Plastic pipes have long been an excellent alternative to metal products. This popularity is explained by the strength and durability of polymer materials. In addition, polypropylene pipes have a composite structure, which allows the material to withstand high temperatures and pressure (without deformation), not be subject to corrosion, and not react to aggressive components.

In addition, the installation of such pipelines is much simpler: the plastic is easily processed and heat welded. In this article we will look at the key parameters that will be useful to both the home handyman and the professional plumber.

Scope of application of pipes made of polymer material

Considering that polypropylene pipes are able to function in almost any conditions, the products have a wide range of applications. In particular:

- Hot and cold water supply in multi-storey and private buildings.

- Sewerage.

- Installation of a “warm floor” system in the house.

- Disposal of groundwater and wastewater.

- Creation of drainage, irrigation and reclamation systems.

- Ventilation.

- Pneumatic systems.

- Pipelines for transporting chemically active substances.

It should be noted that depending on the application, different types of pipes are used. Subject to operating conditions, these products can last about 50 years without loss of functionality.

Dimensions of metal products

Sewage pipes made of cast iron can be divided into several types based on their functionality:

- S.M.U. These products do not have a detachable connection, that is, both sides will be smooth;

- SME. A bell is installed at one end. The other side of the product is smooth.

The size specified in the marking characterizes the internal diameter. For example, the index DN 100 will mean that the parameter is 100 mm. In this case, the total volume of the product, including the walls, is 110 mm.

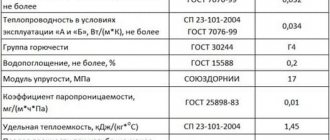

Physico-mechanical characteristics

- Melting point: +149C (GOST 21553).

- Density: 0.9 g/cu.m. cm (GOST 15139).

- Yield strength (tension): from 24 to 25 N/kV. mm (GOST 11262).

- Tensile strength: from 34 to 35 N/kV. mm (GOST 11262).

- Elongation at yield point: 50%.

- Expansion coefficient: 0.15 mm/mmS (GOST 15173).

- Thermal conductivity (at +20C): 0.24 W/mS (DIN 52612).

- Specific heat capacity (+20C): 2 kJ/kgC (GOST 23630).

Advantages of plastic

Any structural element made from the above materials has the following advantages:

- Resistant to a variety of chemicals, for example, solvents or alkalis.

- Strength , allowing the part to be immersed in the ground at a distance of up to 16 m.

- a smooth surface inside , creating an obstacle to the formation of plaque.

- Low weight . With a length of one hundred centimeters, an element with a circumference of 110 mm weighs about 1.5 kg.

Advantages and disadvantages of plastic pipes

Polypropylene has a number of undeniable advantages over metal pipelines. The strengths of the material include the following:

- Long service life . Manufacturers claim that pipes used in cold water supply can last at least 100 years .

- Low weight . Polypropylene is a lightweight material. If we compare products of similar length and diameter made of plastic and metal, the former will be about 9 times .

- Easy installation . A person who does not have special skills and knowledge can handle the installation of such a water supply system.

- Increased level of sound insulation . Pipes in residential buildings do not allow noise to pass through.

- Corrosion resistance . The inner surface of the pipe is processed using a special technology, which eliminates the appearance of solid formations that reduce the throughput of the pipeline.

In addition, one can note high resistance to low temperatures and dynamic loads. Such pipes do not require special maintenance and are sold in an affordable price segment.

The material also has some disadvantages. In particular:

- There remains a high probability of linear expansion, which requires the installation of special compensators .

- Accelerated aging of the material under the influence of direct sunlight .

- Low thermal stability , which implies the mandatory use of insulation.

In addition, wall mounting pipelines are not allowed to sag, so the number of fastening elements increases significantly.

Properties of polypropylene

A white and solid substance produced by the polymerization of propylene, it is one of the most common types of modern plastics.

Polypropylene has a number of useful consumer qualities that affect its wide range of applications. The material successfully combines low density with the ability to withstand heavy loads.

An important property of polypropylene is its resistance to large temperature changes, from – 10 to + 170 degrees.

Plastic has dielectric properties and can be easily processed through various processing methods such as sawing, welding, bending and drilling.

The material can withstand exposure to aggressive chemical environments, acidic liquids and harmful fumes. At the same time, polypropylene itself is an absolutely non-toxic and environmentally friendly type of plastic.

Its use as domestic structures is harmless to people and nature.

Symbols - markings

By marking polypropylene pipes you can learn about the raw materials used for production and the technical features of the material. The symbols given above indicate the ability of pipes to withstand a certain pressure inside the pipeline.

Now let's look at the markings, which indicate some properties of the material. In the construction market, you can find pipes of the following categories:

- PPB are products with high resistance to mechanical damage and water hammer, used in underfloor heating and cold water supply systems.

- PPH are large diameter pipes, which are usually used when installing ventilation systems.

- PPR is a universal product, equally effective in hot and cold water supply.

Regardless of the marking, polypropylene pipes are made of plastic. However, manufacturers usually add active additives to the raw materials that increase the elasticity and heat resistance of the material.

Marking of polypropylene pipes

As has already been said, it is impossible to determine by the outer diameter what pressure the pipe is designed for. Moreover, determining the type of material is also difficult. Therefore, all this information is indicated in the markings that are applied to the pipe. It repeats itself approximately every meter, so it’s simply impossible not to see it.

Marking of polypropylene pipes: let's look at an example

The first place is usually the name of the company or its logo. It is better not to buy unnamed pipes. But there is also a danger of falling for a fake if the company is well-known. You need to study the logo well and buy only if it matches completely. The following information is provided:

- The material from which the pipe is made. For polypropylene it is PP. A reinforcing material may also be specified. If it's aluminum it costs AL.

- Fiberglass - GF.

- Composite material with fiberglass - PPR-GF.

- PP-R100. These are pipes for pipelines with temperatures up to 100°C.

Decoding SDR for polypropylene pipes

So there is complete information that is necessary in order to decide where to use and under what conditions.

| Designation of the service class of PP pipes | Temperature of the transported medium (operating/maximum) in °C | Area of use |

| HV | up to 20 | Only for cold water supply. |

| 1 | 60/80 | For DHW with operating temperature 60°C. |

| 2 | 70/80 | For DHW with an operating temperature of 70°C. |

| 3 | 40/60 | For underfloor heating with coolant temperatures up to 40°C. |

| 4 | 60/70 | Heating and underfloor heating systems with an operating temperature not exceeding 60°C. |

| 5 | 80/90 | Heating and underfloor heating systems with an operating temperature not exceeding 800°C. |

Additionally, we recommend reading the article “How to choose the best polypropylene pipes.”

Types and classification

There are 4 classification groups, which are divided according to operating pressure parameters. It looks like this:

- PN 10 . They are used for transporting liquids at low temperatures – up to +45 degrees.

- PN 16 . Suitable for arranging a gas or liquid transport system, provided that the coolant temperature does not exceed +60 degrees.

- PN 20 . Widely used pipes that can withstand temperatures up to +95 degrees.

- PN 25 . Products for supplying hot water and steam, with coolant temperatures up to +100 degrees.

The numerical designation of each group indicates the pressure value in atmospheres inside the line. Design pressure depending on service life and temperature:

| Temperature (°C) | Service life (years) | Pipe type | |||

| PN 10 | PN 16 | PN 20 | PN 25 | ||

| Permissible excess pressure, kgf/cm2 | |||||

| 20 | 10 | 13,5 | 21,7 | 21,7 | 33,9 |

| 25 | 13,2 | 21,1 | 26,4 | 33,0 | |

| 50 | 12,9 | 20,7 | 25,9 | 32,3 | |

| 30 | 10 | 11,7 | 18,8 | 23,5 | 9,3 |

| 25 | 11,3 | 18,1 | 22,7 | 28,3 | |

| 50 | 11,1 | 17,7 | 22,1 | 27,7 | |

| 40 | 10 | 10,1 | 16,2 | 20,3 | 25,3 |

| 25 | 9,7 | 15,6 | 19,5 | 24,3 | |

| 50 | 9,2 | 14,7 | 18,4 | 23,0 | |

| 50 | 8,7 | 13,9 | 17,3 | 23,5 | 21,7 |

| 25 | 8,0 | 12,8 | 16,0 | 20,0 | |

| 50 | 7,3 | 11,7 | 14,7 | 18,3 | |

| 60 | 10 | 7,2 | 11,5 | 14,4 | 18,0 |

| 25 | 6,1 | 9,8 | 12,3 | 15,3 | |

| 50 | 5,5 | 8,7 | 10,9 | 13,7 | |

| 70 | 10 | 5,3 | 8,5 | 10,7 | 13,3 |

| 25 | 4,5 | 7,3 | 9,1 | 11,9 | |

| 30 | 4,4 | 7,0 | 8,8 | 11,0 | |

| 50 | 4,3 | 6,8 | 8,5 | 10,7 | |

| 80 | 5 | 4,3 | 6,9 | 8,7 | 10,8 |

| 10 | 3,9 | 6,3 | 7,9 | 9,8 | |

| 25 | 3,7 | 5,9 | 7,5 | 9,2 | |

| 95 | 1 | 3,9 | 6,7 | 7,6 | 8,5 |

| 5 | 2,8 | 4,4 | 5,4 | 6,1 | |

By type, products are divided into reinforced and non-reinforced. For the second group, reinforcement with the following materials is allowed:

- Fiberglass.

- Internal reinforcement with perforated foil.

- External - a layer of aluminum.

- Composite: internal layers made of glass or fiberglass.

For the installation of hot water supply or heating systems, only reinforced pipes are used.

System planning

When developing a design for a heating system for a cottage or house, the area of living quarters and the degree of wall insulation are taken into account. The standard heat rate per square meter is 41 kcal. The technical characteristics of the battery indicate the thermal power of one section. Based on these data, the number of radiator sections is calculated.

Additional calculations include:

- Length of polypropylene pipe routing;

- Number of turns and adapters;

- Availability of thermostats and bypasses;

- Installation of vertical and horizontal structures;

- Connection diagram to the boiler room (bottom, side, two-pipe or single-pipe version.

Important! Ignoring calculations at the initial stage can increase the cost of the project in the future. Extra sections of radiators will create discomfort in the apartment, and an insufficient number of them will result in poor heating.

Materials and characteristics

Knowing the diameter is only half the battle, but when you come to the store, you will be faced with a variety of materials. Polypropylene pipes for heating comply with GOST R 52134–2003. They are made from three types of plastic, two of which can be used for hot water supply and heating systems:

- consisting of identical structural units. Their molecular bonds do not withstand heating and, accordingly, are not applicable for systems with high operating temperatures;

- consisting of different structural units. The heterogeneity of bonds between molecules makes them resistant to heat, while the material does not lose its natural elasticity;

- consisting of crystals. They have the most durable and temperature-resistant structure, but at the same time they lose elasticity.

Be sure to choose reinforced products. Aluminum and fiberglass are used as reinforcement materials. It is better to give preference to the latter, since during installation there is no need to remove the reinforcement layer to the depth of the connection of the circuit with couplings and fittings. Aluminum reinforcement is carried out:

- monolithic layer;

- layer with multiple holes.

Reinforcement of polypropylene with perforated aluminum

Both aluminum and fiberglass reinforcement layers are sandwiched between two layers of plastic. Reinforcement is needed only to compensate for the increase in length of the contour when heated. There is no question of strengthening the product, since the plastic is already very durable. Non-reinforced products are not suitable because they have a too high coefficient of linear expansion, which is 0.15 mm/m. For comparison, for reinforced products it is 0.02 mm/m. Polypropylene pipes for heating have standard sizes. They are sold in lengths of four meters.

For clarity, let's carry out the calculation. Let's take one meter of circuit in which water heated to 80 degrees circulates. Multiply the temperature by the coefficient of linear expansion and get the following values:

- for reinforced products – extension by 1.6 mm;

- for non-reinforced products - extension by 12 mm.

The marking also indicates the nominal pressure. Denoted by the Latin letters PN. For example, a product marked PN16 can withstand 16 atmospheres, but this is not the maximum of its capabilities. It can withstand larger short-term increases. Nominal pressure is the indicator at which the service life of polypropylene pipes will be half a century

The calculation was performed using special programs, where the water temperature is set to 20 degrees. This is important; as the temperature increases, the service life will naturally be shorter, since when the plastic heats up, it changes its mechanical characteristics

Water pipes

Polypropylene pipe products are very often used for arranging water supply circuits in private homes or multi-storey buildings. To properly design the system, clearly calculate the passage capabilities of the channels. This will avoid future accidents and ensure reliable functioning of the water supply system.

When performing calculations, take into account the diameter of the products. But this parameter is not key. Remember that its value is directly proportional to cross-country ability. The larger the structure, the higher the criterion considered.

You also need to take other parameters into account. The most important criterion is the friction index of the carrier on the channel surface. It is different for each type of transported material. In addition, to calculate the parameter under consideration, it is necessary to take into account the difference in pressure at the two ends of the water supply. You also need to take into account the number of shaped products used for arranging the structure.

Calculation of throughput capacity can be carried out in a tabular manner. In one calculation option, the key parameter is the temperature of the liquid. When the temperature changes, the media expands, increasing friction against the channel surface.

The table below will guide you through this method.

The most accurate method for determining the throughput of a polypropylene water supply system is performed using Shevelev tables. They contain not only standard values, but also formulas that allow you to calculate the parameter in question most accurately. They can be used to solve any problems related to the determination of hydraulic parameters. Professionals prefer this technique.

To cope with the task using the mentioned plates, you must take into account:

- purpose of the pipeline;

- line length;

- duration of operation of the circuit;

- pipe wall thickness;

- the value of their internal and external diameters.

Assortment of fittings

Companies specializing in the production of propylene pipes usually produce separate modifications of fittings for them. Depending on the connection method, they are either threaded or designed to connect sections of the main line using a press method.

When choosing a particular type of fitting or coupling, the operating conditions of the pipeline should be taken into account. When you need to connect a water meter or storage tank, you need to purchase a detachable threaded element, and if it is a flexible hose, then it is better to use a permanent type connection.

Types of fittings differ in their purpose and are as follows:

- tees - needed for connecting propylene pipes for heating or arranging their branches;

- couplings - are intended to ensure the transition of pipes from one diameter to another, as well as to threaded connections of products and are used to splice straight sections of utility lines;

- angles - necessary for arranging 45 or 90 degree turns in the pipeline from pipes.

Standard Size Charts

Considering that pipes of this type are used almost everywhere, manufacturers produce products in a wide size range. Product sizes vary within the following limits:

- Diameter – from 5 to 400 mm . Small pipes are usually used when laying pneumatic systems, medium pipes are used for private and multi-storey construction, large pipes are used for the improvement of buildings where high throughput of engineering communications is required.

- Length - the standard value is 4 meters , however this is not a standard characteristic and remains at the discretion of the manufacturer.

- Wall thickness – 1.9-15.1 mm .

It should be clarified that polypropylene pipes can be made in the form of a monolayer or multilayer structure. The second option involves reinforcement: a five-layer structure, where there is an aluminum spacer between the layers of plastic. The thickness of the reinforcing layer usually varies between 0.1-0.5 mm .

| Outer diameter, mm | PN10 | PN20 | PN30 | |||

| Inner diameter | Wall thickness | Inner diameter | Wall thickness | Inner diameter | Wall thickness | |

| 16 | 10.6 | 2.7 | ||||

| 20 | 16.2 | 1.9 | 13.2 | 3.4 | 13.2 | 3.4 |

| 25 | 20.4 | 2.3 | 16.6 | 4.2 | 16.6 | 4.2 |

| 32 | 26.0 | 3.0 | 21.2 | 5.4 | 21.2 | 3.0 |

| 40 | 32.6 | 3.7 | 26.6 | 6.7 | 26.6 | 3.7 |

| 50 | 40.8 | 4.6 | 33.2 | 8.4 | 33.2 | 4.6 |

| 63 | 51.4 | 5.8 | 42 | 10.5 | 42 | 5.8 |

| 75 | 61.2 | 6.9 | 50 | 12.5 | 50 | 6.9 |

| 90 | 73.6 | 8.2 | 6 | 15 | ||

| 110 | 90 | 10 | 73.2 | 18.4 | ||

See size tables for water and gas steel pipes. Learn about nominal diameter and how to avoid confusion between inches and mm. Go to article >>>

| Equivalent passage, mm | Outer diameter, mm | ||

| Steel gas pipelines | Steel water pipes | Polymer | |

| 10 | 17 | 16 | 16 |

| 15 | 21.3 | 20 | 20 |

| 20 | 26.8 | 26 | 25 |

| 25 | 33.5 | 32 | 32 |

| 32 | 43.2 | 42 | 40 |

| 40 | 48 | 45 | 50 |

| 50 | 60 | 57 | 63 |

| 65 | 75.5 | 76 | 75 |

| 80 | 88.5 | 89 | 90 |

| 90 | 101.3 | ||

| 100 | 114 | 108 | 110 |

| 125 | 140 | 133 | 125 |

| 150 | 165 | 159 | 160 |

| 160 | 180 | 180 | |

| 200 | 219 | 225 | |

| 225 | 245 | 250 | |

| 250 | 273 | 280 | |

| 300 | 325 | 315 | |

| 400 | 426 | 400 | |

| 500 | 530 | 500 | |

| 600 | 630 | 630 | |

| 800 | 820 | 800 | |

| 1000 | 1020 | 1000 | |

| 1200 | 1220 | 1200 | |

Polypropylene drain elements

To regulate the quality of production, which produces plastic sewer pipes of various sizes, the table TU 4926-002-88742502-00 is used. According to the conditions specified in the document, the diameter of the finished product can be 50, 100 and 150 mm. The wall thickness parameter varies from 3 to 5 mm and depends on the value of the circumference. Such products can be used when installing risers, or for organizing a discharge line from a plumbing fixture.

It may be mentioned that well-known global manufacturing companies use polypropylene in the manufacturing process of industrial pipes. The circumference of such products can reach 1.2 meters.

Some important installation nuances

The installation of plastic pipes is somewhat different from their metal counterparts. In particular, during installation the following conditions must be observed:

- Polypropylene pipes do not bend at right angles; tees and fittings are used here to change the direction of the line.

- Plastic does not collapse under the influence of temperature changes: the pipe increases in length. Therefore, if the length of the pipeline section exceeds 10 meters , temperature compensators must be installed.

- Under the influence of high temperatures, pipes are subject to linear expansion, so rigid fixation of the pipeline inside wall structures is not allowed: thermal gaps must be left.

- For hot water supply, only reinforced products are used, which are less susceptible to linear expansion.

- Slight bending of the pipe is allowed. This can be done by heating the surface with a hair dryer (temperature about 140 degrees ).

It should be noted that storing plastic pipes in open spaces is not recommended. To protect products from direct sunlight, which destroys the structure, canopies must be installed.

Sewage pipe diameter

Sewer pipes are not exposed to prolonged exposure to high temperatures and pressure, and for this reason, the cheapest polymer materials are used in their production - polyethylene, polyvinyl chloride and polypropylene.

Table parameters for the diameters of plastic pipelines for pressure sewerage are given in GOST R 52134-2003, however, for gravity sewerage, which is used in most apartment buildings and private buildings, there are no recommendations in the regulatory document. According to the old GOST 22689.1-89, there are only three standard sizes that determine the diameters of polyethylene pipes - 50, 90 and 110 mm. In 2014, the interstate standard for the CIS countries (GOST 22689-2014) expanded the range of non-pressure sewer pipelines made of polyethylene to 14 standard sizes from 32 to 315 mm.

Non-pressure sewerage pipelines made of PVC or polypropylene are produced on the basis of technical specifications that are developed by the manufacturer itself and agreed upon with customers in contracts for the supply of such products.

Key selection criteria

To buy high-quality pipes that will easily reach the service life declared by the manufacturer, you must follow the selection recommendations:

- Selection of components.

During installation, you will definitely need couplings, fittings, and wiring tees. The ideal option would be combined elements with threaded inserts or metal frames. Such products will provide a high-quality transition between plastic and metal pipes. - Manufacturer.

The products are in consistently high demand all over the world, so plastic pipes are produced by domestic, European and Asian companies. Pipes produced by German, Czech and Russian companies have proven themselves well. Products from Turkish and Chinese manufacturers should be treated with caution: low cost implies low quality.

- Marking.

Here you need to pay attention to the pipe capacity, resistance to water hammer and temperature changes. The best option is to choose a pipe whose characteristics slightly exceed the required values.

It should be noted that the durability of a plastic pipeline is affected not only by the characteristics of the product, but also by the correct installation.

Which pipes are best suited for plumbing?

According to their technical characteristics, all polymer products can be used for laying utility networks. The only difference is the wiring method and the operating temperature of the pipeline.

For hidden wiring, polypropylene products with the highest tightness of connections are most suitable. In second place are metal-plastic pipes with push fittings. On the third - low-pressure polyethylene with welded joints.

All plastic pipes are acceptable for outdoor installation, taking into account diameter, operating pressure and price.

Rating of trusted manufacturers

Among companies engaged in the production of polypropylene pipes, the most popular brands are:

- WAWIN ECOPLASTIK . A Czech company that has managed to win a high rating among builders all over the world. The manufacturer's revolutionary solution is all-plastic FIBER pipes, which have minimal weight, but at the same time show high strength and resistance to linear expansion.

- FV-PLAST . Another Czech company presented on the market with reinforced pipes with perforated aluminum inserts. The products produced have a wide size range and are ideal for installing hot and cold water supplies.

- PRO AQUA . A Russian enterprise engaged in the production of multifunctional polypropylene pipes. The company's products are distinguished by high technical characteristics, while being sold in an affordable price range.

In addition, you can pay attention to the products of such companies: BANNINGER REISKIRCHEN (Germany) and VALTEC (Italy). Plastic pipes of these brands are in the high price segment, but have almost standard quality.

How to choose the right size of polypropylene fittings for your home line

Those who are faced with the purchase of risers for the first time do not know what internal diameter of a polypropylene pipe is required. Selecting all the design elements will not be any problem, since all products have special markings. All technical characteristics that are necessary for the work are indicated. The buyer only has to carefully select all the accessories according to the same parameters.

It is recommended to buy all elements from one manufacturer, then there will be no difficulties. If the manufacturer of pipes and fittings is different, then compatibility can be checked. You just need to try it on, insert the edge of one product into the other, if it fits tightly, then they fit perfectly.

Polypropylene is one of the best materials; it has many advantages. All designs have high strength and durability. They can be used for private cottages, as well as in apartment buildings.

Universal tips for choosing sewer pipes

When determining the minimum diameter of sewer pipes, the requirements of SNiP 2.04.01-85 must be met. The parameter depends on the level of filling and height (pressure) of the drains. Complete filling of the internal diameter of the pipes with waste water corresponds to one, but an indicator of up to 0.6 is considered optimal.

Main types of sewer PVC pipes

After determining the diameter, you need to find out the angle of inclination of the sewer pipes, and it is directly dependent on the size and materials of manufacture. The greater the slope, the higher the sewer flow rate, the less clogged they are, and the more they can serve a larger room. V× (H / D)½ ≥ K – formula for determining the angle of inclination:

- V – speed of movement of sewage waste;

- H – degree of filling of the sewer pipe;

- D – pipe diameter;

- K – internal surface roughness coefficient, for polymers 0.5.

The slope of the sewer depends on the diameter of the pipes

To facilitate the selection of diameters and angles of inclination, there is a special table.

Table 1. Selection of sewer slope based on pipe diameter.

| Node name | Recommended sewer pipe diameter, mm | Minimum slope in millimeters per linear meter |

| Toilet | 100 | 12 |

| Branches from the riser | 75 | 10 |

| Combined drain | 50 | 18 |

| Shower, sink | 40 | 12-15 |

| Bidet, sink | 30 | 12 |

- The riser must have the largest diameter, which will ensure free flow of the maximum volume of sewerage. Despite the fact that it is located vertically, the diameter is at least 100 mm.

- The more turns a sewer system has, the more potential clogs it has. Accordingly, the more revisions need to be provided, it is in turns that blockages most often form.

- It is not recommended to make slopes less than 12 mm per linear meter for all sizes and purposes of sewer pipes.

Correctly chosen slope angle is the key to reliable sewerage operation

Failure to comply with generally accepted rules causes disruption of the functionality of sewer systems. Modern projects provide for a hidden type of installation of sewer pipes, and this creates very great difficulties when it is necessary to carry out repair work.

Practical advice. If possible, it is recommended to replace one 90° turn with two 45° turns. Due to this, the thickness of solid deposits on the inner surface is reduced.

Prices for PVC pipes for sewerage

Sewer pipes

Options

The standard marking for cast iron pipelines is from DN 50 to DN 400. Products that do not have sockets, that is, with smooth sides, have an increased margin of safety. Their length is three meters. SMU pipes can be produced in lengths of 15 cm or more.

The wall thickness of a cast iron pipe is almost identical to plastic products and is 4-5 mm. However, despite similar dimensions in length, wall thickness and diameter, the weight of the metal structure is 10 times greater than the weight of the plastic pipeline. For clarity, a meter of metal product will weigh about 15 kilograms. Accordingly, a plastic pipe of identical dimensions will weigh only 1.5 kilograms.

Current regulatory designations for pipe sizes

Until now, not all users understand the difference between the designations of pipe diameters.

- D is the outer diameter of the pipe. This size is required for the selection of sockets, couplings, angles, threaded connections and other mounting and connecting plumbing fittings. It is this that is indicated on the labeling; it will help you to focus on it when compiling a list of elements of the sewer system.

- d – internal diameter of the pipe. The dimensions of internal automatic and semi-automatic shut-off valves are tied to it, and the speed of fluid flow is calculated. The wall thickness of sewer pipes is determined by the difference between the external and internal diameters. The internal diameter can be calculated using the formula d = D – 2S. S – wall thickness.

- Dу – conditional passage. The value is used mainly by specialists; for ordinary consumers this parameter is not decisive; many have not heard of it at all.

Basic parameters of a sewer pipe

Find out which metal-plastic pipes to choose for water supply, and also familiarize yourself with their types and features in a special article on our website.

Prices for metal-plastic water pipes

Metal-plastic water pipes