wood or ash-based, non-calorific coal. However, an excellent indicator is 80% or more, indicating a successful and efficient boiler design.

Minimum required power

For a standard uninsulated or weakly insulated house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2 of area. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 120 m2, the minimum required heating capacity of heating equipment is 120/10 * 1.2 (20% reserve) = 14.4 kW, that is, 15 kW.

If the boiler is double-circuit, it is advisable to add another 10-15% reserve so that heating the water does not affect the heating. If the house is located in the south or north of the country, is well insulated, has high ceilings or a large glass area, correction factors are taken into account, changing the result by 5-30% up or down.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

So which boiler should you choose for your home?

Variety of boilers

The choice of a solid fuel or electric boiler for a home depends, first of all, on the initial conditions.

It is impossible to install a solid fuel heating system if there is no access to a chimney or the ability to store fuel: firewood, coal or pallets. On the other hand, if there is no stable power supply, you should not install an electric boiler.

An important condition when choosing is the availability of the necessary space for installing the boiler, the required power and the method of its installation. Don’t forget about the energy saving factor when choosing a specific model.

Each of the presented options has its pros and cons, but the right choice can only be made based on each individual situation.

The best known manufacturers and models: characteristics and prices

Teplodar Cooper Praktik 14

One of the best wood-electricity combination boilers for heating a private home. Known for its reliability, affordable price, efficiency (thanks to the successful inclined design of the firebox), practicality and ease of cleaning. The boiler also has very compact dimensions. The power of the heating elements is always 6 kW.

The model is the best in terms of price-quality ratio, takes prizes in a variety of ratings, according to installation experience and reviews from owners, there have been no serious service complaints for more than 6 years of operation.

The only drawbacks noted by the owners are the permissible operating pressure of only 1 bar and the gas outlet being too hot, which can cause temperature-unresistant materials, for example, those used in chimneys made of sandwich pipes, to melt or burn.

ZOTA Topol M 14

Another famous combination boiler. It is distinguished by its technology: vertical and horizontal doors for loading fuel, a three-pass heat exchanger, a water jacket cools the ash pan and prevents its deformation, the body is insulated with basalt cardboard, which reduces heat loss through the water jacket. In addition to wood and coal, anthracite can be burned, the maximum pressure is 3 bar, the boiler can be used in a closed heating system.

The main disadvantage is the questionable reliability and build quality. Despite the fact that many boilers have been operating without problems for more than 7 years, there are cases of heat exchanger leakage due to corrosion. Therefore, a prerequisite is the use of purified soft water as a coolant + installation of a softening filter in the system.

Karakan 16TPEV 3

Very compact two-circuit model. It has the simplest design possible, a large loading hole and firebox, is not demanding on fuel and is absolutely omnivorous. The permissible pressure is 3 bar, which allows the boiler to be used in closed systems. The top of the boiler is the cooking surface. There have been no service complaints over more than 5 years of operation.

EVAN WARMOS TT-18

Unpretentious to fuel, but not the most efficient combi boiler. You can burn sawdust, any waste fuel and traditional types of fuel without any problems. It also features a spacious combustion chamber: the burning duration on one load of wood is up to 8 hours, and on coal – up to 15. Despite the simple design, a layer of thermal insulation is provided under the body. There is a standard thermostat that controls the heating element, but the heater power is only 2 kW.

The disadvantages are mediocre quality, reliability and a rather high price for such a simple design.

Nuances of installation and connection

When connecting heating equipment with heating elements, first of all it is necessary to provide a connection point for the electrical network. The installation of this type of device must involve a professional electrician who can correctly calculate the required wire cross-section and select the appropriate circuit breaker. Otherwise, the connection of solid fuel units with electric heaters completely copies the connection diagram of conventional boilers.

Considering that there is water in the heating system, it is necessary to provide grounding or install an RCD (residual current device).

Fire safety requirements

A solid fuel boiler can only be considered correctly installed and providing the required level of safety if it is installed in accordance with Fire Safety Standards (FSN) and Building Codes and Regulations (SNiP). This can be done with truly high quality by specialist installers with engineering knowledge and many years of experience. Long-burning pyrolysis boiler you will find the answer in the link.