Among the many heating systems produced in European countries, one of the leading positions is occupied by gas boilers from Vaillant.

They demonstrate exemplary performance, with a service life of 20 years or more.

The high quality of the equipment is due to the long history of the company, which dates back about 140 years.

During this time, extensive technological experience has been accumulated, which has made it possible to create installations known for their quality and operational stability throughout the world.

Let's consider the features of operation of gas boilers ]Vaillant[/anchor].

Gas boilers Vaillant turboTEC

The TEC series is a group of wall-mounted gas boilers, one of the most popular among users.

The parameters and specifics of these installations are optimally suited for use in private houses or medium-sized apartments, which are most common in our country . The equipment is manufactured at the company’s factories in Europe, all processes undergo multi-stage quality control and technology compliance.

As a result, high-quality equipment is produced for heating and supplying hot water to residential premises of a certain area, which is reliable and has a long service life. The boilers are capable of operating on natural and liquefied gas and are resistant to slight fluctuations in power supply voltage.

It is possible to simultaneously supply coolant to a radiator-type heating circuit and to a heated floor system.

Installation of a Vaillant gas boiler

The main condition for ensuring correct and stable operation of the boiler is the correct choice of room. If the installation is not in the kitchen or other living room, it is necessary to provide frost protection.

At the same time, it is necessary to organize high-quality ventilation and install grounding, without which the unit will not be able to operate. When installing, you must observe the established gaps and distances from the nearest walls or window openings.

Connecting pipelines must be done carefully so as not to confuse them with each other . All gas connections are checked for leaks using a soap solution.

NOTE!

It is not recommended to install Vaillant boilers yourself, as this excludes the possibility of warranty service for the boiler. It is necessary to entrust the installation to technicians from the service center.

Types

There are two types of TEC series boilers:

- Single-circuit (VU marking).

- Dual-circuit (VUW).

The first type is capable of servicing only the heating circuit, the second has the ability, together with heating the coolant, to prepare hot water for domestic needs. Single-circuit installations are cheaper, they have fewer components and structural elements, which makes them more reliable and resistant to external loads.

At the same time, from the standpoint of convenience and rationality, double-circuit boilers are more convenient and efficient, since they allow you to create a full-fledged autonomous heating and hot water supply system in your home.

The ability to not depend on tariffs and the whims of resource providers is a big plus for homeowners.

PLEASE NOTE! When choosing an installation for your home, it is recommended to choose dual-circuit models. They can only work for heating, but, if necessary, they will solve the problem with hot water supply.

Models

The Vaillant turboTEC range of gas boilers is represented by single- and double-circuit units of varying power from 12 to 36 kW, depending on the specific model.

There are two lines:

- Vaillant turboTEC Pro.

- Vaillant turboTEC Plus.

The first line is a basic model that has a limited power choice - only 24 kW is offered. Units from the Plus line have expanded functionality and power, giving the user a choice of models from 12 to 36 kW.

This makes it possible to select a unit for the existing area or configuration of the home, and obtain the optimal design option for the existing working conditions.

Features of single and double circuit models

Single-circuit wall-mounted boilers, such as Vaillant Turbotec plus VU, are characterized by their simple design and compact size. Their main disadvantage is that they do not provide the user with hot water supply. In order to heat running water with it, you will have to additionally purchase and install an indirect heating boiler.

Vaillant Turbotec plus VU boilers

Double-circuit models such as the Vaillant 240 are equipped with a steel secondary heat exchanger with thin walls, allowing heat to be transferred from the coolant to running water.

Double-circuit devices with a built-in boiler are also available. They are large in size. The water tank is located at the bottom of the body. This is how Vailant models such as AtmoCompact and AtmoVit Combi are designed. Let's look at how a typical double-circuit boiler works.

Specifications

Let's look at the technical characteristics of the installations:

| Parameter | Meaning |

| Thermal power range | 9-36 kW |

| Nominal thermal load | 26.7 kW-34.8 kW |

| Hot water consumption | 1.5-17.3 l/min |

| Fuel type | Natural or liquefied gas |

| Chimney type | Coaxial 60/100 mm |

| Dimensions | 800/440/338 mm |

| Power supply | 220 V 50 Hz |

| Gas pipeline connection size | 15 mm (R 3/4) |

| Heating connection dimensions | R 3/4 |

| Water pipes | R 3/4-R 1/2 |

Area of use and technical characteristics

Vailant gas boilers are designed for heating domestic and industrial premises. Depending on the model they have different power ranges. From small devices, for example, Eco Compact at 4 kW, to devices with higher power, for example, Eco Craft VKK at 294 kW. Also, if necessary, a number of models can be connected in a cascade to accumulate the generated thermal energy.

Both wall-mounted and floor-standing units are available. Depending on the type of combustion chamber, atmospheric and turbocharged series are produced. For example, Vailant T3 and T4, where T3 is equipped with an atmospheric combustion chamber, and T4 is equipped with a closed combustion chamber. The heat exchanger is made of copper, stainless steel or cast iron.

All devices are equipped with modern protection devices: against freezing, overheating, fire extinguishing and lack of draft. Some devices can operate on both natural and liquefied gas. All boilers have an electronic control system and automatic ignition. Modulating burners allow you to smoothly change the required work intensity.

Equipment Features

The advantages of any Vaillant wall-mounted gas boiler are:

- compact size and light weight. Due to this, the equipment is easily mounted in the right place and does not disturb the interior of the room;

- wide choice of equipment capacities. If desired, you can choose Vaillant gas boilers with a power of 12 kW, capable of heating 120 sq. m. The maximum size of premises heated by such units is 360 “squares” (power – 36 kW);

- the ability to provide hot water supply with a flow rate sufficient to operate 1–2 water distribution devices;

- high operational reliability, which is ensured by the presence of special protective systems and full automation of all operating processes of Vailant wall-mounted gas boilers.

Principle of operation

Let's look at the operating principle of Vailant gas boilers. They are designed for space heating and water heating for domestic use. They are connected to a heating system with radiators located throughout the house. When the coolant inside cools down to a certain temperature, the thermostat is activated. It sends a signal to the control board.

From there comes a signal to turn on the circulation pump, open the gas valve and supply electricity to the ignition electrodes. The gas begins to burn in the burner, above which the main tubular heat exchanger is located. In it, heat is transferred from the combustion of gas to the coolant in the tubes.

When the water in the heating system heats up to the temperature set in the settings, the thermostat is activated again and the boiler stops operating. When you turn on a hot water tap, a three-way valve is activated, which directs the heated coolant to the secondary heat exchanger. There, through the thin walls, heat is transferred to the tap fluid.

In some series, for example, Vailllant Turbo, it is possible to connect an external room thermostat. In this case, you can adjust the heating to the desired room temperature.

Vaillant Turbo boilers

Condensing models such as Vailant ecoTEC have a specially designed heat exchanger that allows additional use of the heat of volatile combustion products during their condensation.

Equipment selection

When choosing specific models of Vaillant gas boilers, you should be guided by the following:

- the size of the heated room. With an average ratio of heated area to power of 10:1, you can choose a unit to maintain heat on 100 “squares” or 300 square meters. m;

- hot water consumption. If you do not need DHW at all, you should purchase a model with one circuit that provides only heating. If you need to at least sometimes use warm water, you should pay attention to Vailant double-circuit gas boilers;

- ease of maintenance and functionality. The more expensive Vaillant turbotec plus has maximum capabilities. At the same time, Vaillant turbotec pro also has a fairly decent set of functions, and is somewhat cheaper.

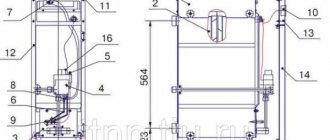

Construction of Vailant boilers

Electrical diagram

Let's look at the design of the Vailant boiler using pictures and diagrams from the installation manual. For correct settings during installation and troubleshooting, a circuit diagram is required. It shows exactly where all the components of the device are connected to the electrical control board.

The electrical circuit for a specific model of gas heating apparatus may differ slightly from the standard one. To make repairs and adjust a specific model, you need to use the operating instructions that come with each device.

Hydraulic circuit

The hydraulic diagram of the boiler operation shows all the nodes that the liquid passes through during the heating process. There are five pipes located below, two each for hot water supply and heating and one supplying gas.

Cooled coolant from the heating system enters the right outer pipe. The liquid passes through a three-way valve, a circulation pump and enters the primary heat exchanger. There it heats up and exits through the filter from the left outer pipe into the heating system. If hot water supply priority is set, it passes through a secondary heat exchanger, heating water for domestic use. A three-way valve controls the direction of coolant flow.

In the second pipe on the right side, cold, clean water enters, goes into the secondary heat exchanger, and from there the already heated water exits into the second pipe on the left.

How to configure it correctly before launching

Setting up a boiler is a complex procedure that includes a number of items:

- Setting the minimum and maximum gas pressure.

- Setting the pump run-on, which determines how long after stopping it still pumps water, helping to cool the heat exchanger.

- Setting the maximum heating power (power limitation helps save gas).

- Burner blocking time, etc.

All these parameters are adjusted in accordance with the design features of a given boiler model and require the presence of a specialist.

IMPORTANT! You must ask the technician to show the location of all shut-off devices in order to be able to shut off the flow of gas or water in an emergency.

Advantages and disadvantages

The advantages of turbocharged gas wall boilers of the TEC series include::

- Adaptation to Russian technological conditions - independent adjustment to fluctuations in gas pressure, partial compensation for fluctuations in power supply voltage.

- Low gas consumption, economical operation.

- Simplicity and accessibility of unit control.

- Reliability and durability of equipment. The service life of boilers often exceeds 20 years.

- With compact dimensions, the installations demonstrate high power.

- Efficient removal of smoke and combustion products, absence of odors in the house.

- The presence of a self-monitoring system that constantly monitors the condition of the boiler components and systems.

The disadvantages are considered to be:

- Requirement for electricity availability.

- High cost of boilers, maintenance and spare parts.

- Some models produce limited noise, which many users find too loud.

Additional disadvantages include low quality of service and lack of qualifications among technicians. The poor organization of warranty repairs is noted by many users; complaints are heard in different regions of the country and can be considered a common problem .

User manual

The boiler is turned on by simply pressing a button. After this, the display will turn on.

A flashing symbol will indicate low water pressure. Having opened the feed tap, fill the system, checking the flashing indication . When the nominal pressure is reached, the indicator will stop flickering.

If the pressure drops, then there is a leak in the system that needs to be found and repaired.

By double pressing the left button of the “I” group, the current and permissible pressure values will be displayed, which is very convenient and useful for the operation of the boiler.

Basic error codes and their interpretation

The operation of all boiler components is constantly monitored by a sensor system. When abnormal situations occur, they give a signal to the control board, which is displayed on the display.

The most common error codes:

| Code | Decoding |

| F.00 | Supply thermistor circuit open |

| F.01 | Open return thermistor circuit |

| F.02-03 | Opening the temperature thermistor or storage sensor |

| F.04 | Return thermistor break |

| F.10 | Supply thermistor short circuit (exceeding 130°) |

| F.11, F.14 | Short circuit of the return thermistor (exceeding 130°) |

| F.22 | Dry running (pump fault) |

| F.23 | Lack of water. Determined by the temperature difference between the forward and return lines |

| F.27 | Parasitic Flame |

| F.28 | Ignition lock |

| F.29 | Failure in operating mode (occurs when the flame goes out and the ignition attempt fails) |

| F.35 | Error in gas outlet |

| F.37 | Unstable or abnormal fan speed |

| F.72 | Error in forward and/or return line sensor readings |

| F.75 | The pump is unable to raise pressure |

| F.76 | Primary heat exchanger overheating |

The appearance of one or another error does not always mean a breakdown. You need to restart the boiler and see if the error appears again or not.

If after several attempts the error appears again, you should contact a repair company..

First start

The first start of the boiler will require filling the system with water, the quality of which must meet all existing requirements.

To start you need to do the following::

- Open the valves of all radiators in the system.

- Slowly fill the system with water to allow air to escape.

- Bleed remaining air from the radiators and boiler.

- Check the pressure on the display and fill in the missing amount (or remove excess).

- Turn off the feed tap and disconnect the system from the supply pipeline.

Before starting, you must once again check the tightness of all connections. If the check shows that everything is in order, the boiler is turned on using the button and the required temperature of the heating system is set.

From this moment the system will begin to work.

Optimal operating mode

The boiler operating mode must be configured in such a way that all parameters are within the limits permitted by the instructions.

At the same time, the design of the unit is such that the very concept of “optimal” is vague and very vague. The installation works perfectly in any mode, the main thing is that the gas and water pressure is not below or above the limit values.

In addition, Vaillant boilers are sensitive to a stable power supply voltage and are phase-dependent - when connected, the phase must be connected to the desired electrode, otherwise the boiler will not start.

How often and how to properly service

Vaillant boilers are serviced annually. For this purpose, a specialist from the warranty workshop with the appropriate qualifications and approval is invited.

He cleans and makes the necessary adjustments to the boiler and performs other necessary work. Maintenance (scheduled work) should not be confused with repairs, which are carried out as necessary at any time.

To perform this, you should also use the services of technicians from the service center.

Connecting a room thermostat

A room thermostat is a device that controls the temperature in a room and regulates the heating system accordingly.

Using this device allows you to save about 20% on heating. This effect is achieved through more rapid adjustment of the system temperature. The boiler's own sensor is guided by the temperature of the coolant.

When it warms up outside, the house becomes too hot, but no changes occur for the boiler system as long as the coolant temperature is within the specified limits.

The room thermostat is guided by the air temperature, so it immediately sends a command to change the heating mode.

To connect the device, the corresponding contacts on the control board are used, connected in normal mode by a special jumper.

NOTE!

Connection and initial setup should be entrusted to a specialist from the service center.

How to increase or decrease the temperature?

The temperature is adjusted using the corresponding buttons located on the control panel.

In the display menu, select the “temperature setting” area, after which the “+” or “-” buttons adjust the value of this parameter . It is necessary to take into account that the temperature in the room rises gradually; you should not expect an instant change.

You can check how successful the adjustment is only after 20-30 minutes, after which you can make additional adjustments.

How to raise or lower pressure?

The pressure in the boiler should be between 0.8-2 bar (0.08-0.2 at). For adjustment, use the feed tap and buttons on the control panel.

By double pressing the “I” button, the system pressure menu is called up, where the current parameter value will be displayed. Using the make-up valve, the pressure increases to the required value, after which the valve is closed.

To reduce, a relief valve is used, which can also be activated automatically when the limit value is reached.

Where is it used?

The optimal place for using Vaillant turboTEC boilers is private houses and cottages, as well as apartments in apartment buildings.

The main condition for effective operation is that the boiler power matches the area of the room. If there is not enough power, it will not be possible to achieve the expected thermal conditions in the room . At the same time, purchasing a boiler that is too powerful means a waste of money and poor operation of the unit.

The use of boilers in industrial workshops is irrational. Alternatively, they can be installed in office or public buildings, if the area and other conditions meet the operating requirements.

Main models and their prices

Are you planning to purchase a Vaillent double-circuit gas boiler? Then we suggest you familiarize yourself with the main models. There are not very many of them, so we will try to describe them in as much detail as possible.

Vaillant turboTEC plus VU 122-362

This is one of the simplest double-circuit models from Vaillant. But the simplicity of the technique is only apparent. In fact, we have before us an advanced turbocharged heating boiler. It is designed to work with a coaxial chimney and is equipped with a closed combustion chamber with forced removal of combustion products. The power of the model range varies from 12 to 36 kW in increments of 4 kW. The device does not require special maintenance and pleases with impeccable operation.

The model is equipped with a built-in circulation pump, expansion tank, as well as many automation systems - they control gas pressure, draft, water pressure and other parameters. It is impossible not to note the presence of a modulating burner (smooth temperature change in the circuits). The double-circuit gas boiler from the Vailant brand is controlled using a multifunctional panel with an LCD display. The price varies from 48 to 71 thousand rubles.

Gas boiler Vailant atmoTEC plus VUW/5-5

This wall-mounted gas double-circuit boiler from Vaillant has established itself as a reliable unit for creating autonomous heating systems. Store shelves will offer us models with a power of 20, 24 and 28 kW. This series is distinguished by the presence of an open burner with natural removal of exhaust gases. Thanks to this, the design is somewhat simplified, which has a positive effect on its reliability. However, this is a classic difference between single-circuit and double-circuit models.

The boiler is equipped with a plate heat exchanger, built-in piping, various protective systems, reliable chromium-nickel burners, electronic ignition and other goodies typical of double-circuit equipment. This model uses electronic control with service information displayed on the LCD display. The boiler is designed for use in private houses and apartments with autonomous heating systems. The price of one copy varies from 63 to 73 thousand rubles .

Double-circuit boiler Vailant atmoTEC pro VUW240/5-3

The model range appeared in 2015, so this is the latest equipment available in domestic and foreign stores. Here, two heat exchangers are used at once; this approach guarantees a long service life of the equipment and increases its reliability. If you choose the most reliable equipment, then only with a separate heat exchanger for DHW. The boiler is equipped with a natural smoke removal system and includes a safety group and built-in piping. The primary heat exchanger here is copper, and the second is made of steel.

The model is characterized by high efficiency, allowing maximum heat to be transferred into the heating system. As usual, here we will find electronic control, various protective modules, self-diagnosis functionality and much more. The device can control operating parameters, is easy to install and does not require frequent maintenance. All user actions come down to setting the required temperature in the circuits. The power of the device is 24 kW .

In parallel with this model, double-circuit wall-mounted gas boilers Vailant turboTEC pro VUW240/5-3 are produced. They are distinguished by the presence of a forced scheme for removing combustion products.

Double-circuit boilers Vailant atmoTEC pro

Another series of relatively simple double-circuit wall-mounted gas boilers from Vaillant. The design includes a second heat exchanger, a modulated burner, piping, a safety group, protection systems and much more that can be found in similar equipment. Adjustment of operating parameters is carried out using a simple control panel that even a child can handle. If necessary, these units will be able to operate at half power.

This series uses a natural smoke removal system, which increases the reliability of the device. In addition, this operating scheme implies a low noise level. The boilers were equipped with a self-diagnosis system, so they themselves can find faults within themselves, which is very convenient for maintenance and “glitches” in operation. The kit includes everything you need for installation work. An ideal device for a private home, apartment or cottage. The boiler power is 24 kW, the average price is 58.5 thousand rubles .

ecoTEC pro boilers

If you are an advocate for preserving the environment, you will certainly like the double-circuit wall-mounted condensing gas boilers from the Vaillant company. The use of condensing technology makes it possible to increase the efficiency of heating equipment and make it more environmentally friendly (by saving energy resources). The maximum efficiency rate is up to 109%. The series includes boilers with a power of 23, 28 and 34 kW.

These boilers are notable for their efficient hot water circuit, which is achieved through a special system for increasing power when working to prepare hot water. Inside we will find all the necessary equipment - this is an expansion tank, a circulation pump and a safety group. Despite the complexity of condensing technology and the need to use additional components, this does not affect the control of gas double-circuit boilers - this series is extremely easy to operate. The cost varies from 83 to 92.5 thousand rubles .

According to the manufacturer, these boilers can save up to 20-25% of natural gas compared to traditional convection models of similar power.

Operating diagrams and control of Vaillant Turbotec / Atmotec boilers

___________________________________________________________________________

- Vaillant turbotec 242 - Design and installation

- Errors and malfunctions of Vailant boilers

Control and maintenance elements for Vaillant Turbotec / Atmotec gas boilers The control panel of the Vaillant Turbo Tec / Atmo Tec boilers consists of two temperature potentiometers, a DIA system display, with a button panel located at the bottom (4 buttons), a place for installing a regulator and a power supply.

A pressure gauge is available as an option. If the device does not have an analog pressure gauge, then the standard pressure indication is on a digital display. The corresponding set temperatures are adjusted smoothly. When setting the temperature, the corresponding set value is shown on the display of the DIA system. After approximately 5 seconds, this indication is deleted, and the standard indication of the device's operation appears on the display again. What's new is that on instruments with an analogue pressure gauge, both temperature and pressure readings appear on the display as standard. Switching from pressure to temperature indication occurs by pressing the “-“-“ key. A short press—the reading is reset, a long press—the -°C symbol starts flashing. When the blinking stops, the readings switch to a constant display. Setting for summer mode Summer mode B i.e. only water heating is activated by turning off the heating, and the heating temperature regulator is set to the extreme left position, the same position is the setting for the boiler’s freeze protection. Setting the maximum flow temperature The maximum set flow temperature (rightmost position of the regulator) is set via the DIA system in diagnostic point d.71. Setting range from 40 to 85 °C. Factory setting 75°C. Activation of the Aqua Comfort system of Vaillant Turbotec / Atmotec plus boilers The “hot start” function is activated by turning the warm water temperature regulator to the maximum position, and deactivated by turning it to the minimum position. “Hot start” B is the start of the boiler from a hot position. When the “hot start” is activated, the symbol C is displayed on the display. Display of boilers Vailant turbo tek / atmo tek The display of the DIA system shows three-digit codes: temperature, status, diagnostics or faults. The DIA system has three service buttons and one reset button. Pressing the “Reset” reset restarts the device from the locked state to the operating position or restarts during operation. Fig.2. Vaillant Turbotec / Atmotec Pro boiler display The display has three fields for different readings. At the bottom there are three colored diodes. They show working condition. Red B emergency, green B hot water analysis, yellow flame control.

Fig.3. Vaillant Turbotec / Atmotec Plus boiler display The symbols on the display indicate the operating status. Wide service buttons with Click function. Functional diagram of the Vaillant Atmotec plus / pro boiler Vaillant Atmotec series boilers are devices operating on the flow principle for heating and heating hot water. These combustion devices use the air of the room in which they are installed, so it is always necessary to provide fresh ventilation for the normal functioning of the device. Exhaust gases are discharged through the chimney outside under natural draft. New flue gas sensors detect, in addition to the exit of combustion products into the room, also the reverse flow of gases!

Fig.4. Functional diagram of the Vaillant Atmotec plus boiler Draft stabilizer and flue gas sensors Air flow control is a safety unit that separates combustion processes from the influence of external factors. Boilers with an atmospheric combustion chamber can be installed in apartments only in cases where it is known for sure that carbon monoxide cannot accumulate in dangerous concentrations. Therefore, Vaillant Atmotec boilers, like all boilers with an open combustion chamber, are equipped with flue gas sensors, which, when flue gases appear, turn off the device after approximately 2 minutes. Flue gas sensor, AtmoGuard system The Vaillant Atmotec plus gas wall-mounted boiler is equipped with an AtmoGuard sensor. Unlike earlier solutions, AtmoGuard detects not only the accumulation of gases, but also their reverse flow. Improved sensitivity is achieved by the new location of the sensor on the flue gas side. Now it is located on the side at the upper outlet of the traction stabilizer, and the second is located inside and controls the gas flow. When flue gases exit into the room, hot flue gases flow past this temperature sensor and an increase in its temperature is detected, which leads to automatic shutdown of the burner. The device restarts automatically approximately 15 to 20 minutes after switching off. If the shutdown is repeated twice during interrupted heat consumption, the device is permanently blocked. The fault message “F.36” appears on the display. Unlocking and restarting follows after pressing the reset button. If the device has been turned off three times in succession, then it is prohibited to turn it on without subsequent monitoring of the gas path. Functional test of flue gas sensors - block the flue gas path with a Vaillant fan. — start the device. The device should automatically turn off within 2 minutes. The device restarts automatically approximately 15 to 20 minutes after switching off. The burner is blocked all this time. By pressing the reset button the device can be restarted again. Functional diagram of the Vaillant turbo tec boiler The Vaillant Turbotec series gas boiler is independent of the indoor air and is used for heating and preparing hot water according to the flow-through principle. These combustion appliances draw in fresh air through flue systems and exhaust gases are exhausted outside by a built-in fan. All devices are certified only with original Vaillant flue gas removal and combustion air supply systems.

Fig.5. Functional diagram of Vaillant Turbotec boilers Exhaust manifold - functional diagram The accumulator collects the flue gases that appear in the combustion chamber when burning fuel and removes it from the device with a fan through the chimney.

Fig.6. Exhaust manifold - functional diagram: Fan, exhaust manifold Fan / Air pressure sensor / pitot tube The air pressure sensor (presostat) and the pitot tube control the flow of gas-air masses. The pitot tube is located at the outlet of the fan, along the path of the flue gases. The pitot tube creates a pressure difference depending on the flow of air. A differential pressure appears between the pitot tube outlet (vacuum) and the low pressure chamber. Differential pressure only occurs when the intake combustion air flow is sufficiently dense to close the microswitch of the air pressure sensor. This information goes further to the electronics. The pressure switch on for the presostat ranges from 80 Pa to 68 Pa. During maintenance, it is necessary to check the pitot tube for contamination that can significantly impair its function (for example, insects) Exhaust gas diaphragms When the device is operating, the fan must create pressure to overcome the resistance that arises when gases move throughout the entire path (combustion chamber, air inlet, outlet combustion products). The maximum possible length of exhaust gas and air exhaust systems is determined by the fan power and the cross-section of the chimney systems. Adjustment of air volume to different lengths and cross-sections of pipes is carried out using exhaust gas diaphragms. The pressure transfer solution is new, because in previous models there was a danger of water getting into the pressure switch through the connecting hoses. In the new generation of boilers, a more reliable system (differential pressure: Venturi - UDK) should reduce the occurrence of malfunctions, which results in the formation of a weaker pressure signal than before. To increase the low pressure signal, Vaillant Turbotec boilers are supplied with new, pre-installed flue gas diaphragms. These diaphragms are made of a special artificial material reinforced with fiberglass. They amplify the pitot tube pressure signal. As a result, there is no need for one of the two tubes to the pressure switch. The built-in hose blower further reduced sensitivity to condensation. Electrical installation of boilers Vailant turbo tek / atmo tek The rated voltage in the network should be 220 V; at voltages above 253 V and below 190 V, functional disturbances may occur. The Vaillant Turbotec / Atmotec boiler is equipped with a cable with a plug having a protective corner contact. The cable is connected to the device at the factory. The socket must be accessible to the user so that the plug can be disconnected at any time. The socket outlet must not be located in protection zone I or II. Connecting Regulators, Accessories and External Unit Components

Fig.7. Connection diagram for Vailant turbo tech boilers

Fig.8. Vaillant Turbotec pro/plus boiler wiring diagram

Fig.9. Wiring diagram for Vailant atmo tech boilers

Fig. 10. Vaillant Atmotec pro/plus boiler wiring diagram Operating principle of PTC flue gas sensors Since boilers operate in the range between full load (100%) and ignition mode (40%), the temperature of the flue gases can be different. Therefore, two sensors are installed in Vaillant Atmotec boilers. One of them is located directly in the flue gas flow to measure the actual temperature of the combustion products, and the second sensor is located at the outer part of the draft stabilizer, from where the flue gases can enter the room. If the temperature difference measured by the internal and external sensors is large enough, then the device operates normally. If combustion products escape into the room, the temperature difference becomes smaller, and the electronics of the device recognizes this phenomenon as combustion products exiting into the room. If combustion products enter the room within 115 seconds, the device turns off for 20 minutes. After the third 20B minute shutdown, the electronics check the flue gas conditions again. If this time the release of combustion products into the room is noted, the device is turned off and blocked. During the 20B minute time delay when polling the status, the status message “S.52” appears. After the third attempt with the release of combustion products, the fault message “F.36” appears on the display.

___________________________________________________________________________

___________________________________________________________________________

- Malfunctions of the AOGV-23 ZhMZ boiler

- Parameters and design of gas boilers AOGV and AKGV

- Boiler automation Baxi Luna-3 Comfort

- Installation and installation of the Baxi Slim boiler

- Adjustments and maintenance of the Beretta Chao boiler

- Determination of error codes and malfunctions of Rinnai boilers

- Errors and malfunctions of the Termet gas boiler

- The meaning of error codes and malfunctions of Vailant boilers

- Determination of malfunctions and errors of Visman boilers

- Questions about servicing Navien boilers

- Questions about malfunctions of Kiturami diesel boilers

- Junkers boilers - Experts answer user questions

- Experts answer questions about Electrolux boilers

___________________________________________________________________________

___________________________________________________________________________

- Answers from Nova boiler repair experts

- Questions about Hermann boiler service

- Answers from Daewoo boiler service technicians

- Questions about servicing Ferroli boilers

- Questions from users regarding the repair of electric boilers Evan

- What causes an AKGV gas boiler to light up and immediately go out?

- What is wrong with the Alpha Color boiler if it shows error code E01

- Why does the AOGV boiler light up and go out quickly?

- How to eliminate error E01 on the Baltgaz boiler

- What is the problem if Dani’s boiler lights up but immediately goes out?

- Why does a Danko boiler light up but quickly go out?

- The Demrad boiler has stopped holding pressure, what is the problem?

- Why did the Gaslux boiler start to get hot and make noise?

- What is the reason if the Keber gas boiler lights up but quickly goes out?

- How to eliminate error code 01 on the Kiturami boiler

- What causes a Conord boiler to light up but immediately go out?

- What is the reason if the Lemax boiler lights up and goes out quickly

- Why does a Mimax boiler light up but suddenly go out?

- Why does the Hearth boiler light up but immediately go out?

- Why does a Ross gas boiler light up but go out quickly?

- What is the problem if the Siberia boiler lights up and goes out suddenly?

- Why does the boiler Signal light up and suddenly go out?

- What can cause a Termet boiler to make noise and get hot?

- Why does the Termotechnik gas boiler light up but suddenly go out?

- How can you eliminate error E01 on a Thermon boiler?

- For this reason, the Electrolux double-circuit boiler began to hum and heat up

- For what reasons does a Ferroli gas boiler display an error code A01?

- For what reason does the Immergaz boiler not operate on hot water supply?

- Why does the Navien gas boiler constantly turn off when heating and then turn on immediately?

___________________________________________________________________________

___________________________________________________________________________

- Heating boiler piping

- STS boilers

- KVT boilers for solid fuel

- Pellet boiler Peresvet

- Steel floor standing boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the Termet gas boiler

- Termona boiler repair

- Boiler repair Nova

- Hermann boiler service

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Daewoo boiler maintenance

- Demrad boiler malfunctions

- Mora boiler malfunctions

- Westen boiler repair

- Malfunctions of Immergaz boilers

- Types of solid fuel boilers

- Models and design of combination boilers

- Liquid fuel and double-circuit boilers

- Cast iron boilers on coal

- Boilers with modeling burners

- Imported boilers for heating systems