How to insulate the floor in an old house, including without removing the covering

In old, but still reliable houses, cold floors are often found. There are many options for its designs, but each can be turned into insulated, and even heated. Warm floors are always a welcome feature in the house, and it’s not difficult to make it yourself. Let's look at the most typical options.

Without removing old floors - how to insulate

Not everyone wants to do the serious work of tearing out old boardwalk and then putting it back in place. To insulate an old floor without removing the flooring, there are two options:

- get to the subfloor through the basement, or by partially removing the covering in the form of working hatches, and insulate from below;

- insulate over the old coating, but this is possible if the height of the ceiling and doorways allows.

Both options are good if there are prerequisites for them. Let's look at it in more detail below...

Typical insulation of an old wooden floor - remove the flooring and place the insulation between the joists

We have a typical ventilated underground and wooden joists. The laid insulation layer must be ventilated from the street, with the exception of samples that are not saturated with water. Therefore, the vapor barrier membrane is located on the room side. Leaky insulation on the side of the ventilation stream (underfloor) must be protected by a windproof membrane so that its layer is not blown through.

- We tear out the old floor.

- We stuff counterbeams, lower sheathing, and thrust beams under the joists and lay boards and plywood on them scattered - we do everything possible under the given conditions to create a basis for laying the insulation.

- We put a windproof membrane and mineral wool 15 cm thick. Polystyrene is not advisable here due to the threat of damage by rodents...

- We cover everything on top with a vapor barrier with a bloat on the walls and install the flooring.

But with appropriate protective measures, you can also use any insulation - polystyrene foam, self-leveling penoizol (recommended), vermiculite, ecowool, expanded clay (if the layer is thick), leaves and straw with lime...

We fill the low underground with ash and expanded clay

Often, old floors were made directly along a shallow trench, only 30–50 cm, slightly more than the height of the log itself. A popular insulation option in this case is to fill the low subfloor with ash and expanded clay, as well as close vents and cracks, and prevent air from blowing through the insulation. A layer of ash-slag from coal, 40 cm thick, even moistened from the ground, gives an excellent thermal insulation effect, comparable to expanded polystyrene foam 7 - 10 cm thick.

On top, the logs with backfill are insulated with a vapor-resistant membrane and covered with wooden flooring.

We insulate with soil - we insulate the foundation on the sides

The soil directly under the house can also serve as a heat insulator - yes, yes, just cold, cold earth... You just need to ensure that there is no ventilation of the subfloor, fill the space between the joists with soil, stone, or preferably expanded clay or slag if possible, and put a vapor barrier membrane on top, and then ordinary flooring.

- We tear off the foundation around the perimeter of the house, insulate it to a depth of at least 0.8 meters below the soil level, as well as the base of the house with 5 cm extruded polystyrene foam.

Now the top layer of soil under the house with a thickness of 0.7 - 1.0 meters will have an increased temperature and serve as an excellent thermal insulation layer.

We insulate the old floor without tearing the coating - we use polyurethane foam

If it is possible to more or less freely reach the coating from below, then you can use sprayed polyurethane foam, with a layer thickness of only 7 - 10 cm. Let us recall that this heat insulator has the lowest thermal conductivity coefficient, about 0.03. But the possibility of creation must be agreed in advance with the specialists who will do the spraying. Polyurethane foam is a vapor barrier, forms a continuous layer, holds the structure together, no additional use is required here.

We measure the height - is it possible to insulate over the old flooring?

A comfortable height in the house is 2.4 m, perhaps 2.2 meters if the residents are not tall and are willing to put up with a low ceiling. Therefore, it is not possible to lay a layer of insulation and coating 12–15 cm thick everywhere. Additional obstacles:

- The height of doorways must remain sufficient to avoid the appearance of a “head impact area” sign. Replacing the door hatches will also help here; the height of the top crossbar in modern versions can be only 3.5 cm.

- the old radiator system should be placed between the floor and the window sills; in extreme cases, a niche is left in the covering for the radiators themselves...

Thus, having completed the necessary measurements, you can come to a conclusion about how best to insulate the floors in the house, whether it is possible to lay layers on top of the existing flooring...

We insulate over the flooring

On the old boardwalk we put a vapor barrier with a screw on the wall, then a couple of layers of extruded polystyrene foam, with a total thickness of 10 - 12 cm (thermal conductivity coefficient - 0.033), then a separating polyethylene film, and a damper tape along the walls. We lay a prefabricated dry screed - two layers of gypsum fiber, laid with overlapping seams and leaving thermal gaps between the sheets of 2 mm, and fastened with screws at 30 cm intervals.

Making a heated screed

Only a thin prefabricated screed can be placed on top of old wooden floors - approximately 50 kg per square meter. A thick 8 cm reinforced concrete screed is unlikely to be suitable here - only on floors on the ground, or on joists installed on intermediate supports. For a thin screed, it is most correct to use a profiled heat insulator and metal heat distributors. Here, extruded polystyrene foam is already needed for economic reasons from 12 cm, and preferably 15 cm.

Hydraulics can often be made into short circuits - up to 30 m; in this case, the temperature in the circuits can be adjusted with a simple adjustment valve, by limiting the amount of coolant, without installing mixing units.

You can also install heat distribution plates on a wooden counter-lattice, laid staggered, on an already well-insulated underground - how to do it...

How to insulate a floor in an old wooden house

Hello! We got an old village house. A good-quality wooden frame, quite warm, but cold floor. We often visit it in the off-season and, no matter how hard we fire the stove, you can’t walk on the boards barefoot, your feet get cold. Tell me how I can insulate it, maybe lay something on top? After all, today there are a lot of different insulation materials; the store advised us to use foil Teplon.

There is no simple answer to your question. Or, rather, there is: most likely, you can only put a traditional rug on the floor of an old village house - and nothing more.

The fact is that in Russian huts (and German houses, by the way, too) they did not not only insulate, but also waterproof the floor, although these technologies have long been known. An unfilled underground space is best combined with stove heating, providing optimal humidity, warmth in winter (the ground does not freeze) and coolness in summer. If your house is really built in accordance with the canons of folk architecture, most likely, under thick floorboards and one or two powerful joists there is open ground, probably well-trodden clay. Yes, you yourself mention something similar. Therefore, even if your hut is built in a dry place, moisture penetrates from the “damp ground” into the underground space. It can go outside through holes in the foundation or into the room through holes in the floor, gaps between boards, and even the wood itself.

Neither waterproofing nor floor insulation was done in a traditional wooden house - only ventilation

If this is the case and there is no waterproofing, placing a thin layer of insulation (cork, foamed polyethylene of any brand, insulated linoleum) on the boards that is impenetrable to water vapor will lead to waterlogging of the floor boards and their accelerated destruction. And the low ceiling of the hut will not allow building an additional layer on top with a breathable heat insulator, a ventilated gap and a new flooring.

Our advice: put carpet on the floor, only on a woven, not solid PVC base. The presence of natural fibers in the pile will make it warmer to the touch. Remove the wool rug from the wall and place it on the floor.

If the carpets do not give the desired result, and the desire to increase the comfort in the home is great, you will have to open up the floors.

Work on joists

This insulation option is distinguished by its simplicity, but at the same time high efficiency, since it is possible to significantly reduce thermal energy losses.

The procedure is as follows:

- Install wooden joists.

- Attach the panels to the boards on which the heat insulation will subsequently be laid. They should be hemmed from the bottom.

- Between the logs, insulation, gyro- and vapor barriers are laid.

- Finally, the installation of floorboards and final finishing of the floor covering takes place.

Maybe

How to insulate floors in a private house without removing the old floor

Cold winters still exist, and you need to prepare well for them so that living in your home is 100 percent comfortable. Warm floors are the basis on which it depends how pleasant it is to be indoors when it’s cool outside. There are convenient options for insulating this part of the building without removing the top layer - it’s easy to do yourself if you follow simple recommendations.

Any wooden house quickly loses heat, this is due to the nature of the material. Therefore, insulation of all parts related to the external environment is mandatory. Walls are only part of the overall structure, which must undergo a thorough thermal blocking procedure. The process of working with the floor will solve problems such as:

- excessive energy consumption for heating the room;

- high humidity – important for transitional seasons;

- rotting of wooden building elements;

- the appearance of fungus and mold, which poses a danger to the health of the residents of the house.

Most often, cottages have insulated floors above a cold basement, because... in the cold season, they quickly cool down and have a low temperature even if the room is heated using its boiler system. Poor thermal insulation or its absence means icy floors on which it is useless to lay carpets. The problem can only be solved by proper insulation; there are simple techniques that can be used without removing the old floor. It is better to spend money once on such an event than to constantly spend extra gas or electricity on double heating of rooms.

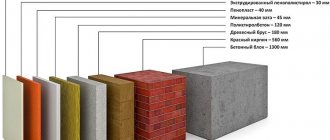

Floor insulation scheme

If the building has already been built and there is a need for additional insulation of the floors, it is more advisable to do this from below, i.e. without removing floor coverings. Advantages of the lower technique:

- The ceiling height in the rooms will remain the same, because... there will be no need to raise the floors due to insulation;

- there is no need to specifically spend money on insulating compounds of increased density and rigidity due to the load of furniture, appliances and other items in the house;

- you will protect not only the floor itself, but also all floor structures from freezing, which will extend their service life and generally make your home warmer;

- there will be a change in the location of the dew point from the inside to the surface of the ceiling - this will help get rid of rotting of wooden elements.

The method of insulating the floor from below has only one limitation - the subfloor is too low, in which it is impossible to be in for work. Such cottage buildings are quite rare. If this is your case, choose the option of insulating the floors from above, i.e. with the procedure for opening it and filling it with suitable insulating material.

Mineral wool is a building insulation material consisting of many fibers, presented in three separate types: glass; stone or basalt; slags For working with the floor, basalt cloth is preferable, because... it is easiest to install under the floor structure. Of the two options - rolled and mats in the form of slabs - choose the second one, because... it holds its shape well. Advantages:

- good level of thermal insulation;

- simple installation technology;

- relatively low level of perception of moisture from the environment;

- reasonable price;

- heat resistance and fire safety;

- The material does not harbor bacteria, mold or mildew.

- When laying with your own hands, you must use special protection - gloves, clothing, a respirator, glasses, because... there will be many particles of fibers and dust in the air, causing irritation to the skin and respiratory system;

- protection from moisture is required, because the structure is susceptible to vapor absorption;

- If installed incorrectly, severe shrinkage may occur;

- when laying between the joists, you need to leave a gap of 5 centimeters to the main structure.

Floor insulation with mineral wool

If you decide to choose mineral fiber, select the material of the desired thickness. Specific data depend on the climatic zone, for example, for central Russia, an indicator of 100-150 millimeters is suitable. Basalt wool is suitable for all types of floors, including attics.

Polystyrene foam consists of foamed PVC granules containing a maximum of air inside, this gives it good thermal insulation qualities. Advantages:

- has strength, stability, rigidity;

- almost does not absorb moisture - the percentage is lower than that of mineral mats;

- is light in weight;

- easy to install, because does not change shape;

- inexpensive;

- durable, does not mold, does not rot.

- susceptible to fire;

- fragile to break;

- Base ventilation is required, because does not allow steam and air to pass through.

Polystyrene foam is also used for floor insulation

For insulating floors in an ordinary private house, foam boards of the PSB-S-15 brand ten centimeters thick are suitable. When purchasing, do not confuse them with granulated polystyrene foam, which easily crumbles into small PVC balls. The latter can also be used as insulation if the renovation budget is very small. The material has good thermal conductivity, but has a relatively short service life - no more than ten years.

This building material consists of two types of foam - light and hard. To work with the floor, the second option is used, because it does not require special vapor barrier from the basement and has better thermal insulation characteristics. The first type is very similar to mineral wool - in the same way, when working with it, you will have to leave gaps for ventilation and waterproof the lower surface. PPU consists of two components:

- 1. polyol or hydroacid with emulsifiers, polyesters and reagents responsible for foaming;

- 2. isocyanate or polyisocyanate and diphenylmethane diisocyanate mixed with each other, which are strong reagents in combination.

The chemicals are kept liquefied in two different containers. During installation, they are fed through hoses into a special apparatus, mixed and supplied to a sprayer, with the help of which the finished foam is applied to the surface. They must be fed into the equipment strictly in a one-to-one ratio, because the first is responsible for thermal conductivity, and the second is the density of the structure.

High-quality floor insulation with polyurethane foam

- fills all cracks and corner spaces thanks to spraying technology;

- suitable for installation from below;

- does not shrink, is fireproof;

- does not require protection from vapors;

- durable - lasts up to 50 years;

- high level of adhesion to all materials;

- high installation speed;

- complete environmental friendliness;

- has no seams, because represents a single canvas after drying.

Penoplex

This material has high thermal insulation properties, due to which it is widely used in the construction industry. In fact, this is a type of expanded polystyrene, or rather, its extruded version. In its production, the extrusion method is used (foaming followed by pressing into a special shape).

Penoplex is ideal for insulating floors in a dacha, and here's why. The end result is a granular material with cells (the voids in them are filled with gas). With its low weight, penoplex does not allow moisture to pass through and reliably retains heat. Usually produced in sheets 600 mm wide, and the length can be 1200 mm or 2400 mm.

As for its other positive qualities, we can highlight the following advantages:

- Resistant to mold and mildew.

- Durability.

- Easy to install (no experience required).

- Resistance to deformation.

- Ability to withstand temperature changes.

However, there are also disadvantages. For example, ultraviolet rays have a destructive effect on the material. For this reason, finishing on top of the insulation is necessary, and it is done immediately.

In addition, this is a flammable material; when burned, it emits not only acrid smoke, but also toxins (hydrocyanic acid, hydrogen bromide, phosgene). This should be taken into account when choosing this material for insulating the floor in the country house.

Why insulate a wooden floor?

Wood is a fairly warm material compared to concrete, but when building a frame private house or a house made of timber with your own hands, it is not always possible to achieve a rational balance of the thickness of the structure in terms of strength and thermal conductivity. To reduce the consumption of materials on walls and foundations, thermal insulation is necessary. It is possible to carry out insulation work both in an old building that has been commissioned for a long time, and in new construction.

Insulating the floor in a wooden house can prevent the following problems:

- the appearance of excessive dampness in the room;

- reducing the temperature in the task;

- condensation, which causes mold to appear;

- the appearance of fungus and other microorganisms dangerous to humans;

- increased heating costs;

- destruction of wooden structures from the inside.

By doing the work yourself you can significantly reduce costs. Now there are many materials, the use of which does not require special skills and high qualifications.

Diagram of all heat losses of a wooden house.

Warm floor system

Installing a heated floor system is the easiest way to create comfort when staying at the dacha in the cool season. The system can operate either on electricity or on a water heating circuit.

Most often, such systems are installed by professionals during the construction of a country floor. This is due to the fact that independent installation of such structures is quite labor-intensive and requires an exact sequence of installation instructions.

Which floors require insulation?

The following structures need protection:

- cold basement floor pie;

- attic floor;

- interfloor slab design.

In the case of an interfloor option, the material is used as sound insulation. In this case, you need to provide a layer 3-5 cm thick.

Insulating the floor of the first floor in a wooden house allows you to provide comfortable living conditions. Most heat loss occurs through the ceiling of the upper floor, so it is necessary that the insulation is selected and installed correctly.

Materials for work

To properly insulate the floor in a wooden house, you need to choose high-quality insulation that has all the necessary properties. Insulation can be carried out both from the inside of the room and from the cold air side.

To insulate an attic floor from the inside or a basement floor with your own hands, it is better to use lightweight materials that can be easily attached to the floor pie from below. In this case, it would be correct to use:

- mineral wool in rolls;

- Styrofoam;

- polyurethane foam.

These materials will ensure maximum convenience when insulating the ceiling with your own hands.

When insulating a frame house, a house made of timber or logs, you can carry out work from inside the room for the floor of the first floor and outside for the last floor. In this case, it is better to insulate the floor along joists or beams, since this will prevent the load from being transferred to the fragile material. For this type of work you can use the following materials:

More information about insulation with sawdust and expanded clay can be found in the articles “Insulation of floors with expanded clay” and “Insulation of floors with sawdust.” These materials have such advantages as natural origin and low cost, so if you need to reduce construction costs or insulation in an old building and ensure complete environmental friendliness, it is better to use them. However, they are less technologically advanced compared to other materials.

Recently, the method of insulating floors with foam (polyurethane foam) is also gaining popularity. This method is good for its low labor intensity and high efficiency.

Floor insulation with polystyrene foam also deserves attention due to the relatively low cost of the material and ease of installation. The method of floor insulation with Penoplex (extruded polystyrene foam) is less popular in wooden floors due to the high cost of the material - it is more suitable for insulation under screed.

Thermal insulation in the case of a low underground

This technology is the most labor-intensive, since it involves dismantling the old flooring. This is due to the limited size of the underground space, which does not allow the thermal insulation material to be secured to the joists from below.

The steps themselves are as follows:

- The plinth and floorboards are carefully dismantled. Along the way, it’s worth labeling each element of the “mosaic” so that you don’t mess everything up when reassembling it.

- Inspect all joists for integrity. If necessary, all problem areas should be cut out and instead of damaged elements, solid beams of equal size should be installed. The extension is made using boards that are attached to the left and right sides of the joists. Use galvanized screws as fasteners (for obvious reasons).

- A cranial block is attached to the lower edge of each joist and the same on both sides. This will serve as support for the subfloor.

- In accordance with the distance between the logs, lumber is prepared, which will be used to form the rough flooring. In this case, the length of each section of the board should be 10-20 mm shorter than the step for installing the logs. Thanks to this, the flooring parts will be laid freely, but this will not interfere with the subsequent insulation of the subfloor.

- Now the actual formation of the subfloor is the laying of the prepared boards.

It is not recommended to join them tightly to each other, otherwise, due to the characteristic movements of the wood, mounds and steps will form.

Floor insulation technology

It is important to lay the insulation correctly, observing the correct order of all layers. The floor pie when insulating the attic floor, the floor of the second floor or the first has not always noticeable, but significant differences.

Insulation of the floor of the first floor from below

Scheme of floor insulation above a cold underground

In this case, when carrying out work with your own hands, the materials should be correctly laid in the following order:

- waterproofing;

- insulation;

- vapor barrier;

- ceiling design.

When building a house from timber or frame, the material is secured along the beams. After which the filing is performed. As a protection against moisture and steam, you can use ordinary polyethylene film. As a second option for waterproofing, moisture-proof membranes are used. If all layers are laid correctly, the structure will be reliably and competently protected from the cold from the point of view of heating engineering.

This method is very labor-intensive and is used only if it is not possible to insulate from the inside.

Also, for insulation from below, the method of insulating the ceiling with foam is perfect.

Insulation of the ground floor floor from the inside

Carrying out work under the ceiling is quite inconvenient, so When constructing a frame house or a building made of timber, insulation of the first floor floor is often carried out using beams from above. In this case, in addition to the previously mentioned materials, you can use bulk materials such as sawdust and expanded clay. When carrying out insulation with your own hands, correctly lay all layers in the following sequence:

- floor design;

- waterproofing;

- insulation;

- vapor barrier;

- clean floor.

The vapor barrier must be placed from the inside of the room, so it will work correctly, preventing damage to the floor along the timber beams.

Insulation of interfloor ceilings

In the first case, the insulation dampens airborne noise: human speech, music, etc. In the second case, the structure is also perfectly insulated from impact noise - steps, jumps, etc.

Proper sound insulation of interfloor ceilings is the key to comfortable living for all family members.

Insulation of the ceiling of the upper floor from the inside

Installing insulation from the inside does not provide maximum protection for structures, but it can be used as a second option for laying insulation. In this case, the insulation is mounted on the beams from below the floor. It would be correct to arrange the layers in this order:

- vapor barrier;

- insulation;

- waterproofing;

- beam-based floor structure.

Double protection

With this floor insulation scheme, the height to the ceiling will be reduced to around 12-20 cm. This is worth taking into account, and if conditions allow, you can proceed to work. The algorithm here is:

- Remove the baseboards, then inspect the floorboards and make repairs if necessary. All cracks are filled with polyurethane foam, a mixture of sawdust and wood glue. A combination of paste and moistened paper is also suitable.

- Place the logs, the step between them should be from 60 to 70 cm, but not more than 90 cm.

- Before you start insulating the floor in your dacha, you need to check the height of the logs with a building level. If it is exceeded, remove the excess with a plane; if there is a deficiency, compensate by placing roofing material under the beam.

- A waterproofing layer or vapor barrier is laid as a continuous sheet.

- The “boxes” between the joists are filled with the selected thermal insulation material. At the same time, one should not forget about the ventilation gap.

- Cover everything with another insulating layer.

- Lay boards, plywood, GVLV or any other similar material to form the finished floor.

- At the final stage, the floor covering is laid and the baseboard is put in place.

If the foundation of the house is supported on piles (including bored and screw modifications), then, regardless of the technological scheme for insulating the floor, it is necessary to provide protection using a wind barrier. It is located outside.

How to insulate floors in a private house with your own hands without removing the old floor - instructions

In connection with the general trend towards reducing housing heating costs, the issue of floor insulation has become acute. Although the floor releases less heat into the atmosphere than walls, when cold it can reduce the temperature of the home and lead to excess heating costs. In a private home, cold floors can lead to frequent respiratory diseases among its inhabitants.

Insulation without removing the old coating is relevant for those houses in which the floor has a structural function and serves as a roof for the basement.

Features of steam insulation

Wooden floors in a private home are the easiest to insulate with your own hands; it can be easily done without removing the old floor. Wood is easy to process and easy to insulate. Wooden floors must have the following layers of insulation:

To insulate against steam, you should use modern materials that allow air to pass through but retain moisture. Vapor barrier is one of the main components of insulation; without it, the floor quickly wears out, and the desired effect of saving energy resources is not achieved.

Video: film for floor vapor barrier

Insulation material

After choosing a vapor barrier material, you should decide on the insulation. There are many materials on the market that have both advantages and disadvantages. Here is their list:

Polystyrene boards are relatively inexpensive, have good performance qualities and a wide variety of sizes. They can be laid in one or several layers. They are non-biodegradable, easy to install, durable and hold their shape well.

Extruded polystyrene slabs differ from the previous type by their increased density, which allows them to be laid on any surface, including ground.

Polyurethane foam boards are used only as a vapor barrier. They are reinforced with various substances, it can be fiberglass, aluminum, or other materials.

Mineral wool has excellent thermal insulation properties. It is very environmentally friendly, does not burn, is inexpensive and does not require additional equipment during installation. This type of cotton wool is a soft material sold in large rolls.

Insulation with expanded clay requires considerable effort; it should be compacted and filled with cement.

The choice of material for insulation depends on the financial and technical capabilities in each specific case.

A small but necessary retreat

Now it’s worth paying attention to an important point. All further actions will depend on the extent to which the rocks under the foundation are saturated with moisture. The rough flooring and joists must be covered with a layer of vapor barrier. Thanks to this barrier, the thermal insulation material will be reliably protected from the effects of steam that rises from the surface of the earth. However, this does not prevent the removal of condensate from the thickness of the insulation.

If the house is built on an area with high groundwater, a vapor barrier membrane is not suitable. Instead, it is necessary to arrange waterproofing using roofing felt or glassine.

The process of laying a floor on an old wooden one

In order to insulate the floors in a private house with your own hands without resorting to removing the old floor, you should collect the following building materials:

- Plaster or polyurethane foam

- Sand

- Sheets of roofing felt

- Vapor barrier material

- Construction stapler or nails

- Thermal insulator

- Chipboards

Using the materials from the first point, the gaps between the boards of the old covering are covered. The floor prepared in this way is covered with roofing felt, and sand is poured on top. Its layer should be no more than 0.5 cm thick.

Next, the process of laying the floor occurs according to the following instructions.

A vapor barrier material is laid on top of the sand. Depending on its thickness, nails or staples from a construction stapler are used for fastening.

The insulation itself is laid on top of the vapor barrier. It also needs to be fixed with nails of suitable length.

Chipboard is laid on top of the insulation layer. The external flooring will be installed on it - parquet, laminate, or other options.

This method is suitable for wood floors. For buildings with a concrete base, a slightly different installation technique is used.

Thermal insulation of a wooden base

Insulation of wooden floors is usually carried out using mineral wool along the joists. The old wooden floor is removed. After inspecting the boards, it is necessary to remove the old paint, sand them and treat them with antiseptic substances. After they dry, you need to lay them horizontally.

Debris and dust from the rough base must be removed. Rotten logs need to be replaced, and the resulting structure needs to be treated with an antiseptic and allowed to dry. When laying dense polyethylene, it is advisable to insulate the joints with construction tape. Secure the waterproofing to the joists using a stapler.

Then you need to cut the mineral wool and lay it tightly between the joists. Next, you should provide a layer of vapor barrier over the entire structure, connect the joints with tape and secure with a stapler.

The next step will be laying the old boards and installing the baseboard. The protruding parts of the waterproofing must be cut off and then the coating must be painted.

Insulation with expanded polystyrene should begin with the removal of the final finish. Then you need to inspect the base and check its level. If the height difference exceeds 1.5 cm per linear meter, it is necessary to level the base.

Then you will need to remove debris and dust, as well as pour a cement screed of the required height and wait until it dries.

We cut out polystyrene foam and lay thick polyethylene. We connect the edges of the canvas with tape, place it on the walls and secure it.

The insulation must be laid in two layers. The first layer should be laid with ligation of vertical joints. The second - in the same way, only its location should be strictly above the seam of the first layer;

We install a reinforcing mesh with a post height of 3 cm. Prepare the mixture for the screed. We concrete the base in parts, smoothing the compartments with a trowel and checking the level, waiting for drying (this process usually takes a whole month). We carry out finishing work.