The underfloor heating system as a type of room heating method is gradually developing and modernizing. Familiar to many boxes with a ready-made solution, previously used only partially in bathrooms and kitchens and only with tiled flooring, today, if used correctly, can even completely replace the radiator heating method, or be combined with it, and they are not only installed in floors.

Electric heated floors are a type of direct heating, that is, the air in the room is heated by the heat generated by the device itself, and an intermediary in the form of a coolant is not involved in the process. There is a subtype of water heated floors, where the coolant is still involved, but they will be discussed in a separate article.

| Radiator type heating using film IR underfloor heating |

Heating with heated floors is one of the most environmentally friendly and useful and is welcome if there is an allergy sufferer, asthmatic or children in the house. Unlike the uneven heat generated by radiators, when the temperature is lower near the floor and higher under the ceiling, heated floors provide uniform heating of the air. There is no electromagnetic radiation emitted by the cable in expensive and certified systems, since the cables are used with two-core, shielded cables.

| Single and double core heating cables |

On average, the comfortable temperature in a room heated by heated floors is 2 degrees lower than that with a radiator system and is 20 degrees. This is a consequence of the lack of convection currents and uniform heating of the air through a heated floor.

Maximum heating surface temperature

| Dry heated floor | 29°C - rooms with constant occupancy; 31°C - premises with temporary occupancy of people; 35°C - edge zones of heated rooms; 27°C - wooden (laminate, parquet board) covering; |

| Damp or wet underfloor heating | 31°C - pool bypass paths, bathroom floor; |

| External wall | 35°C - at a height of up to 1 meter; |

| Interior wall, ceiling | 28°C - at a height of up to 2.8 meters; 30°C - at a height of up to 3.0 meters; 33°C - at a height of up to 3.5 meters; 36°C - at a height of up to 4.0 meters; 38°C - at a height of up to 6.0 meters; |

These temperatures must not be exceeded during operation.

Modern electric floors are no longer considered expensive heating systems. With proper calculation of power, the correct installation location and setting of the room thermostat and proper installation, the cost of heating even completely with a warm floor of a 100 m2 house is comparable to the cost of central heating from a boiler room. It is not entirely profitable to heat large areas with high ceilings in this way.

Electric heated floor power calculation

When building a house or renovating, you should decide for what purpose the heated floor will be used: a complete replacement of radiator heating, a combined version of “warm floor + radiators” or an additional heating system in individual rooms.

Depending on the task, you can use the following formula for calculation:

- 100 W per 1 m2 - when using a heated floor as a means of fully heating the room. It should be taken into account that heated floors warm up slowly and should be turned on in advance for periodic use.

- 150 W per 1 m2 - when using an additional heat source together with radiators or when heating, for example, a corridor.

- 200 W per 1 m2 - when used in bathrooms where the installation area is limited and in tiled rooms where a higher temperature is required.

Heated floors with increased power can be used in a garage or industrial premises, especially with high ceilings. However, for residential premises you should not use heated floors with more power than necessary.

Electric heated floors are divided into:

— cable (in the form of a separate heating cable or mats);

| Heating cable | Cable heated floor in the form of a mat |

— infrared (film and rod).

| Film infrared floor | Rod infrared floor |

Types of electric heated floors

Electric heated floors can be divided into two types according to the heating principle:

- Cable;

- Infrared;

- Self-regulating.

In cable heated floors, the electric cable is heated, which gives off heat to the surrounding material or environment - air, screed, substrate. This type of system includes:

- Wire;

- Single-core;

- Twin-core;

- Cable mats.

Infrared heated floors produce heat in the form of infrared radiation. It heats up solid structures such as flooring and screed. They can be divided into two types:

- Film;

- Rod.

Film electric heating

Film electric heated floor

The design of the system is based on a special carbon heating film. When connected to the network, the system begins to produce infrared rays with the parallel release of anions. The functions of the emitter in this system are assigned to a special paste on a carbon (carbon) basis. It is applied to the material in parallel or curved stripes. In expensive versions of the system, the paste is usually applied continuously, resulting in higher heating efficiency.

Schematic diagram of connection

Electricity is supplied through copper-silver conductors. The main working elements of the system are sealed with layers of polyester. The power supply is regulated using a thermostat.

Film heated floor ENERPIA FILM

Film systems are widely represented in the assortment of many manufacturers of similar products. When choosing a brand, focus primarily on the reputation of the manufacturing company, user reviews, and personal preferences. If possible, enlist the help of specialists. Knowledgeable people will be able to give a realistic assessment of the tasks assigned to the heating system and help you choose the best option.

Advantages

Film infrared heated floors are easy to install with your own hands

The key advantage of film electric underfloor heating is its versatility in terms of compatibility with finishing materials. On top of such a film you can lay tiles, linoleum, vinyl panels, as well as laminate, carpet, etc.

The second important advantage of film systems is the possibility of arranging mobile heating based on them. For example, the film can be attached to the back of the carpet and removed when there is no need to use heating.

Electricity consumption of film heated floors

Flaws

Firstly, the main disadvantage of such a system is the large number of hidden contacts. In order for the further operation of the heated floor to be effective, reliable and safe, before accepting the system for permanent use, its performance must be thoroughly tested. In addition, the installation of the finishing coating must be carried out in strict accordance with the technology.

Secondly, when arranging the system, there is a need for additional financial expenses for the purchase of connectors. Without these products it is impossible to achieve high-quality contact between the wire and the film.

Thirdly, if ceramic tiles or other similar materials are laid on top of the heated floor, you will have to spend additional money on arranging the screed. At the same time, the consumption of the adhesive composition also increases - its layer cannot be thinner than 1.5 cm.

Wired systems

This type of underfloor heating is suitable for installation on an existing floor covering. There is no need to hide it in a screed. The cross-section of the wire is small, it does not produce as much heat as a single-core or double-core cable. But this is compensated by the installation method.

The wire is usually laid in a snake pattern, in increments of no more than 5 cm. Due to this, the thermal power is sufficient for efficient heating of the room. Since the distance between the wires is small, laminate can be laid on them. It will not sag or deform. Also, such warm floors are installed in a layer of tile adhesive.

Experts advise using a substrate when installing this type of heated electric floor. This way it will be possible to achieve more uniform heating. The wire itself will heat the air, which will distribute evenly in the space between the substrate and the floor covering. Accordingly, laminate, parquet or floorboards will heat up more evenly.

conclusions

When choosing a heated floor technology, it is necessary to take into account not only its cost, but also installation features:

- Often in apartment buildings it is undesirable to install heated floors in screeds due to low ceilings in the rooms. In such cases, it is most advisable to use film TCs, despite their higher cost.

- Most types of heating cables and mats based on them can be mounted not only on the floor, but also on the walls.

- For constant heating or use as the main source of heating, it is undoubtedly better to install a water heated floor, which is the most economical.

https://www.youtube.com/watch?v=RiBDhzF5arE

Single core cable

This is the most common type of heated electric floors. It is a regular cable wound on a drum. It is laid in a screed or a special substrate. The cable design is as follows:

- Conductor (heat source);

- Insulation;

- Reinforcing braid;

- Water-repellent screen;

- External protective coating.

For the cheapest cables, the reinforcing braid is also grounding. In more expensive options, the grounding conductor is separate from the braid.

The disadvantage of single-core cable heated floors is the installation method. It should start and end in the same place (see diagram below). In simple terms, one end of the cable needs to be connected to the positive, and the other to the negative.

Method of laying and connecting a single-core cable heated electric floor.

Selection principles

The choice of the type and characteristics of a heated floor is carried out in several stages:

- First of all, you need to determine whether the heated floor will be the main heating system, or used in addition to the existing one. In the first case, the calculation must be carried out based on heat loss in order to fully provide the room with heat to heat to the required temperature. The power of the heated floor in this case depends on the climatic characteristics of the region, but on average the system is selected based on the specific value of 120.0–140.0 W/m²; for an additional system, 80.0–100.0 W/m² is sufficient.

- Next, choose the type of heated floor. If installation is planned in a screed, then select the type that can be installed in this way. Most often this is a cable or mat. For installation in a bathroom or kitchen under tiles, it is advisable to use a heating mat. It is better to use infrared film directly under the decorative coating.

- When the type and power have been selected, it is necessary to purchase the heated floor itself and additional materials and carry out installation.

Important! To save money and materials, there is no need to install heated floors under massive furniture and household appliances, or a bathroom.

During installation, you must follow all manufacturer's recommendations and building codes.

Twin cable

Like the previous single-core option, the two-core cable can be laid in a screed or underlay. This type of cable has two separate conductors that are insulated from each other. Its design is as follows:

- Conductive conductors;

- Insulation;

- Reinforcing braids (separate for each core);

- Water-repellent screen;

- External insulation;

- Grounding.

Twin-core cables can have one or two grounding connections. The illustration shows an option with one - it is located outside the reinforcing braids. In the case of two, they are usually located inside the braids of each core.

When laying a two-core cable, there is no need to connect the other end to a power source. At one end of the cable, you need to connect the current-carrying wires together, and on the other side, connect them to the controller, network, etc. Laying is carried out according to the following scheme:

Method of laying and connecting a two-core cable heated electric floor.

Cable mats

The easiest type of heated electric floor to install. Installs only in screed or tile adhesive. It is a plastic mesh to which a conductive cable is attached. In most cases, cable mats are single-core, but you can also find two-core ones.

Electric heating mats are made of thin cable and substrate no more than 10 mm thick. The distance between the cables does not exceed 12 cm. Due to this, they can be laid under tile adhesive. There are options with a self-adhesive backing.

The width of the mat is usually 0.5-0.6 meters. The length varies from 1.5 to 30 meters. Long mats can be cut as needed, and individual parts can be connected in series. Individual sections can be connected using:

- Perehodnikov;

- Detachable connections;

- Rations;

- Twisting veins.

Laying a cable mat for a warm electric floor.

Preparation of the base for all types and options of heated floors

One of the most important elements is the basis for a heated floor in a private house, which must be prepared even before installing the heating system itself. There are a number of requirements for the base - it must be strong enough, even and not allow heat to pass through. Each requirement is important, but it is thermal insulation that requires special attention - without it, the generated heat will simply go under the floor. Various pipe insulations are used, which must be selected for specific conditions.

The technology for preparing a base with expanded clay insulation includes the following steps:

- Dismantling . The first step is to remove the old covering, under which there may be concrete, soil or wooden supports. All dirt and unnecessary elements must be removed.

- Marking . Using a building level along the entire perimeter of the walls, it is necessary to mark a line along which the base will be leveled. In the case of expanded clay, you need to leave more free space so that the thickness of the thermal insulation layer is sufficient to effectively retain heat.

- Bedding . The base is covered with a layer of sand, the thickness of which should be about 10 cm. The sand cushion must be compacted after backfilling.

- Waterproofing . A waterproofing material is laid on the compacted sand layer (polyethylene is the cheapest, but a waterproofing membrane is a more reliable option).

- Arrangement of beacons . Now you need to install the supports on which the beacon profiles will be located. The beacons need to be very accurately leveled.

- Laying thermal insulation . All free space between the beacons is covered with expanded clay. For greater reliability and efficiency, it is worth mixing expanded clay with liquid cement mortar.

- Filling the screed . Actually, after laying the heat-insulating layer, you can begin pouring the screed, which should reach the previously measured level. The screed is leveled along the profiles.

- Alignment . When the screed has set a little, the beacons need to be removed and the resulting holes must be sealed. The seams are rubbed down, after which the floor must be left until the solution has completely hardened.

In addition to expanded clay, a number of other materials can be used as thermal insulation:

- Polystyrene boards, which are usually reinforced with reinforcing mesh and attached to the base with anchors to increase strength;

- Rolled foil materials, excellent for use in combination with electric heating elements;

- Polymer mats designed specifically for laying water-heated floors, for which purpose the material has special protrusions between which pipes are laid.

Infrared (film) heated floor

This type of underfloor heating is installed on top of the subfloor. They are rolls of film coated with heat-generating carbon elements. The film thickness does not exceed 0.5 mm. The elements themselves heat up and emit in the IR range.

The individual parts of the film floor are connected to each other by soldering or using detachable connections. Due to the large area of the heating elements, they provide uniform heating of the floor covering.

Design of infrared film heated floor:

- Protective polyethylene film;

- Copper strip;

- High temperature absorber;

- Silver stripe;

- Substrate (base);

- Carbon heating element.

Construction of infrared film floor.

The diagram shows an infrared film floor with carbon strips, copper and silver backing. There are also options with:

- Solid carbon heating element;

- Two copper strips;

- Two silver stripes.

What it is?

Traditional methods of heating premises are based on the emission of thermal energy from a specific source. This can be one large heater (such as a furnace) that is enough to maintain the required temperature throughout the entire house. Radiator systems in which hot liquid (coolant) circulates are most often used. Radiators that radiate heat are located in each room and provide convection heating.

Such heating methods are widespread, but ineffective. Circulation of the coolant requires the creation of certain conditions (slope of pipelines, using the rise of heated layers of liquid upward), or the use of circulation pumps. The loss of thermal energy is quite large, and convection does not allow uniform heating of the entire room - there are always warmer and colder areas of the room.

A warm floor is a heating system based on a different principle of thermal energy transfer. Instead of individual point elements, the entire area of the room is used as a source. This approach allows for significant savings on fuel. In addition, losses inherent in traditional heating systems practically disappear. The entire area of the room is heated evenly, eliminating the appearance of cold and warm areas.

The design of a heated floor is one source of thermal energy, evenly distributed under the floor covering over the entire area of the room. Different types of heaters are used, from hot water pipes to electric heating cables or infrared film structures. All types have their own characteristics, limitations and advantages.

Infrared mats with carbon rods

The design of this type of infrared floor consists of two longitudinal cables, between which carbon fiber heat-generating elements are laid. Such mats can be with or without a backing.

The rods and cables of infrared mats have a diameter of no more than 1 cm, so they can be laid in adhesive under the tiles. But due to the large distance between the elements, heating will not always be uniform. Therefore, it is better to install them in a screed.

The width of the rod mats is usually 0.6-0.9 meters, length – up to 30 meters. They can be cut if necessary, and individual parts can be connected by soldering, adapters or connectors.

Cove of infrared rod heated floor.

Design features of such systems

What kind of underfloor heating is installed in your home?

WaterElectric

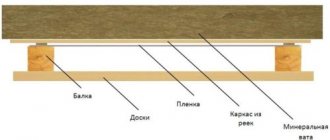

The general composition of any underfloor heating system is a multi-layer structure made up of the following elements:

- thermal insulation layer. It is laid on the subfloor and serves to cut off heat loss through the ceiling;

- heater. This could be a piping system, heating cable or film;

- screed layer (used only for water systems or heating cables;

- support system of panels with bosses (used for installation of heating cables or water systems);

- layer of waterproofing film;

- flooring.

This is the general scheme of a heated floor pie. During installation, some deviations from it are possible, the use of additional components or coatings is possible. Let's consider the design features of different types of heaters:

Water systems

A water heated floor is a network of pipelines laid in zigzags on a heat-insulating lining and filled with cement screed. If the length of the pipeline is too long, the coolant will cool down and will not provide the proper temperature. Therefore, several sections (loops) are used, which provide more uniform heating.

Hot water from centralized networks or from its own autonomous source is used as a coolant. The water temperature in the pipes is much lower than in the network. The floor surface heats up to 26-30° (depending on the floor covering), so the coolant should have a temperature no higher than 55°. To do this, install a manifold with a mixing unit that adds a certain amount of cooled return flow to the direct flow.

You can adjust the mode manually, but more often a special room thermostat is used. This is a device that measures the air temperature in the room and gives a command to the heater for correction. This is much more convenient than conventional coolant temperature sensors, since additional factors are taken into account - open windows, drafts, etc.

Hydronic floors work best with ceramic tile flooring. The pipeline is poured into a layer of screed on which the tiles are laid. During operation of the system, there is virtually no heat loss, which is typical for other types of coating.

The main problems with water heated floors are leaks. They arise for various reasons, most often from mechanical damage. Finding and restoring a damaged area is a very complex undertaking, so installation should be trusted to competent and experienced specialists.

Underfloor heating systems are prohibited from being installed in rooms under which residential premises are located. However, this prohibition does not apply to residents of lower floors.

Heating cable

A heating cable is a special wire whose temperature increases when an electric current passes.

The principle of its operation is similar to the operation of heating coils of irons or heating elements, but the temperature is much lower.

There are two main types of heating cable:

- resistive _ This is a common type of wire that heats up based on resistance (or length). The temperature of such a cable is the same along its entire length;

- self-regulating . This cable is more complicated. A matrix is installed between two current-carrying conductors, the resistance of which varies depending on the heating. If the cable section is located in a cooled area, the matrix resistance drops, increased voltage begins to flow, causing the cable section to heat up more. Using a self-regulating heater allows you to use energy more efficiently, heating the cable more precisely where it is needed.

The cable is laid on special shields with bosses. The plane of the shield serves as a heat insulator, cutting off useless heating of the ceiling. The bosses are installed evenly over the entire surface of the shield. The wire is laid in zigzags between them and connected to the power source. Another flat sheet material (thick plywood or chipboard) is laid on top of the board, which rests on the bosses and forms a surface for laying the flooring.

This installation option is also used for water heated floors. Its advantage is the ability to open the deck and repair the damaged area of the heater. However, the top flooring is a screen that cuts off thermal energy. To obtain the expected effect, you have to heat the cable more.

Expert opinion

Torsunov Pavel Maksimovich

Electricity consumption with this heating method is quite high. Therefore, a heating cable is rarely used as the main heating. Most often, this is an additional or backup heat source necessary to solve a problem in the event of a failure of the main heating system. installation of such a heater changes the floor height by 5 cm or more. what should be taken into account when choosing a suitable model.

Infrared film floor

These are heaters, which are a thin film into which infrared emitters are fused. Its thickness is only a millimeter, but for installation it requires underlying and covering layers. Typically, plywood or other rigid insulation is installed first, and a layer of waterproofing is placed on top.

Film heated floors are gradually gaining a leading position. They do not require complicated installation; they cannot be poured with cement mixtures or laid under tiles. In addition, these devices differ in their operating principle. They do not produce direct floor heating by convection.

The transfer of thermal energy occurs by emitting infrared waves, which heat all objects in their path. Since the emitter is located under the floor covering, it is the floor covering that heats up. At the same time, there are no restrictions on the use of such heaters; installation even on a balcony is allowed.

Typically, film heated floors are laid under laminate or linoleum. It is necessary to use special types of coatings designed to work with such heaters. On the reverse side there should be an icon in the shape of a snake or two lightning bolts.

Rod mats

These are structures consisting of individual rods connected in a chain and attached to a support system - mats. Most core flooring systems are self-adjusting systems that can be installed under furniture. This is convenient, since any rearrangement in the room will not require changing the location of the heating elements.

It is recommended to lay the rod structures in a 3-5 cm screed, or in a layer of leveling agent (at least 1 cm thick). This allows you to keep fragile rods intact. Rod heaters provide energy savings - they consume 60% less than a heating cable. Most varieties have a long service life (according to manufacturers, the system can last up to 20 years).

Self-regulating systems

This is a new technology that uses semiconductors and carbon fiber instead of conventional metal cables. Depending on the heating level, the properties of the heating element change, in particular electricity consumption. For example:

- At t=20°C, consumption is 170 W/sq.m.;

- At t=60°C, consumption is 125 W/sq.m.

The values are given as an example , because everything depends on the cable cross-section and laying pitch.

Now self-regulating heated floors are available in three versions:

- Rod mats;

- Single-core cables;

- Twin-core cables.

Cable floor

Electric cable flooring is usually installed in city apartments and country houses as part of a combined heating system. It is good where minimal screed or tiles with glue are planned (that’s why it is so often installed in the kitchen or bathrooms).

This heated floor in the house is not suitable for main heating, but it is good, for example, for heating in the off-season.

SubnusFORUMHOUSE Member

A cable to the floor is not heating, but additional heating with all that it implies.

An electric floor may use resistive or self-regulating cable. Resistive can be single-core or two-core (the method of laying a heated floor depends on this; two-core is much more convenient), self-regulating - only two-core.

| Variety | Advantages | Flaws |

| Single-core resistive cable. The unheated end is connected to the temperature regulator, the main cable is placed in a “snake” under the floor, the second unheated end is pulled into the initial connection and also connected to the thermostat. | The maximum heating temperature is several times higher than that of a two-wire one. Consumes little electricity. It's inexpensive. | A resistive cable has uniform heat transfer in all areas; overheating of the floor covering under the furniture is possible and the system may fail. It is better that there is no heating cable under large furniture - this will have to be taken into account during the design. |

| Two-core resistive cable. It is enough to connect it to the thermostat at one end. This is convenient for large areas and complex house layouts. | Easy to install, you can lay a highly complex heating channel. The voltage that passes through the wire does not affect the electromagnetic pulses. | |

| Self-regulating cable (two conductive cores are in contact with a matrix made of a special polymer material). | Depending on the temperature in the room, it independently changes the heating power. Well protected from mechanical impact. It cannot overheat due to the design features. It lasts a long time and almost never needs repairs. Compatible with any surface and under any furniture. You can make contours of different sizes (and less than 1 sq.m). Easy installation of heated floors. | Expensive. Special ballasts are required. Provides a comfortable temperature only on the floor surface and is not able to quickly warm up the room. |

When installing a resistive cable floor, it is important:

- calculate cable length

- pay attention to the material (brass, nichrome or copper). They have different properties and electrical resistance indicators

- strictly observe the permissible distance between heating elements specified by the manufacturer (usually no more than 12 cm)

- perform the calculations correctly - it is impossible to remove or add part of the wire at the installation stage

When making calculations, they usually rely on the following data (per square meter of room):

- Bedroom – 100-150 W/sq.m;

- Kitchen, hallway, corridor - 150 W/sq.m;

- Bathroom - 150 W/sq.m

- Balcony -200 W/sq.m

Types of heated floors for laminate, tile, linoleum

Each floor covering has its own type of warm electric floor. Let's look at their features.

It is best to lay infrared film under the laminate. This type of warm electric floor will allow you to evenly heat the entire coverage area. In this case, there will be no need to fill the screed or trench an existing one.

It is best to use mats or wired heated floors under the tiles. They have a small height, which allows them to work effectively with an adhesive layer of 15 mm or more. If you are just pouring a screed, you can lay a cable heated floor. In this case, the layer of tile adhesive will be small, and the heating efficiency will be high.

As for linoleum, any option will do. It all depends on how much you are willing to spend on installation. If the screed has already been laid and leveled, it makes sense to install film infrared heated floors. If not, choose any of the options depending on the thickness of the screed, the shape of the room, etc.

Infrared carbon floors

This is a progressive floor heating system, the operation of which is based on the use of infrared radiation. The rays are absolutely harmless to humans and allow you to quickly increase the temperature in the room to a comfortable level.

Infrared heated floors heat objects in the room, not the air.

This type of floor is actively used in residential apartments and private houses. It is suitable for any floor covering, with the exception of ceramic tiles. Infrared floors come in film and rod types.

Film

The peculiarity of this variety is that it does not require a screed. To install this system, it is enough to lay the film under a clean floor covering.

Installing an infrared film floor is not difficult at all. This will take a little time. In addition, the system can be dismantled and used again in another location. It should be noted that it is quite enough to “cover” 75% of the floor surface to achieve the desired result.

If any section breaks, the floor will continue to heat the room as before. The film system is not recommended for use under carpet, carpet tiles or linoleum on felt - they significantly reduce the heating efficiency.

Rod

A system of this kind is able to independently regulate the temperature in the room, which is why it is often called a “smart floor”. For example, if the floor temperature under the furniture increases significantly, the power consumption of the heating elements will decrease, and vice versa.

The core floor is laid in the screed, or it is immersed 2 cm in a layer of tile adhesive. You will also need mandatory thermal insulation of the rough base. It is not recommended to use combined insulation with low thermal conductivity for the substrate, such as fiberglass, fiberglass, or foil insulation.

The rod floor is reliable, so it can be installed in a bathroom, workshop, or gym. It is also suitable for loggias and winter gardens, as one of the elements of the anti-icing system.

This type of electrical system goes well with any type of flooring, including natural wood, parquet and laminated boards. Since the core floor is mounted on a thin layer of screed, it is also suitable for covering tiles or porcelain stoneware.

Having assessed the features, pros and cons of heated floors, and having decided on the room in which you plan to install it, choosing the best option will not be difficult.

Pros and cons of different types of underfloor heating

The underfloor heating system has a number of advantages compared to other types of heating (radiators, convectors, etc.):

- Low power consumption;

- Uniform heating of the entire area of the room;

- Uniform heating across the height of the room;

- High service life;

- They do not dry out the air.

But warm electric floors also have their disadvantages:

- Expensive installation;

- Heating with electricity is more expensive than central heating with gas or solid fuel;

- In most cases, underfloor heating cannot be easily removed.

Cable, film and rod mats

The main problem with these systems is the fixed width. They are inconvenient to install in rooms with complex geometry and furniture. It will take quite a long time to combine the position of the individual parts to ensure uniform heating. There may be a large number of connections.

The advantage of cable and rod mats is their low height. This allows them to be laid under tiles and stones in a layer of adhesive.

Infrared mats are ideal for laying under linoleum or laminate. At the same time, they can be easily dismantled, since they are not laid in a screed.

Wired and cable heated floors

The advantage of such systems is that they can be used to ensure uniform heating of the entire floor area. For rooms with a lot of furniture and complex geometry, they are perfect.

The disadvantage of these systems is longer installation. They are laid in screed or tile adhesive. Unlike mats, when installing, you must accurately measure and follow the laying step.

Water heated floor

A water heated floor is a pipeline through which heated coolant moves. The flooring is heated by hot water coming from the heating system or boiler. The coolant is regulated using a collector unit equipped with a pump. The temperature supplied to the pipes should not exceed 45 degrees.

The water system has many advantages:

- warms the room evenly;

- economical - operating costs are not significant;

- Laying over the entire area is permissible - there is no risk of overheating the surface under heavy furniture.

The disadvantages of this type include:

- complex installation process and time-consuming;

- the design reduces the height of the ceilings, because more often it is filled with concrete screed;

- the complexity of repair work in the event of a leak, since the entire “pie” will need to be dismantled.

It is important to know! In high-rise buildings, such devices are rarely installed, because permission to connect to a common heating system is required. In addition, there is a risk of flooding the neighbors below.

As for the material from which pipes for warm water floors are made, there are several varieties.

Copper

Copper is the most suitable option for underfloor heating pipes. It is not subject to corrosion and tolerates mechanical loads and pressure exerted on the material inside the pipe. Withstands temperatures from -100 to +250 degrees. If the coolant inside the circuit is frozen, the pipes do not crack.

For your information! When using a warm water floor with copper pipes, it is not recommended to drain water from the circuit.

There are a number of limitations when using a copper pipeline:

- It is not permissible to lay steel and copper pipes in the same circuit;

- It is not recommended to carry out installation yourself, since the work is complex and requires professional equipment;

- You cannot use coolant with an acidic or alkaline environment so that the line lasts longer.

The cost of copper pipes is high, but it will pay off due to its long service life - more than 50 years.

It is recommended to install warm water floors with copper pipes in houses with intermittent residents, where there is a danger that the main line may freeze.

Metal-plastic

Metal-plastic is a relatively new material, consisting of an outer and inner layer, as well as reinforcement with aluminum foil.

Pipes made of this material have high performance characteristics. They:

- durable - up to 50 years;

- resistant to corrosion;

- immune to mineral deposits;

- biologically inert - do not release harmful substances;

- resistant to chemicals - it is possible to fill with water with various additives or antifreeze;

- lightweight - so it’s easy to install it yourself, without special equipment;

- have good soundproofing properties.

For your information! Despite the ease of installation of metal-plastic pipes, it is advisable to have at least some experience in this work. Since incorrect installation can lead to loose fittings during operation. Therefore, it is better that the part of the contour filled with screed is solid. In addition, a pipeline made of such material has temperature restrictions, from -10 to +95 degrees.

Polypropylene

Polypropylene contours have a reasonable price, despite this, their performance characteristics are high, but they are not recommended for heated floors. The reason lies in the rigidity of the material, which complicates the process of bending the contour. Therefore, experts advise laying them in TP in exceptional cases, and in rooms not exposed to sub-zero temperatures.

Cross-linked polyethylene (REX)

This material is relatively new, but has already proven itself well. It has good properties:

- temperature range from 0 to +95 degrees, although it can withstand -50 and +150 for a short time;

- the presence of deformation memory, that is, when a crease occurs, it is enough to direct hot air to restore the shape;

- has pressure resistance;

- REX pipes are easy to bend;

- it is not afraid of corrosion;

- there is no release of toxic substances during operation.

Cross-linked polyethylene is sensitive to ultraviolet rays. This indicator is not important if there are pipes located in the “pie” of the heated floor, but this should be remembered when storing the product.