SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

Given the rise in energy prices, the issue of energy saving is extremely pressing. That is why a large number of models of heating devices have been developed that are economical in fuel consumption. However, the equipment itself is not enough. A thermostat for a heating boiler (thermostat) will help you spend energy resources most efficiently, allowing you to control and maintain the set air temperature in a heated room.

The thermostat is designed to set the optimal room temperature

Purpose of thermostats for heating boilers

To be able to control the energy consumption of heating equipment, it is equipped with special devices - thermostats. These devices allow efficient use of fuel by shutting off the equipment when the set temperature level is reached. Thermostats are used for electric boilers, gas and solid fuel boilers, as well as convectors, heaters and other heating systems.

The thermostat is capable of responding to temperature changes and turning heating equipment on and off automatically

To achieve economical operation of the heating boiler, the thermostat turns on the equipment when the temperature drops below the set value and turns off when the set value is reached. This method allows you to avoid unnecessary consumption of gas or electricity when, for example, some of the rooms are located on the sunny side and less heat is needed to heat them than for other rooms.

Helpful advice! Even a slight decrease in temperature within 1 degree helps reduce energy consumption by 4-6%.

In addition, using thermostats, you can set the operating mode of the heating system, in which the temperature in the absence of people in the house or at night will be 4-5°C lower. Thanks to this, it is possible to achieve savings in electricity or gas consumption of about 30%. Thus, if your heating equipment does not have such a built-in device, it would be advisable to buy a thermostat for the heating boiler. The temperature regulator will provide a solution to the problem of excessive energy consumption.

Using a thermostat, you can set different heating modes for different times

Types of thermostats for heating boilers

Equipping heating equipment with thermostats allows you to maintain a given temperature climate in the room with an accuracy of 1 to 0.5 degrees. They control the operation of the heating system using various actuators. There are electromechanical and electronic thermostats. The design of a mechanical thermostat for a heating boiler has an on/off key and a rotary button for controlling the temperature regime.

Electronic or programmable thermostats have a more advanced structure, but are simple and easy to use. With their help, you can adjust the daily temperature cycle: in this case, the boiler will automatically switch to the set mode. Such devices can regulate both the entire heating system and individual heating blocks.

There is a classification of devices into wired and remote controlled. For the former, the connection of conductors, as well as external protection from mechanical damage, is important. The quality of the signal supplied from the boiler to the controller, notifying the entry of coolant into the circuit, depends on this. During installation, the question may arise about how to disguise the signal line so that it is invisible.

The simplest type of thermostat is mechanical

In a wireless boiler thermostat, control occurs through the transmission of a radio signal. Such a device has two blocks, one of which is mounted in close proximity to the heating boiler, connecting to the equipment terminals. The second node is located indoors. There is a dedicated radio communication channel between the two blocks. The control unit is equipped with a display and control keyboard.

Depending on the degree of automation, thermostats can be digital or analog. The operation of digital devices is based on the signal of microcircuits, thanks to which the device can record and apply several specified modes. Analog thermostats are controlled manually using a mechanical regulator connected to a rheostat.

What is it needed for?

Even modern gas boilers of domestic and foreign production, as a rule, have the simplest system for regulating the level of heating of the coolant. The user sets the temperature parameters using a mechanical or electronic regulator.

The sensor monitors the heating of the liquid in the heating system and sends signals to turn off or turn on the gas supply. The main feature of such a device is its lack of efficiency, which is explained by the lack of taking into account the air temperature inside the heated room.

Installation work on installing a remote-type room thermostat for a gas boiler will become relevant if it is necessary to ensure the most accurate temperature control. Installing a special sensor indoors can reduce fuel costs by about 16-20%.

Thermostat for a heating boiler (thermostat): which one is better to choose

Before buying a thermostat for a boiler, you need to decide on the type of device. To do this, you need to understand the fundamental difference between the models of mechanical room thermostats and electronic ones. There is an opinion that the latter are difficult to configure and they are unreliable, but this is not the case.

Electronic thermostat is more accurate and has flexible settings

The principle of operation of a mechanical thermostat for a heating boiler

In most cases, mechanical thermostats for heating boilers are used in gas installations. This is due to the fact that gas boiler manufacturers initially produce devices that are compatible specifically with mechanical models of thermostats. The design of a mechanical thermostat has a gas membrane, inside of which there is a special gas.

When the temperature deviates from the norm, the volume of gas inside the membrane changes and the mechanism for closing or opening the power supply system of the heating boiler is activated accordingly. This is a fairly simple way to control the operation of a boiler, when its operation depends on the temperature not of the coolant, but of the air in the heated room.

Using a mechanical model of a thermostat, you can set an acceptable temperature regime by turning the round button with divisions, which is connected to the membrane. Thus, the walls of the membrane approach or move away from the control device: this is how we set the temperature at which the connection or rupture of the contact will occur.

The thermostat allows you to regulate the room temperature with an accuracy of 1 degree

Helpful advice! The simple design of mechanical thermostats for heating boilers allows you to make the device yourself.

Among mechanical devices, Siemens room thermostats have proven themselves well. Models RAA21, RAA31 have a temperature setting range of 8-30°C. Devices with a laconic design are mounted like ordinary switches and do not violate the integrity of the interior line. Easy to install and operate. The approximate price of a room thermostat for a gas boiler is 1,500 rubles.

The advantages of mechanical thermostats include low cost, repairability and resistance to power surges. The disadvantages include the low sensitivity of the device to temperature changes. Inaccuracy may be up to 3°C.

Advantages of electronic wireless thermostats for gas boilers

The use of programmable wireless thermostats for gas boilers makes it possible not only to control the operation of heating devices, but also to do this remotely. Electronic regulation allows you to set different operating modes of the boiler depending not only on temperature, but also on a certain time of day.

A programmable electronic thermostat allows you to set the desired heating mode for a certain period of time

By purchasing a wireless thermostat for a gas boiler with programmable functions, you can count on significant fuel savings. The purchase of a relatively expensive device pays for itself within two heating seasons.

Modern models of thermostats are equipped with the GSM standard, which allows you to transfer information to a mobile phone via SMS messages. Considering the fact that boilers from leading manufacturers support Wi-Fi technology, and their electronic control unit is connected to a thermostat, it is possible to configure the operation of heating equipment via the Internet. Know-how in this area is the development of special applications for smartphones.

A convenient operating system, no need for wires, and automatic control of equipment are important advantages in using a wireless room thermostat for a gas boiler. You can buy devices with additional options, such as joint control of the gas burner unit, adjustment of equipment depending on the outside temperature, system diagnostics and other functions.

New generation thermostats allow you to control the room microclimate through special applications using your phone

Among the disadvantages of programmable room thermostats, one can highlight, perhaps, the possible incompatibility of the latter with boilers, depending on their manufacturer. This problem arose due to the large number of manufacturers of electronic equipment and gas heating equipment.

Helpful advice! Before buying a thermostat for a gas boiler, you need to inquire about the compatibility of the device with the model of gas equipment from a specialist from the selling company.

An excellent example for autonomous heating are the models of room thermostats for the Baxi gas boiler. The devices allow you to set the temperature depending on the time of day and season, and regulate the temperature in different rooms. In addition, they provide an economical operating mode for gas equipment. The approximate price of the thermostat for the Baxi heating boiler model AURATON 2030 RTH is 6,900 rubles.

How does the draft control work?

The main part of the air regulator is a mechanical thermoelement placed in a cylindrical housing. Through a lever and a chain, it regulates the rise of the air damper on the ash pan door.

The device is a sealed flask filled with a heat-sensitive liquid that expands greatly when heated. The flask stands inside the housing, which is screwed into the sleeve of the boiler's water jacket and is in contact with the coolant. How a thermostat with a chain drive works is shown in the diagram:

The operating principle of the automatic draft regulator is based on controlling the flow of air flowing into the firebox under the influence of chimney draft. The algorithm looks like this:

- When solid fuel burns and the coolant heats up, the liquid inside the element expands and acts on the actuator and lever, overcoming the elastic force of the spring.

- The lever weakens the chain, the valve begins to close and reduce the flow area. Less air enters the firebox, and the combustion process slows down.

- The temperature of the water in the boiler tank decreases, the liquid is compressed and the return spring forces the lever to open the damper again through a chain.

- The cycle is repeated until the wood in the firebox is completely burned out, then the spring opens the door as wide as possible.

The draft limiter works on the opposite principle - the higher the water temperature in the boiler tank, the more the damper closes.

The adjustment handle at the end of the thermostat serves to limit the stroke of the lever and, accordingly, the air damper. This sets the maximum coolant temperature.

Reference. In addition to mechanical regulators that do not depend on electricity, there is automation for solid fuel boilers with a controller and a blower fan (or smoke exhauster). The latter supplies air to the firebox at the command of the electronic unit, which is guided by the signals from the temperature sensor. Similar automation kits are installed on all pyrolysis and pellet boilers.

Functions of room thermostats for gas boilers

Before you buy a room thermostat for a gas boiler of one type or another, you should familiarize yourself with its functionality. It should be noted that when choosing between analog and digital models, the latter have a lot of advantages and, accordingly, their price is higher.

Installing a room thermostat for a gas boiler will help reduce fuel costs for heating the room

However, the use of a programmable room thermostat for a heating boiler can significantly reduce the frequency of equipment switching on/off, which has a positive effect on its overall operation.

An extremely important feature of a room thermostat for a boiler is the programming function, which makes it possible to set a comfortable microclimate depending on the time of day, weather conditions and other factors. The available timer allows you to set the necessary parameters, taking into account the days of the week (working, weekends), calendar season and other settings. This is very convenient for those who have a shift work schedule or work part-time.

The main advantages of a programmable room thermostat for a gas boiler:

- remote control of the heating device;

- the “day/night” setting makes it possible to set an individual heating level taking into account a certain time of day;

- ease of control allows you to quickly reconfigure the temperature in the room;

Operating principle of a room thermostat for a gas boiler

- the programming option makes it possible to configure the operation of the equipment taking into account weather changes;

- Due to minimal switching on/off, wear is minimized and the service life of heating equipment is extended;

- significant savings in energy consumption;

- high accuracy and reliability in operation.

Helpful advice! By purchasing a room thermostat for a programmable boiler, you get the opportunity to control heating equipment at any time of the day, regardless of your presence in the house.

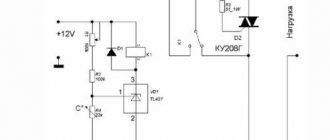

Connection diagram of the thermostat to the heating boiler

After the model is selected, the question arises of how to connect the thermostat to an electric boiler or gas heating unit. The device is connected according to the recommendations specified by the manufacturer in the technical data sheet for the equipment. You just need to find the necessary section in the documentation, which will describe the method of connecting additional devices to the boiler and provide all the required diagrams.

Connection diagram of a room thermostat to a heating boiler

On some models of thermostats, the diagram is shown on the reverse side of the decorative cover. All modern boiler models have connection points for a thermostat, which will control the operation of the heating equipment. The device is fixed using a terminal on the boiler at the appropriate point or using a thermostat cable (included in the kit).

According to professionals, wireless room thermostats should be installed in living rooms away from existing household electrical equipment (TV, refrigerator, lamps, etc.), since proximity to the heat emitted from them can lead to incorrect operation of the device. Some recommendations for installing a wireless thermostat for a gas boiler:

- To correctly measure the room temperature, it is necessary to ensure free access of air to the thermostat;

- It is not recommended to cover the devices with pieces of furniture or heavy curtains;

- the device should be located in the coolest rooms or in living areas where residents spend the most time;

The thermostat must be installed in an open area away from heating devices.

- Avoid exposing the device to direct sunlight;

- Do not install the device near heating radiators or heaters;

- The devices must not be located in the area of drafts.

Helpful advice! The room thermostat sensors for heating are triggered when the room temperature changes by 0.25 degrees.

Heating control using a thermostat for a gas boiler

You can control the operation of heating equipment using manual settings or using a thermostat for a gas heating boiler. I would like to note that using manual settings you can set the temperature of the coolant in the system. This operation of the equipment does not respond in any way to changes in the air temperature in the room, and if this occurs, you will have to manually reconfigure the boiler again.

You can control the operating modes of a gas heating boiler either manually or through a thermostat

The operation of the boiler in the case of manual control is associated with frequent switching on and off of the equipment, as well as the functioning of the circulation pump, regardless of what mode the unit is in: operating or standby. This causes heating equipment to wear out quickly and does not contribute to efficient fuel consumption.

If we are talking about control using a thermostat for a gas boiler, then such a device sets the optimal mode for the unit, taking into account the air temperature in the heated room. If, for example, there is a sudden warming and the room receives additional heat from the sun's rays, the thermostat will instantly respond and give a signal to the control device to turn off the boiler.

Considering that using a thermostat (temperature regulator) for a gas boiler you can set the required temperature in the room, heating will only occur if it decreases. Thus, if the device is set to 20°C, and during the day the room has also warmed up due to solar heat or the operation of cooking appliances, the boiler will be in the standby stage for a long time.

The thermostat helps reduce heating costs by 30-40%

In this case, fuel consumption will be significantly lower. Before you buy a thermostat for a gas heating boiler, you should ask how to properly configure the device.

Setting up a thermostat (temperature controller) for a heating boiler

After you buy a thermostat for your heating boiler and connect it to your heating equipment, you will need to configure it. Each product comes with instructions that outline how to set it up. Having carefully studied it, you can independently set the necessary mode that meets the individual level of comfort of the microclimate.

On the external panel of the device there are buttons and switches through which settings are carried out. The switches allow you to control heating and air conditioning, delay switching on (does not allow the boiler to start operating during a short-term drop in temperature, for example, a draft) and temperature deviation (if you set the fluctuation value to 1°C, switching on or off will be available when the temperature increases or decreases by 0.5 degrees).

To correctly configure the operation of the thermostat for a heating boiler, it is better to contact specialists

Using the buttons, two modes are set: optimal and economical. Thus, during the day the temperature will be provided at an optimal value, at night the temperature will drop to a level sufficient for a pleasant sleep. This mode will allow you to significantly save on energy resources. Various models of thermostats have several set modes, one of which can be selected for use.

Helpful advice! In rooms where children and the elderly are most often present, it is recommended not to lower the temperature below 22°C.

ELECTRICAL WIRING FOR ELECTRIC BOILER

Now that the required power of the boiler for heating the house has been determined and a specific model has been selected, we make electrical wiring for it.

To do this, we will use the data from the article “Diagram for connecting an electric boiler to the electrical network,” which shows in detail all the main diagrams for connecting any electric boilers to electricity, and also provides recommendations for choosing the cable cross-section and circuit breaker.

Our boiler “ZOTA - 12” is three-phase, designed to operate in a network with a voltage of 380 V, this information is reflected in the documentation for the boiler, in addition, the power consumption indirectly indicates this; 220 V boilers are rarely more than 8 kW.

In addition, you can look at the number of installed heating elements (tubular electric heaters) and their connection diagram. 380 V boilers usually have at least three installed.

There are at least two possible schemes for connecting the boiler to a three-phase network. one is used when heating elements are designed for 220 V and connected in a “star”, and the other is used in cases where heating elements of an electric boiler are designed for a voltage of 380 V and connected in a “delta”.

There are several ways to determine which connection diagram is suitable for your boiler. The easiest way is to refer to the diagram in the documentation; for the ZOTA - 12 boiler it is located on the back of the control panel and looks like this:

As you can see, this boiler has a “Star” connection diagram, which means the heating elements are designed for a voltage of 220 V. This is also confirmed by direct inspection of the contacts for connecting wires to the heating elements; they are also prepared for star connection. Their contacts for connecting the neutral conductor are connected by a jumper; phases will be connected to the free contacts one by one, each with its own phase.

It follows that we are suitable for connecting a three-phase electric boiler to electricity with 220 V heating elements, a star connection.

All that remains is to select the required cable cross-section for the electric boiler in terms of power and the rating of the circuit breaker. To do this, look at the table from the article:

It follows that with a route length of up to 50 meters, we will need to install a three-phase electric boiler with a power of 12 kW. five-core cable VVGngLS with a core cross-section of 4 sq. mm. (VVGngLS 5×4 sq.mm.) and install a 25A differential circuit breaker. or a combination of an automatic circuit breaker (AB) designed for 25 amperes - C25 and a residual current device (RCD) for 32A.

Now, having selected an electric boiler and decided on the connection diagram and wiring parameters, you can install it, after which we will continue connecting to electricity.

Connecting the ZOTA electric boiler to the electrical network is described in the next part of the article - HERE!

Thermostats for electric heating boilers: how to choose a device

In places where gas supply is not available, electric boilers are used for space heating. Among the advantages of such equipment are the absence of the need for a chimney, ease of installation, environmental friendliness, silent operation, high performance and being equipped with a control unit for automatic operation.

It is enough to install and configure the thermostat for the heating boiler and it will maintain the temperature automatically

The disadvantages of electric heating include one, but quite significant drawback - significant electricity consumption. This results in high costs for electric heating systems. Installing a thermostat for an electric heating boiler will reduce energy costs by 20 to 30% and set an individual heating mode for each room.

As with other types of heating equipment, it is possible to use an electronic or mechanical room thermostat for electric boilers. The type of device is selected depending on what options are needed in your particular case. Mechanical models are simple and inexpensive, but can be inaccurate. Electronic programmers are accurate, multifunctional and allow the equipment to operate in an economical mode without owner intervention.

Design of a wall thermostat for an electric heating boiler

Before buying a thermostat for an electric boiler, you need to decide on the temperature regime used and take into account the area of the heated room. It is recommended that the purchased thermostat and electric boiler be manufactured by the same manufacturer. Models produced by Baxi, Ariston, Salus Controls ltd, BOSH and others are popular.

Helpful advice! A voltage stabilizer will help ensure uninterrupted operation of the electric boiler and electronic thermostat during possible voltage drops in the network.

Where to buy thermostats for heating boilers

You can buy thermostats for gas boilers, electric and solid fuel heating equipment at specialized points selling heating equipment, as well as on websites and online stores selling elements of heating systems. The catalogs present a huge selection of modern thermostats of various types from leading manufacturers. All devices are accompanied by a manufacturer's warranty.

The modern market offers a huge selection of thermostats, both simple and the latest models.

The product range includes wired and wireless models, mechanical and electronic thermostats for solid fuel boilers, gas, electric and diesel installations, as well as convectors, infrared heaters and underfloor heating systems. All products from the catalog have quality certificates.

You can place an order and buy a thermostat for heating using a convenient search system on the Internet resource. Here you can not only preview the functions and appearance of the devices, but also consult with experts about the compatibility of the devices with a specific type of heating equipment. Experienced managers are ready to share any necessary information regarding thermostats and their functionality.

By purchasing a thermostat through an online store, you will receive a high-quality device and qualified advice from specialists

Another advantage of online purchasing is that it is possible to get acquainted with the cost of devices in different companies and make a comparative review of prices. Having chosen a thermostat, you can get competent advice on its installation, connection and configuration. Some companies offer device installation and setup services. All questions you are interested in can be clarified by phone numbers located in the contact section.