Today, there is quite a large demand for extruded polystyrene foam due to the development of both private and commercial construction. Foamed polystyrene has better consumer properties compared to conventional polystyrene, has practically zero moisture absorption, and increased rigidity. Depending on the production technology, foamed polystyrene is of the following types: pressed polystyrene foam EPS - pressless expanded polystyrene PSB XPS - extruded polystyrene foam The price of expanded polystyrene depends on this. Produce extruded foam polystyrene began to be used quite a long time ago; at first, foaming was carried out using hard freons, then a mixture of hard and soft freons was used, then they switched to using only soft freons. After it was proven that freons contribute to the destruction of the ozone layer, foaming with CO2 began to be used instead of freons. For foaming, mixtures of general purpose polystyrene and EPS (expandable polystyrene) are used, pigments or dyes, nucleators, and flame retardants are also added.

The additives used depend on the necessary requirements for the finished product. Foaming occurs using the free foaming method through a flat die, then the resulting web passes through a non-vacuum calibrator consisting of two cooled plates or through cooled forming rolls. When using cooled plates, a thin sheet of fluoroplastic is attached to them to reduce friction between the foaming sheet and the metal of the plates. The calibrator began to be used relatively recently, but previously cooled forming rolls were used.

After pre-cooling and forming, the web passes through a pulling device. After the pulling device, the web is given space for final air cooling, usually this distance is from 10m to 20m, during this distance the web cools almost completely and the foaming process is completed, the product is stabilized and ready for surface treatment. The surface of the canvas is cut, both from the sides and from top to bottom, that is, the canvas is of the correct geometric shape, after which it is cut into sheets of a given length. The cut edges are crushed, granulated and re-processed into the product. With high productivity line, an additional device is used to cool the sheets before packaging. This device is an automatic carousel stacker that takes sheets from one conveyor and transfers them to another conveyor. During the transfer of the sheet, it manages to almost completely cool and stabilize, and accordingly the sheet becomes ready for packaging.

The time the sheet remains on the additional cooling device is from 60 seconds. Next, the sheets are stacked and packed in stretch film or stretch-hood. During extrusion, two single-screw extruders are used, the first is used for melting and mixing the raw materials, and the second as a melt pump, also in the second In the extruder, the foaming additives included in the EPS are completely decomposed. Options for using gear melt pumps are also possible, but they are usually used on low-capacity lines.

Equipment for the production of foam plastic - ready-made production lines or separate installations that can be used to complement the existing configuration. Finished products in the form of expanded polystyrene sheets are used in the construction industry for insulating buildings, creating sound insulation, and finishing external and internal surfaces. This material is supplied in packaging of several sheets up to 100 mm thick each.

Expanded polystyrene production technology

Automated lines and other equipment ensure the preparation of feedstock in the form of granules of a polymer substance, which is loaded into a pre-foamer and treated with water vapor. Foamed granules are sent to a drying unit for up to two days to stabilize the material. To obtain the finished product, molds are used in which high pressure is applied to the polymer to combine the granules into a single structure.

At the final stage, polystyrene foam products are sent to a warehouse, where they are stored for up to one month. During this time, the moisture content of the sheets decreases and internal stresses are relieved. Expanded polystyrene foam cured in this way is cut into sheets of the required sizes and sent to customers.

Loading raw materials into the hopper of the foaming device

Suspension polystyrene is the raw material for expanded polystyrene.

The raw material for the production of expanded polystyrene is suspension polystyrene, the weight when poured is approximately 500 g per cubic m of volume (after foaming it increases to 15-100 kg). Each batch of raw materials has its own time required for foaming, which must be strictly adhered to. When the time limits are exceeded, the granules are destroyed. The technology for the production of foamed polystyrene takes into account the quality of raw materials.

Raw materials arrive at production warehouses usually packed in 25 kg bags or in so-called big bags - soft containers of large size and carrying capacity, with loop slings for loading. Storage conditions for raw materials must be strictly observed. It should be stored on pallets at a temperature of 20-25ºC. Raw materials are not intended for long-term storage, since temporary foaming indicators may change over time. Storage technology is usually indicated on the packaging.

Before loading raw materials, mechanical mixing of polymer granules with modifier additives is performed. Each of them performs its own function. In addition to those already listed above, to improve the uniformity and fine pore structure, nucleate stabilizers, fire retardant additives are added to increase fire resistance, thermal stabilizers and antioxidants to protect against thermal-oxidative destruction, and abiotic additives to prevent molding. It is possible to introduce antistatic and synergistic additives. The technology for introducing additives is selected taking into account the brand of extruded polystyrene foam.

Approximate configuration of areas for the production of polystyrene foam:

- pre-foamers with steam supply at temperatures above +100 °C; steam generators and steam accumulators (gas, electricity, diesel fuel); fan; secondary blowers to reduce the weight of the finished product; drying chambers; storage bins for expanded polystyrene; cyclic block molds for sintering polymers; installations for vacuuming; cutting apparatus for vertical and horizontal cutting of polystyrene foam using nichrome strings.

The price of installations for the production of expanded polystyrene depends on the configuration, brand of individual elements, productivity, and durability.

Existing configurations can always be expanded with additional components, taking into account the actual operating conditions of the production site (compressors, vacuum accumulators, waste crushers, etc.). The reliability and durability of the installations guarantees a quick payback with a low cost of raw materials and maintenance with a minimum number of personnel.

Business organization

Opening an enterprise for the production of extruded polystyrene foam requires solving a number of organizational issues:

- market research;

- development of a detailed business plan, including preliminary financial calculations;

- registration of activities with the tax authority;

- location determination;

- search for space for production and development of the administrative part;

- hiring employees in a quantity determined by the operating hours, as well as the planned production volumes;

- acquisition and installation of equipment;

- launching an advertising campaign, working with the client base.

When registering with the Federal Tax Service, it is recommended to give preference to the LLC form. This will provide an opportunity to seamlessly cooperate with state-owned enterprises. The registration procedure includes several stages:

- preparation of a package of documents;

- contacting the tax authority;

- choosing a taxation system, indicating the appropriate OKVED code;

- receipt of a registration certificate within 5 working days.

The following documents will be required for registration:

- founder's passport;

- application for registration;

- decision to establish a legal entity;

- information about fixed capital;

- charter of the company;

- receipt of payment of state duty.

The start of production will be possible only with the permission of the fire inspectorate.

Selection of premises

The premises for the production of extruded polystyrene foam must meet a number of requirements:

- location in an industrial zone or outside the city;

- presence and operation of the ventilation system;

- equipped with all necessary communications (hot and cold water supply, heating, electrical network (380W), sewerage);

- ceiling height is not lower than 8 meters.

The area of the room should be from 300 m2, since it will include 3 blocks:

- production workshop – 170 m2;

- warehouses for storing raw materials and finished products – 90 m2;

- room for staff needs and office - 40 m2.

The premises must meet all fire safety requirements, since they will produce and store flammable products.

Search for personnel for production

The production equipment of the workshop is almost completely automated, so for the production of polystyrene foam only specialists will be needed to service the machines. The staff will include:

- operator;

- handyman;

- technologist;

- industrial premises cleaner;

- loader;

- storekeeper;

- supervisor;

- manager responsible for selling products and purchasing raw materials;

- accountant;

- driver.

Selection of suppliers and raw materials

Polystyrene granules, which belong to the class of plastics, are used as raw materials for the production of extruded polystyrene foam. Many enterprises cooperate with foreign manufacturers, purchasing raw materials from them. This is due to the ratio of quality and cost of their products. In addition to quality, the price of raw materials is determined by the size of the fraction, which can vary from 0.2 to 3.5 mm (in diameter). Polystyrene purchased abroad allows us to obtain high-quality products with a minimum amount of defects. When purchasing raw materials, it is necessary to take into account the duration of their storage: granules that have been manufactured a long time ago require more time for foaming and do not achieve the required density the first time. In addition to polystyrene, for the production of extruded polystyrene foam you will need:

- steam produced at a temperature of +110 °C;

- cold water.

Advantages of using automated lines:

- the ability to purchase installations of high or low productivity, taking into account the requirements for the quantity of finished products at a particular enterprise; collapsible design of most modules that can be quickly dismantled and replaced; automatic control of production process parameters, a wide selection of settings and adjustments, emergency mode signaling; ease of access to structural components elements to replace faulty elements or upgrade components.

The catalog presents equipment whose manufacturers guarantee trouble-free operation and perform installation and commissioning work.

Equipment for the production of foam concrete or expanded polystyrene is used in the production of rectangular blocks or sheets, which are in demand in the construction of housing, public, industrial and other buildings. The materials are used for the construction of horizontal enclosing structures inside buildings, creating sound and heat insulation. Finished blocks or sheets of expanded polystyrene are delivered to construction sites in batches on pallets (up to 50 pcs.) in plastic packaging and packs of 5–10 sheets.

Equipment selection

To produce polystyrene foam you need equipment:

- foaming agent for repeated foaming - 140 thousand rubles;

- receiving bunker – 30 thousand rubles;

- steam generator – 35 thousand rubles;

- aging bunker with a fan – 40 thousand rubles;

- block form – 10 thousand rubles;

- cutting machine, mechanical – 30 thousand rubles.

The full catalog of equipment can be viewed here.

To reduce the volume of production waste, it is recommended to purchase a crusher for crushing foam plastic scrap.

When making extruded foam, you need to use an extruder; the corresponding production line costs from $100 thousand. This equipment is characterized by high temperature and pressure, which make the resulting material stronger and more efficient in terms of thermal insulation.

There are machines on sale with different capacities, so you should determine in advance the volume of production of extruded foam.

Production of foam plastic and foam concrete

For the production of foam concrete, automatic complexes with the following equipment are used:

- vibrating screens, belt conveyors for grinding and feeding raw materials; weighing dispensers, strain gauges, gates, vibrating units with electric or pneumatic drive; mixers with a foam generator and unloading devices; automatic equipment for adjusting dosing and supply of raw materials;

The price of such equipment is determined depending on the set of components, technical characteristics of the finished product and the degree of automation of all technological processes.

Market analysis: target audience, competition and risks

There are several ways to analyze the market for foam manufacturers:

- searching for information on the Internet;

- visiting large construction supermarkets in the city and obtaining information about the foam manufacturer;

- a combination of two methods.

As a rule, more than 80% of entrepreneurs involved in the sale of building materials purchase finished products from suppliers. Hence, there is a high markup on the product, which includes built-in costs for transportation, inflation, wages and much more. Such entrepreneurs cannot be considered competitors, although in the end they sell the same product.

It is necessary to identify direct producers of foam plastic in the region, determine their level in business (working period, scale of activity, price segment) and compare with your indicators. If possible, it is necessary to set the price of the product no higher than competitors, and preferably 3–4% lower.

Target audience of the project:

- construction companies;

- metallurgical industry;

- advertising business for the installation of external structures;

- manufacturing enterprises of various types;

- logistics related companies;

- businessmen who own catering outlets;

- shops, supermarkets, shopping centers.

Depending on the scale of the project, a businessman can cooperate with either one intermediary or several at the same time, fulfilling orders for the production of foam plastic for different areas of activity.

Possible business risks:

- Poor quality raw materials - the problem is solved by changing the supplier, as well as constant monitoring of product quality.

- Failure or premature wear of equipment is a risk typical for used equipment, as well as in the absence of a warranty from the seller.

- The human factor - violation of foam plastic production technology directly depends on the employees of the enterprise, therefore, in order to exclude any emergency situations, it is necessary to carefully select personnel, conduct training and periodic tests on knowledge of their duties.

- Competition is a serious risk, especially if a competitor appears after the enterprise has started operating. In this case, the entrepreneur needs to review in detail the financial plan of the business project, analyze opportunities to reduce prices, as well as launch an advertising campaign and create new offers on the market.

- Financial crisis in the country and the world - the solution to the problem is to regularly monitor the state of the economy in the country, exchange rates and other nuances, including the political situation, which can directly or indirectly affect business.

Features of foam production technology

When producing foam concrete or expanded polystyrene, the raw materials in the form of sand or polymer substances undergo preliminary preparation and are then fed to the line for forming finished products. To obtain polystyrene foam, polystyrene granules are foamed, which are then dried, steamed, vacuumed and sheets of expanded polystyrene are formed under pressure.

Finished products are packaged using automatic devices and unloaded into storage areas. Expanded polystyrene packaging is lightweight and therefore does not require complex lifting equipment. Heavier foam blocks are placed on pallets, which can be lifted with a forklift or cranes with the appropriate sling set.

Search for personnel for production

The main feature of the business is that it does not require the selection of specialists with certain skills and knowledge. The foam production process is quite simple; most of the work is done by machinery. People just need to be able to manage it and carry out related work.

The following employees will be needed:

- Technologist. He monitors the workers, accepts the finished foam, evaluates its quality and compliance with standards.

- Workers in the amount of 3-4 people (1 shift). They are directly involved in the work process, monitoring the equipment and the storage process.

- Organizing a business as a legal entity. Individuals are advised to hire a qualified accountant who is competent in tax matters.

- To ensure the cleanliness of the premises, you need to hire a cleaner.

- The distribution of polystyrene foam to retail outlets and all logistics issues should be handled by a hired driver with a vehicle.

Advantages of equipment for foam materials:

- the cost of automated lines quickly pays off due to the reduction in maintenance costs and the involvement of a minimum number of personnel; the installations are compact in size and do not require the allocation of premises or large areas; the modular design ensures the quick replacement of faulty units, the modernization of the existing configuration when performance requirements change; new location, dismantled lines are transported by conventional vehicles.

Companies that offer to buy machine equipment for the production of foam materials provide a guarantee for their products, organize delivery, and perform installation and commissioning work. Specialists from such manufacturers conduct classes with staff, teaching the basics of technological processes, maintenance and repair of installed models. Almost all equipment is designed for long-term and intensive use, which eliminates work stoppages due to sudden breakdowns.

Extruded polystyrene foam is a synthetic thermal insulation material consisting of polystyrene granules mixed at high pressure and temperature with the introduction of a foaming component and subsequent extrusion from the extruder. It is also called extruded polystyrene foam, abbreviated as EPS, or XPS.

Competitor assessment

There are not many foam plastic manufacturers on the large Russian market. There are now about 150 companies - many of them large enterprises. They are engaged in wholesale and retail sales, selling goods directly, through dealers and distribution companies.

It is recommended to start a business and gain clients in settlements where there are no competitors producing foam plastic within a radius of 50-150 km. In this case, it will be more profitable for retail stores, wholesalers, and private buyers to purchase products from a company located nearby - its trade margin is significantly lower due to the absence of large expenses on logistics.

The more competitive the prices, the more often customers (especially wholesalers) will contact the company without intermediaries.

Production technology and composition

The chemical composition of the material is similar to polystyrene foam.

Its main component is polystyrene foam granules. They are mixed with fire retardants, which reduce flammability, and substances that increase the strength and improve the characteristics of polystyrene foam, and then melted at elevated temperatures. After obtaining a homogeneous molten mass, a foaming agent, carbon dioxide, is introduced into it under high pressure.

After this, the material goes through an extrusion process. The resulting hot mass is forced through the rectangular hole of the extruder.

As the pressure drops to normal levels, carbon dioxide expands and foams the mass. Using the size of the extruder hole, the thickness and width of the resulting strip are adjusted. The XPS strip is sawn into slabs of specified dimensions.

The use of extruded polystyrene foam complies with the requirements of SNiP 21-01-97 “Fire safety of buildings and structures”. Federal Law No. 123 regulates the toxicity of combustion products.

High-quality EPS has a T2 rating and is classified as a moderately dangerous insulation material. Wood materials, such as parquet, have the same indicator. Production, testing methods, labeling of extruded polystyrene foam are regulated by the requirements of GOST 32310-2012.

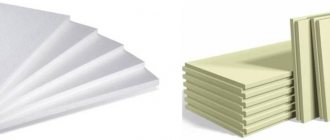

EPS and XPS polystyrene

EPS - expanded polystyrene boards - are formed by pre-pelletizing the granules and then “gluing” them into a block form, which is then cut into boards of the required sizes. The structure of the surfaces cut in this way is quite porous, which mainly affects the increase in absorption in the case of prolonged contact with water.

XPS - extruded polystyrene boards - are manufactured in molds with target plate sizes onto which granules are pressed and undergo foaming. Therefore, these plates have a more uniform closed cellular structure with smooth surfaces. This reduces their susceptibility to soaking with water even after prolonged immersion.

Extruded polystyrene - preferably from available insulation materials - works as insulation for foundation and basement walls, ground floors, and decks.

XPS boards are characterized by much greater hardness and mechanical strength than EPS boards. It is easy to distinguish them from ordinary polystyrene foam because the boards are painted. Additionally, the most common plate size is:

- from expanded polystyrene (EPS) – 500-1000 mm;

- from extruded polystyrene (XPS) – 600-1250 mm.

Thermal insulation – thermal conductivity coefficient:

- EPS EPS – = 0.030-0.042 W / (m • K);

- Expanded polystyrene XPS – 0.028-0.035 W / (m • K).

Soundproofing:

EPS and XPS are poor. An exception is flexible polystyrene boards used for acoustic insulation of floors (in so-called floating floors).

Fire resistance:

EPS and XPS are self-extinguishing materials; in the flames they melt and on a fire, they do not support the fire; after subtracting its source, they come out.

Options and applications

EPS polystyrene is available in several varieties. Most Popular:

- simple - white plates;

- graphite – silver, gray or black plates with a reduced coefficient;

- with reduced water absorption - mostly blue.

Currently, manufacturers mainly use the heat transfer coefficient of this material on packaging - W / (m • K) - the lower it is, the better the thermal insulation. They also define a typical application:

- façade curing;

- roof/floor – flat roofs, floors on the ground;

- roof/floor/parking area – especially busy floors on the ground, such as in garages where truck traffic is expected;

- foundation - the basics, these are varieties with reduced absorbability; – acoustic – construction of floating floors.

Extruded polystyrene XPS, despite differences between individual products, always has very low absorbency and high mechanical strength. Therefore, it can be replaced with polystyrene foam in:

- floors;

- funds;

- inverted and green roofs.

The first classification, relating the compressive strength of expanded polystyrene foam to a specific application, no longer applies. He recommended, for example, polystyrene EPS 70 for double-layer walls, EPS 100 for floors. And while many people are used to it, there is no easy translation between the old and new standards.

Therefore, some manufacturers place an additional label on their products with the designation CS (10).

It is worth adding that the density of polystyrene foam in itself does not determine its thermal insulation. Higher density results in increased compressive strength. When weighing polystyrene foam produced by some manufacturers, it should be considered as a check to see if the information provided on the label is reliable - if this parameter is not true, others may be similar.

Marking

Foamed polystyrene foam is marked according to GOST and European standards.

According to GOST, the marking must contain the following data:

- Product name Name or trademark of the manufacturer and its address Work shift, date of manufacture, workshop of the manufacturer Fire safety class Thermal resistance Thermal conductivity Nominal thickness Marking code Type of cladding or coating, if any Length and width Number of products in the package and their total area, if necessary

European standards for marking XPS are specified in document EN 13164:2001. However, different manufacturers have their own designations for the main characteristics. For example, material under the Penoplex brand has the following markings:

- Type indication – 30, 35, 45 Identification of the corrugated surface Identification of the selected quarter Slab thickness in mm

This marking looks like this: 35GS-30.

Cutting and assembling a fireplace

From a sheet of foam plastic you need to cut two rectangles measuring approximately 60 by 40 cm and two more 40 by 20 cm for the side surfaces. Since polystyrene foam does not adhere well even to PVA, for reliability, fix the joints with toothpicks. You need no more than four of them for one cut.

Pin the side parts to one of the large rectangular blanks with toothpicks, having previously greased the joints with PVA glue.

Prime the seams.

On the inside, mark the “firebox” and cut it out using a sharp knife. The thinner the blade, the more accurate the cut.

Attach the back of the fireplace with toothpicks and glue. Along the upper and lower perimeters, additionally fasten all the parts with masking tape.

Prime the resulting frame.

Let dry for about 12 hours. If necessary, apply the primer again, and after drying, sand it with fine sandpaper. Pre-soak the tape for decorating the firebox in PVA glue, then carefully glue it along the cut of the firebox, simultaneously priming the surface. Dry for at least two hours. Glue small decorations in the corners and cover with gold.

The lid, which will serve as a mantelpiece, slightly larger than the fireplace itself, is attached on top of the finished box. To further decorate it, it is necessary to prime the narrow side surfaces and cover them with gold. Also process the cuts of the firebox.

The base of the fireplace remains open, but you can place it on hard cardboard if you wish.

Release form

XPS is produced in the form of slabs, substrates and decorative elements.

The slabs have dimensions of 600x1200 and 600x2400 mm. Some manufacturers produce slabs with a width of 600 and 580 mm. Their thickness ranges from 20 to 100 mm.

They are supplied to stores in packages. The number of slabs in a package varies and depends on their thickness. Thus, 50 mm thick EPS is sold in packs of 8 pieces, 100 mm thick - 4 pieces.

In addition to slabs, the material is produced in the form of a base for flooring.

There is a substrate for parquet, laminate and linoleum. Also, various decorative elements that are made from gypsum can be made from expanded polystyrene. At the same time, the appearance of the products is practically no different from plaster.

Opening a workshop: step-by-step algorithm

The opening of a production workshop is carried out in several stages:

- Registration as an individual entrepreneur or legal entity. Doing business as an individual entrepreneur is much easier (including due to reporting), but some potential clients (large organizations) work only with legal entities. persons. The organizational and legal form also depends on the volume of output.

- Select equipment. It is recommended to consult with a specialist before purchasing.

- Select premises for the workshop. Install equipment into it.

- Hire staff, prepare for work.

- Select suppliers and purchase raw materials.

- Debug the process (resolve logistics issues, etc.) and begin production of expanded polystyrene.

No permit is required to begin work. You just need to settle the issues with the fire department.

The business production plan given in the article makes it possible to open a profitable business that will begin to generate net income within 3 months. Given the high demand and growth in construction volumes, this idea will allow the entrepreneur to organize a work process with little investment and quickly achieve success.

Extruded polystyrene foam: characteristics

Strength within 2-3.6 kgf/sq.

cm at 10% linear deformation and 4-7.1 kgf/sq. cm for static bending. The strength indicator of EPPS directly depends on its thickness and density. Volumetric weight is 15-29 kg/cubic.

m and 30-36 kg/cu.m. m. The first is used for insulating houses and industrial buildings and is attached to unloaded structures - walls, ceilings, interfloor ceilings.

The second is used for insulating foundations, floors, roofs and other horizontal and inclined surfaces. There is virtually no shrinkage of the material under any operating conditions. Thermal conductivity is 0.026 W/mC at an average temperature of 10 C. As an insulation material, polystyrene foam is noticeably superior to other materials. For example, 50 mm thick foam insulation will be equivalent to 20-30 mm EPS. Frost resistance.

The material loses only 5% of its thermal resistance after 1000 freeze-thaw cycles. The temperature range in which it does not change the physical and thermal conductivity parameters is from -50 to +75 C. Water absorption is not higher than 0.5% of the volume for 30 days. Low moisture absorption is due to the low capillarity of the material.

This allows it to be used in conditions of high humidity and for insulating basement floors, foundations and roofs. Water absorption occurs only on the surface due to the fact that there are destroyed cells there. Vapor permeability depends on the thickness and density of the EPS. Plates with a thickness of 20 mm have a vapor permeability equivalent to one layer of roofing felt.

Expanded polystyrene of the Penoplex brand has a vapor permeability coefficient of 0.007-0.012 mg/(mchPa). The fire resistance class of conventional EPS is G3-G4. The addition of fire retardants raises the class to G1. The material is not completely non-flammable, but has sufficient fire resistance for use in the construction of buildings and structures. The cost of the material is calculated per square meter or cubic meter.

Depending on the manufacturer and brand, it ranges from 55-80 rubles/sq. m. or from 3800 rub./cub.

m. Sound insulation. Impact noise reduction index – 25 dB. XPS refers to materials used for insulation against impact noise. Environmental friendliness.

The insulation is classified as moderately hazardous and has a toxicity class of T2. It is not subject to decomposition in the environment, the appearance of fungi and mold. The service life of extruded polystyrene foam is comparable to the service life of the building. High-quality material lasts more than 40 years, subject to compliance with installation technology.

Selection of premises

The production of polystyrene foam cannot be done at home. To work, you need a room of about 200 square meters. m, of which 50 sq. m will be occupied by a warehouse. The rest will go to the production floor.

Primary requirements:

- electricity;

- water supply;

- ventilation system;

- heating;

- high ceilings (3-5 m).

Most of the workshop will be occupied by equipment. For equipment with a capacity of 20 cubic meters. m you need to allocate at least 100 sq. m. m. The warehouse must be protected from direct sunlight and moisture.

A good ventilation system in production is important due to the harmful fumes. The temperature in the workshop (warehouse) should not fall below 15° C.

When producing polystyrene foam, an even larger room will be required (at least 250 sq. m).

Advantages and disadvantages

Advantages of extruded polystyrene foam over analogues:

- Very low moisture absorption Durability Easy to use and install High thermal insulation ability Strength and ability not to lose shape and volume under different operating conditions

Along with its advantages, it has some disadvantages.

Among these is a low level of vapor permeability. As insulation, it is not suitable for all types of premises. If you insulate a residential building with it, it will turn into a thermos that cannot breathe.

Another disadvantage is the cost, which is higher than other insulation materials. Although the technical characteristics and price of extruded polystyrene foam are adequate to each other. Finally, the sound absorption of XPS in practice is quite low.

Product promotion

The product can be sold wholesale or retail. Most of the buyers are construction companies. A businessman needs to make efforts to enter the market and establish business relationships with buyers.

There are several ways to attract customers: offering products at lower prices, providing discounts for large volumes, providing free delivery services, and having experts visit the site to determine the required volume of foam.

You can contact distribution companies and sell through them. Plus, such companies already have an established client base. The downside is that the products will be sold at a premium. Or you will have to pay extra to the intermediary for “better work.”

Products should also be sold at retail, through hardware stores. Here, a lot will be decided by the initial price that the entrepreneur sets.

Installation methods

Eps boards are mounted on special adhesives and then reinforced with mushroom dowels.

There are two common options for fastening with dowels - one in the center of the slab or four in the corners at the joints between the slabs. We found out what extruded polystyrene foam is and what differences and advantages it has over other insulation materials. It is easy to purchase in retail and wholesale stores, as well as online. Expanded polystyrene is a popular construction and industrial material discovered in 1839.

German pharmacist. It is used for packaging food, making disposable tableware, life jackets, advertising banners, and energy absorbers in the automotive industry. Expanded polystyrene is indispensable for thermal insulation of road surfaces to prevent freezing during the cold season. The material is used in the production of refrigeration equipment.

Extruded polystyrene foam is an improved form of the standard composition. It has a synthetic base and is produced by foaming the polymer composition during extrusion or pressing of the material using a die. Extruded polystyrene foam is waterproof, resistant to loads, deformations, and solvents, and retains its properties at ambient temperatures from -500 to +7500 C. Its low thermal conductivity makes it indispensable for insulating structures. Expanded polystyrene is lighter and safer than similar materials.

A width of 2 cm is enough to perform the main functions, while a wooden sheet will require 2.5 cm, mineral wool 3.8 cm. How is extruded polystyrene foam produced? To create a suitable composition, a base of polystyrene granules and a foaming element are used. Freons are used as a foaming agent. Due to the negative impact of hard or soft freons on the ozone layer, European and Russian manufacturers are coming to the use of a freon-free CO2 system. The technology for creating extruded polystyrene foam determines its performance properties, practicality, wear resistance, and wide range of applications.

Assessing demand in the foam market

Polystyrene foam is used in various fields:

- construction sector (thermal insulation);

- trade sector (product packaging and decoration);

- for the production of non-food products (clothing, various equipment, furniture, fillers for life jackets);

- creation of outdoor advertising structures;

- certain areas such as shipbuilding, etc.

The construction sector accounts for more than 85% of the consumer market. Insurance companies buy this building material in wholesale quantities - to cooperate with them, it is advisable to open a small warehouse and create large volumes of products. There is also a demand for the material in retail trade - this opens up opportunities for supplying retail outlets (construction stores and hypermarkets).

Foam plastic sells well in all Russian regions, because the volume of construction of apartment buildings is growing.

Stages of producing polystyrene foam, from granules to finished slabs

— at the first stage, the granules are poured into the pre-foamer compartment, deformed, and take on the shape of balls. To achieve the finished material with minimal weight, the foaming procedure is repeated several times, the granules swell to a large size.

— in the second stage, the granules are placed in a storage bin for 24 hours. During this time, the pressure stabilizes. Using the suspension polymerization method, a separate step is drying the spherical granules.

— the third stage is to give the material a convenient form for use.

Small balls are impractical in construction. To ensure their gluing, they resort to hot steam and a mold. So after cooling, a ready-made polystyrene foam block is obtained.

— the final stage is drying the finished material.

When exposed to steam, moisture is retained between the granules. It is impossible to cut a wet base without damage and deformation. After 24 hours of drying, the polystyrene foam block can be easily divided into thin slabs, ready for use.

The technology of foaming granules and squeezing them out of an extruder under the influence of high temperatures makes it possible to obtain a universal material.

It does not absorb water, retaining heat, which makes it perfect and modern. It is fireproof, rodents and insects are indifferent to it. To adjust the slab to size, just use a sharp knife.

Popular polystyrene foam manufacturers

The building materials market boasts expanded polystyrene from a variety of manufacturers, both foreign and domestic. Let's get acquainted with the most popular brands.

• Europlex . This company is a leader in the production of thermal insulation for the construction industry. Among Europlex products you can find both stepped and corrugated slabs with a wide variety of physical properties that can satisfy the requirements of the most demanding customer.

• "URSA XPS" . The material from this company is characterized by increased strength, which makes it indispensable for professional construction. If you need polystyrene foam for floor insulation that can withstand increased loads, slabs from URSA are your best choice!

• "Penoplex". This is the largest Russian manufacturer of expanded polystyrene, which produces insulation for both private and industrial buildings, as well as for various utilities. Manufacturers can boast of a variety of forms and types of polystyrene foam at affordable prices, which distinguishes this company from many other manufacturers.

• Stirex. Another Russian manufacturer producing panels for both civil and industrial construction. Styrex cannot boast such a wide range of products as Europlex, but this company produces panels for aviation and road construction. In addition, the company in question pleasantly surprises with its prices.

As you can see, extruded polystyrene foam is a universal material that can become a reliable protection for your home from cold, excess noise and other troubles. With such insulation, installed in compliance with the technology, your home will forget about all the problems for decades!

Polyurethane foam: types, properties, application

Ecowool - properties, application methods, manufacturers

Two ways to create high quality extruded polystyrene foam

— suspension polymerization takes effect during the foaming of the granules.

They are poured into autoclave reactors with a volume of up to 50 cubic meters. m. Inside, the compartments are filled with demineralized water mixed with a solvent that stimulates polymerization and stabilizes the emulsion.

Pressure and temperature changes from 40 to 1300C affect the granules for 14 hours. Using a centrifuge, the foamed polymer is separated from the aqueous suspension. The advantage of the technique is the increased shelf life of the material and uniform heat distribution.

— polymerization in oil is carried out at high temperatures from 80 to 2200C, in the complete absence of water. The reactor mixers are interconnected, and polystyrene foaming occurs in them. Polymerization continues until 90% of the starting material is melted.

Residues are eliminated in the final reactor with vacuum. Fire retardants and stabilizers are added to the resulting melt to create granules. This method guarantees high density of the finished material, flexibility, and a minimum of waste.

Extruded polystyrene foam includes the stage of extruding the melt with the addition of foaming particles using a press extruder. The finished product results in a heat insulator with compartments with a diameter of up to 0.2 mm. A feature of extruded polystyrene foam is the minimum cell size, which improves performance characteristics.

What it is

How to choose material and lay larch flooring. House made of larch: advantages and disadvantages Disadvantages and limitations in the use of larch

Today, the range of various finishing materials is so large that you can simply get lost in its richness. Thus, one of the most popular coatings, which has many positive qualities, is extruded polystyrene.

This product is a special material of synthetic origin, which was first released in the USA in 1941. Currently, polystyrene is used for a variety of purposes. It is this raw material that is used for thermal insulation of structures such as foundations and roofs. In addition, extruded polystyrene has good contact with facade plaster.

Materials for production

Since there are several types of such material, accordingly, it is produced from various raw materials. The most popular today are products from:

- polystyrene;

- polyurethane;

- polyvinyl chloride;

- polyethylene.

Let's take a closer look at the production of each of these types of foam:

- Polystyrene foam is made from styrene polymers. This substance has minimal strength and can be easily dissolved with gasoline or acetone. This type of foam is formed by gas-filling styrene granules. Also, the procedure for obtaining such substances involves the use of additional substances that improve the structure or color the product itself.

- Polyurethane foam has good technical characteristics, which depend on the procedure for obtaining such a substance. Polyurethane polymers are very often used in various industries. The structure of foam made from such substances can be different (hard or elastic), which is obtained from certain types of these raw materials. This material is obtained by foaming using special gases.

To obtain polyvinyl chloride foam, they resort to heating the raw material and then foaming it under the influence of various gases. To obtain a material with the original characteristics, the resulting mixture can be pressed.

The mechanical properties of polystyrene foam are also controlled using special substances that are added during its production process.

Polyethylene is used as a raw material for the preparation of such products. The foam made from it is soft and almost colorless.

Such products are used as wrapping for packaging various plumbing fixtures and household appliances. Such material is also obtained under the influence of gases that penetrate the pores of polyethylene.

Polystyrene foam is popular as insulation, and therefore it is often used to insulate the facades of houses.

Watch the video to see how polystyrene foam is made:

All stages of foam production technology are considered. The equipment needed to produce this material is listed. Recommendations are given that you should definitely read before purchasing.

Many of us have come across expanded polystyrene more than once, tried it to the touch, made something from it, used it in construction, for home improvement. However, not everyone knows what the foam manufacturing technology is and what its features are.

Oddly enough, there is nothing super complicated in the production of this material. And it is noteworthy that now quite a lot of low-quality polystyrene foam has appeared on the market, which is made without taking into account the relevant norms and regulations.

Some craftsmen manage to create a small production line even in an ordinary garage. Yes, don't be surprised.

And this must be taken into account when purchasing - not all Vasya Pupkins strictly adhere to the prescribed technological standards. And what standards can there be in a garage?

External wall insulation with penoplex

The disadvantages of external insulation of the walls of a house with penoplex lie in its high density and, as a result, poor adhesion - the material does not absorb the adhesive composition well enough. Because of this, over time, the fastening of the slabs to the wall, as well as the finishing finish, may weaken, condensation will begin to appear, and the facade will lose its beautiful appearance. In order to neutralize such disadvantages of external insulation of the walls of a house with penoplex, it is very important to use a sufficient number of additional fasteners (fungi), which in practice many neglect, especially in small areas. Many craftsmen recommend insulating the base with penoplex, and insulating the outside walls not with penoplex, but with polystyrene foam, which has good adhesion. One thing to keep in mind is ventilation. The low vapor permeability of penoplex can also be a disadvantage. Therefore, during construction, it is necessary to ensure good air movement both in the facade structure (ventilation gap) and sufficient ventilation of the premises for the timely removal of excess moisture.

Pentane content in polystyrene foam

At each stage of processing, pentane is released from polystyrene foam, which is spent on the technological cycle.

Pentane losses during the production of polystyrene foam

- 25% - pre-foaming;

- 15% - exposure;

- 20% - molding;

- 40% remains in the details. This amount is reduced by ≈25% during the first day of storage. The higher the ambient temperature, the faster pentane evaporates.

When pre-foaming at 15-25 kg/m. cube loss of pentane up to 2% within 24 hours after pre-foaming.

Therefore, if you smell a smell when purchasing polystyrene boards for insulation, this is a material with a broken manufacturing cycle.

The bulk density of the foam can be set by pre-foaming and molding parameters. From the same brand of polystyrene you can produce polystyrene foam of various densities. Finished foam blocks are processed with cutters, saws, and hot wire.