In private homes, the main source of heat is a heating boiler. In order to control the heating process of the equipment, a temperature sensor is needed for the heating boiler. It is on its normal operation that both the comfort throughout the house and the safety of the heating equipment largely depend.

Design and principle of operation

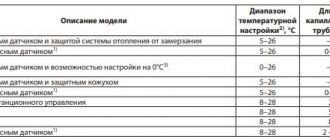

Heating boilers can be supplemented with temperature sensors, both internal and external (remote).

The built-in ones are responsible for adjusting the heating installation depending on the temperature of the liquid inside the heating system.

External ones help to adjust the operation of the heating installation in accordance with the readings of either room or street temperature. The joint use of a pair of such sensors makes it possible to more accurately regulate the operation of the boiler installation, which means there is energy saving when weather conditions change.

The operation of the devices consists of constant measurement of processes:

- resistance;

- pressure;

- thermal expansion.

Which are in direct connection with the temperature of the heating system filler.

Automatic thermostats work according to the program embedded in them, controlling the operation of heating devices.

Mechanical controllers, when exposed to high temperatures, are capable of changing their thermal conductivity by closing/opening the connections of the corresponding valves.

All temperature sensors are placed in a special, small-sized block housing with installation directly into the heating structure.

The results obtained can be transmitted over a wireless communication channel, such as WI-Fi, or transmitted over wires.

Both electric and solid fuel boilers can be controlled by temperature sensors.

The programming function using a thermal relay paired with temperature sensors allows you to automate the procedure for adjusting the heating system. In addition, this makes it possible to significantly reduce heating costs.

In general, the entire structure can be equipped with three temperature monitoring devices:

- Indoor.

- Street.

- For water-based underfloor heating systems.

Rating of top 5 thermostats for electric boilers

Without certain information, you can spend a lot of time choosing a good device, so I have compiled five points that will demonstrate the differences between models from different manufacturers.

Guided by the facts provided, which were collected by monitoring reviews and opinions of experts, you will be able to prepare for a successful purchase long before visiting the store.

Teplolux MCS 350

First place went to this Russian-made product; the touch screen is quite convenient, and the possibility of independent installation will be a nice addition.

The functions can be controlled via the Internet, which makes the thing practical. It is impossible not to note the efficiency; when calculating payment receipts, you can find figures of 70%. Among the positive aspects it is worth highlighting:

- Value for money.

- Remote control via the SST Cloud program.

- Electricity consumption statistics are available.

- IP21 protection.

Terneo RK 32A

In second place in the rating was a unit distinguished by a rare body shape; it is somewhat unique, but this did not have a detrimental effect on productivity. It can be used for a boiler, heated floors, the three-digit screen will seem simple, the brightness and contrast remain at a high level.

You can only configure all the indicators manually; the advantages include:

- High degree of protection.

- Possibility to regulate pipe heating.

Caleo C450

The third place was secured by a room thermostat with an affordable price; it involves the installation of a surface-mounted version. Mechanical control allows you to level the temperature from 10 to 35 degrees, there are specific points that you need to get used to.

Due to the simplicity of the device, the price is quite low; any owner can afford to purchase the model. Among the shortcomings, it is worth noting the lack of gradation, there are only divisions around the knob, for some people this will create some difficulties. The package includes two sensors, one is responsible for the temperature, and the second starts the self-diagnosis mode.

There are few advantages:

- Low price.

- Moisture protection.

Nest Learning Thermostat 3.0

Fourth place went to a functional device that costs a lot of money; some functions, due to their abundance, even seem superfluous. Visually, the unit resembles a hockey puck, the display is very bright and on it you can easily see all the data about the system.

The rotary ring is used for control; there is the possibility of wireless regulation. Automation can safely be called widespread, but the model will be in demand exclusively in a “smart home”. Manufacturers have noticed that if the device is placed in the far corner from the electric boiler, problems with some functions may arise.

REXANT R200

The last fifth place was occupied by a device with a large touch display; the package includes an external and internal sensor. It is possible to control not only the heating system equipment, but also the heated floor, as well as infrared elements.

Some owners will like the fact that the device can be programmed for 6 periods of time, configured at their discretion, and it will work for the entire coming week.

According to the manufacturer, the thermostat for an electric boiler is capable of turning off the equipment when the temperature in the system rises to the maximum safety level. Most users questioned the protection against moisture and dust according to IP20; at the slightest contact with liquid, the device gets confused and gives inaccurate readings.

There are often specimens that work for no more than 6 months, which should be considered a defect. The positive aspects include touch control and dual-zone metering.

Classification of types of temperature sensors

In order to choose the right boiler temperature sensor, you need to know where it (temperature) will be controlled:

- from inside the boiler plant;

- ambient air temperature in the rooms;

- coolant inside the heating structure itself.

The correct installation location of the meter affects not only the efficient operation of boiler equipment, but also the safety of its use.

There are two main criteria by which the temperature sensor is selected correctly:

- How is temperature determined?

- How the sensor interacts with the thermostat.

Types of sensors by method of determining temperature

There are several ways to measure temperature:

- Dilatometric. It is directly dependent on the state of the bimetallic plate with a large coefficient of thermal expansion, which can expand under the influence of heat. Magnets specially placed inside increase the sensitivity of the sensor.

- Thermoelectric. It consists of a pair of dissimilar conductors, which, during thermal expansion, are capable of producing thermo-emf. It is distinguished by increased accuracy due to the fact that the length and cross-section of the cables do not have a significant impact on the measurement result.

- Manometric. They measure how much the state of liquids or gases in a certain limited volume changes when heated.

- Resistive. Special alloys with high thermal expansion are used. They are sensitive to the slightest temperature changes. Usually presented in the form of a coil with copper-plated wire, placed in a plastic case.

- Semiconductor. Available in two versions:

- nonlinear temperature thermistors with a simultaneous decrease in resistance when heated;

- posistors with a nonlinear dependence, which is expressed in an increase in the resistance coefficient when heated.

Types of contact sensors

A special temperature sensor for the boiler can be connected to the equipment in two ways:

- using wires through which temperature data is transmitted to the control controller;

- using wireless technology. They operate on a dedicated radio frequency.

But it should be taken into account that there are no miniature wireless devices for heating systems. To power the device, read information and simultaneously transmit a signal, a control controller is required. Therefore, a wireless thermostat can only be paired with a room sensor. And the temperature sensor itself is for small-sized boiler equipment.

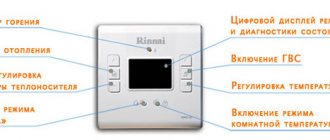

Heating control using a thermostat for a gas boiler

You can control the operation of heating equipment using manual settings or using a thermostat for a gas heating boiler. I would like to note that using manual settings you can set the temperature of the coolant in the system. This operation of the equipment does not respond in any way to changes in the air temperature in the room, and if this occurs, you will have to manually reconfigure the boiler again.

You can control the operating modes of a gas heating boiler either manually or through a thermostat.

The operation of the boiler in the case of manual control is associated with frequent switching on and off of the equipment, as well as the functioning of the circulation pump, regardless of what mode the unit is in: operating or standby. This causes heating equipment to wear out quickly and does not contribute to efficient fuel consumption.

If we are talking about control using a thermostat for a gas boiler, then such a device sets the optimal mode for the unit, taking into account the air temperature in the heated room. If, for example, there is a sudden warming and the room receives additional heat from the sun's rays, the thermostat will instantly respond and give a signal to the control device to turn off the boiler.

Considering that using a thermostat (temperature regulator) for a gas boiler you can set the required temperature in the room, heating will only occur if it decreases. Thus, if the device is set to 20°C, and during the day the room has also warmed up due to solar heat or the operation of cooking appliances, the boiler will be in the standby stage for a long time.

The thermostat helps reduce heating costs by 30-40%.

In this case, fuel consumption will be significantly lower. Before you buy a thermostat for a gas heating boiler, you should ask how to properly configure the device.

Where can I buy

Electronics for heating boilers are available for purchase in specialized stores in your city. But there is another option that has recently received significant improvements. You no longer need to wait a long time for a parcel from China: the AliExpress online store now offers the opportunity to ship from transshipment warehouses located in various countries. For example, when ordering, you can specify the “Delivery from the Russian Federation” option.

Follow the links and choose:

| Thermostat for gas boiler with Wi-Fi and remote control, 3A | Smart Wi-Fi thermostat Tuya for boiler | Smart Wi-Fi Touch Thermostat, Wireless |

| Digital LCD Thermometer with Water Temperature Gauge | Thermostat for gas boiler TUYA, wireless | Intelligent Thermostat, Temperature Controller |

Thermostat for heating boiler (thermostat): types, functions, prices

Given the rise in energy prices, the issue of energy saving is extremely pressing. That is why a large number of models of heating devices have been developed that are economical in fuel consumption. However, the equipment itself is not enough. A thermostat for a heating boiler (thermostat) will help you spend energy resources most efficiently, allowing you to control and maintain the set air temperature in a heated room.

Thermostats for boilers: photos, types of thermostats, operating principle, connection diagram.

Placements

Naturally, the sensor must be placed in the zone of influence of the heater. Therefore, they are distinguished by the method of placement:

- overhead - installed with tight contact directly on the heated surface;

- submersible - placed inside the coolant;

- room - the room temperature is controlled;

- external - the state of the external environment outside the house is measured. They have a waterproof body.

Thermostat for a heating boiler (thermostat): which one is better to choose

Before buying a thermostat for a boiler, you need to decide on the type of device. To do this, you need to understand the fundamental difference between the models of mechanical room thermostats and electronic ones. There is an opinion that the latter are difficult to configure and they are unreliable, but this is not the case.

An electronic thermostat is more accurate and has flexible settings.

The sensor controls the boiler

In order to more fully ensure comfortable living in a house with a minimum of thermal energy consumption, various devices are used. Such a temperature sensor for a gas boiler allows it to be programmed for different operating modes. The user just has to set the necessary parameters.

Mechanical thermostats

These models are the simplest. Without extensive functionality. They work through the use of membrane sensors located in a sealed capsule filled with liquid. When heated, the liquid expands and at a certain temperature puts pressure on the membrane and the thermostat makes it clear to the heating boiler that the power can be reduced/increased.

Mechanical devices are equipped with an expressive temperature selection dial. Due to their 3-4° accuracy and the wired connection method, these regulators are inexpensive.

Electromechanical

A slightly improved version of the previous temperature controller - electromechanical devices.

The principle of temperature regulation is similar to mechanics, but the operating principle is slightly different. The design uses heat-sensitive metals. When the heating changes, a micro-discharge is created or the resistance changes.

There are models with a small display for heating control and the possibility of adjustments in reduced steps. These changes were reflected in a slight increase in the accuracy of the device and in its price - it became more expensive than mechanics.

Electronic

More accurate electronic models are the most popular. These are more modern thermostats. They are multifunctional and easy to use.

- Can be used in conjunction with underfloor heating temperature sensors.

- Possibility of programming.

- There is protection against overheating and freezing.

- Warns that the circulation pump has stopped working.

- The measurement error is within 0.5–0.7 °C.

More advanced versions are equipped with built-in Wi-Fi for wireless connection to the boiler. Such a wireless room sensor, despite its high price, has a short payback period if used correctly.

Why does an electric boiler need a thermostat?

There are many types of products, some types of design are simple, while others allow you to configure more than 50 parameters for a comfortable stay in a house or apartment.

There are models that allow you to program equipment performance for one day or even a whole week; the main functions include:

- Temperature maintenance and control.

- Protection against freezing or overheating of the device.

- Saving resources.

- Remote control of the boiler.

A small device is capable of adjusting all functions of electrical equipment as accurately as possible, because comfort in each room is an important indicator for any owner.

Managing such devices is quite simple; modern models can connect to the phone using special programs, which allows manipulations to be carried out remotely.

How to choose a remote temperature sensor

What to look for when buying a temperature sensor? There are several options:

- A temperature meter needs extreme sensitivity and a wide range of measured temperatures. To quickly respond to changes in heating;

- sensor type - submersible or external. Is there a place for installation? It must match the dimensions of the water heater;

- temperature sensor parameters. Is there a need for additional voltage? At what speed is the signal transmitted and with what error. Ability to work in the right conditions;

- service life, maintenance frequency, need for additional calibrations;

- output signal level;

- permissible current, resistance, etc.;

When going to the store to buy a new device, it is better to take with you the technical data sheet for the heating installation.

Paired with thermostat

See how the temperature sensors will work with the boiler - with thermostat support or directly.

Many modern thermostats have the ability to adjust heating control depending on the weather. In this case, the power of the heating installation can be adjusted automatically if the thermostat is paired with an outdoor temperature sensor.

An outdoor thermostat is a single structure consisting of the sensor itself and a long (2–6 meters) wire for connection to the thermostat.

Should be considered:

- in what temperature range can the sensor for a gas boiler operate;

- level of moisture protection;

- the magnitude of the error in indoor air measurements. Permissible ± 1 °C. Good ± 0.5 °C;

- connecting cable length. Out of the box there is a wire up to 6 meters long with an attached temperature sensor.

Direct connection to the boiler

As a rule, those boilers that are purchased are already equipped with temperature meters and they are developed by the same supplier. If you want to install remote control of the boiler using a controller, you need a cable (usually two-wire). But you need to buy it yourself. The wire cross-section and resistance can be found in the instructions for the sensor.

They are usually connected to a thermostat. When automatically controlling the operation of boiler equipment, the connection is made to the controller, which brings the boiler to operating modes.

In any case, the connection is strictly regulated, according to the attached instructions.

Additional control devices, if necessary, can be recommended by the manufacturer of the boiler apparatus. This way you can guarantee the compatibility of devices and their correct operation.

If at the time of purchase the factory-recommended sensor for a gas boiler is not available, it must be replaced with certified analogues.

Outdoor sensor connection

An outdoor temperature sensor for boiler equipment is mounted on the outside of the building wall, subject to the following conditions:

- the temperature sensor should not be directly heated by the sun;

- the wall of the premises building should not be sheathed with metal;

- exclude the laying of cable lines in places where there is a possibility of rainfall;

- avoid contact with chemicals that may damage the insulation;

- the maximum height for placing a temperature sensor is 2/3 of the height of the house;

- exclude the influence of extraneous factors that may affect the external temperature sensor.

- protect the wire with an additional corrugated tube;

An external temperature sensor is connected, observing the polarity, when the boiler is not supplied with power. The main condition is that the cable with a cross-section of 0.5 mm² must be solid, and the length should not exceed 30 meters. The places where the cable is connected to the boiler and the meter must be insulated and sealed.

After connection, the quality of installation work is checked and the thermostat is adjusted. Additional inspection may reveal errors. In this case, a complete rework is required. Improper installation of an outdoor sensor can lead to either failure of the boiler equipment or poor heating of the premises.

Connecting the sensor inside the building

A room temperature sensor for a gas boiler is installed from the inside of the room on the outer wall, without violating the following conditions:

- Avoid being near heaters or air conditioners.

- Free access to the interior space. Eliminate all interior items that obscure the room sensor.

- The permissible height is 1.2–1.5 meters from the floor.

- There should be no nearby electrical wiring.

The method of connecting the device to boiler equipment is similar to an external temperature sensor.

Connecting a temperature sensor for a gas boiler

The temperature sensor for the gas boiler must be installed on the controller itself. As an option, installation on a gas valve is allowed.

Sequence of actions for self-connection:

- The instructions for the gas boiler must include a diagram. It contains the heating boiler itself and the place where the device is connected, its markings and the location of the contacts.

- Now on the gas heater itself you need to remove the front panel. It blocks access to the board and contacts.

- You need to remove the factory jumper between the terminals.

- Connect the wires from the sensor contacts to these terminals. The polarity of the wires does not matter.

- If a wireless air temperature sensor is installed to the relay unit, connect a three-wire wire with 220 V grounding.

If there are any doubts about the correct installation, it is recommended to refer again to the instructions for the gas boiler.

Programmable room thermostat

A programmable electronic room thermostat allows you to select the desired and comfortable temperature at any time; it is easy to reconfigure and change the operating mode. The timer allows you to set a different heating pattern on weekdays and weekends. Some timers allow you to set different settings for each day of the week, which can be useful for people who work part-time or shift work. Many Terneo and KChM models are equipped with such thermostats.

Programmable room thermostat

A programmable room thermostat allows you to set individual heating standards for each day in accordance with your lifestyle and maintain the temperature of the house all the time, regardless of the presence or departure of the owners. Video: Connecting a room thermostat to a gas boiler

If the heating system is controlled by a boiler with a radiator, as a rule, only one programmable room thermostat is needed to control the entire house. Some patterns need to be adjusted in the spring and fall as the clocks move forward and backward or certain changes in climatic conditions occur. We also recommend changing the temperature settings when changing from day to night.

This climate controller has several options that expand its capabilities:

- “Party”, which stops heating for several hours, then resumes;

- “Override” allows you to temporarily change the programmed temperatures during one of the configured periods;

- “Holiday” increases the heating intensity or reduces it for a certain number of days.

Operating and safety features

Thermal sensors help improve the microclimate, but their normal operation depends on following simple rules:

- the element itself that measures room temperatures must be immersed as much as possible in the environment where it is necessary to improve heat transfer;

- Correct and long-term service of the room temperature detector depends on timely inspection and calibration in full accordance with the recommendations from the manufacturers;

- eliminate the negative impact of external factors that may affect the accuracy of temperature measurements for boilers;

- Operation of electrical sensors with damaged insulation is prohibited;

- Do-it-yourself disassembly of the thermostat is strictly prohibited;

- All preventative work is carried out with the equipment disconnected from the 220V network.

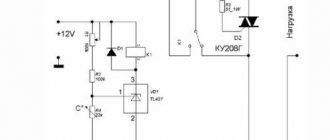

Connection diagram of the thermostat to the heating boiler

After the model is selected, the question arises of how to connect the thermostat to an electric boiler or gas heating unit. The device is connected according to the recommendations specified by the manufacturer in the technical data sheet for the equipment. You just need to find the necessary section in the documentation, which will describe the method of connecting additional devices to the boiler and provide all the required diagrams.

Connection diagram of a room thermostat to a heating boiler.

On some models of thermostats, the diagram is shown on the reverse side of the decorative cover. All modern boiler models have connection points for a thermostat, which will control the operation of the heating equipment. The device is fixed using a terminal on the boiler at the appropriate point or using a thermostat cable (included in the kit).

According to professionals, wireless room thermostats should be installed in living rooms away from existing household electrical equipment (TV, refrigerator, lamps, etc.), since proximity to the heat emitted from them can lead to incorrect operation of the device. Some recommendations for installing a wireless thermostat for a gas boiler:

- To correctly measure the room temperature, it is necessary to ensure free access of air to the thermostat;

- It is not recommended to cover the devices with pieces of furniture or heavy curtains;

- the device should be located in the coolest rooms or in living areas where residents spend the most time;

The thermostat must be installed in an open area away from heating devices.

- Avoid exposing the device to direct sunlight;

- Do not install the device near heating radiators or heaters;

- The devices must not be located in the area of drafts.

On a note! The room thermostat sensors for heating are triggered when the room temperature changes by 0.25 degrees.

Replacement and connection

If the thermostat breaks down, then finding out the source of the breakdown is not difficult at all and can be done by the owner of the heating installation:

- If the water does not heat up, the source of the disease lies in both the temperature sensor and the thermostat. In this case, we do not consider the breakdown of the heating element. We assume that it is working properly.

- The temperature sensor is removed from the boiler and all wires are checked for breaks using a tester in the “continuity” mode.

- If the temperature measurements show zero when the thermostat is running, it is definitely faulty. You can’t fix it yourself; it’s better to buy a new one and replace it.

- If the thermostat responds to the boiler in the “call” mode, you need to set the minimum temperature value and take measurements again.

- If it is working properly, then in the “heating” mode its contacts should be open, and the resistance at the input and output should increase.

Replacing the thermostat with a similar one is described in detail in the instructions for the heater. If there is no such thing on sale, a similar one with the appropriate parameters is looked for.

Setting up a thermostat (temperature controller) for a heating boiler

After you buy a thermostat for your heating boiler and connect it to your heating equipment, you will need to configure it. Each product comes with instructions that outline how to set it up. Having carefully studied it, you can independently set the necessary mode that meets the individual level of comfort of the microclimate.

On the external panel of the device there are buttons and switches through which settings are carried out. The switches allow you to control heating and air conditioning, delay switching on (does not allow the boiler to start operating during a short-term drop in temperature, for example, a draft) and temperature deviation (if you set the fluctuation value to 1°C, switching on or off will be available when the temperature increases or decreases by 0.5 degrees).

To correctly configure the operation of the thermostat for a heating boiler, it is better to contact specialists.

Using the buttons, two modes are set: optimal and economical. Thus, during the day the temperature will be provided at an optimal value, at night the temperature will drop to a level sufficient for a pleasant sleep. This mode will allow you to significantly save on energy resources. Various models of thermostats have several set modes, one of which can be selected for use.

On a note! In rooms where children and the elderly are most often present, it is recommended not to lower the temperature below 22°C.

Types of control devices

Thermostats for heating boilers with the option of temperature control are divided into several types:

- mechanical models with one function;

- programmable models with a large range of auxiliary settings.

Wireless models

Also, similar designs are wireless and wired. Thermostats are installed in the selected location, a temperature sensor is connected and connected to the control device.

Design diagram of the control device

Note! Thermostats must be provided with constant air access to prevent overheating. It is also not recommended to install electrical appliances nearby.

Selecting a room programmable device

The option of an electronic temperature sensor for a heating boiler helps you select the appropriate temperature mode and change it at your discretion. The room thermostat sets the set values every day. Some setpoint values can be programmed, for example when day turns to night.

Such controllers have additional options. For example, a function that allows you to stop heating for a while and then resume it. You can also change the programmable temperatures for the duration of the configured periods. Another useful option is the ability to change the heating intensity.

Room type regulator

Thermostat as a central element

The central thermostat for the heating boiler (temperature regulator) is located at a certain distance from the heating unit and allows you to turn off and turn on equipment throughout the house.

Installation diagram of thermostats in the heating system

Related article:

Thermostat for heating radiator. What task does this device perform and what is its advantage? What is the operating principle and correct installation? Prices also matter. More details in a special publication.

Models from previous years are connected directly to the heating unit by wires, while more modern designs are distinguished by remote control. The latest devices are mounted in dual-circuit units Beretta, Ferroli and AOGV. Room control mechanisms for boilers of the Protherm and Gsm brands are popular. They differ in their dilatometric mechanism.

Protherm equipment models

Room devices stop heating when necessary. They monitor the air temperature and turn on the heating when the temperature drops. The best place for a microcontroller is considered to be the bedroom and living room.

Installing a controller will allow you to obtain accurate data on the microclimate of the room

Helpful information! The recommended temperature for the thermostat is 20 degrees, and in the children's room - 21-22 degrees. At night, the temperature can vary from 19 to 21 degrees.

Thermostatic valves for regulation

Such a device allows you to create a certain coolant temperature by mixing the forward and return flows. The device helps control temperature values by changing the flow of hot water through the battery. In this case, the mechanism controls the supply of hot water through the battery, but not through the boiler. It is installed in any room where you need to maintain a certain temperature.

Thermostatic valve design using the example of a specific model