Effective heating control is a vital part of running your boiler and home heating system efficiently. Proper use of controls will reduce the energy consumption of the unit, while creating a comfortable temperature in every room of the house, avoiding overheating of the premises. A thermostat (or programmer) controls the operation of the boiler depending on the room temperature.

Up to 20% of the volume of energy consumed can be saved by using this type of automation. And energy prices are quite high and every normal person wants to reduce their expenses.

We consider a situation where the boiler is calculated correctly, the necessary insulation of the premises has been completed, and the heating system is functioning normally.

Main types of boilers and temperature control

There are several types of boilers: solid fuel, gas, electric and liquid fuel.

Boilers have become widespread throughout the world. There are domestic samples, and there are also imported boilers. Material of manufacture: steel or cast iron. Easy to use, economical, with the function of adjusting the coolant temperature. In cheaper models, this function is implemented using a special device - a thermoelement.

Structurally, a thermoelement is a metal product, the geometric dimensions of which decrease or increase under the influence of temperatures (depending on the degree of heating). And this, in turn, changes the position of a special lever that closes and opens the draft damper. The photo shows an example of such a regulator:

Photo: thermostat sample

The more the damper is open, the stronger the combustion process, and vice versa. Thus, the volume of air that enters the closed combustion chamber is completely controlled by the thermostat, and if necessary, its supply is stopped and the combustion process is extinguished. More modern models are equipped with controllers that, depending on the specified thermal conditions, control the air flow, turning on (or off) a special fan (see photo below):

Boiler with temperature controller

Gas boilers are the most common and cheapest units to operate. Boilers are single-circuit and double-circuit. Single-circuit boilers have one heat exchanger and are intended for heating only. The connection diagram is shown in the figure below:

Switching diagram for a single-circuit boiler

Double-circuit boilers have two heat exchangers and are designed for heating and producing hot water. The boiler switching diagram is presented below:

Switching diagram for a double-circuit boiler

Some boilers have separate controls for heating and hot water temperatures.

Installation of the draft regulator

The draft regulator can be installed by you yourself. This element must be located in the front or side of the equipment. The device must be installed in a special hole. The installation work is carried out using screw connections that can be adjusted, this aligns the element in the correct position, which can be horizontal or vertical.

Once all the screws can be aligned, they must be secured and sealed using special means. The lever must be installed in such a way that the hole through which the chain will come out is located above the damper. As soon as the draft regulator is installed, the boiler equipment can be heated and the coolant can be brought to 60 °C. This temperature should be set on the regulator. The regulator lever is connected using a chain, and the damper should be open approximately 2 mm or less. When calibrating the device, the damper must be closed; this must be done manually or by shortening the chain.

Electric boilers

A fairly common alternative to gas and solid fuel boilers. Lots of advantages, high efficiency, but long payback period. The connection is simple, like with gas boilers, but without a cold water supply. Temperature regulation and overheat protection are provided.

Mechanical boiler timer

Using a simple mechanical timer for an electric boiler, there are three options for starting the central heating system :

- The boiler is turned off;

- The boiler supplies warm water;

- The boiler turns on and off at the set time.

Mechanical timers usually have a large round dial with a 24-hour scale in the center. By turning the dial, you can set the desired time, and then leave it in that position. The boiler will turn on at the right time. The outer part consists of a set of tabs for a 15-minute period, which are inserted for easy adjustment of operation and mode settings. Emergency reconfiguration is possible, which is performed with the boiler connected to the network.

Mechanical timers are easy to set up, but the boiler always turns on and off at the same time every day, and this may not satisfy the owners if the family is large and bathing procedures are carried out several times a day at different times.

Description of traction force

This parameter depends on many factors, including:

- weather;

- chimney section;

- gas temperature.

All this can affect the operation of the device, so specific conditions must be considered individually. Another parameter that may escape the attention of consumers, but has a great influence on traction force, is the type of equipment. When using a gas device, the thrust force may change slightly, but the final value is stable. This is due to the fact that the flue gases have almost the same temperature.

The deviation occurs only when the chimney warms up, and the value changes briefly. Solid fuel equipment shows different data. It is impossible to judge the influence of models on traction. This is due to the use of different types of fuel. The heterogeneity of indicators also depends on the type of solid fuel boiler.

Types of thermostats

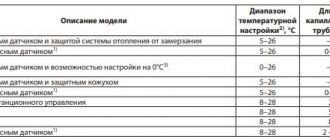

Based on the type of functions, they can be divided into several groups:

— with one function (temperature maintenance);

Thermostat with one function

- with a large number of functions (programmable).

Programmable temperature controller

Based on their design, thermostats are divided into types: wireless and with wires for communication with the boiler. Install the thermostats in a convenient place, connect the temperature sensor, connect it to the boiler control system and use it.

Room thermostats need a constant flow of air to function properly and properly, so they should not be covered with curtains or blocked by furniture. Devices adjacent to the electric thermostat may interfere with the correct operation of the device: lamps, televisions, heating devices located nearby.

Instead of a preface

Today, high technologies make it possible to create various automation tools; thanks to them, boiler equipment works independently, and there is almost no need to pay attention to it. But most of them use electricity, which is not very convenient. Along with power outages, the house is filled with cold; this situation cannot be called rare. The reason is the automatic shutdown of the heating device.

However, on sale today you can find fairly simple automation equipment that does not require electricity to operate; this includes a draft regulator, which is used in conjunction with mechanically driven boilers.

Programmable room thermostat

A programmable electronic room thermostat allows you to select the desired and comfortable temperature at any time; it is easy to reconfigure and change the operating mode. The timer allows you to set a different heating pattern on weekdays and weekends. Some timers allow you to set different settings for each day of the week, which can be useful for people who work part-time or shift work. Many Terneo and KChM models are equipped with such thermostats.

Programmable room thermostat

A programmable room thermostat allows you to set individual heating standards for each day in accordance with your lifestyle and maintain the temperature of the house all the time, regardless of the presence or departure of the owners. Video: Connecting a room thermostat to a gas boiler

If the heating system is controlled by a boiler with a radiator, as a rule, only one programmable room thermostat is needed to control the entire house. Some patterns need to be adjusted in the spring and fall as the clocks move forward and backward or certain changes in climatic conditions occur. We also recommend changing the temperature settings when changing from day to night.

This climate controller has several options that expand its capabilities:

- “Party”, which stops heating for several hours, then resumes;

- “Override” allows you to temporarily change the programmed temperatures during one of the configured periods;

- “Holiday” increases the heating intensity or reduces it for a certain number of days.

Carrying out the adjustment

The draft regulator for the boiler has two types of markings, which are used in different positions. If we are talking about the RT 10 device, then we can say that its red scale is used for working in a horizontal position, and the yellow one for working in a vertical position. You can adjust the product by disconnecting the lower end of the chain from the air damper. This loosens the screw. After choosing the scale color, you need to set the desired temperature value.

The heat generator ignites and warms up, during which the temperature of the coolant is controlled. As soon as the temperature level reaches the desired value, you should put the end of the chain on the ash pan door. When calibrating the chimney draft regulator, the chain must be tensioned and its free play should not be more than 1 mm. The handle is then secured with a screw.

Central thermostat

This thermostat is located far away from your boiler and usually allows you to turn the heating on or off throughout the house. Older versions are connected by wires to the boiler; newer systems tend to send signals to the device's command post. It is the new type of devices that are equipped with quite expensive but effective appliances: double-circuit boilers Ferroli, Beretta and domestic AOGV.

The most famous are room thermostats for double-circuit boilers of the Gsm and Protherm brands. They have a built-in dilatometric thermostat for the boiler, which, depending on the model, can operate remotely; this technology is often used for an electric boiler or solid fuel units.

The room thermostat turns off the heating of the system as needed. It works by measuring the air temperature, turning on the heating when the air temperature drops below the thermostat setting, and turning it off when the set temperature is reached.

Adviсe:

- It is recommended to set the thermostat to 20°C;

- At night, the set temperature should be between 19-21° C.

- It is advisable that the temperature in the children's room is about 22 ° C.

- The temperature should not fall below 22°C in rooms for elderly and disabled people.

As a rule, the temperature of the entire house or individual rooms is based on only one climate microcontroller in the heating system. The best option is to place it in the living room or bedroom, which should probably be the most visited place in the house.

Room thermostats need free air flow to measure temperature, so they should not be covered with curtains or blocked by furniture. Devices adjacent to the electric thermostat may interfere with the correct operation of the device. These include lamps, TVs, neighbors' boilers through the wall, touch switches.

TOP 5 most popular models on the market

Zilon ZA1 - the flagship in the line of mechanical options

The simplest mechanical model, designed for equipment that supports the connection of “mechanics”. Relatively small temperature range ( from +10 to +30 ). Not recommended for use in rooms with high humidity.

| Sensing element | bellows (filled with gas) |

| Operation temperature, C | 10…30 |

| Ambient temperature, C | 5…30 |

| Protection class | II |

| Degree of protection | IP 20 |

| Resource (number of cycles) | 10 000 |

| Execution | wall-mounted |

| Dimensions, mm | 80 x 80 x 40 |

| Color | white |

| Relay output | 16 (4) A / 250 V~ |

| Differential | t=0.4/0.8 K |

| Rate of temperature change | 1 K/15 min |

| Working conditions | normal environment; not installed in rooms with high humidity and in aggressive environments |

| Peculiarities | built-in on/off switch, indicator |

Protherm Exacontrol - a budget device with temperature programming capabilities

It can work both with the equipment of the manufacturer and with boilers of other types. It regulates the temperature only in the heating circuit, the range is from +5 to +35. Equipped with a light display.

| Dimensions (height x depth x width) | 95 mm x 40 mm x 130 mm |

| Connection | Wired |

| eBus control interface | – |

| Regulation | |

| Adjustable temperature range (heating), °C | 5–30 |

| Adjustable temperature range (water supply), °C | 38–65 |

| Control Panel | |

| Liquid crystal display | • |

| Mode indication | • |

| Temperature display | • |

| Time indication | • |

| Low battery indication | • |

| Control | |

| Heating system | • |

| Hot water supply | — |

| Programs | |

| Daily allowance | • |

| Weekly | • |

| Vacation | • |

| Comfort | • |

| ECO | • |

| Frost protection | • |

| Electrical connection | |

| Alkaline batteries 1.5V, Type/pcs | AA/2 |

| Electrical protection class | IP20 |

| Dimensions | |

| Height, mm | 95 |

| Depth, mm | 40 |

| Width, mm | 130 |

FH-CWP. The most prominent player in the market from Danfoss

Equipped with an LCD display and two-position adjustment function. To turn heating on/off according to time, there is a built-in timer and 4 customizable modes. Range – from +5 to +35 .

| Dimensions | 86 x 99 x 19mm |

| Frost protection | Yes, if enabled: less than 5 °C heating turns on above 7 °C the heating is switched off |

| Ambient temperature, C | — 10 °C — 60 °C |

| Adjustment accuracy | ±1 °C |

| IP class | IP 30 |

| LCD Backlight/Night Light | Yes |

| LCD screen | Yes |

| Maximum load, induction | 1A |

| Maximum load, resistive | 3A |

| Installation | Concealed installation for European and Chinese built-in sockets |

| Power consumption | 2 W |

| Backing up settings | Settings are saved in the memory chip in case of power failure |

| Sensor, floor adjustment range | 20-45 °C |

| Sensor, room - adjustment range | 5-35 °C |

| Antistatic protection | Yes |

Auraton 2025 - a reliable, time-tested wireless programmer

Has 4 independent temperature settings. The LCD display is equipped with 3 types of night backlight, and a built-in timer can completely turn off the display backlight at night.

| Temperature control range | 4° - 35°C |

| Hysteresis | 0.4°C (±0.2°C) |

| Programs | 9 of them 6 are customizable |

| Temperature levels | 2 + vacation pay |

| Antifreeze temperature | adjustable from 4°C to 10°C |

| Work cycle | weekly |

| Operation status monitoring | LCD display |

| Maximum load current | 16 A with active load |

| Nutrition | 2 AA batteries |

Electronic room thermostat VT.AC 701.0 with two-position control - classic is always in fashion

Electronic thermostat with two-position control. The temperature value is displayed on a monochrome LCD display . Range – from +5 to +40 .

| Degree of protection | IP20 |

| Display type | LCD |

| Number of control keys | 2 |

| Presence of a timer | No |

| Storage temperature | -20°C to +50°C |

| Average total service life | 15 years |

| Permissible air humidity | 65% |

Thermostatic control valves

The thermostatic valve is a simple solution to the problem of obtaining a coolant at a given temperature by mixing colder water with warmer water. The three-way valve is shown below:

Three-way valve

Scheme for connecting a three-way valve to the heating system:

Scheme for connecting a three-way valve to a heating system

Piping diagram for a solid fuel boiler using a thermostatic three-way valve:

Piping diagram for a solid fuel boiler using a thermostatic three-way valve

Piping diagram for a gas boiler using a thermostatic three-way valve:

Piping diagram for a gas boiler using a thermostatic three-way valve

The thermostatic radiator valve allows you to control the temperature in the room by varying the flow of hot water through the radiator. They regulate the flow of hot water through the radiator, but do not control the boiler. Such devices must be installed to adjust the temperature needed in each individual room.

This idea should be considered as an addition to the thermal control installation. Also, such devices require periodic readjustment and regular performance checks (every six months when changing operating modes).

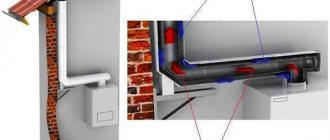

Installation of the draft regulator:

The draft regulator can be installed in three ways: vertically and horizontally (from the side or front of the boiler).

1 Install the draft regulator in a vertical or horizontal position in a special 3/4 hole in the boiler body. Use special products to seal threaded connections.

2 If it is necessary to align the draft regulator relative to the boiler body, loosen screw 3 and bring the draft regulator to the required position. Fix screw 3.

3 Use the screw (2) to secure the lever (1) in the draft control body so that the hole for the chain is above the damper.