To ensure heat supply and water heating in an individual residential building, owners most often install gas boilers with closed coolant circulation. To install and operate a gas boiler, it is necessary that a gas pipeline runs nearby. If there are no gas supply networks nearby, bottled liquefied petroleum gas can be used for heating.

The dual-circuit design allows you to increase the pressure of the working medium in the system circuit. A decrease in pressure contributes to problems during the operation of the heating system. Let's take a closer look at what the causes are and what methods can be used to eliminate this unpleasant problem.

Norm and control

The heating system is adversely affected by both excessively high and low pressure, measured in atmospheres. In this case, the normal level is 1.5-2 atmospheres.

Healthy! In multi-storey buildings with central heating, this standard is slightly higher, since here the pipes must also withstand water hammer.

Types of pressure in the system

In double-circuit heating systems, pressure is divided into the following types:

- static - formed under the influence of gravitational forces on the coolant; increases by 0.1 bar with an increase in height by one meter;

- dynamic - created through forced operation of the pumping unit or an increase in temperature when the working medium moves;

- working - static + dynamic;

- excess - the difference between atmospheric and measured;

- absolute - excess + atmospheric;

- nominal - indicated by the manufacturer in the technical documents for the gas boiler;

- maximum - the maximum permissible, threshold value that the device can withstand;

- limit (pressure testing) - the value at which the device is tested; can exceed the operating level by one and a half times.

Control devices

Gas boilers contain various components responsible for regulating the parameters of the equipment and maintaining it in working condition. This system requires constant monitoring of the functioning of the system. Pressure gauges and thermomanometers are used to control fluid pressure.

Interesting! Thermomanometers allow you to additionally control the temperature level.

Some systems use electronic sensors instead of conventional dial gauges. The sensors transmit the received information to an electronic unit, which processes it and displays it on the screen.

If the heating unit does not have a pressure gauge, then it is provided with a safety group, which consists of the following components:

- The pressure gauge itself or the thermomanometer.

- Air bleeder to prevent airing of the circuit.

- Safety valve for relieving coolant pressure when it increases greatly.

Selecting a refueling option

Several methods are used to replenish the coolant supply:

- Manual recharge is the cheapest and most versatile option, suitable for all types of wiring.

- Automatic replenishment from the water supply is practiced only in systems operating under pressure.

- To fill a closed network with non-freezing coolant, a manual pressure test pump is also used. The design of an automated circuit with an electric pumping station connected to a container with antifreeze is practiced in industrial boiler houses.

At home, antifreeze is pumped into the heating network using a pressure test pump

Note. If the radiator network and heated floors are filled with antifreeze, simple replenishment is done with a small hand pump. But most often, filtered tap water is used in the heating system, because of the price of non-freezing coolants (especially harmless propylene glycol).

The operating principle of the automatic make-up unit is based on the operation of a pressure reducing valve that responds to a decrease in pressure in the heating network. When it drops below the set value, the valve mechanism opens and releases water from the main line. A pumping station operates in a similar way, pumping antifreeze from a separate tank.

Unit with gearbox (left) and station pumping coolant from the tank (right)

Let us take the liberty of recommending the use of a manual recharge scheme. Causes:

- The unit consists of 2-3 inexpensive elements and will never turn on without the knowledge of the homeowner.

- No matter how reliably and efficiently the heating network is installed, there is a possibility of leakage and valve operation.

- Situation: pipe break, prolonged leakage of coolant in the absence of the owners. A completely autonomous “smart” recharge will flood the entire house, ruining the flooring and causing expensive repairs.

- Imagine an identical situation in an apartment building - a leak from an individual system and the activation of automated replenishment will flood the neighbors below.

- Fine sand will accumulate under the valve seat and the element will lose its seal over time. Under pressure from the water supply of 4-7 bar, spontaneous replenishment will begin. The most harmless scenario is the release of excess coolant through the fuse on the boiler safety group.

To eliminate the consequences of the described troubles, it is better to allocate a little time for personal control over your heating. Having discovered signs of loss of coolant, you will make your own decision - to recharge the system immediately, look for a leak, or make repairs. For a negative example of using such automation, watch our expert’s video:

Causes of pressure drop and solutions

A drop in pressure can adversely affect the normal operation of the heating system. In this situation, water stops flowing into the unit and it automatically turns off. Therefore, it is important to provide for timely maintenance, inspection and repair.

The reasons for a drop in pressure can be different, let's look at the most common ones.

The pressure in the system drops when hot water is turned on

This problem is quite common. This phenomenon is explained by the special design of boiler units.

According to experts, in reality it is just a pressure gauge that reflects an incorrect value. The pressure drop may be caused by air leaks into the circuit or improper operation of the three-way valve.

For information! If, when you open a hot water tap, normal operation of the system is not restored over time, it means that the pressure is decreasing, and the problem really exists.

Pressure drops due to leaks

To eliminate this type of problem, the owner needs to diagnose and inspect the entire heating system, since liquid can escape through any component.

The cause of the leak may be a loose connection, worn-out heat exchangers, cracks in pipes and batteries. Most often, the level of tightness is checked when the circuit is put into operation, however, the tightness can be compromised during operation itself.

Nodes that need to be inspected and checked first:

- connecting fittings;

- radiators;

- expansion tanks;

- double-circuit boilers.

Detected problems must be corrected, after which the system will be recharged with liquid until the normal pressure level is restored.

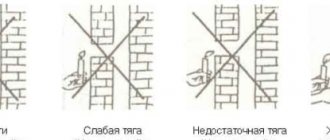

Air jams

The formation of cracks and depressurization of the heat supply system leads not only to leaks, but also to the opposite effect - the suction of air masses into the circuit. The result of this is the formation of air bubbles.

Bubbles also form when the circuit is not filled correctly, which is why air pockets appear in it, causing a significant drop in pressure.

Recommendation! This problem is solved by simply de-aerating the system, thanks to the installation of bleeders.

Problem with expansion tank

There are cases of problems with expansion tanks. A gap forms here or the nipple may leak air. The inside of the tank consists of two compartments separated by a membrane. One compartment contains air, and the other is filled with coolant. When the liquid working medium is heated, it expands and presses on the membrane with greater force. The membrane, in turn, affects the compression of the gas mixture.

When the equipment operates for a long time, the nipple wears out and begins to leak air, which leads to a decrease in pressure.

The only solution to this problem is to completely replace the tank, however, before doing this, you should make sure that the problem lies precisely in this, and not in leaking pipes, radiators and airing of the system.

Measuring equipment malfunction

Sometimes diagnosing a system for the integrity of its components may not yield results. If you have not been able to find a visible cause, then you should think about checking the proper operation of the boiler automation and control equipment. This equipment may break down and give incorrect readings.

It is quite difficult to determine this type of malfunction on your own, so it is better to seek help from specialists. The problem is solved by replacing control and measuring instruments.

Cracks in the heat exchanger in the boiler

Over time, microcracks can form on the walls of heat exchangers, allowing water to pass through from the heating system. Since the water in the boiler evaporates quickly, it is by no means easy to identify this breakdown yourself in the same way as in the previous situation. In addition, cracks can occur during washing, which is carried out for prevention or due to manufacturing defects. This problem is eliminated by sealing the detected area with a crack.

How to drain water from pipes for the winter

With the advent of the first cold weather, many owners of private houses and summer cottages have a need to drain water from the pipes of their plumbing and heating systems. Many people think about how to drain water from pipes with their own hands, they think that it is very difficult, and the help of specialists is needed. In fact, you can do this on your own.

Adviсe

When preparing water pipes for conservation, it is worth remembering that all work must be carried out at an outside air temperature of at least 5 ⁰C.

In order to properly drain water from water pipes, their design must include the following details:

- A tee and a drain valve must be installed on the pipe valve supplying water from a well or well caisson.

- Water pipes must be made of low-density polyethylene or polypropylene. This will prevent them from being damaged during emergency defrosting.

- A water drain valve must be installed at the lowest point of the pipeline branch.

- If drain taps are not installed, a tee must be installed. A car compressor is connected to it. It is used to blow through pipes.

- If a water heater is connected, it is necessary to install a tee and a tap to drain the water. They must have a hose attachment to the check valve on the incoming water heating pipe. Also, a tee with a tap should be installed on the outlet pipe from the water heater to quickly supply air when draining the water.

Note! It is recommended to use classic ceramic faucets and taps with a rubber seal. They will not be damaged if residual water in the pipeline freezes.

Stages of draining water from a pipeline

To drain water from the heating system, you must perform the following steps:

- Turning off the heating boiler or closing the distribution valve on the pipe extending from the riser.

- Shutting off the valve that collects water into the heating system.

- A hose must be attached to the radiator system drain valve. Here you should correctly calculate its length. It must be sufficient to drain water into the street or into a sewer well.

- The drain valve on the heating radiator must be opened.

- On the heating system, it is necessary to open the valves with air valves. This will ensure a faster drainage rate.

- Leaks may occur during the draining procedure. To avoid unpleasant incidents, it is necessary to place a deep container in advance and place it under the junction of the tap and the drain hose.

- After completing the draining procedure, you must disconnect the hose and drain the remaining water into a container.

We drain water from the central and autonomous water supply

In modern summer cottages, many people install a pipeline system. The pipeline can be connected:

- to the central water supply,

- to an autonomous water supply system.

How to increase the pressure in the boiler

If the reason is a malfunction of the expansion tank, then its volume was calculated incorrectly or the membrane was damaged. In this case, you should either more accurately calculate the required volume, or simply replace the tank.

If the pressure begins to drop immediately after the initial start-up, then this is normal. There is a large amount of air present in a circuit that has recently been filled with tap water. Over time, it will turn into bubbles and be removed from the pipeline, and the circuit parameters will return to normal. To remove bubbles faster, use a manual air release.

Before carrying out measures to increase the pressure in the system, it is necessary to ensure its tightness. To do this, you need to inspect the following parts of it:

- heating appliances - leaks often appear at the junctions with pipes, and leaks that occur between separate sections are also possible;

- pipes - even very small cracks can often lead to coolant leakage;

- fittings - often cause leaks;

- boilers - models with two circuits have a complex internal structure: for example, you should carefully inspect the circulation pump, three-way valve and heat exchanger.

Elements of the make-up device

The recharge scheme for heating networks will depend on the hourly productivity of the standard recharge. For large main heating networks, in which the standard recharge is hundreds and sometimes thousands of cubic meters of water per hour, the complex includes: a water tank, chemical water treatment, automation, electric pump and shut-off and control valves. When performance decreases, the number of circuit elements can be significantly changed.

Boiler gearbox

The reducer is installed on the return pipeline in front of the boiler to supply make-up water to the network circuit. Water from the city water supply flows through the valve when the pressure in the network pipeline drops due to leaks or release of an air lock. If the diagram provides for the installation of a circulation pump, then it is installed second. Otherwise, the operation of the entire heating system may be disrupted.

Preventing the formation of air jams

Preventative measures against the occurrence of air locks are as follows:

- Pay attention to the correct installation of pipes and connections of heating devices. Many problems are caused precisely by mistakes made at this initial stage.

- To prevent air locks, proper commissioning of the equipment is necessary, before which it is important to first check all components and connections.

- Before putting devices into operation, check them for functionality. Using a compressor, you need to apply a pressure level that is ¼ higher than its normal operating value. If it does not weaken within 30 minutes, then everything is in order and the system is ready for operation. If the pressure drops sharply, then leaks are possible, which should be promptly identified and repaired before starting operation.

To organize uninterrupted heating and water supply to a private home, many citizens use gas boilers with a closed circuit through which the coolant moves. However, during their operation, consumers often encounter such a problem when the pressure in the boiler drops. To eliminate it, it is important to understand the operating principle and possible problems.

Signs of a critical coolant shortage

Not all owners of private houses monitor the technical condition of their water heating; it works - and that’s okay. When a hidden leak occurs, the system continues to function for some time until the amount of coolant drops to a critical level. This moment is monitored by the following criteria:

- In an open system, the expansion tank is first emptied, then the main riser rising from the boiler is filled with air. Result: cold batteries when the supply pipeline overheats; turning on the maximum speed of the circulation pump does not help.

- The lack of water during gravity distribution manifests itself in a similar way; in addition, the gurgling of water in the riser can be heard.

- On a gas heater (open circuit), frequent starts/turns of the burner are observed - clocking, the TT boiler overheats and boils.

- The lack of coolant in a closed (pressure) circuit is reflected on the pressure gauge - the pressure gradually decreases. Wall-mounted models of gas boilers automatically stop when they fall below a threshold of 0.8 Bar.

- Floor-standing, non-volatile units and solid fuel boilers continue to regularly heat the remaining water in a closed system until the volume vacated by the coolant is filled with air. The circulation will stop, overheating will occur, and the safety valve will operate.

Important clarification. When a TT boiler operating in an open gravity system boils, there will be no explosion, since the coolant communicates with the atmosphere. The water heated by the heater will evaporate, and then a fire will start in the boiler room. Although the described process takes a lot of time, such situations are far from uncommon.

We will not explain why the system needs to be recharged - this is an obvious measure to maintain the functionality of the heating. All that remains is to choose a method for replenishing the heating network.

Causes of pressure drop

There are many factors that explain why blood pressure drops. Among them:

- Coolant leaking from the heating system.

- Power outages for a long time.

- Problems in the operation of the expansion tank.

- Incorrect selection and operation of equipment.

When the coolant pressure decreases, the heating unit stops functioning because water does not enter the tank. If the gas pressure decreases, the system automatically turns off. To prevent such troubles, it is necessary to timely service the boiler and take measures when it is turned off.

Pressure drops when hot water is turned on

If the pressure in the heating system drops when hot water is turned on, this may be due to air leaks into the heating circuit or malfunctions in the 3-way valve. A similar problem is associated with the special structure of boilers.

When figuring out what to do if a wall-mounted boiler begins to release pressure when you open a hot water tap, it is important to understand the specifics of its operation. To successfully eliminate defects, you should seek help from a specialist.

Formation of air jams

If cracks appear anywhere in the system and depressurization occurs, this leads to coolant leakage and air suction into the circuit. As a result, air bubbles form. Their appearance is also facilitated by incorrect filling of the circuit, which leads to sudden pressure surges. To troubleshoot problems, it is enough to carry out the procedure for de-aerating the installation by installing vents.

Expansion tank defects

The reasons for the pressure drop in a gas boiler include problems with the expansion tank. There may have been a rupture in the structure or depressurization of the nipple, causing it to leak air.

On the inside of the container there are 2 compartments with a membrane partition. One part contains air masses, and the second contains coolant. As the liquid consistency warms up, it expands and increases in volume, beginning to exert great force on the membrane. Under this influence, the membrane leads to compression of the gas mixture.

If the Navien boiler has a problem, you will need to purchase a new tank and replace it. However, before purchasing, you need to make sure that the problem is related to this factor. Cases of leaking pipes, radiators or airing of the heating circuit cannot be excluded.

If the membrane is damaged, the expansion tank ceases to cope with its tasks, and the pressure level decreases. To detect this defect, just knock on the structure (the sound will become dull). And when you briefly press the nipple, water will spill.

Safety valve defect

The task of the safety valve in the Navien boiler is to protect the heating system from excess pressure. If the permissible values are exceeded, the part opens and begins to discharge excess water. The standard response threshold is 2.5 bar.

If the valve is not selected correctly, many false alarms will occur, causing the pressure to continually drop. To fix the problem, you need to replace the valve.

While still using this element, particles of dirt, scale and other debris may accumulate under the seat, preventing it from closing freely. You can try to get rid of the problem yourself by twisting the valve cap in a given direction.

Next, you should monitor the pressure readings using a pressure gauge for 1-2 hours. If the situation has not changed, you will need to find another cause of the breakdown.

Leaks in the heating system

Constant leaks in the heating circuit are one of the key reasons why the pressure has dropped. The rate of decline is determined by the degree of failure. Sometimes the pressure is released instantly, and in other cases it is released slowly and gradually. If the leak remains visible, it can be identified by water puddles or the appearance of condensation on the surface of the walls.

About connecting the make-up

The ideal place to create a recharge unit is an area with minimal pressure, preferably at the lowest point. Make-up is done on the return line, however, so that too cold water does not enter the heat generator (this is not very good for the heat exchanger of a working boiler), the pressure reducing valve is somewhat removed from the boiler or even placed on the DHW pipe if the heating device is double-circuit. In order to be able to service/repair the automatic make-up unit and not turn off the heating during this time, it is connected using a bypass and shut-off valves.

Describe your question in as much detail as possible and our expert will answer it

The make-up tank in the photo has a ball installed at the top.... maybe there is a pipe below in the tank itself? And why such tanks, if there are balls right below.

Is it necessary to turn off the boiler when recharging a closed heating system?

Before the start of the heating season, it is necessary to carry out comprehensive maintenance of the heating circuit. Such measures include flushing the system and checking the functionality of the equipment. After this, you need to fill the closed heating system and bleed all the air. There are several ways to fill a contour. It is very important to monitor the pressure level while performing work. The optimal operating pressure values are indicated in the passport of each circuit element.

How to solve the problem of pressure drop

If you have never had to restore boiler equipment yourself before, you should not attempt DIY repairs. Without knowing the circuits and operating principles of the units, you can make mistakes and damage the entire system.

To repair equipment, you need to carry out a number of complex measures. First of all, it is important to determine why the pressure in the boiler drops in a double-circuit installation.

In devices with forced circulation, liquid leakage causes problems. To determine the location of the leak, it is necessary to conduct a comprehensive inspection of the connection points.

During the initial inspection, it can be difficult to find the location of the leak. If a puddle appears under the pipeline, repairs must begin as quickly as possible. Otherwise, the breakdown will lead to disastrous consequences. In most cases, repairs involve replacing old pipes that have been subjected to corrosive processes.

If there is a complex wiring, the process of finding the leak location can cause a number of difficulties. If the pressure is unstable and there is no way to find the cause of the breakdown, you will need to call a specialist who will use special instruments to quickly and effectively determine the error.

Before carrying out repairs, you need to disconnect the radiators and boiler from the system and find the damaged area. If the pipe is deformed, it should be replaced with a new one. If a leak occurs at the junction of the pipes, resealing is performed. A special tape or sealant is used as a sealing compound.

If the problem is related to malfunctions in the expansion tank, it means that the wrong volume was selected or the membrane was damaged. Repairs will require re-calculations or replacement of the tank.

When releasing pressure after the first start, there is no need to worry about failure of the heating system. This is a normal reaction due to the fact that there is a large amount of air in the circuit. During normal operation of the equipment, bubbles will leave the pipeline, and the characteristics of the circuit will stabilize. To remove bubbles faster, you will need to use a manual mechanism to bleed the air.

If the heat exchanger is damaged due to heavy use and wear, it will be difficult to find the source of the problem without specialized equipment.

To prevent numerous problems in the operation of the heating system, including a decrease in pressure, it is important to carry out comprehensive prevention and follow a number of rules of use. It is worth monitoring the correct connection of the pipeline and heating elements, since many mistakes are made at the installation stage.

To avoid the formation of air locks in the heating circuit, it is important to properly secure the working units, make sure the valves and connections are working properly, and also carry out diagnostics. The pressure is supplied by a compressor ¼ more than the standard value. If after 30 minutes the readings do not drop, this will indicate that the error has been eliminated and you can begin operating the boiler in the previous mode. If sudden pressure surges are noticed, the system will need to be re-checked for leaks.

2017-06-13 Evgeniy Fomenko

Automatic make-up unit

If you are firmly confident in the reliability and quality of the system, you can install an automated circuit that adds water from the cold water pipe. What you need to buy:

Important point. The water entering the reducer must be pre-cleaned with a coarse strainer, otherwise the valve will quickly become clogged. If such a filter is not provided at the entrance to the building, install it in front of the make-up unit.

In this diagram, the pressure gauge shows the pressure on the side of the heating network; bypass and taps are needed to service the recharge module

The main executive element of the circuit - the gearbox - consists of the following parts:

- fine filter on the inlet pipe;

- spring seat valve with rubber seals;

- pressure regulator handle with a printed scale, range – 0.5…4 Bar (or higher);

- manual shut-off valve;

- check valve at the outlet.

Note. There are more expensive models of make-up reducers with a built-in pressure gauge that measures the pressure on the side of the heating system. Since this device is already in the safety group or boiler, there is no point in spending extra money and duplicating it. The exception is the situation when the make-up is installed far from the heat source (read the next section).

As you can see, the pressure reduction machine already contains all the necessary elements - a filter, a check valve and a regulator. All that remains is to assemble a simple circuit with a bypass and service taps designed for removing and servicing the gearbox.

Operating the valve is simple - use the regulator to set the minimum pressure threshold in the heating network, open the direct line taps, and close the bypass. How to properly adjust the automatic valve is shown in a short video:

Advice. If you plan to install a coarse filter in front of the gearbox, provide an additional service tap in order to clean the mesh without turning off the water in the entire house.

To organize the automatic addition of antifreeze to the system, you can adapt a “hydrofor” - a water station with an electric pump designed for water supply from a well. The pressure switch of the unit must be reconfigured to a minimum pressure of 0.8 Bar, a maximum pressure of 1.2...1.5 Bar, and the suction pipe must be directed into a barrel with non-freezing coolant.

The appropriateness of this approach is highly questionable:

- If the “hydrofor” works and starts pumping up antifreeze, you will still have to look for and eliminate the cause of the problem.

- If the owners are absent for a long time, replenishment will also not save the situation in the event of an accident, since the size of the container is limited. The pumping station will extend the heating operation for some time, but then the boiler will turn off.

- Placing a large barrel is dangerous - you could flood half the house with toxic ethylene glycol. Non-toxic propylene glycol is too expensive, as is spill cleanup.

Examples of organizing automatic refueling from containers of different capacities

Conclusion. Instead of additional pumps and automatic gearboxes, it is better to purchase an electronic unit of the Xital type. After a relatively inexpensive installation, you will be able to control the heating operation via a cell phone or computer and quickly respond to emergency situations.

Why does the water pressure in the heating system drop and how to increase it?

Sometimes it happens that your boiler releases pressure and turns off. Let's look at several reasons why the boiler does not maintain pressure in the heating system and how this can be corrected.

If there is a constant decrease in pressure, even after refilling, then your radiators in your heating system may be leaking. At first glance, you may not notice this, since the leak will not be noticeable if the batteries are hot and the moisture on them evaporates.

Take a paper napkin and wipe the joints, tap connections, and joints with it. Look at the floor, you may be able to spot dried puddles. If nothing is found, you can use a compressor.

The batteries are cut off from the boiler using valves, water is drained from the radiators, a compressor is connected to the drain taps using hoses and air is pumped. In places where there are fistulas or other defects, you will hear a characteristic sound.

Using tow or sealant, eliminate the leak; if the faucet is at fault, replace it. If your heating system is built into the wall and wet spots do not appear on it, you will have to contact specialists, since a leak can only be detected using a thermal imager. A thermal imager can detect problem areas. To eliminate the leak in this case, you will have to open the problem area.

Another reason for low pressure in the system may be incorrectly selected unit power. The main parameter in the calculation is the volume of the room and the presence of standard radiators. If you have regular pipes installed instead of radiators, the volume of liquid in them will be larger, and accordingly, the volume of expanded liquid will also be larger.

Manual recharge scheme

The easiest way to replenish the heating circuit with water is to refill it manually. In order to fulfill it, it is necessary to stretch a pipeline from the city water supply and connect it to the return line of the heating network. A shut-off valve and a water purification filter are installed in this area.

The scheme functions perfectly in simple heat supply systems for one-story small-area households. The line is connected to the return line before the circulation electric pump, since this section has the lowest pressure and temperature of the network water.

For open heating networks, the make-up system organizes the supply of water not to the return, but directly to the expansion tank. To do this, you do not need to go into the attic to check the recharge level. According to the diagram, the expansion tank is connected with 3 independent terminals: make-up, supply and return pipelines.

The level in the tank is controlled by opening the valve on the control pipe directed to the sewer. When water flows after opening the valve, this means that the system is full; if not, the make-up valve opens, which is kept open until there is overflow from the control pipe.

Low water pressure in the boiler - what to do?

If no leaks are found in the radiators, then the reason why the pressure is lost lies in the boiler. Why does this happen and how to increase (gain, pump up, increase) blood pressure? If you frequently pump up water and the boiler does not hold pressure, there is a possibility that microcracks have formed in the heat exchanger. When the boiler heats up, the cracks increase and leakage occurs. The intervention of a specialist is urgently required, or you can eliminate the fistula yourself.

Soldering the heat exchanger

The reason for the appearance of microcracks is wear of the heat exchanger, frequent washing with reagents, poor quality of the metal from which it is made, water hammer when the pressure in the line increases sharply. They usually happen after accidents in water mains.

Places where there are microcracks can be identified by the scale layer. If removing the heat exchanger is easy, you can try to solder them. Bithermal heat exchangers are almost impossible to repair due to their design features; they will have to be replaced.

The pressure in the boiler does not rise (gain) when the feed tap is flowing. If the pressure in the line is higher than the pressure in the boiler, the liquid through the make-up valve increases the pressure in the boiler to a critical point, and a discharge occurs through the safety valve.

What to do when gas pressure disappears?

A drop in gas pressure may occur for the following reasons:

- Increasing the load on the gas main during severe frosts and holidays, connecting additional consumers to the main. Contact the gas service with a request to increase the gas pressure.

- The gas filter is clogged - clean the filter.

- The gas hose is clogged, replace it with a new one.

- The injectors are clogged, clean them with a brush.

- Gas valve is faulty. If after disassembling and cleaning it the situation does not change, replace it with a new one.

- The old pipes on the gas main are rusty, there is a leak - notify the gas service.

What to do if the problem with the gas supply occurs constantly - some users connect a gas cylinder between the gas pipe and the boiler, using it as a receiver. In this case, when the unit is turned on, gas will flow directly from the cylinder, without creating a vacuum in the gas pipeline.

There are models of units, for example, Buderus, Bosch, Deo (Daewoo), which operate at reduced pressure; when buying a boiler, you should pay attention to this.

Another solution to the problem is replacing the gas boiler with an electric boiler. Using it will undoubtedly be more expensive, but you will always have heat and hot water. Below are the gas supply pressure values for some models.

Types of pressure

The pressure in a 2-circuit (double-circuit) boiler is divided into the following types:

- static, formed under the influence of gravity, with an increase in height for each meter it becomes higher by 0.1 Bar;

- dynamic, created by pump operation (the greater the pump power, the higher the dynamic pressure) or by increasing temperature;

- working, is obtained by adding two types of pressure - static and dynamic;

- excess, that which is recorded by the pressure gauge, is the difference between the atmospheric and the measured;

- nominal, set in accordance with the physical parameters of the materials from which the gas boiler blocks are made; when operating in this range, the service life declared by the manufacturer is guaranteed;

- maximum, maximum permissible, guaranteeing the exclusion of emergency situations and malfunctions;

- crimping, this pressure is used to test the parts of the unit in production; it can exceed the working pressure by 1.5 times.

First start-up of the boiler and its testing

The first start-up and adjustment is carried out by service specialists. Before starting, you should check the tightness of joints and assemblies for gas leaks using a special device, and check for grounding. If you have an open combustion chamber, there is an air flow.

Checking the network voltage

We check the voltage supplied to the boiler; if it is higher than 220 V, it is necessary to install a surge filter or stabilizer. The gas pressure at the inlet to the heat generator and in the expansion tank is checked. Before turning it on for the first time, it is necessary to flush the heating pipes, regardless of whether they are old or new.

Use the fill valve to slowly fill the system with liquid. On models where antifreeze is allowed, add it. When filling, watch the pressure gauge; as soon as you reach the reading indicated in the instructions, close the refill.

Bleed the radiators using a bleeder, if equipped. If not, open and close the Mayevsky valve on the batteries until liquid flows out of them.

If there is not enough pressure, add water to the system again, as the pressure will decrease after removing the air. Then remove air from the circulation pump. This is done as follows. After turning on the device, the circulation pump will start, making gurgling and other uneven sounds.

Using a screwdriver, unscrew and tighten the bolt in the center of the pump several times; water will flow out from under it. When all the air is released, the pump will operate smoothly without making strange sounds.

Then the ignition is triggered and the boiler starts; if the readings on the pressure gauge decrease, add liquid to the system from time to time. You will have to bleed air and add water for several days until the unit works stably.

The operation of the heat generator is tested in heating mode and hot water heating mode, and the temperature is adjusted if necessary. Next, the minimum and maximum modulation value of the gas valve is set using switches on the control board.

This adjustment will allow you to use your heat generator more efficiently and economically. After adjustment, the switches are returned to their original position.

In conclusion, we offer a video about one of the reasons for poor pressure in a heating boiler:

How does the make-up valve work?

The valve is installed in order to maintain operating pressure in the internal circuit of the heating network by adding water from the city water supply. The standard pressure for the heating network depends on the number of floors of the building and internal pressure losses in the network; usually, a pressure of 2 to 2.5 atm is sufficient.

A pressure reducing valve is used as an automatic filing device. At the same time, if the water pressure drops, the pressure on the valve stops, the spring acts on the rod, moving it lower, and thus opens the hole in the seat. Through it, water from the city water supply or tank enters the network. As the system fills, the pressure will increase and close the membrane and hole.

The pressure reduction valve is especially often triggered in systems with an automatic air vent, which removes air from the network. In order to protect the system from the reverse movement of the medium through the reducer, a check valve is installed into the municipal water supply.

Which faucet to choose

The gas boiler feed tap is installed on almost all modifications of both domestic and foreign boilers: boiler feed tap Ariston, Baxi, Immergas, Ferroli and Vaillant. Usually the user is forced to replace such a faucet if the factory model malfunctions. In this case, it is best to install one similar to the one that was supplied with the boiler. When choosing another model, you need to pay attention to the dimensions, operating pressure and water flow.

Popular gas boiler feed taps:

- Ariston electromagnetic boiler feed tap, price: 1,780 rubles;

- Baxi Main boiler feed tap, price: RUB 1,590;

- boiler feed tap Bosch ZW23-1KE/AE, price: 1090 rub.;

- boiler feed tap Daewoo Gasboiler 100-300 ICH, price: 1820 rub.;

- make-up tap for boiler Vaillant Max, Pro, Plus, price: 590 rub.;

- make-up tap Immergas Mini 1.015093, price: 320 rub.;

- feed tap for Ferroli Divatech, Divatop double-circuit gas boiler, price: 800 rub.;

- make-up tap Protherm Panther v18, price: 560 rub.