Features of operation

Each model is accompanied by instructions in which the user can familiarize themselves with the rules for operating the heater, its connection diagram, design features, settings and adjustments.

The system is filled gradually, at a rate of no more than 8 l/min. The water is fresh. Filling is continued until liquid appears in the overflow tube of the expansion tank.

Description of the ignition process:

- ventilate the combustion chamber for 5–10 minutes, the main valve must be closed;

- checking traction by bringing a paper strip closer to the viewing window;

- opening the air supply gate and igniting the flame;

- closing the door;

- temperature control by coil valve.

Installation and strapping

The installation of boilers should be carried out by specialists, but even users benefit from knowing the installation rules. If the piping is carried out according to the gravity scheme, the heater is placed lower than the return pipes - this improves the movement of the coolant. The chimney is located inside the structure.

If the chimney passes through unheated rooms, it must be insulated.

Connecting additional equipment

All products are easy to use, but it would be a good idea to equip the device with a thermostat - this device will make the equipment operate as efficiently as possible. You can also purchase an additional coil in advance in case of breakdown. As standard, the heaters are equipped with an adjustable front damper.

Installation and connection to heat supply and hot water systems

There are practically no special features during installation. The boiler must only be installed on the floor. The base must be durable and non-flammable. This is especially true in cases where the boilers will operate on solid fuel. The size of the pre-furnace non-combustible sheet must be at least 0.5 m². It can be made of steel or simply have a concrete base over a larger area than the boiler itself.

The heating system is connected using threaded connections. For more efficient use of the boiler, you can install a circulation pump on the return pipeline through a bypass. With a closed heating system, to ensure safe and trouble-free operation, install a safety group on the supply pipeline.

The hot water supply circuit is connected as follows. The water supply is also connected from the water supply to the coil at the inlet via a threaded connection, and a pipe is connected from the inlet to the mixer. This hot water supply system has one big disadvantage: it only works when the heating equipment is running. In the warm and summer months, the issue of hot water supply must be resolved in a different way.

Recommendations for installation

Installation of solid fuel units does not require special permits. At the same time, this does not mean that the owner should not monitor the quality of construction work and comply with fire safety standards.

Expert advice:

- The boiler should be installed on a flat concrete base, with a distance of at least 0.5 meters from the wall.

- When installing the boiler on a wooden floor, under it and half a meter in front of its front wall, a sheet of asbestos cardboard or felt soaked in a clay solution is laid on the floor, and steel sheets are laid on top of it.

- For normal fluid circulation in the system, the boiler must be installed in such a way that its lower pipe is at a lower level compared to the outlets from the heating batteries.

- Connections to pipes can be made using both threads and welds.

Don’t forget about the features of installing chimney ducts:

- chimney pipes are double-circuit, with thermal insulation between the structures. Thus, no water vapor is formed;

- for the construction of a chimney, asbestos-cement pipes are often used;

- the diameter of the chimney pipe must be similar to the diameter of the outlet pipe of the boiler equipment;

- the chimney must be installed above the roof level, read the SNiP rules;

- the chimney pipe must be level, without ledges.

Design features and main characteristics

Like most solid fuel models, the Don 16 boiler is a steel device with a water jacket. Its main part is the firebox. Manufacturers deliberately increased its size so that it could hold more fuel, thereby ensuring longer combustion. The fuel chamber is made of a special alloy, which makes it resistant to corrosion.

Photo 1: Steel universal solid fuel boiler Don 16

The second significant part of the Don 16 hot water boiler is the heat exchanger. Its task is to ensure maximum heat removal and transfer it to the coolant. To ensure maximum heat removal, the heat exchanger is designed in such a way that smoke pipes pass through it. For even better heat transfer, turbolizers are installed inside them. The heated coolant is supplied to the heating system through the upper pipe. The water is returned to the solid fuel boiler through the return line pipe. The temperature of the coolant is controlled by a temperature sensor.

Photo 2: Ash pan of the Don 16 boiler of the old modification

In Don 16 double-circuit boilers, a coil is installed inside the heat exchanger around the smoke pipes. Due to its proximity to the heat source, the water in it quickly heats up, uninterruptedly providing the home owner with hot water for sanitary needs. The flow rate is controlled by a valve or mixer.

The front panel contains the screwing and loading doors. They serve for loading and removing ash, as well as cleaning internal surfaces. The draft, and therefore the combustion intensity, is adjusted using the damper handle.

Photo 3: Gas burner for a solid fuel boiler with a water circuit Don 16

In addition to the universal boiler with a power of 16 kW, 30 kW models are also available. The line also includes devices capable of operating only on solid fuel. Here are some technical characteristics provided by the manufacturer on the official website:

| Model | KS-TG-16/20S | KS-TG-30/40S |

| Power (coal/gas), kW | 16/20 | 30/40 |

| Room area (coal/gas), m² | 160/200 | 300/400 |

| Efficiency (coal/gas), % | 86/90 | 86/90 |

| Gas consumption, m³/h | 1,3 | 2,5 |

| Price, rub | 19 800 | 45 000 |

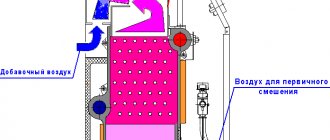

To ensure operation on gas, the screw door and grate are dismantled, and an automatically controlled gas burner is mounted in the lower hole of the front panel. The upper part of the firebox is covered with a firebox sheet close to the front wall.

Don 16 by installing a pellet burner and a hopper with a control unit can easily be converted into a Russian-made pellet heating boiler. Unlike gas equipment, connecting equipment for working with pellets does not require registration. Pellets are much more efficient than firewood and coal and will help you save significantly on heating your country house or cottage.

Advantages and disadvantages ↑

Steel heating boilers "DON" are designed for heating premises with an area of up to 400-500 sq.m.

Consumers appreciate the compliance of the equipment with domestic conditions of use (severe and long frosts, hard water), and the energy independence of its mechanisms. Previously, consumer interest was aroused by the good technical characteristics of the lines; now the stability of demand is supported by such qualities as:

- excellent thermal insulation and high safety (provided by an 8 mm casing);

- an impressive period of independent combustion with low fuel consumption (the presence of a lined chamber makes the Don 16 boiler capable of operating on one load for up to 8 hours);

- durability (due to the case being made of 3 mm steel);

- maintainability (parts can be replaced).

Specifications ↑

These products of the Rostov association are presented in five varieties. Without a pre-installed gas burner, only Don KS-T-16 boilers are available, which take only firewood. The remaining solutions (T-R, TG, TVm, TGVm) are equipped with the circuits necessary for the transition. General properties:

- power (kW): 16;

- Efficiency on solid fuel/gas (%): 75/82;

- gas consumption (m3/h): 2;

- weight (kg): 139-154;

- length/width/height (mm): 700/470/1030;

- heated area (m2): 160.

Only one unit in the line is equipped with a traction regulator, which makes operation easier. In improved solutions, the shortcomings associated with its absence are compensated by the decent adaptability of gas burner systems and the good performance of the DHW circuit. The modest design of the classic version is explained by the desire to ensure ease of use.

Minuses

The main disadvantage of all solid fuel units is the impossibility of fully automating the process. To ensure optimal operation of the heating system, you will need to constantly add logs to the combustion chamber, as well as clean the equipment, removing combustion products.

Devices for servicing boiler equipment (scoop, poker, etc.) are usually not included in the standard kit; they will need to be purchased separately.

It is worth saying that the solid fuel boiler Don takes quite a long time to cool down. This is inconvenient when it is urgent to start repair work. After stopping the unit, you will have to wait a long time until all the parts become cold.

Solid fuel boiler Don KS-T 30 RT

Firewood quality

The best firewood for a solid fuel boiler has always been oak firewood. Due to its high quality, these raw materials belong to the elite class. The cost of oak firewood is high, so it is not affordable for everyone. But such firewood is often indispensable when it comes to the taste of baked bread, pizza or other pastries. Here oak logs are simply irreplaceable.

Let's look at the characteristics of firewood from different types of wood:

- Oak: an elite, expensive variety. Burns powerfully, giving off a huge amount of heat;

- Birch: Best quality/cost ratio;

- Alder: excellent firewood, the house warms up quickly. In addition, the ancestors considered alder firewood to be “medicinal”, since in a house heated with its help, people were less likely to get colds;

- Pine: hot and aromatic firewood that burns well due to its resin content.

Gas boilers Conord: review, design, automation

It's no secret that imported floor-standing gas boilers are of higher quality compared to domestic boilers. This applies to the material used to make the elements, the reliability of the automation, and the assembly of the device. However, the price of imported analogues differs noticeably upward. Our task is to find a Russian-assembled gas boiler with an optimal price-quality ratio.

I propose to disassemble Conord floor-standing gas boilers, reviews of which can increasingly be found on various thematic forums. Let's consider the model range, technical characteristics, device, types of automation (gas burner devices), using the instructions for use.

Model range and description of Conord boilers

Conord floor-standing gas boilers are available with capacities from 8 to 30 kW. They come as single-circuit: KSts-G-8, KSts-G-10, KSts-G-12, KSts-G-16, KSts-G-20, KSts-G-25, KSts-G-30; and double-circuit: KSts-GV-10, KSts-GV-12, KSts-GV-16, KSts-GV-20, KSts-GV-25, KSts-GV-30.

Single-circuit ones can only be used for heating from 30 to 300 m2. Conord double-circuit gas boilers can be used for both water heating and hot water supply (DHW).

Floor-standing gas boilers Conord

There is no point in buying, for example, a double-circuit boiler KSts-GV-12 with a power of 12 kW. It will not give us a good volume of hot water.

Boilers can be used in both open and closed heating systems.

Installation of floor-standing gas boilers Conord

The boiler consists of a steel firebox 3 mm thick, a casing, a water jacket, smoke pipes with turbulators built into them to increase the efficiency of the boiler, a gas burner device (automation), a layer of thermal insulation made of basalt cardboard, and a thermometer to monitor the temperature of the coolant. In double-circuit models, a special coil for the water circuit is installed around the smoke pipes.

The coolant inlet and outlet, as well as the DHW coil, are located on the rear side of the boiler body. The thread diameter of the heating connection pipes for all models of this brand is 2 inches or 50 mm. For DHW circuit 1/2 or 15 mm. The chimney diameter for models with power from 8 to 12 kW is 115 mm, for 16 kW and above - 150 mm.

Conord boiler design

Automation for gas boilers Conord

Three types of automation can be installed on floor-standing boilers of this brand:

— domestic type AGU-T-M

- Italian Euro SIT

In general, the automation, although not particularly sophisticated, is unpretentious. In the event of a breakdown, it is not difficult to find spare parts for it. For example, a bimetallic strip that often fails costs about 50 rubles.

Automation type AGU-T-M

Ignition occurs by pressing the piezoelectric element button or using a match. The coolant temperature is provided by the gas valve and set by the thermostat knob.

Automation Euro SIT

Ignition is carried out by pressing the handle to the right of the thermostat and then turning it to the stop position to operate the boiler in economical mode.

— wide model range — three types of automation — cost-effectiveness — high efficiency — in case of boiler malfunction it’s easy to find spare parts — good thermal insulation

Disadvantages of Conord boilers

— build quality — steel thickness no more than 3 mm — price

The price of Conord boilers starts from 13,000 rubles for the most budget and low-power model. Still, it's a little expensive. For similar money you can already buy, for example, an imported floor-standing gas boiler “Protherm Wolf”, assembled in Slovakia. But it's up to you. Let's watch the video.

The first start-up of the heating system is a crucial moment on which the serviceability of its elements, coherence and uninterrupted operation depend.

How to turn on a gas boiler, fill the radiators with coolant, bleed the air, check everything and not forget anything.

Consider the procedure and rules for putting the heating system into operation.

If the boiler is new and you do not want to lose the possibility of warranty service, you will have to invite service employees. They will make a corresponding note in the passport stating that the first launch was carried out according to all the rules.

Floor-mounted solid fuel boilers Don

The low price of Don floor-standing solid fuel boilers does not mean that these devices are of poor quality, as many of our compatriots are accustomed to thinking. The thing is that the Don boiler is produced in the Russian Federation by Concord. Therefore, the cost of production does not include the costs of delivery from abroad, import taxes and other duties that are imposed on foreign goods.

Model range of boilers Don

Don solid fuel boilers are produced with a power from 11 to 40 kW. All of them are universal and can work on wood, coal, briquettes and pellets. Does not depend on the power grid. They are marked with letters and numbers, for example, KS-T-1R or KS-T-11P, where:

- K – boiler;

- C – steel;

- T – solid fuel;

- numbers – rated thermal power;

- P – draft regulator;

- P – plate.

The efficiency of all units is 80%. A gas heater can be inserted into each boiler, then it can operate on natural or liquefied gas.

One of the most popular models is the Don 16 boiler with a gas burner. The technical characteristics of this unit allow it to be used for operation in open and closed heating systems (see Horizontal heating system: general information and recommendations).

The line also includes solid fuel heaters that can operate in automatic mode. Pellets are used as fuel. To automate the process, a pellet hopper is attached to the boiler. A pellet burner is inserted into the firebox. It operates from the mains, consumes 300 W when igniting, and 70 W/hour to maintain combustion. The burner weighs 18 kg.

From the hopper, pellets are fed through a pipe into the burner using an electric pump. All that is required of the homeowner is to replenish the pellets in the bunker, remove the ash once a week and clean the boiler several times a season.

Design features of solid fuel boilers Don

The Don heating boiler is made of steel. It has a built-in water circuit through which the coolant from the heating system circulates. The liquid is heated in a heat exchanger installed in the upper part of the firebox. The combustion chamber is quite large, it can accommodate logs up to 60 cm long. It is made of a special alloy that is not susceptible to corrosion.

The quality of Raden bimetallic radiators, according to reviews, is at a high level - you can safely buy them.

And domestic Monolit heating batteries are by far the strongest.

Smoke pipes pierce the heat exchanger so that the boiler can take maximum heat from the fuel and transfer it to the water. Thus, it was possible to use even the thermal energy of the exhaust gases. To make the heat removal process even more efficient, turbulators are installed in the smoke pipes.

In double-circuit boilers, the Don coil for the DHW system is located above the heat exchanger for heating. It is installed in such a way that there are smoke pipes inside the spiral. The water in such units heats up faster due to an increase in the heat removal area.

To produce biodiesel, you need plants: corn, rapeseed, etc.

A biofireplace installed at home has many advantages compared to a wood fireplace.

The boiler is equipped with a temperature sensor, thanks to which the degree of heating of the coolant is regulated. This happens automatically by increasing or decreasing the supply of secondary air. There are two doors on the front side of the heater: loading (fuel loading) and screwing (draft and secondary air control, ash removal).

Switching from solid fuel to gas

To convert a Don solid fuel boiler into a gas boiler, you need to purchase a special burner. It is connected to the electrical network and has an automatic system that regulates the degree of gas supply. In order to install the burner, you first need:

- remove the security door;

- dismantle the grates.

There are many benefits to switching to gas. There is no need to constantly add firewood. There is also no need for storage space for solid fuel. Those who use coal have another problem - where to put the sludge? With gas everything is much simpler. Even if you do not have a central gas pipeline, you can connect a cylinder or gas holder to the boiler.

In addition, there is no soot from the gas; it practically does not pollute the heat exchanger and chimney (see How to clean a chimney with your own hands). The temperature of the exhaust gases is also lower, which leads to the formation of condensation. Therefore, the chimney must be properly insulated. On the Internet you can find both positive and negative reviews about Don boilers. Below in the video you can see a review from a person whose boiler leaked after a year of operation.

Advantages

- The thoughtful design of the burner allows you to maintain a stable temperature.

- Works on any type of fuel.

- Quick temperature set, the room heats up to the set values in minutes.

- The body is made of thick, high-quality steel, designed for long-lasting operation of the equipment.

- The small size of the boilers simplifies their installation and transportation.

- Thanks to the vertical installation of doors and chimneys, the process of cleaning the burners and chimney is simplified.

- The presence of built-in automation allows the owner not to worry about maintaining the set temperature. Automation is a guarantee of reliability and safety.

- High efficiency - 90%. A number of modifications are equipped with a draft regulator, which saves up to 30% of natural gas.

- Does not depend on electricity. There is no need to lay a cable or connect to the electrical network. When there is a power outage, they continue to operate stably.

- Convenient to use. Universal and interchangeable. Instead of a boiler that has exhausted its service life, it is easy to install another one without changing the heating system. Easily converted to alternative fuel. You can install a gas burner or a pellet burner.

- Reliable performance. They work uninterruptedly for a long time. Domestic developers took into account all the operational features: pressure in main gas pipelines, water quality, low temperatures in winter and much more. The material of the combustion chambers is carbon steel, resistant to corrosion. The coil is replaced if necessary, and the operation of the equipment is extended.

- Galvanized metal with a polymer coating is used for cladding; it extends the service life of the equipment and gives it an attractive appearance.

Model overview

Let's describe the best models.

KS 16

Of all the models presented by domestic manufacturers, one of the most popular is the “Don” KS 16. Its main advantages: excellent technical characteristics, convenient operation and economical consumption of energy resources.

Having domestic assembly and components, it is ready to work in the most difficult climatic conditions. It is the Russian climate that does not allow many European analogues to compete with domestic developments. This line includes modifications that differ in the number of circuits and a number of smaller differences.

Key technical parameters:

| Heating area, m² | 160 |

| Natural gas consumption, m³/h | 2,0 |

| Thermal power, kW | 16 |

| Efficiency,% | 90 |

| Weight, kg | 139 |

| Dimensions (HxWxD), mm | 1030x470x700 |

| Cost, rub. | 22 000 |

KS-T-11

Steel. Non-volatile. For small objects. Operates on gas or solid fuel - the burner is changed.

Automation installed. Thanks to the Honeywell regulator, energy consumption is reduced by 30%. The firebox material is carbon steel, resistant to corrosion. Adapted to hard water.

| Heating area, m² | 110 |

| Natural gas consumption, m³/h | 2,0 |

| Thermal power, kW | 11 |

| Efficiency,% | 80 |

| Weight, kg | 65 |

| Dimensions (HxWxD), mm | 680x470x580 |

| Cost, rub. | 12 500 |

- Floor installation.

- Steel heat exchanger.

- The exhaust of combustion products is a chimney.

"Don Eco"

An economical version, the main difference of which is its compactness. The small device contains reliable Italian automation and an efficient heat exchanger. It features stable burner operation and high heat transfer.

The boilers are designed for heating small areas; they can be used with a flow-type water heater (“DON” or “CONORD”). In tandem with a water heater, this model will provide a small home with heat and hot water.

As an example, here are the technical characteristics and design features of the Don Eco KS-G-12S:

| Heating area, m² | 120 |

| Natural gas consumption, m³/h | 1,32 |

| Thermal power, kW | 12 |

| Efficiency,% | 90 |

| Weight, kg | 34,3 |

| Dimensions (HxWxD), mm | 650x230x573 |

| Cost, rub. | 13 500 |

- Heating system pressure (min/max) - 0.1/1.2 bar.

- The coolant is water.

- One circuit.

- Floor-standing version.

- Open firebox.

- Steel heat exchanger.

- Gas removal is through a vertical chimney.

- Body color: white.

- Warranty - 2 years.

DonStail

New gas equipment from DonStail models with increased performance. Powerful heaters with a strict and stylish design. The white color and decorative perforations on the body create a feeling of lightness; the device fits harmoniously into a modern interior.

Thanks to the special design of the heat exchanger and Sit automation and Polidoro burner, these modifications have high efficiency, low energy consumption and are completely safe.

Characteristics of the single-circuit version of DonStail KS-G-12 S:

| Heating area, m² | 120 |

| Natural gas consumption, m³/h | 1,32 |

| Thermal power, kW | 12 |

| Efficiency,% | 92 |

| Weight, kg | 73 |

| Dimensions (HxWxD), mm | 835x343x515 |

| Cost, rub. | 18 000 |

- Floor-standing version.

- Open firebox.

- Steel heat exchanger.

- White color.

- Warranty - 3 years.

- Piezo ignition.

Powerful boilers "Don"

For heating large cottages, industrial and warehouse buildings, high-power devices are used:

- At 40 kW. Efficiency - 76%. Heats a room up to 400 m². Weight - 290 kg. The dimensions are small - 700x850x1430 mm.

- At 50 kW. Consumption 3 m³/h. Provides heat for cottages up to 50 m². Efficiency - 85%. Dimensions - 850x700x1430 mm.

- At 100 kW. The most powerful option is for 1000 m². Efficiency - 87%. Weight - 560 kg. Dimensions - 1280x900x1090 mm. An ideal solution for large country houses and non-residential premises.

Floor-standing gas boilers Conord

The Russian company Conord, whose head office is based in Rostov-on-Don, has been producing heating equipment for about half a century.

An analysis of the development trends of modern heating technology and Russian operating conditions led Conord engineers to a completely different understanding of the tasks of heating equipment.

Unlike Western manufacturers, who rely on increasing functionality and the presence of additional systems, Russian technologists have tried to simplify their gas boilers as much as possible, eliminating all insignificant components and parts from the design.

As a result, a number of floor-standing energy-independent boilers were obtained, optimal for use in Russian conditions. They are reliable and stable, the lack of additional functions has not somewhat deteriorated performance, but, on the contrary, has increased the demand and preference of users.

Conord floor-standing gas boilers do not need to be connected to the power supply. This means that the use of fans or pumps is eliminated.

The combustion chamber of all units is of an open type (atmospheric), circulation of liquids occurs either naturally or using an external circulation pump.

The fundamental difference in design is only the functional features:

- Single-circuit boilers designed for heating.

- Double-circuit, capable of preparing hot water for household needs simultaneously with heating the coolant for the heating system.

In addition, there are differences in the design of the heat exchanger:

- Steel heat exchangers 3mm thick.

- Cast iron components with increased efficiency.

In addition, there are different types of control automation. These are mechanical gas supply and adjustment units.

Exist:

- Italian SIT nodes. In the boiler marking they are designated by the letter S.

- Thermohydraulic elements. They are designated by the letter N.

Recently, American-made components have been installed in some boiler models, which expands the range of boilers. In the marking they are designated by the letter M.

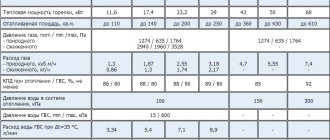

Technical characteristics and dimensions

Please note that the technical characteristics of various models, as well as their prices, will differ depending on the maximum size of the heated area

Although the total cost is significantly influenced by additional components that are purchased optionally

These include draft regulators, fasteners, various angles and tees with special, temperature-resistant insulation, as well as sandwiches of 0.5 and 1 meter. In the same category are replacement coils, which are necessary in case of damage or wear of previously installed ones.

Although the total cost is significantly influenced by additional components that are purchased optionally. These include draft regulators, fasteners, various angles and tees with special, temperature-resistant insulation, as well as sandwiches of 0.5 and 1 meter. In the same category are replacement coils, which are necessary in case of damage or wear of previously installed ones.

The characteristics common to all models, including those equipped with gas burners, can be described as follows:

- universal, since they can use both natural gas and firewood, peat layers or pellets for heating;

- safe and economical because they do not transfer temperature from the combustion chamber to the casing;

- durable, because the thickness of the walls of the combustion chamber is at least four millimeters;

- adapted to hard water and the consequences of its use, this is possible thanks to the removable coil;

- have a long service life, the boiler can work in autonomous mode for up to eight hours in a row (this only applies to options for using solid fuel).

Possible equipment dimensions:

- heating area up to 140 m²: dimensions - 1030 by 430 by 410;

- heating area up to 180 m²: dimensions - 1180 by 430 by 410;

- heating area up to 300 m²: dimensions - 1430 by 650 by 650.

Boiler Don connected and working

Useful tips

Advice! When choosing a boiler, it is better to consult with professionals. At the same time, these people should not only be experienced installers, but also be able to make a thermal energy calculation that allows you to calculate the required power of the equipment as accurately as possible. If this rule is not followed, then there is a high risk of the system freezing, and, consequently, its failure in severe frosts.

Before installing the heating boiler, the instructions must be carefully studied. It is attached to the supplied equipment and contains not only a thorough description of the technical parameters, but also detailed installation instructions. With the right approach to installation, the equipment will serve you for many years without the need for additional repairs.

For additional information, you can always watch a video on our website about the operation of any of the models, although in the photo everything is quite clear and understandable even for a beginner in the field of heating.

For reliable operation of Don boilers, proper installation of the chimney for a solid fuel boiler is very important. The optimal solution may be to choose a Sandwich pipe

It consists of two parts with different diameters, and the entire structure is insulated using absolutely non-flammable mineral wool

Such a chimney will be very inexpensive, will be quite easy to install and will extend the life of the equipment

It consists of two parts with different diameters, and the entire structure is insulated using absolutely non-flammable mineral wool. Such a chimney will be very inexpensive, will be quite easy to install and will extend the life of the equipment.

Diagram of the chimney and ventilation system

How to choose

Thermal power. When choosing it, you need to know not only the area that is supposed to be heated. If a device is selected for heating a private home, you must also take into account what material it is made of and how insulated it is.

In apartments, the location is important - central or corner. In the latter it is always colder, so the power must be chosen with a reserve. The approximate power of the device is determined by the ratio - 1000 W for every 10 square meters of area

And for every cubic meter - 40–60 W. But it is recommended for cold houses and apartments to take boilers with a heating capacity reserve of 30%. Firstly, there will be no problems with heating in the most severe frosts, and secondly, the equipment will not wear out and will last longer

The approximate power of the device is determined by the ratio - 1000 W for every 10 square meters of area. And for every cubic meter - 40–60 W. But it is recommended for cold houses and apartments to take boilers with a heating capacity reserve of 30%. Firstly, there will be no problems with heating in the most severe frosts, and secondly, the equipment will not wear out and will last longer.

Dependence on power grids. This parameter is more important for reliability and stability than for efficiency. If boilers require electricity consumption, for example for ignition, it is insignificant.

Number of circuits. The capabilities and cost of the heater depend on the choice of this parameter. Single-circuit ones are chosen for heating; double-circuit ones, in addition to heating rooms, can heat water for domestic use.

Installation method. Wall or floor. The choice depends on the area of the room. Wall-mounted versions are more compact.

Heat exchanger material - steel or cast iron. Cast iron ones are more reliable, they are not afraid of corrosion.

Type of combustion chamber. It is more convenient with a closed firebox: they are safer, do not waste the internal air of the premises, they are preferred today by owners of houses and apartments that are not equipped with traditional chimneys.

How much do they cost

Equipment from domestic brands is a priori cheaper than imported ones, and products are no exception.

The price of Don boilers depends on the model and its power. An inexpensive single-circuit device KS-T-16, designed to heat 160 m², costs about 17,000 rubles. The cost of a powerful double-circuit device designed to heat 300 m² is 37,000 rubles.

Reviews

KS-TGVm-16: Nikolay V., Dolgoprudny

We bought it for 18,000 rubles two years ago. The price is attractive; they are much cheaper than their Proterm analogues, for example, or Buderus. We use any fuel - gas and solid. On natural gas the power is 20, on solid fuel 16 kW. We heat about two hundred square meters with it, plus it also heats the water. It looks unprepossessing, rustic, but for me the most important thing is that I can always find any components for it.

KSts-G-20S: Georgy T., Velikie Luki

This device has one plus - ease of maintenance. It is easy to understand its operating principle and troubleshoot simple problems. The rest are shortcomings. During normal operation, it consumes one and a half cubic meters of gas per hour, and if it’s minus 25 outside, then only 2.5 cubic meters. They promise 92% efficiency, but for me 5,000 rubles for heating one hundred cubic meters is too much.

Floor-standing boilers from Rostov are in demand among consumers who are willing to sacrifice the technological “bonuses” offered by their European counterparts. Don heaters are adapted to Russian conditions, reliable and affordable.

Range of boilers Don

The assortment range presented by the Don brand is quite wide. To make it easier to choose the appropriate option, you need to familiarize yourself with the nuances of labeling these heating devices. The numbers in the marking indicate the power of the boilers, and the letters mean the following:

K - this letter is in the marking of all models, because it means the name of the device - “boiler”.

C – is the letter designating the material from which the boiler is made – steel.

T - indicates that the equipment is solid fuel, but can be reconstructed by purchasing and installing a gas burner.

G - installed in the case when the gas burner is included in the standard package.

Vm - designation for an additional DHW circuit.

As an example, let’s take the solid fuel boiler Don KS T 16. This is a single-circuit model, which was manufactured specifically for heating with a power of 16 kW. Well suited for a room with an area of 150-160 m².

The solid fuel boiler Don 16 kW can also be double-circuit. 30 kW models are also available. Here are some technical characteristics of these devices.

| Model | KS TG 16/20S | KS TG 30/40S |

| Power (coal/gas), kW | 16/20 | 30/40 |

| Room area (coal/gas), m² | 160/200 | 300/400 |

| Efficiency (coal/gas), % | 86/90 | 86/90 |

| Gas consumption, m³/h | 1,3 | 2,5 |

| Cost, rub. | 19 800 | 45 000 |

Dual-circuit

These are models KS TVM 16/20, TV 31.5/40, TV 20 and others. A number of dual-circuit heaters can be easily converted from gas to coal/wood and vice versa. Designed for heating areas up to 300 m². Simultaneously with heating, they heat water for domestic needs.

The secondary circuit is a copper coil; if necessary, it can be changed, thereby prolonging the operation of the equipment.

A double-circuit boiler has characteristics almost similar to those of a single-circuit boiler. Also made of steel, but more powerful than single circuit versions. 20, 30 and 50 kW options are available. Their weight is 150–200 kg.

Switching from solid fuel to gas

To convert a Don solid fuel boiler into a gas boiler, you need to purchase a special burner. It is connected to the electrical network and has an automatic system that regulates the degree of gas supply. In order to install the burner, you first need:

- remove the security door;

- dismantle the grates.

There are many benefits to switching to gas. There is no need to constantly add firewood. There is also no need for storage space for solid fuel. Those who use coal have another problem - where to put the sludge? With gas everything is much simpler. Even if you do not have a central gas pipeline, you can connect a cylinder or gas holder to the boiler.

In addition, there is no soot from the gas; it practically does not pollute the heat exchanger and chimney (see How to clean a chimney with your own hands). The temperature of the exhaust gases is also lower, which leads to the formation of condensation. Therefore, the chimney must be properly insulated. On the Internet you can find both positive and negative reviews about Don boilers. Below in the video you can see a review from a person whose boiler leaked after a year of operation.

When planning a heating system in a private home, owners often try to find a universal solution that allows them to easily switch from solid fuel to gas. On the Russian market there are models of heating devices capable of solving this problem. One of such devices is the Don 16 solid fuel boiler. In this material we will talk about the features of its design, advantages and disadvantages, and also provide user opinions.

So what is this model? The Don 16 boiler is a steel household solid fuel boiler with a water circuit, designed for heating houses or other small premises and for organizing hot water supply. Wood or coal can be used as fuel, and with minor modifications, pellets or gas. Let's take a closer look at its design and find out what allows it to achieve such versatility.

Operating principle ↑

The functioning scheme is simple. The elements that make up a regular Don 16 boiler are few, they are simple: a firebox with a water jacket, temperature sensors, a pipe system supplemented with turbulators. When burning fuel, the water cavity heats the injected water, convection amplifiers send the liquid into the general circuit through the upper pipe, and it is replaced by cold flows supplied to the lower one. The meter monitors and corrects the temperature.

Although the devices are manufactured on the same base, they have slightly different structures. The difference is in the details. The letters that make up the brand name will help you figure out what advantages they offer in each case. There are nine letter designations: 1). "K" - boiler. 2). "T" - solid fuel. 3). "G" - gas. 4). "M" - modified. 5). “C” - with a steel heat exchanger. 6). “C” - with cast iron. 7). “B” - with a water coil. 8). “P” - with draft regulator. 9). "TG" - universal.