Designing a private house at the very first stages involves choosing a heating system. It consists of many factors that need to be taken into account. Heating a house with a diesel boiler is beneficial, for example, when there is no gas supply on the site and is not even planned in the near future. This heating option turns out to be the most acceptable in many respects. Let's take a closer look.

Diesel boilers for heating

Advantages

Let's start right away by considering the winning aspects (we'll discuss those that aren't so good later) that characterize heating a country house with diesel fuel. This question is relevant for many owners of private housing, because diesel fuel is not cheap; frankly speaking, a lot of it is required for the heating season.

The rating of this equipment in European countries is quite high, thanks to its advantages. Let's list the main ones.

The efficiency of the equipment under discussion is high, reaching 95% under the following conditions:

- correct installation of the boiler;

- furnace installations in accordance with all rules and regulations;

- high-quality insulation of the house;

- installation of double-glazed windows;

- proper storage of fuel reserves;

- using high-quality fuel;

- timely maintenance;

- competent choice of equipment power, manufacturer, model.

The efficiency can reach up to 98% when using a condensing type boiler, but more on that later.

- Wide range of model range, manufacturers, power characteristics, etc.

- Economical consumption of electrical energy.

- Environmental friendliness, which is a fairly current trend in modern European society. When burned, almost no harmful substances or gases are formed.

- High level of safety compared to gas boilers.

- Autonomous, automatic operation that does not require constant human intervention.

- Inertia is not typical for the design of diesel boilers (unlike solid fuel analogues). Productivity decreases immediately.

- Liquid fuel takes up much less storage space than solid fuel (peat, firewood, coal).

- Possibility to use used engine oils, which are cheaper. At the same time, the issue of recycling waste material, which is completely burned in a diesel unit, is resolved. Again, a reference to environmental friendliness.

Expenses

How to calculate diesel fuel consumption for heating during the season and, most importantly, your costs?

- For the center of the country, with good insulation of the house, you can take the approximate need for thermal energy as 1 kW per 10 m2. Yes, such a scheme is greatly simplified and gives rather mediocre accuracy; but an accurate calculation of the heat requirement is still beyond the scope of the article.

- As practice shows, burning a liter of diesel fuel produces about 10 kilowatt-hours of thermal energy. To provide heat to a house of 100 square meters during the peak of cold weather, we need to burn a liter every hour.

- Again, turning to practice - a correctly calculated heating installation ON AVERAGE operates at half the rated power. That is, if calculations showed that we need a 10-kilowatt boiler, then half the time it will operate at full power and half the time it will be idle. Therefore, in practice, the average fuel consumption will be halved and amount to 1/2 liter per hour.

A month is, as you can easily calculate, 720 hours. The instructions for further calculation are quite simple: we multiply hourly consumption by 720 and get 360 liters of diesel fuel per month, which at current prices will result in 32.5*360=11,700 rubles at the rate of 32.5 rubles per liter.

It is easy to judge the immediate prospects from the table of world fuel prices. We are still moving towards a market economy, which implies leveling prices at the general level.

Flaws

Now let’s look at the points that hold back buyers in their desire to purchase a diesel heating device:

- In the first place is the high price of fuel material. This makes using the equipment expensive. It is justified only by the absence of a gas pipeline near the land plot. Connecting gas communications from afar will be an even more expensive undertaking.

- Diesel fuel contains impurities that clog the nozzle and reduce pump performance. In this case, the installed cleaning filters quickly become clogged with paraffin. Without timely maintenance, the boiler will not operate at its full possible capacity with the same amount of fuel.

- The need for specially equipped fuel storage.

- The need for stable power supply. If situations with power outages are expected, it is better to acquire a stabilizer.

- Strong smell and noise require the installation of a separate isolated room or building.

- Thickening of the heating material under the influence of temperatures below +5⁰ C, which forces the pump to work in increased mode.

How to choose a boiler for heating a private house?

If you still choose a diesel unit, its purchase should be based on the following factors:

- Type of burner. The best option is a replaceable burner powered by a diesel or, if necessary, a gas source. If there is a burner heating system, fuel consumption will be significantly reduced.

- Boiler productivity. It is calculated taking into account the volume of the room and the amount of diesel fuel used. As a rule, 1 kWh of energy is consumed per 10 m². For housing with an area of 150 m², it is necessary to purchase a boiler with a capacity of at least 15 kW, and preferably a little more, so that there is a reserve of power for extreme cold.

- Number of circuits. You need to decide how the water will be heated. Boilers are produced with already built-in boilers, or, for example, with a second circuit for an indirect water heater purchased separately.

- Firebox material. The steel body of the firebox is more economical, but not as wear-resistant and durable. The cast iron firebox is designed for 50 years of operation and is resistant to sulfur-containing condensate and corrosion. At the same time, it is susceptible to cracking due to temperature changes.

- Type of fuel material. The best option, of course, is to work on all types of fuel (diesel, waste oil, gas). But this option will be a very expensive purchase.

How does a diesel boiler work for heating a private home?

Heating equipment with diesel fuel is a set of devices: the boiler itself, an automatic control system, a fuel unit.

The boiler consists of:

- Frame. Produced with combustion chambers:

- open type (communicates with the space of the room for air intake, requires installation of fresh air ventilation in the combustion chamber);

- closed type (chamber is insulated, air enters under pressure).

- Electric ignition unit. Generates a spark in the burner to ignite the supplied fuel.

- Burner. Depending on the method of air supply, there are:

- supercharged (air is supplied by a turbine);

- fan (fed by a fan).

Replacement burners are installed in combination boilers and require operation from different types of fuel, for example, diesel, gas.

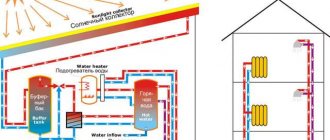

Combination boiler diagram

The automatic control system is divided into blocks:

- working unit (responsible for maintaining a certain temperature of the medium, turning the unit on and off as necessary);

- emergency unit (safety control, emergency stop of equipment during an emergency).

The fuel unit includes:

- fuel tank;

- fuel pump (fuel supply to the burner from the tank);

- chimney (discharges combustion products outside).

Combined water heaters can be useful for a country house >>>

Features of work

Autonomous heating using diesel fuel has an operating principle identical to that of a turbocharged gas system. The air is forced by a fan and mixed with oil. This mixture is sent to the firebox and ignited using electric ignition. During the combustion process, all energy is transferred to the heat exchanger. Identity is present not only in the operating principle, but also in the equipment itself. The modern offer allows you to find dual-fuel installations that can run on both natural gas and diesel fuel. To change it, you only need to replace the burner.

The heating equipment operation process is fully automated. Fuel supply, ignition and fan rotation are carried out automatically using a thermostat.

Diesel boiler operation diagram

Heating equipment for a private house operates according to the following scheme:

- The fuel pump and the air supply system into the combustion chamber are driven.

- The pump pumps fuel from the storage tank into the combustion chamber. Here the fuel material is filtered and heated.

- The nozzle pressure increases to 10-16 atmospheres. This is enough to spray the fuel into a suspension.

- The electric ignition turns on.

- The atomized fuel mixes with the forced air and ignites from an electric spark.

- The thermal energy released during combustion is supplied to the heat exchanger, heating the coolant.

- The coolant circulates through heating appliances, warming the rooms of the house.

- If a condensing boiler is operating, the thermal energy of the released gases is also used for heating.

- The products of fuel combustion are discharged through the chimney outside the house.

Alternatives

Do they exist in cases where there is no main gas nearby, and the electrical power is limited to a relatively small value?

Let's first decide what is important to us in a heating installation.

- Minimum operating costs.

- Maximum autonomy.

- If possible, make a small initial investment.

What can the modern market offer in equipment that satisfies all three conditions?

Top combustion boilers

The Lithuanian company Stropuva began producing them about a decade and a half ago. The concept, however, is so simple that it immediately gained a massive following around the world.

The operating scheme is based on a simple idea: a large volume firebox is filled with wood or coal, after which the fuel is ignited from above and burns ONLY in the top layer. There, a movable and heat-resistant air duct organizes the supply of air for combustion.

A massive metal disk separates the area where the fuel smolders from the upper chamber, where the products of incomplete combustion are burned. The ash is carried away by hot furnace gases.

How long does it take to burn one bookmark with this scheme? A boiler can operate with wood for up to one and a half days, and with coal - up to five. After this, however, the firebox will have to be cleaned and a new portion of fuel loaded.

The great advantage of the scheme is that heating with coal is two to three times cheaper than the same amount of thermal energy extracted from burning diesel fuel. However, we are not talking about complete autonomy.

Top combustion boiler design.

Heat pumps

These devices have already been mentioned. Heating pumps for the home have become widespread in the last 15-20 years. In essence, what we have in front of us is a refrigerator turned inside out, pumping thermal energy from a low-potential (cold) source to a high-potential recipient.

Without going into technical details, we can distinguish three main sources of low-grade heat.

- Geothermal pumps take advantage of the fact that below the freezing point the soil does not cool below 8-12C. Pumps of this type will provide heat to both you and your children; however, both the devices themselves and their installation with well drilling are quite expensive.

- It is cheaper to use water energy. If there is an ice-free river or lake near you, just immerse the heat exchanger in them - and you have an unlimited source of free heat at your disposal.

Let us remind you: approximately 30% of the thermal power will still be taken from the outlet. This electricity, to be precise, will go to power the compressor.

- Finally, for climate zones where the average January temperature is above zero, an excellent solution is to use the heat of the surrounding air. The cheapest solution of this type is a conventional inverter air conditioner, providing 3 kW of thermal power at a cost of 600 watts and a cost of 22 thousand rubles (a typical example is [email protected] CH-S09FTXS).

All heat pumps are completely autonomous. All of them are 3-4 times more economical than solar boilers. Finally, they are the most promising: electricity is rising in price several times slower than fossil fuels.

Expected dynamics of price growth in the coming years.

Types of diesel boilers for heating a private home

Diesel heating equipment differs in several respects. One of them is adjusting the power of the burners. In this case, boilers are:

- Single-stage (burner power is not adjustable, heating temperature is constant).

- Two-stage (burners operate in two positions).

- Modulating (wide range of burner performance adjustment).

In addition to heating the room, a diesel heating boiler for a private home often performs a water heating function. This is very convenient and allows you to significantly save on electricity. According to this indicator, heating systems are divided into:

- Single-circuit. They perform exclusively the function of heating the room.

- Dual-circuit. A double-circuit diesel boiler for heating a country house combines heating of rooms (first circuit) and heating of running water (second circuit). At the same time, there is a decrease in space heating by 20%.

- Double-circuit + built-in water heater. The second circuit is designed to heat water inside the boiler. This way you can significantly reduce your energy costs in winter.

Double circuit diesel boiler

Installation rules

It is best to call specialists to install the equipment, who will make the connection professionally. However, you can install a diesel heating boiler yourself. Its installation does not require special permission, as is the case with gas equipment. But there are separate requirements for installation, as well as arrangement of the combustion room:

- To install the heating boiler, it is necessary to provide a separate building. If this is not possible, at least a separate technical room, for example, in the basement of a house. The main condition for this is that there must be a separate exit to the outside.

- Ceilings in the equipment room are provided at least 2.5 m.

- The volume of a technical room or a separate building should not be less than 15 m².

- Experts strongly recommend installing fuel filters to extend the life of the equipment.

- For boilers with a power of 350 kV, a separate power supply line should be installed from a common circuit breaker.

- It is recommended to install away from doors and windows.

- Cladding of furnace walls with non-combustible finishing materials.

Fuel storage

An important issue when purchasing diesel equipment for heating a home is the method of storing fuel. You can use two options.

The first involves storing flammable liquids inside the boiler room. Moreover, the maximum volume that is allowed for storage is 800 liters. This is not enough; it will not be enough for the entire heating season, especially for regions with a long period of cold weather.

Installation diagram of the fuel tank

Therefore, the second option for storing fuel using an external container (4-10 tons) is still preferable. It is installed on the surface or dug into the ground. It is best to place it at a depth where the soil layer does not freeze, so that the diesel fuel does not thicken due to low ambient temperatures. Additionally, the container is insulated, as is the pipeline for supplying fuel to the combustion chamber.

It is preferable to choose stainless steel fuel containers.

When it is not possible to install gas communications for heating a country house, a diesel boiler can be a good alternative. Heating a private home with diesel fuel costs a lot of money, but it is much more economical than the option using electrical equipment.

Fuel capacity

The choice of a container for storing diesel fuel must be treated as carefully as the choice of a boiler. So what are the requirements for the tank?

Firstly, you need to decide on the storage location of the container. Regardless of whether the tank is located in the boiler room or is located next to the house, one of the main conditions must be met, namely, unimpeded access to the fuel refueling truck. And although the length of the hoses of modern tankers can exceed 30 meters, the experience of the user ar_ca is interesting.

ar_causer

Since the fuel tanker hose is quite heavy and dirty, if you drag it into the house you need to put something on the bends and thresholds. The diameter of the nozzle of the filling pistol is 50 mm and 1400 liters of diesel fuel were poured into me in less than 10 minutes. In case of a fuel spill, you can fill the area with sawdust.

ar_ca also advises paying attention to the following point. After refueling, approximately 50 liters of diesel fuel remain in the tanker hose, and if you do not want to “gift” it to the driver, then the fuel must be drained into a previously stored container