Calculating the heating of a private house is one of the important tasks during its construction or major repairs. It is better to do this at the planning stage. A special online calculator can provide some assistance in calculations. There are many calculators for calculating fuel consumption, furnace power, ventilation system, chimney cross-section, productivity of the “warm floor” pumping and mixing unit and others. However, it should be taken into account that all of them show only an approximate result, because can only calculate the simplest configurations. In fact, when calculating heating, it is necessary to take into account a lot of additional nuances. This must be done in order to correctly calculate the costs of the entire heating system and in the future not to suffer from cold in the house or, conversely, its excess, and therefore unnecessary fuel costs.

For help in calculating heating systems, we turned to Akvahit, a company that specializes in installing heating systems in private homes.

When choosing a boiler for heating a house, you need to take into account all the parameters: both the heating equipment and the residential building Source baraholka.com.ru

Calculation stages

It is necessary to calculate the heating parameters of a house in several stages:

- calculation of heat loss at home;

- selection of temperature conditions;

- selection of heating radiators by power;

- hydraulic calculation of the system;

- boiler selection.

The table will help you understand what power radiator is needed for your room.

Heat loss calculation

The thermal engineering part of the calculation is performed on the basis of the following initial data:

- thermal conductivity of all materials used in the construction of a private house;

- geometric dimensions of all building elements.

The heat load on the heating system in this case is determined by the formula: Mk = 1.2 x Tp, where

Tp - total heat loss of the building;

Mk - boiler power;

1.2 - safety factor (20%).

For individual buildings, heating calculations can be made using a simplified method: the total area of the premises (including corridors and other non-residential premises) is multiplied by the specific climatic power, and the resulting product is divided by 10.

The value of the specific climatic power depends on the construction site and is equal to:

- for central regions of Russia - 1.2 - 1.5 kW;

- for the south of the country - 0.7 - 0.9 kW;

- for the north - 1.5 - 2.0 kW.

A simplified methodology allows you to calculate heating without resorting to the expensive help of design organizations.

Temperature conditions and selection of radiators

The mode is determined based on the temperature of the coolant (most often it is water) at the outlet of the heating boiler, the water returned to the boiler, as well as the indoor air temperature.

The optimal regime, according to European standards, is the ratio 75/65/20.

To select heating radiators, before installing them, you should first calculate the volume of each room. For each region of our country, the required amount of thermal energy per cubic meter of space has been established. For example, for the European part of the country this figure is 40 W.

To determine the amount of heat for a specific room, you need to multiply its specific value by cubic capacity and increase the resulting result by 20% (multiply by 1.2). Based on the obtained figure, the required number of heating devices is calculated. The manufacturer indicates their power.

For example, each fin of a standard aluminum radiator has a power of 150 W (at a coolant temperature of 70°C). To determine the required number of radiators, you need to divide the amount of thermal energy required by the power of one heating element.

Hydraulic calculation

There are special programs for hydraulic calculations.

One of the most expensive stages of construction is the installation of the pipeline. A hydraulic calculation of the heating system of a private house is needed to determine the diameters of the pipes, the volume of the expansion tank and the correct selection of the circulation pump. The result of the hydraulic calculation is the following parameters:

- Coolant flow in general;

- Loss of heat carrier pressure in the system;

- Pressure loss from the pump (boiler) to each heating device.

How to determine coolant flow? To do this, you need to multiply its specific heat capacity (for water this figure is 4.19 kJ/kg * deg. C) and the temperature difference at the outlet and inlet, then divide the total power of the heating system by the result obtained.

The diameter of the pipe is selected based on the following condition: the speed of water in the pipeline should not exceed 1.5 m/s. Otherwise the system will make noise. But there is also a lower speed limit - 0.25 m/s. Pipeline installation requires an assessment of these parameters.

If this condition is neglected, airing of the pipes may occur. With correctly selected sections, a circulation pump built into the boiler is sufficient for the functioning of the heating system.

The pressure loss for each section is calculated as the product of the specific friction loss (indicated by the pipe manufacturer) and the length of the pipeline section. In the factory specifications they are also indicated for each fitting.

Choosing a boiler and a little economics

The boiler is selected depending on the degree of availability of a particular type of fuel. If gas is supplied to the house, there is no point in purchasing solid fuel or electric. If you need to organize hot water supply, then the boiler is not selected based on heating power: in such cases, they choose to install double-circuit devices with a power of at least 23 kW. With lower productivity, they will provide only one water collection point.

Standards for room temperature conditions

Before carrying out any calculations of system parameters, it is necessary, at a minimum, to know the order of the expected results, and also to have standardized characteristics of some tabular values that need to be substituted into formulas or be guided by them.

By calculating parameters with such constants, you can be confident in the reliability of the desired dynamic or constant parameter of the system.

For premises of various purposes, there are reference standards for temperature conditions in residential and non-residential premises. These standards are enshrined in the so-called GOSTs

For a heating system, one of these global parameters is the room temperature, which must be constant regardless of the season and environmental conditions.

According to the regulations of sanitary standards and rules, there are differences in temperature relative to the summer and winter periods of the year. The air conditioning system is responsible for the temperature regime of the room in the summer season; the principle of its calculation is described in detail in this article.

But the room temperature in winter is provided by the heating system. Therefore, we are interested in temperature ranges and their deviation tolerances for the winter season.

Most regulatory documents stipulate the following temperature ranges that allow a person to stay comfortably in the room.

For non-residential office premises with an area of up to 100 m2:

- 22-24°C - optimal air temperature;

- 1°C is an acceptable fluctuation.

For office-type premises with an area of more than 100 m2, the temperature is 21-23°C. For non-residential industrial premises, temperature ranges vary greatly depending on the purpose of the room and established labor protection standards.

Each person has their own comfortable room temperature. Some people like it to be very warm in the room, others feel comfortable when the room is cool - it’s all quite individual

As for residential premises: apartments, private houses, estates, etc., there are certain temperature ranges that can be adjusted depending on the wishes of the residents.

And yet, for specific premises of an apartment and house we have:

- 20-22°С - living room, including children's room, tolerance ±2°С -

- 19-21°С - kitchen, toilet, tolerance ±2°С;

- 24-26°С – bathroom, shower, swimming pool, tolerance ±1°С;

- 16-18°C - corridors, hallways, staircases, storerooms, tolerance +3°C

It is important to note that there are several more basic parameters that affect the temperature in the room and which you need to focus on when calculating the heating system: humidity (40-60%), concentration of oxygen and carbon dioxide in the air (250:1), air movement speed mass (0.13-0.25 m/s), etc.

Calculation of different types of radiators

If you are planning to install sectional radiators of a standard size (with an axial distance of 50 cm in height) and have already chosen the material, model and desired size, there should not be any difficulties in calculating their number. Most reputable companies that supply good heating equipment have on their website the technical data of all modifications, including thermal power. If it is not the power that is indicated, but the coolant flow rate, then it is easy to convert to power: the coolant flow rate of 1 l/min is approximately equal to the power of 1 kW (1000 W).

To make life easier for customers, many websites install a specially designed calculator program. Then the calculation of heating radiator sections comes down to entering data on your premises in the appropriate fields. And at the output you have the finished result: the number of sections of this model in pieces.

The axial distance is determined between the centers of the coolant holes

But if you’re just evaluating possible options, then it’s worth considering that radiators of the same size made of different materials have different thermal power. The method for calculating the number of sections of bimetallic radiators is no different from calculating aluminum, steel or cast iron. Only the thermal power of one section can be different.

To make it easier to calculate, there are averaged data that you can use as a guide. For one radiator section with an axial distance of 50 cm, the following power values are accepted:

- aluminum - 190W

- bimetallic - 185W

- cast iron - 145W.

If you are just figuring out which material to choose, you can use this data. For clarity, we present the simplest calculation of sections of bimetallic heating radiators, which takes into account only the area of the room.

When determining the number of heating devices made of bimetal of a standard size (center distance 50 cm), it is assumed that one section can heat 1.8 m2 of area. Then for a room of 16 m2 you need: 16 m2/1.8 m2 = 8.88 pcs. Let's round up - we need 9 sections.

We calculate similarly for cast iron or steel bars. All you need is the following rules:

- bimetallic radiator - 1.8m2

- aluminum - 1.9-2.0 m2

- cast iron - 1.4-1.5 m2.

This data is for sections with an interaxial distance of 50 cm. Today, there are models on sale with very different heights: from 60cm to 20cm and even lower. Models 20cm and below are called curb. Naturally, their power differs from the specified standard, and if you plan to use a “non-standard”, you will have to make adjustments. Either look for passport data, or do the math yourself. We proceed from the fact that the heat transfer of a heating device directly depends on its area. As the height decreases, the area of the device decreases, and, therefore, the power decreases proportionally. That is, you need to find the ratio of the heights of the selected radiator with the standard, and then use this coefficient to correct the result.

Calculation of cast iron heating radiators. Can be calculated by area or volume of the room

For clarity, we will calculate aluminum radiators by area. The room is the same: 16m2. We count the number of sections of standard size: 16m2/2m2=8pcs. But we want to use small sections with a height of 40 cm. We find the ratio of radiators of the selected size to standard ones: 50cm/40cm=1.25. And now we adjust the quantity: 8pcs * 1.25 = 10pcs.

How heat-saving film is used for windows - pros and cons of use

In search of energy savings, consumers are looking for new building materials that will help save heat in their home or apartment. A special place in this series is occupied by heat-reflecting film for windows, which can reduce energy consumption by up to 30 percent.

How advisable is it to use this material and what properties, besides heat conservation, does the film have?

Types of batteries

There are several types of batteries, and we will list the characteristics of each to make it easier for you to choose the right option.

Steel

Not the most common option. The reason for their low popularity is their heat transfer characteristics. Advantages: reasonable price, light weight and easy installation. However, the walls have insufficient heat capacity - they quickly warm up and cool down quickly. In addition, water hammer can cause leaks in the places where the sheets are connected. At the same time, inexpensive models (without a protective coating) may rust. Such options last much less than others and their warranty period is more limited.

It is often difficult to determine the number of steel radiators for one room, since their solid design does not allow adding or removing sections. Thermal power must first be taken into account. It all depends on the width and length of the space in which you are going to install them. Some tubular models allow you to add segments. The craftsmen do it to order when they make them.

Cast iron

Each of us has seen such products: standard accordions. Even though their design was extremely simple, the design made it possible to effectively heat houses and apartments. The heat output of one accordion is 160 W. The calculation of sections of prefabricated cast iron radiators is simple, since their number could be unlimited. Modern proposals have become improved; they fit into different interiors. There are also exclusive models with relief patterns. Advantages of cast iron pipes:

- heat is retained for a long time at high output;

- resistance to water hammer and sudden temperature changes;

- Corrosion resistant.

You can use different coolants, as they are suitable for autonomous and central heating systems. Disadvantages include the fragility of the material (it cannot withstand direct impacts), the complexity of installation (due to its large size). In addition, not every wall will support their weight. Before starting the boiler in winter, test the system, fill the pipes with water to determine if there are any problems.

Aluminum

They appeared not so long ago, but quickly became popular. They are relatively inexpensive, minimalistically designed, and their material has good heat transfer. Aluminum models can withstand high pressure and temperature. The heat output of each section is up to 200 W, but at the same time its weight is small - no more than 2 kg. They do not require large coolants. They are stackable, so you can add or remove radiator sections based on the area of the room. There are also solid models.

Flaws:

- Aluminum is susceptible to corrosion. There is also a high probability of gas formation, so aluminum pipes are more suitable for an autonomous heating system.

- Non-separable models may leak at the joints; they cannot be repaired and will have to be completely replaced.

The most durable options are made from anodized metal. They remain resistant to corrosion for a long time

Their designs are roughly similar, and when you make your choice, pay attention to the documents. How to correctly calculate the number of radiator sections per room according to the instructions.

Bimetallic

The bimetallic radiator model is no less reliable than the cast iron one. Good thermal output makes them better than aluminum ones. This is facilitated by the features of their design. One segment consists of steel manifolds. They are connected by a metal channel. Craftsmen assemble them using threaded couplings. Due to the aluminum coating, good thermal output can be obtained. Pipes do not rust. High strength and wear resistance are combined with excellent heat dissipation.

Calculation of heat loss in the house

According to the second law of thermodynamics (school physics), there is no spontaneous transfer of energy from less heated to more heated mini- or macro-objects. A special case of this law is the “striving” to create temperature equilibrium between two thermodynamic systems.

For example, the first system is an environment with a temperature of -20°C, the second system is a building with an internal temperature of +20°C. According to the above law, these two systems will strive to balance through the exchange of energy. This will happen with the help of heat losses from the second system and cooling in the first.

We can definitely say that the ambient temperature depends on the latitude at which the private house is located. And the temperature difference affects the amount of heat leakage from the building (+)

Heat loss refers to the involuntary release of heat (energy) from some object (house, apartment). For an ordinary apartment, this process is not so “noticeable” in comparison with a private house, since the apartment is located inside the building and “adjacent” to other apartments.

In a private house, heat “leaks” to one degree or another through the external walls, floor, roof, windows and doors.

Knowing the amount of heat loss for the most unfavorable weather conditions and the characteristics of these conditions, it is possible to calculate the power of the heating system with high accuracy.

So, the volume of heat leakage from the building is calculated using the following formula:

Q=Qfloor+Qwall+Qwindow+Qroof+Qdoor+…+Qi, where

Qi is the volume of heat loss from a homogeneous type of building shell.

Each component of the formula is calculated using the formula:

Q=S*∆T/R, where

- Q – heat leakage, V;

- S – area of a specific type of structure, sq. m;

- ∆T – difference in ambient and indoor air temperatures, °C;

- R – thermal resistance of a certain type of structure, m2*°C/W.

It is recommended to take the very value of thermal resistance for real existing materials from auxiliary tables.

Additionally, the thermal resistance can be obtained using the following relationship:

R=d/k, where

- R – thermal resistance, (m2*K)/W;

- k – coefficient of thermal conductivity of the material, W/(m2*K);

- d – thickness of this material, m.

In old houses with damp roofing structures, heat leaks occur through the upper part of the building, namely through the roof and attic. Taking measures to insulate the ceiling or insulate the attic roof solves this problem.

If you insulate the attic space and roof, the overall heat loss from the house can be significantly reduced

There are several other types of heat loss in the house through cracks in structures, ventilation systems, kitchen hoods, and opening windows and doors. But it makes no sense to take into account their volume, since they constitute no more than 5% of the total number of main heat leaks.

What to do if the accrual is incorrect?

Unfortunately, many consumers are increasingly faced with the problem of incorrect charges. An unscrupulous accountant of the management company, errors in accruals, any inattention caused by someone else - all this ultimately falls on the shoulders of the thermal energy consumer.

Before paying the received receipt, you must check all the data given in it with your calculations.

If an error is identified at this stage, there are several ways to solve the problem:

- Write a statement/complaint to the management company.

- File a complaint with the State Housing Inspectorate.

- File a complaint with Rospotrebnadzor.

- File a complaint with the prosecutor's office.

- Apply to the court.

When submitting a written application to the Management Company, you need to make sure that there has been no increase in the tariff. If the tariff remains the same, then often, after writing such a statement, the company will find an error in the charges and agree to a meeting.

Using a claim, you can determine the procedure for returning overpaid funds:

- return in money;

- recalculation against future payments.

You can file complaints with Rospotrebnadzor and the State Housing Inspectorate if the management company deliberately inflates tariffs. In this case, the application/claim is submitted in person or sent by registered mail. Based on the results of the inspection of these structures, an administrative penalty may be imposed on the Management Company.

An appeal to the prosecutor's office occurs when previous authorities do not solve the problem that has arisen. And when going to court, it is necessary to have irrefutable evidence of identified violations in the calculations.

Diameter selection

General information

Polypropylene pipes

Intermediate pipes between thermal elements (radiators, registers) are a kind of coolant line for heating systems, which must have sufficient throughput to ensure normal movement. That is, the normal operation of the system as a whole will depend entirely on how well this parameter is selected.

However, unlike a highway, where the principle “the wider the better” applies, the heating system needs optimal values, since the presence of pipes with a cross-section that is too large will be as undesirable as the use of a small diameter. An insufficiently large size will cause noise - due to increased circulation speed.

An excessively large diameter requires the presence of a large amount of coolant (in this case, water) in the system, which in turn will lead to large heat losses and uneven heating of the premises. In such cases, what usually happens is that the water heating radiators in the room that is closer to the boiler warm up quite well, while in the remaining rooms the temperature in the heating elements begins to drop sharply.

Stainless steel pipes

Also, an irrationally large cross-section causes a large amount of resources to be spent on maintaining the required temperature due to the increased amount of coolant. Accordingly, the smaller the size, the lower the cost of heating the room.

Selection formula

To calculate the diameter, you need to determine how much energy consumption will be required to heat a particular room. Initially, you need to calculate the square footage of the room - measure the length and width of the room, and then multiply both values together. Thus, as a result you will get the exact number of square meters.

To heat 10 square meters of area with a ceiling height of no more than 3 meters, 1 kW of energy will be required. Based on this standard, the total energy consumption of all rooms in the house is calculated.

Selecting the diameter of a copper heating pipe

That is, to heat a room of 40 square meters, you need 4 kW of energy + 20%. Through these calculations, the diameter of the heating pipes is selected based on the list provided below.

It also contains a designation of the optimal circulation speed, which should be no less than 0.2 and no more than 1.5 meters per second.

If the speed of water movement is less than 0.2 m/sec, this will lead to air jams and poor heating.

If it exceeds 1.5 m/sec, then there is a high probability of extraneous noise appearing, which is a consequence of the coolant passing through various obstacles:

- wiring,

- turns, etc.

The most optimal value is the range from 0.3 to 0.4 m/sec.

Radiator with two-pipe system

- For 3 - 5 kW it is more advisable to use 20 mm, the coolant speed will be 0.2 - 0.4 m/sec;

- For 6 - 9 kW, the optimal value is 25 mm, the value of the coolant speed in this case will be 0.3 - 0.4 m/sec;

- For 10 - 15 kW, it is advisable to use pipes with a cross section of 32 mm, in which the circulation will be 0.3 - 0.4 m/sec. It is acceptable to use pipes with a cross-section of 20 mm, but in this case the coolant speed will be from 0.5 to 0.7 m/sec;

- For 16 - 21 kW - the optimal value will be 40 mm, the value of the coolant movement speed in this case will be from 0.3 to 0.4 m/sec;

- For 22 - 32 kW, the best value will be 50 mm, the circulation speed in this case will be in the range of 0.3 - 0.4 m/sec;

Hydraulic calculation of water supply

Of course, the “picture” of calculating heat for heating cannot be complete without calculating such characteristics as the volume and speed of the coolant. In most cases, the coolant is ordinary water in a liquid or gaseous aggregate state.

It is recommended to calculate the actual volume of coolant by summing all cavities in the heating system. When using a single-circuit boiler, this is the best option. When using double-circuit boilers in a heating system, it is necessary to take into account the consumption of hot water for hygienic and other domestic purposes

Calculation of the volume of water heated by a double-circuit boiler to provide residents with hot water and heat the coolant is made by summing the internal volume of the heating circuit and the actual needs of users for heated water.

The volume of hot water in the heating system is calculated by the formula:

W=k*P , where

- W is the volume of the coolant;

- P - heating boiler power;

- k - power factor (number of liters per unit of power, equal to 13.5, range - 10-15 liters).

As a result, the final formula looks like this:

W = 13.5*P

Coolant velocity is the final dynamic assessment of the heating system, which characterizes the speed of fluid circulation in the system.

This value helps to evaluate the type and diameter of the pipeline:

V=(0.86*P*μ)/∆T , where

- P - boiler power;

- μ - boiler efficiency;

- ∆T is the temperature difference between the supply water and the return water.

Using the above methods of hydraulic calculation, it will be possible to obtain real parameters that are the “foundation” of the future heating system.

Boiler heat transfer - why calculations are needed

The heating system must completely compensate for all heat loss in the house, which is why the boiler power is calculated. The building constantly releases heat to the outside. Heat loss in a house varies and depends on the material of the structural parts and their insulation. This affects the calculated performance of the heat generator. If you take the calculations as seriously as possible, you should order them from specialists; based on the results, a boiler is selected and all parameters are calculated.

It is not very difficult to calculate heat loss yourself, but you need to take into account a lot of data about the house and its components, and their condition. An easier way is to use a special device for detecting heat leaks - a thermal imager. The screen of a small device displays not calculated, but actual losses. It clearly shows the location of leaks, and measures can be taken to eliminate them.

Or maybe no calculations are needed, just take a powerful boiler and the house will be provided with heat. Not so simple. The house will really be warm and comfortable until it’s time to think about something. The neighbor has the same house, the house is warm, and he pays much less for gas. Why? He calculated the required boiler output, which is one third less. The understanding comes that a mistake has been made: you should not buy a boiler without calculating the power. Extra money is spent, some of the fuel is wasted and, what seems strange, an underloaded unit wears out faster.

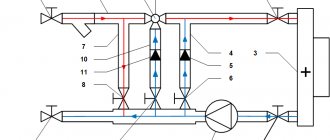

Heating system

A boiler with insufficient power will not heat the house and will constantly work with overload, which will lead to premature failure. And it will not only consume fuel, but eat it, and still there will not be good heat in the house. There is only one way out - install another boiler. Money went down the drain - buying a new boiler, dismantling the old one, installing another - everything is not free. And if we also take into account the moral suffering due to a mistake made, perhaps the heating season experienced in a cold house? The conclusion is clear - you cannot buy a boiler without preliminary calculations.

How to reduce payments

To reduce the amount of monthly payments for heat, the only way is to install individual heat meters. But before that, you may encounter several problems:

- Obtaining permission to install an IPU is a time-consuming process. In order for the installation to be approved, the technical specifications must be confirmed or improved. Based on them, the appropriate type of meter is selected.

- To regularly pay for heating using an individual meter, you need to send meters for verification in a timely manner. To carry it out, the meter is dismantled and reinstalled, which entails additional costs. If the verification takes place during the heating season, then payment for heating the apartment for a time without IPU is carried out according to the established standard. Therefore, it is better to return meters in the summer, although there may be long queues at this time.

- Expensive installation of IPU. Payment for the installation of one meter can reach 25 thousand rubles. Some companies charge a separate fee for dismantling. In addition, verification is also paid. And if the meter does not pass verification by the technical service or breaks down, it must be replaced in a timely manner.

Despite the complexity and large investment during initial installation, using a custom appliance can significantly reduce your monthly heating bills.

Selection of heating radiators

Traditionally, it is recommended to select the power of a heating radiator according to the area of the heated room, with a 15-20% overestimation of power requirements, just in case.

Using an example, let’s look at how correct the methodology for choosing a radiator is “10 m2 area - 1.2 kW”.

The thermal power of radiators depends on the method of their connection, which must be taken into account when calculating the heating system

Initial data: corner room on the first level of a two-story individual housing construction building; external wall made of double-row ceramic bricks; room width 3 m, length 4 m, ceiling height 3 m.

Using a simplified selection scheme, it is proposed to calculate the area of the room, we consider:

3 (width) 4 (length) = 12 m2

Those. the required power of the heating radiator with a 20% increase is 14.4 kW. Now let’s calculate the power parameters of the heating radiator based on the heat loss of the room.

In fact, the area of the room affects the loss of thermal energy less than the area of its walls, facing one side outside the building (facade).

Therefore, we will calculate exactly the area of the “street” walls present in the room:

3 (width) 3 (height) + 4 (length) 3 (height) = 21 m2

Knowing the area of the walls that transfer heat “to the street,” we will calculate the heat loss for a difference in room and street temperatures of 30° (in the house +18°C, outside -12°C), and immediately in kilowatt-hours:

0.91 · 21 · 30 : 1000 = 0.57 kW,

Where: 0.91 – heat transfer resistance m2 of room walls facing “outside”; 21 – area of “street” walls; 30 – temperature difference inside and outside the house; 1000 is the number of watts in a kilowatt.

According to building standards, heating devices are located in areas of maximum heat loss. For example, radiators are installed under window openings, heat guns are installed above the entrance to the house. In corner rooms, batteries are installed on blank walls exposed to maximum exposure to winds.

It turns out that to compensate for heat loss through the façade walls of this structure, with a 30° temperature difference in the house and outside, heating with a capacity of 0.57 kWh is sufficient. Let's increase the required power by 20, even 30% - we get 0.74 kWh.

Thus, real heating power requirements may be significantly lower than the trading scheme “1.2 kW per square meter of room area.”

Moreover, correct calculation of the required power of heating radiators will reduce the volume of coolant in the heating system, which will reduce the load on the boiler and fuel costs.

Final Conclusion

There are many reasons for large heating bills. Obvious: a building with thick brick walls loses less heat than reinforced concrete “nine-story buildings.” Hence the increased energy consumption recorded by the meter.

But before you undertake the modernization (insulation) of the building, it is important to establish control and accounting - install heat meters in all rooms and on the supply line. The calculation methodology shows that such technical solutions give the best results.

Radiator calculations

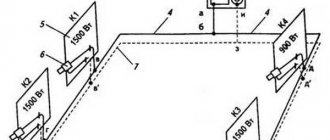

In our case, we will use standard aluminum radiators with a height of 0.6 m. The power of each fin of such a radiator at a temperature of 70 ° C is 150 W. Next, we will calculate the power of each radiator and the number of conventional fins:

- room 1: 28 m3 · 40 W · 1.2 = 1344 W. We round up to 1500 and get 10 conventional fins, but since we have two radiators, both under the windows, we will take one with 6 fins, the second with 4.

- room 2: 28 m3 · 40 W · 1.2 = 1344 W. We round up to 1500 and get one radiator with 10 fins.

- room 3: 56 m3 · 40 W · 1.2 = 2688 W We round up to 2700 and get three radiators: 1st and 2nd with 5 fins each, 3rd (side) with 8 fins.

- hallway: 22.4 m3 · 40 W · 1.2 = 1075.2 W. We round up to 1200 and get two radiators with 4 fins each.

- bathroom: 11.2 m3 · 45 W · 1.2 = 600 W. Here the temperature should be a little higher, you get 1 radiator with 4 fins.

- toilet: 8.4 m3 · 40 W · 1.2 = 403.2 W. Round up to 450 and get three edges.

- kitchen: 43.4 m3 · 40 W · 1.2 = 2083.2 W. We round up to 2100 and get two radiators with 7 fins each.

As a final result, we see that we need 12 radiators with a total capacity:

900 + 600 + 1500 + 750 + 750 + 1200 + 600 + 600 + 600 + 450 + 1050 + 1050 = 10.05 kW

Based on the latest calculations, it is clear that our individual heating system can cope with the load placed on it without any problems.

Video description

In our video we’ll talk about heating in a private country house.

Our guest is the author and presenter of the Teplo-Voda channel Vladimir Sukhorukov: The heating system is not only a stove and radiators. It includes:

- Boiler;

- Pumping station;

- Pipes;

- Radiators;

- Control devices;

- Sometimes an expansion tank is needed.

This is roughly what the diagram of a house heating system looks like Source lucheeotoplenie.ru

How much heat should the pipeline supply?

Let's take a closer look at the example of how much heat is usually supplied through pipes, and select the optimal pipeline diameters.

There is a house with an area of 250 sq. m., which is well insulated (as required by the SNiP standard), so it loses heat in the winter by 1 kW per 10 sq. m. To heat the entire house, 25 kW of energy is required (maximum power). For the first floor - 15 kW. For the second floor - 10 kW.

Our heating scheme is two-pipe. One pipe supplies hot coolant, and the other pipe cools it to the boiler. Radiators are connected in parallel between the pipes.

On each floor, the pipes branch into two wings with the same thermal power, for the first floor - 7.5 kW, for the second floor - 5 kW.

So, 25 kW comes from the boiler to the interfloor branch. Therefore, we will need main pipes with an internal diameter of at least 26.6 mm so that the speed does not exceed 0.6 m/s. A 40mm polypropylene pipe is suitable.

From the interfloor branching - along the first floor to the branching on the wings - 15 kW is supplied. Here, according to the table, for a speed of less than 0.6 m/s, a diameter of 21.2 mm is suitable, therefore, we use a pipe with an outer diameter of 32 mm.

7.5 kW goes to the wing of the 1st floor - an internal diameter of 16.6 mm is suitable, - polypropylene with an outer diameter of 25 mm.

Accordingly, we use a 32mm pipe on the second floor before branching, a 25mm pipe on the wing, and we also connect the radiators on the second floor with a 20mm pipe.

As you can see, it all comes down to a simple choice among the standard diameters of commercially available pipes. In small home systems, up to a dozen radiators, in dead-end distribution circuits, 25 mm polypropylene pipes are mainly used - “per wing”, 20 mm - “per device”. and 32 mm “to the main line from the boiler”.

The most accurate calculation option

From the above calculations, we saw that none of them is perfectly accurate, because... Even for identical rooms, the results, albeit slightly, are still different.

If you need maximum calculation accuracy, use the following method. It takes into account many coefficients that can affect heating efficiency and other significant indicators.

In general, the calculation formula is as follows:

T=100 W/m2 *A *B * C * D * E * F * G * S,

- where T is the total amount of heat required to heat the room in question;

- S – area of the heated room.

The remaining coefficients require more detailed study. Thus, coefficient A takes into account the characteristics of the glazing of the room.

Features of room glazing

The values are as follows:

- 1.27 for rooms whose windows are glazed with just two glasses;

- 1.0 – for rooms with windows equipped with double glazing;

- 0.85 – if the windows have triple glazing.

Coefficient B takes into account the insulation features of the walls of the room.

Features of insulation of room walls

The dependency is as follows:

- if the insulation is low-effective, the coefficient is taken equal to 1.27;

- with good insulation (for example, if the walls are laid with 2 bricks or are purposefully insulated with a high-quality heat insulator), a coefficient of 1.0 is used;

- with a high level of insulation - 0.85.

Coefficient C indicates the ratio of the total area of window openings and the floor surface in the room.

The ratio of the total area of window openings and the floor surface in the room

The dependency looks like this:

- with a ratio of 50%, coefficient C is taken as 1.2;

- if the ratio is 40%, use a coefficient equal to 1.1;

- with a ratio of 30%, the coefficient value is reduced to 1.0;

- in the case of an even smaller percentage, coefficients equal to 0.9 (for 20%) and 0.8 (for 10%) are used.

Coefficient D indicates the average temperature during the coldest period of the year.

Heat distribution in a room when using radiators

The dependency looks like this:

- if the temperature is -35 and below, the coefficient is taken equal to 1.5;

- at temperatures up to -25 degrees, a value of 1.3 is used;

- if the temperature does not drop below -20 degrees, the calculation is carried out with a coefficient of 1.1;

- residents of regions where the temperature does not drop below -15 should use a coefficient of 0.9;

- if the temperature in winter does not fall below -10, count with a coefficient of 0.7.

The E coefficient indicates the number of external walls.

Number of external walls

If there is only one external wall, use a factor of 1.1. With two walls, increase it to 1.2; with three – up to 1.3; if there are 4 external walls, use a coefficient of 1.4.

The F coefficient takes into account the features of the room above. The dependency is:

- if there is an unheated attic space above, the coefficient is taken equal to 1.0;

- if the attic is heated - 0.9;

- if the neighbor above is a heated living room, the coefficient can be reduced to 0.8.

And the last coefficient of the formula - G - takes into account the height of the room.

Room height

The order is as follows:

- in rooms with ceilings 2.5 m high, the calculation is carried out using a coefficient of 1.0;

- if the room has a 3-meter ceiling, the coefficient is increased to 1.05;

- with a ceiling height of 3.5 m, count with a factor of 1.1;

- rooms with a 4-meter ceiling are calculated with a coefficient of 1.15;

- when calculating the number of battery sections for heating a room 4.5 m high, increase the coefficient to 1.2.

This calculation takes into account almost all existing nuances and allows you to determine the required number of sections of the heating unit with the smallest error. In conclusion, all you have to do is divide the calculated figure by the heat transfer of one section of the battery (check in the attached data sheet) and, of course, round the found number up to the nearest integer value.

Heating radiator calculator

For convenience, all these parameters are included in a special calculator for calculating heating radiators. It is enough to indicate all the requested parameters - and clicking on the “CALCULATE” button will immediately give the desired result:

Energy Saving TipsEnergy Saving Tips

Happy calculations!

Example of thermal calculation

As an example of a thermal calculation, we have an ordinary 1-story house with four living rooms, a kitchen, a bathroom, a “winter garden” and utility rooms.

The foundation is made of a monolithic reinforced concrete slab (20 cm), the external walls are concrete (25 cm) with plaster, the roof is made of wooden beams, the roof is metal tiles and mineral wool (10 cm)

Let us designate the initial parameters of the house necessary for the calculations.

Building dimensions:

- floor height - 3 m;

- small window on the front and rear of the building 1470*1420 mm;

- large facade window 2080*1420 mm;

- entrance doors 2000*900 mm;

- rear doors (exit to the terrace) 2000*1400 (700 + 700) mm.

The total width of the building is 9.5 m2, length 16 m2. Only living rooms (4 units), a bathroom and a kitchen will be heated.

To accurately calculate heat loss on the walls, you need to subtract the area of all windows and doors from the area of the external walls - this is a completely different type of material with its own thermal resistance

We start by calculating the areas of homogeneous materials:

- floor area - 152 m2;

- roof area - 180 m2, taking into account the attic height of 1.3 m and the purlin width - 4 m;

- window area - 3*1.47*1.42+2.08*1.42=9.22 m2;

- door area - 2*0.9+2*2*1.4=7.4 m2.

The area of the external walls will be 51*3-9.22-7.4=136.38 m2.

Let's move on to calculating heat loss for each material:

- Qfloor=S*∆T*k/d=152*20*0.2/1.7=357.65 W;

- Qroof=180*40*0.1/0.05=14400 W;

- Qwindow=9.22*40*0.36/0.5=265.54 W;

- Qdoors=7.4*40*0.15/0.75=59.2 W;

And also Qwall is equivalent to 136.38*40*0.25/0.3=4546. The sum of all heat losses will be 19628.4 W.

As a result, we calculate the boiler power: Rboiler = Qloss * Room heating * K / 100 = 19628.4 * (10.4 + 10.4 + 13.5 + 27.9 + 14.1 + 7.4) * 1.25/100 = 19628.4 * 83.7 * 1.25/100 = 20536.2 = 21 kW.

We will calculate the number of radiator sections for one of the rooms. For all others, the calculations are similar. For example, a corner room (on the left, lower corner of the diagram) has an area of 10.4 m2.

This means N=(100*k1*k2*k3*k4*k5*k6*k7)/C=(100*10.4*1.0*1.0*0.9*1.3*1.2*1.0*1.05)/180=8.5176=9.

This room requires 9 sections of heating radiator with a heat output of 180 W.

Let's move on to calculating the amount of coolant in the system - W=13.5*P=13.5*21=283.5 l. This means that the coolant speed will be: V=(0.86*P*μ)/∆T=(0.86*21000*0.9)/20=812.7 l.

As a result, a complete turnover of the entire volume of coolant in the system will be equivalent to 2.87 times per hour.

A selection of articles on thermal calculations will help you determine the exact parameters of the heating system elements:

- Calculation of the heating system of a private house: rules and calculation examples

- Thermal engineering calculation of a building: specifics and formulas for performing calculations + practical examples

Eventually

As you can see, calculating the heating capacity comes down to calculating the total value of the four above elements.

Not everyone can determine the required capacity of the working fluid in a system with mathematical accuracy. Therefore, not wanting to perform the calculation, some users act as follows. To begin with, fill the system to approximately 90%, after which the functionality is checked. Next, the accumulated air is released and filling continues.

During operation of the heating system, a natural decline in the coolant level occurs as a result of convection processes.

In this case, there is a loss of power and productivity of the boiler. This implies the need to have a reserve tank with working fluid, from where it will be possible to monitor the loss of coolant and, if necessary, replenish it. Date: September 25, 2022