20-30% of heat is lost through the ceiling space in private homes. There are two ways to cover losses:

- put thermal insulation materials on the roof;

- insulate the ceiling, which is several times simpler and cheaper.

Therefore, homeowners most often choose the latter: insulate the ceiling. It should be remembered that the insulation requires protection from water in a vapor state: with increasing humidity it loses its thermal insulation properties, and under certain conditions it can become wet due to condensation. And this is a favorable environment for the development of mold and mildew.

Practice shows that home craftsmen either ignore vapor barriers or violate installation rules: they use the wrong type of film. To help owners carrying out repair and construction work on their own, we will tell you in detail how to properly install a vapor barrier on a reinforced concrete and wooden ceiling.

Why do you need a ceiling vapor barrier?

In modern homes there is much more moisture in a vapor state than, for example, half a century ago.

Its sources are the bathroom, kitchen, indoor plants, etc. Part of the moist air escapes through the ventilation ducts (if the natural one cannot cope, you need to install forced ventilation). But even with optimal air exchange conditions in an apartment or house there will be higher humidity than outside (with the exception of a few days when the humidity outside is about 90%). But even in this situation, due to the higher partial pressure indoors (it’s simply warmer inside an apartment or house), steam molecules will break through the structural elements of the building (floor, walls, ceiling) to the outside.

As a result, the uninsulated ceiling under a cold roof will freeze. After thermal insulation, a second problem arises: the dew point shifts into the insulation, creating a new headache (what the “dew point” is and the processes occurring inside the insulation layer are described in the article “Rules for the selection and technology of installing vapor barriers for the roof”).

Attention: for those who do not want to look at the link, let us clarify a little: vapor barrier is not needed when insulating the ceiling between the floors of a residential building and between the living and attic premises - there is no critical temperature difference that causes the formation of condensation.

Scheme of vapor barrier from inside the room.

A vapor barrier film helps prevent the accumulation of moisture in the insulation - it puts a barrier in the path of steam molecules. It allows:

- extend the life of the ceiling, especially wood;

- eliminate the problem of accumulation of vaporous moisture in the insulation, preventing the formation of condensation in the winter;

- keep the insulation dry - any material in a dry state holds heat better.

Should I do it?

Hydro- and vapor barrier of wooden floors is carried out at the stage of assembling the ceiling or floor after the main part of the structure has already been installed. The ceiling itself is a multilayer element; moisture and steam can affect it in several ways:

- Below . They can come from the basement or from the lower floor, and are able to overcome concrete barriers, since cement perfectly allows steam and water molecules to pass through.

- From indoor air . Human life is somehow connected with water. Moisture and steam come to the floors from cooking, taking a bath, caring for plants, from animals and even from human breathing.

If the impact of moisture is insignificant, it does not have much effect on the condition of the floors. But more often, liquid and steam act on wood for a long time. To avoid negative consequences, hydro- and vapor barrier of the floors in the room is carried out, both above and below relative to each span.

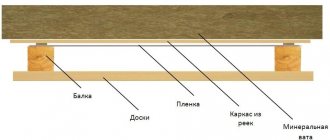

The ceiling structure consists of:

- flooring on the top floor or attic, can be rough or finished, depending on the purpose of the room;

- vapor barrier layer;

- load-bearing supporting elements, beams, logs;

- thermal insulation, which is placed between the structural parts that hold the ceiling;

- the very base of the ceiling (ceiling, for example, for one of the floors), board.

The waterproofing layer comes first; it protects the entire contents of the floor from liquids entering it.

The vapor barrier is laid higher, after the heat-insulating layer, since it is designed not only to block the penetration of steam from the atmosphere into the wood, but also at the same time removes condensation that forms from the insulation. Why do we need hydro- and vapor barrier for wooden floors:

- They save you from condensing moisture, which is formed due to temperature fluctuations inside the room and settles on the ceilings.

- Extends the service life of wood and other floor elements.

- Reduces the likelihood of damage to insulation and the appearance of rot, mold and other microorganisms.

Waterproofing prevents water molecules from seeping into the floors. Vapor barrier helps to ventilate condensation, which inevitably accumulates on their surface and can cause damage to thermal insulation.

Consequences of absence

What are the consequences of violation or absence of layers that protect against moisture:

- Deformation of wooden elements. Beams, joists, and boards first swell from moisture and change shape. Afterwards they dry out and become brittle, break easily and can collapse.

- The appearance of rot, mold, fungus. It is dangerous to live or work in such a room.

What will happen if the hydro- and vapor barrier is installed incorrectly, the video will tell you:

Types of vapor barrier films

Vapor barrier materials differ in the material from which they are made, the principle of operation and the level of vapor permeability, which must be kept in mind when choosing a vapor barrier for the ceiling.

Type of material

For the ceiling, you can use roll and coating (painting) vapor barrier.

Rolled vapor barrier materials. Various types of vapor barrier films are classified as roll insulators. They can be in the form:

- films - do not allow steam to pass in both directions. This is a silent, although sometimes relative, vapor barrier. The vapor barrier film for the ceiling can be one-, two-, or three-layer, with or without reinforcing mesh;

- diffusion membranes that allow vapor to pass through from the side of higher partial pressure. Construction specialists and manufacturers sometimes say that these are membranes with one-way flow, which is fundamentally wrong. If you look at the material in cross-section (the diagram is shown below), you can see that vapor molecules can move in any direction. They cannot get to the insulation due to the higher vapor pressure in it. Therefore, the membrane can be laid on the ceiling on either side;

- foil films - used as reflective vapor barriers. Produced for baths, steam rooms and saunas. They are not used for residential premises - acquisition costs are disproportionate to the functions performed. Simply put, simple, cheap plastic wrap will work just as well.

Coating vapor barrier. Coating vapor barrier materials are represented by various types of mastics on a bitumen-polymer base. They can only be used outside and on concrete floors.

For a ceiling that is also a flat roof, in addition to mastic, liquid rubber is sometimes used.

Principle of operation

Vapor barrier film for ceilings can be of several types: A, B, C, D, F.

- A (some manufacturers mark it with the letters AM) - creates an insurmountable barrier to water molecules and allows steam to pass in both directions. Used to remove steam from the insulating layer;

- B is a typical representative of vapor barrier materials: does not allow steam to pass in both directions;

- C is a type of film B, only reinforced;

- D - laminated polypropylene;

- F - foil film.

Vapor tightness

Based on the level of vapor permeability, films are divided into classes:

- Class I - foil and foil films;

- Class II - vapor barriers made of propylene;

- Class III - soft material with a high coefficient of vapor permeability.

Sometimes, instead of a class, marking with the letters “SD” with a digital value of vapor permeability is used. For example, SD 50 means that in an hour, steam equal to 1 molecule of water will break through 50 m2 of film. For the ceiling, this indicator should be at the SD level of 30-40.

Which side to lay the vapor barrier on?

After installation of insulation is completed, vapor barrier work is carried out. Surprisingly, not all builders know which side to lay the vapor barrier film against the insulation. What can we say about “home craftsmen” in this situation? There is a general rule - the film is always laid with the smooth side towards the insulating layer, and the rough side - inside the room (attic) or outside.

But you don’t have to bother at all - large manufacturers always supply each roll with instructions. And to make it clear which side is which, they put pictograms. The problem only arises if the film has already been cut from the roll and the instructions have fallen out. But there is a simple solution: take a photo of the instructions from another similar roll on your smartphone.

How to distinguish the inside from the outside

Experienced specialists use other tips:

- the outer side is fleecy, the inner side is smooth. Easily identified tactilely, by touch;

- if the sides are of different colors, the lighter one is placed next to the insulation;

- when rolling out a roll, the inner side always faces the floor;

- the logo is always at the top;

- foil materials are laid with foil facing towards themselves.

If there are no marks at all on the roll, then it is a vapor barrier film, not a membrane. It doesn't matter which way you lay it, as it creates a barrier to steam in both directions equally.

How to check which film you purchased

When purchasing several types of film, sometimes it becomes necessary to find out what type it is. To do this, cut off a piece of material and take two glasses (two mugs). Boiling water is poured into one. The second glass is placed on top of the first, with hot water, previously covered with film. If condensation does not appear on the walls, turn the film over and place the glass again.

A dry surface indicates type B - the classic type of vapor barrier. If the walls of the container got wet only once - type A, one-sided membrane. The appearance of condensation twice indicates that the film is a waterproofing material and has nothing to do with vapor barrier.

Features of laying specific vapor barrier materials

Theoretical recommendations for vapor protection devices are discussed above. Many site visitors are interested in which side to lay vapor barriers of different classes or specific manufacturers:

- “Izospan AM” - laid with the brown (dark) side out, the white side facing the insulation;

- “Izospan B” - the smooth side should fit tightly to the insulation, the rough coating should face the inside of the room;

- polyethylene film is laid on either side;

- foil reflective vapor barrier (“Penofol”) is mounted with the metallized side inside the room (baths, steam rooms, saunas);

- membranes are laid in accordance with the pictogram printed on their reverse side;

- polypropylene with one-sided lavsan coating, the smooth side is laid against the insulation, the wicker side is laid inside the room;

- foil films in rooms with standard temperature conditions are laid with the metallized side facing the insulation.

What happens if you lay it on the wrong side?

Among experts to this day there is no single point of view on the processes occurring inside the insulation when laying vapor barrier material on the wrong side.

Some believe that condensation will begin to form not on the outside of the film, but in the insulation, causing destructive processes in it, while others believe that nothing bad happened and there is no point in rushing to redo the thermal insulation if a mistake was made.

There is generally an original explanation for the rough side - this is the result of joining two strips of vapor barrier film during the production process. It is easier to glue to such a surface, but additionally sanding the second side costs money. To explain this technological technique to customers, a fairy tale was invented about different sides of the film with different functions.

If we take anti-condensation protection as a basis, then those who claim that nothing bad will happen are right. But here the debating parties are missing one important point. The film is called windproof. And here there is a very big difference in how it is laid.

To make it easier to understand what we are talking about, you need to conduct a simple experiment: take a fabric with a pile on one side and alternately on each side, placing it tightly to your mouth, and blow through it. From a smooth side there will be practically no resistance, since the fibers flutter freely in the wind. From the pile side, everything is not so simple. You will have to make an effort, since the villi, pressing against the fabric, clog the pores through which air passes.

A simple experiment shows that it is still worth following the manufacturers' recommendations.

Vapor barrier materials

Vapor barriers are produced by specialized enterprises and, according to their performance, are divided into the following groups:

- sheet products;

- rolled materials, including films;

- paint and varnish compositions.

Dry cement-based mixtures are also used as vapor barriers, mixed with water before application to the base.

Sheet materials for vapor barrier

Making vapor barriers from sheet materials is widespread. This is due to the fact that some finishing materials also have vapor barrier properties, so their use solves two problems simultaneously: finishing and vapor barrier.

Examples of such finishing are sheets:

- asbestos-cement (including corrugated slate);

- plaster-based cladding (moisture-resistant dry plaster);

- wood-fiber (hard).

Rolled vapor barrier materials

This group includes polyethylene and polypropylene films (regular, reinforced, foil), aluminum foil and many modern vapor barrier materials with high performance, which are varieties and combinations of these films.

Conventional polyethylene film has high vapor barrier properties in all directions, but is fragile. Film reinforced with mesh or fabric has increased rigidity, which simplifies the installation process and makes the material more durable. There is a perforated type of polyethylene film, which is used where it is necessary to create conditions for the evaporation of condensate.

Polypropylene vapor barrier film has a fleecy cellulose-viscose layer on the outside of the impermeable shell, the pile of which prevents the condensate that forms on it from draining and ensures its gradual evaporation.

There are also so-called “breathing membranes”, which are used as a one-way vapor barrier - they are impermeable to water when open, since they have pores tens of thousands of times smaller than a drop of water, but are permeable to steam in the opposite direction.

This coating is used to insulate wooden roof structures - precipitation does not penetrate through the roof, and steam from the inside is freely removed to the outside. It is also used to protect ceiling insulation from steam, but from the base side, and the material must be laid in a certain way - with the markings facing outward, and the plain side facing the heat insulator.

Paint and varnish compositions

In rooms with low aesthetic requirements for ceiling finishing, various types of bitumen-based polymer mastics are effectively used as an effective means for vapor barrier of wooden ceilings. The advantage of this coating is the ease of application even on complex surfaces and the absence of the need to use frames and fasteners.

Which insulation is better to choose?

The choice of insulating material is directly related to the type of base, its evenness, the purpose of the room and the thermal insulation materials used.

For wooden ceiling

Rolled products are suitable for wooden surfaces, which prevent moisture from penetrating into structures and at the same time do not interfere with the effective ventilation of wood materials.

They cope with this task:

- polyethylene and polypropylene films;

- foil insulators;

- glassine;

- vapor barrier membranes.

Some of the listed materials, for example, polyethylene films, require the creation of a ventilation gap between it and the finishing layer, which will allow moisture condensing on the surface to evaporate without damaging the finish.

For concrete ceiling

To insulate concrete ceilings from moisture, materials that can be attached directly to the base surface are suitable. These are insulating mastics, varnishes and paints, foil insulators.

It is worth noting that foil vapor barriers can be attached either directly to a concrete ceiling surface or to a supporting wooden frame. The latter method is convenient because you can subsequently attach a ceiling made of plasterboard, plastic or wooden panels to the frame.

Features of vapor barrier installation

An important stage in protecting insulating materials is laying a reliable vapor barrier layer. All work is carried out during the repair or reconstruction of a finished building or during the construction of a new building. To correctly install a vapor barrier, you need to understand how to connect membrane sheets and which side to fix them to the insulating base.

Preparatory work

At this stage, work is carried out to select the appropriate type of vapor barrier, taking into account the features of the installation process, operational characteristics and material requirements.

Before laying a vapor barrier, careful surface preparation will be required. It is important to consider the type of material used in the construction of floors, walls, ceilings and roofing structures.

- During the construction of a log house, all structural elements are treated with protective antiseptics and fire retardants.

- When carrying out repair and reconstruction work, complete dismantling of the finishing, cleaning and preparation of surfaces is carried out:

Wooden elements are treated with compounds against aging, rotting and burning. Concrete, block and brick surfaces are treated with deep penetration antiseptic compounds.

Proper preparation of surfaces will ensure a long service life of the insulating material and the entire structure.

Technology for laying vapor barrier on the ceiling

If the roof structure and interfloor ceiling are made of wood, then the installation of a membrane for waterproofing is carried out on a prepared base.

Roll or block insulation is installed in the space between the rafters and joists; the best option is mineral or basalt wool. Next, you can lay vapor barrier protection on the ceiling surface.

When the thickness of the insulation is equal to the height of the logs, an additional slatted counter-lattice is installed to maintain natural ventilation.

It is necessary to install a vapor barrier on the ceiling with a slight overlap on the walls around the perimeter, and special attention should be paid to the corners. It is better to place the joints on the joists and glue them on both sides with tape on a reinforced base.

Important! When installing a vapor barrier, sagging and deformation of the panels should be avoided.

To thermally insulate a flat roof or concrete ceiling, a waterproofing film is mounted from the inside on a self-adhesive tape, then a sheathing made of wood or metal is installed.

The height of the sheathing is determined based on the thickness of the thermal insulation material and the minimum technological gap for ventilation. The installation step is 3 cm narrower than the width of the heat insulator, which allows for high-quality installation of the insulator into the prepared sheathing cells.

Technology for laying vapor barrier on the floor

The installation scheme for vapor barrier protection on the floor is similar to how the material is laid on wall and ceiling surfaces.

The wooden floor is insulated using joists, on which a waterproofing layer is laid. Next, insulation is placed in the space between them - wool on a mineral or basalt basis. After this, vapor barrier material is laid.

The rolled material must be laid with an overlap of 12 cm, with the joints carefully sealed with metallized tape on both sides. A properly laid vapor barrier should completely cover the floor surface with an overlap of up to 10 cm on the walls.

To install a vapor barrier on a concrete base, you will need to install a sheathing, in the cells of which a waterproofing layer and a heat insulator will be laid.

Pie layer diagram

According to current standards, technical solutions for the installation of floor slabs must ensure reliable waterproofing of thermal insulation materials and limit the penetration of water vapor into them as much as possible. And the relative arrangement of the layers should eliminate the prerequisites for the accumulation of moisture in the body of the structure and create conditions for its weathering.

The layout of layers in a multilayer wooden floor:

- Floor board.

- Waterproofing layer.

- Counter-lattice.

- Thermal protection.

- Counter beam.

- Thermal protection.

- Floor beam.

- Rough filing.

- Vapor barrier.

The face or the back of a vapor barrier?

If a breathable membrane is used to create a protective barrier, the main thing is to determine which side to lay the vapor barrier on - face or back.

The vapor barrier cake must be placed so that the protection is directed towards the heat insulator on both sides with the smooth back side, and with the rough front side facing the inside of the room.

The rough surface provides protection from moisture penetration into the insulation, and the smooth surface promotes maximum heat accumulation.

Selection of connecting tapes and adhesives for vapor barriers

A properly designed vapor barrier is a continuous and continuous layer. Moreover, ordinary construction tape for gluing overlaps and junctions is not suitable here - only special vapor barrier tape. Each manufacturer offers its own options for connecting tapes for different tasks.

For example, some of them are intended exclusively for fabric overlaps, while others are intended for adjoining films to smooth surfaces, and others are intended for connecting vapor barriers to porous and rough surfaces. Moreover, it is extremely important to purchase connecting tapes from the same manufacturer as the vapor barrier itself in order to achieve 100% tightness of the layer.

There are also several types of these:

- special glue for film;

- adhesive composition for connecting the membrane;

- construction tape;

- single-sided aluminum tape;

as well as double-sided adhesive tape to ensure the seal of individual panels.

How to choose a high-quality vapor barrier based on technical characteristics?

So, today there are many materials that have high resistance to vapor diffusion and low vapor permeability. For a long time, ordinary polyethylene films were very popular, which, in principle, do their job, but still do not please with high vapor permeability, low breaking characteristics and fragility.

Therefore, modern manufacturers, following their policy of import substitution, produce quite interesting technological solutions, among which there are even metallized membranes. There are many such materials and it is worth studying their characteristics to understand: what is the best vapor barrier for the ceiling of your home?

Let's list the most important characteristics for a vapor barrier:

- Vapor permeability is a characteristic of films and membranes from 0 to 3000 mg per square meter per day. This indicator tells you how many grams of water in the form of steam can pass through each meter of film per day. And the lower the number, the better, of course. If the numbers show vapor permeability in hundreds or thousands of grams, then you have a vapor-permeable membrane in front of you, and it should be placed not under the insulation, but on it.

- Durability . This characteristic significantly influences how easy your installation work will be. Cheap vapor barrier films are quite easy to tear; they lose their integrity even during installation, when tools fall on them or when they are touched. On the other hand, durable vapor barrier also tolerates temperature changes well.

- Water column pressure. The vapor barrier film is designed to retain water. This indicator is mainly important for a vapor-permeable membrane, which can literally get rained on. For the ceiling, this, of course, is not critical, although attic leaks should never be ruled out.

- UV resistance. This indicator varies from several days to a month. Surely you have observed how polyethylene, which has been on the street for a long time, becomes brittle and breaks. But high-quality material retains its strong performance for a long time. This is valuable if your installation work involves storing the exposed vapor barrier film on the ceiling for a long time without internal lining.

And in order to figure it out and clarify whether you have chosen the right vapor barrier for the ceiling according to the technical characteristics, carefully examine the pictograms shown on the packaging. And trust the brand that is known and trusted in the domestic market. Among such brands are Izospan, Izover, Technonikol, Delfa and others.

Vapor permeability as an argument for the design of a pie

All building materials have some degree of vapor permeability, which confirms their ability to pass vaporous water into and through themselves. If the roofing pie is constructed without taking this ability into account, in thermal insulation, i.e. In the main and thickest component of the roofing system, moisture will accumulate, which has a destructive effect on the elements of the building structure.

A properly selected vapor barrier must either prevent vapors from entering the roofing system at all, or sharply limit their penetration. Therefore, the vapor barrier film is selected so that its vapor transmission capacity is the smallest.

If a certain amount of moisture nevertheless passes through the vapor barrier, the thermal insulation layer, together with the waterproofing protection located above the insulation, must have a greater throughput. This pair of building materials should more actively remove water suspended in the air so that it does not stagnate in the thickness of the roofing pie.

Therefore, first on the side of the room, a vapor barrier is placed on the ceiling as a material with minimal throughput. Then, according to the rules for ensuring free diffusion, thermal insulation is installed, the vapor permeability of which should be higher than the same characteristic of the first layer. Before purchasing materials, you must definitely study their technical data in order to correctly select the components of the roofing cake.

Which vapor barrier is better for the ceiling of a wooden house

For wooden houses, as a rule, a vapor barrier membrane or polypropylene film is used. As for the first type, it is worth paying attention to the “smart membrane” - a modern material that can independently regulate the level of humidity in the room. But its cost is much higher than that of others, but maintaining the correct microclimate is ensured. Experts advise choosing the following types of vapor barrier materials when forming a ceiling in a wooden house:

- Penofol A is an easily installed vapor barrier due to the presence of a self-adhesive layer.

- Penofol B has a foil side for better heat retention in the room.

- Penofol S is a vapor barrier for the ceiling in a wooden house, similar to the first two groups with the presence of a self-adhesive layer.

- Izospan is a material with two layers and an improved system for evaporating moisture from the surface.

- Alucraft is a vapor barrier film with three layers, used in rooms with high humidity.

Why did they do without vapor barrier before?

This question can be found quite often and there are answers to it:

- First, let's compare how many sources of steam in residential premises there were before and how many there are now? Previously, toilets were on the street, washing and washing were done in the bathhouse, irons were without steam, there was no running water in the houses, food was cooked in a stove, the chimney of which served as an exhaust hood. Now all of the above is located in our home and is actively floating;

- Secondly, until the middle of the last century, heating in most houses was stove. What is a stove? This is not only a heating device, but also a very powerful hood. For combustion, air is constantly needed, which is taken from the living room. Along with the air, the steam contained in it is also removed into the chimney;

- Thirdly, again about wooden and plastic windows. The old wooden windows really provided a serious influx of fresh air from the street, making ventilation easier. And in the cold season, when the effect of steam on the elements of the house is most harmful, the air outside has very low humidity, that is, it contains almost no steam. Once entering the room, such air constantly displaces warmer and more humid air into the chimney or ventilation. Modern plastic windows have stopped this flow of dry air, and few people install fresh air ventilation systems;

- Fourthly, look at the design of the previous roofs. The currently fashionable mansard roofs were practically never seen in our country, so there was no problem with their vapor barrier as such;

- Fifthly, compare the old and modern design of floors in private houses. Previously, earth, clay and straw, or, at best, furnace slag or its mixture with earth were used as insulation. Insulation materials made from the listed materials do not collapse under the influence of moisture, and most importantly, they have a very low vapor resistance, due to which the steam that gets into them easily comes out. The disadvantage of such insulation is the huge weight and large heat loss.

If we compare multi-storey buildings built in the second half of the 20th century with modern ones, then in most cases they have reinforced concrete floors insulated with loose expanded clay or slag. Reinforced concrete does not allow steam to pass through, but even that part of the fumes that managed to pass through the joints and leaks of the slabs freely escapes through the layer of loose insulation.

If high humidity is detrimental to floor and roof structures, then for normal human life and health the humidity level should always be around 50%. How to ensure this value, read our article “How to use a humidifier: basics of operation”

As you can see, modern buildings are radically different from their predecessors, and therefore the question of the advisability of using a vapor barrier for the ceiling and roof in a wooden house cannot be questioned.

Polypropylene and polyethylene film

The cheapest option of all the above materials are thin polyethylene and polypropylene films. However, low cost does not mean poor quality and low efficiency; such materials provide controlled release of steam from the room.

Reinforced polyethylene film can be of two types: perforated and multilayer foil. Both options are used with great success to create a vapor barrier layer in houses with wooden ceilings. The foil material simultaneously performs a heat-reflecting function. As a result, heat remains in the room, which allows for some savings on heating costs.

Polypropylene film contains hygroscopic fibers, so it simultaneously allows steam to pass through and absorbs moisture. Thus, moisture penetrates the fibers and, gradually evaporating, comes out.

Films made of polyethylene and polypropylene are presented to the consumer in roll form, which determines the method of their installation. Solving the question of how to make a ceiling vapor barrier involves performing the following steps:

- The film is cut into pieces of a certain length.

- Lay the canvases on the ceiling, making an overlap of about 15 cm.

- The joints are hermetically sealed with wide self-adhesive tape.

- Fix the edges of the vapor barrier material using a metal profile or construction staples.

Izospan V has the best vapor barrier characteristics in this group of materials. However, despite the excellent vapor permeability, this isospan for the ceiling in a wooden house has a rather significant drawback - the lowest strength characteristics. This property greatly complicates installation work. When using Izospan B, you should be careful and careful.

The material “Izospan B” is a two-layer polypropylene non-woven fabric. Its top layer has a smooth surface, the bottom layer is fibrous and rough. It is the villi that prevent condensation from penetrating into the insulation and the ceiling. When choosing this material for arranging a vapor barrier layer, you should know one feature: its installation is carried out before the insulation. When vaporizing a ceiling in a wooden house, first of all, lay the Izospan B film, pointing its smooth side down.

The process looks like this:

- The roll is unpacked and the canvas is rolled out. Measure and cut pieces of a certain size.

- The strips are laid with an overlap of 15-20 cm in the horizontal and vertical directions.

- Elements for fixing the canvas are selected depending on the material from which the decorative ceiling will be made. For example, for a plasterboard ceiling, metal profiles are used, for a ceiling covered with clapboard, wooden slats are used.

- Regardless of the material used, it is recommended to purchase self-tapping screws with an anti-corrosion coating.

- The joints of the canvases are sealed with adhesive tape, and this must be done tightly enough.

- The insulation is attached to the ceiling using plastic disc dowels or galvanized self-tapping screws.

- Another layer of Izospan V vapor barrier is installed on top of the thermal insulation.

- Finally, the finishing material is installed. In this case, a free space of about 4 mm should be left between the vapor barrier material and the decorative structure.

Requirements for a moisture-proof layer

On interfloor and attic floors, insulation is used simultaneously as a soundproofing layer. Hydro- and vapor barrier are designed to protect all internal structures and the floor pie from moisture.

Basic requirements for a moisture-protective layer:

- waterproofing characteristics should not change over time, the protective layer should not react to temperature changes, heating or other external factors;

- the material should help preserve everything embedded inside the ceiling and maintain the wear resistance of the structure;

- environmental friendliness and safety, absence of toxins and fumes hazardous to humans or the environment;

- absence of flammable substances, fire resistance;

- there should be no obstacles to coating with finishing materials, plaster, etc.;

- easy application, good adhesion, quick drying of the layer.

For wood, special waterproofing materials are used that are suitable exclusively for wooden surfaces.

Types of waterproofing materials

To protect against moisture penetration into a wooden surface, several types of waterproofing are used. The choice depends on the conditions where the material is used:

Painting .

These include bitumen, polymer and other types of mastics, as well as emulsions and pastes. They are applied in several layers. They can be used at any indoor temperature. The advantages include a continuous layer after application, the absence of seams and joints.- Pasting .

These are rolled floorings and may have a film structure. They cover horizontal surfaces with overlap, so that there is no open space between the pieces of material. Pasting materials include: roofing felt, various membranes, isoplast, brizol, hydroisol and the like. They are mounted using mastic or special glue. Requires repairs periodically. - Cast materials . They cover the prepared surface covered with roll waterproofing. They are distinguished by their reliability, lack of seams and ease of application. Cast waterproofing is only possible on a reinforced surface. The use of a backing is mandatory.

- Impregnating materials . They are also called penetrating. The surface absorbs them, the molecules fill the loose structure of the wood and block the entry of moisture.

Types of vapor barrier materials

There are several options for steam protection, which differ in the structure of the material:

- Glassine . Thick cardboard impregnated with petroleum bitumen has been used for a long time and is productive. Suitable for baths.

- Polyethylene films . Used on floors that border between cold and warm rooms. This material is the most impenetrable; steam does not pass through it (the parameter is called the diffusion coefficient). There are also films with a foil layer; they are used in baths.

- Polypropylene films . Resistant to sunlight. It is recommended to use if construction is delayed and the floors are exposed to the open air for a long time.

- Membranes . This type of material can simultaneously be used as a hydro- and vapor barrier. They may have several layers, one of which will allow steam to pass through, but moisture will not seep through in the opposite direction. Correct installation is important here.

There are also breathable membranes. Their peculiarity is that steam can move from bottom to top and in the opposite direction. Thus, the insulation always remains dry and, with the same efficiency, the overlap pie will be thinner.

Nuances for attics

Under standard weather conditions in Russia, steam moves from the room into the atmosphere. With rare exceptions, in the summer, traffic may be reversed. Therefore, the vapor barrier in the attic is laid as the first layer, after which the heat and waterproofing layers are installed.

To maintain the optimal temperature in this part of the building, which according to the joint venture should be 5-7 degrees, several ventilation holes are created.

The floor pie in the attic looks like this:

- 1st layer – vapor barrier, choose the densest material, most often polyethylene film or membrane, lay it directly on the ceiling;

- 2nd layer – thermal insulation;

- Layer 3 – waterproofing, here a diffusion membrane or perforated polyethylene is used, followed by the floor covering.

If the attic is not planned to be used as a living space and no finishing will be done, the ceiling will not be waterproofed. In this case, protection from moisture is transferred to the roof, to the slopes and helps prevent water from getting from the roof into the room.

Features for interfloor

For the upper floor the floor will be the floor, and for the lower floor it will be the ceiling. Protection from moisture and steam is installed on both sides. If both rooms inside the spans are heated, additional thermal insulation is rarely used, but a layer of sound insulation is required so that every step from above is not heard below.

Therefore, the floor on the top floor will consist of:

- 1 layer – vapor barrier;

- 2nd layer – sound insulation;

- 3rd layer – waterproofing and finishing coating on top.

As for the ceiling of the lower span, it may require enhanced waterproofing if there is a bathroom, kitchen or sauna on the upper floor. Also, protection from moisture is necessary for the ceiling above the attic, and for rooms above which the roof is located immediately, without an attic. It is recommended to carry out waterproofing only in the warm season.

Installation of interfloor vapor barrier - in the video:

For the basement

Before installing waterproofing on the ceilings covering the subfloor or basement, it is necessary to create a barrier from moisture in the cellar or basement itself.

If you do not plan to store anything under the wooden floor, then the layer of earth is first leveled, then laid with a film, on top of which roofing material is laid (you can use old one from the roof or other places).

Next, the protective layer is covered with sand, making sure natural ventilation is created . After this, steam and waterproofing of the ceiling begins.

Initially, the floor above the basement is covered with a windproof layer with a vapor barrier side, which is located inside the room. This way, moisture from the insulation will not condense inside or penetrate from the outside of the ceiling.

The floor of the first floor suffers most from moisture. Its waterproofing needs to be given special attention, regardless of what is underneath, the subfloor or empty space.

What you need to know about steam and waterproofing basement floors:

- For implementation, it is recommended to use two-phase materials. These are membranes consisting of two or more layers that can serve as both hydro- and vapor barriers.

- To ensure reliable protection, a vapor barrier layer is installed both before and after the insulation. Only the finishing finish is installed on top of the vapor barrier.

During installation, workers may confuse the layers of material and lay it down incorrectly. An error leads to the opposite effect of vapor and waterproofing.

How to figure out which layer to put the two-phase material up if there are no instructions:

- The roll is rolled from the outside inward. Accordingly, the part that is located on the outside of the roll is placed on the insulation.

- Hydro- and vapor barrier looks like a double-sided material. One side is with a pile, the other is smooth. The one that is uneven is a barrier to moisture; it should be located on the outside, closer to the floor covering. The smooth side is closer to the insulation.

- If the color of the sides is different or there are inscriptions, the dark one is considered external. The light side of the material is placed against the insulation.

For the bath

Things to consider:

- The hydro- and vapor barrier of the bathhouse must be thought out; for this, the most reliable materials are used - pasted or cast.

- The hydrobarrier is installed not only on the floors, but also on all surfaces of the bathhouse. This is especially true for the roof; the quality of its protection from moisture directly affects the result of the waterproofing of the floors.

- The ceiling is covered with a vapor barrier made of film material with a high permeability coefficient. It is recommended to choose a reflective film, which additionally helps to retain heat inside the steam room. Next, the insulation is laid and a waterproofing layer is placed on top of it.

- For a water barrier, it is recommended to use polypropylene films with good permeability of 1200-3500 g/m2/day. The inscription on the film should look into the room, then the desired effect will be achieved.

It is strictly forbidden to use polyethylene film as waterproofing in a bathhouse. It creates a greenhouse effect, as a result the insulation gets wet and mold and rot occur.

For the floor in the bathhouse, you can use flooring made from adhesive waterproofing or cast materials. It is laid in the same order as for the ceilings of the cellar.

Stages and methods of installation of various materials

Before laying the vapor barrier material, it is necessary to prepare the base for its fastening. If roll vapor barrier is used, the surface is pre-puttyed. If a liquid paint vapor barrier is used on a concrete base, it is enough to smooth out the unevenness. Then the surface is primed, and after drying, a vapor barrier can be applied.

Preparing a concrete ceiling

The materials, which are panels, are attached to the base with a construction stapler. Particular attention should be paid to the corners. Insulation panels are attached along the perimeter of the ceiling with an overlap of 10-15 centimeters.

The film spreads with tension, without allowing sagging of more than 1.5 centimeters. To ensure reliable fastening, the panels are fixed with tape. For fastening between beams, nails with a special enlarged head are used. The pitch between nails is 30 centimeters. The joints are additionally taped with construction tape. If the vapor barrier is attached after the insulating material, slats are attached with screws on top of it.

Sealing ceiling vapor barrier joints

The sheet vapor barrier is laid on an aluminum profile frame, which can be purchased at retail outlets. The profile can be replaced with thin bars, but experts advise preferring a factory profile, which already has grooves for attaching vapor barriers. After installing the solid sheets, all joints are glued with PVC film.

Rolled materials are rolled out from the bottom up and secured with profiles or slats.

Foil materials are placed with foil inside the room. The purpose of this installation is to reduce heat loss due to the reflective effect.

Advice! When purchasing vapor barrier material, it is important to correctly calculate its quantity. It is definitely worth considering that the rolled material is laid overlapping and with allowances, so its size increases accordingly.

Tools for installing ceiling vapor barrier

Tools for creating ceiling vapor barriers

When starting work on installing a ceiling vapor barrier, you should prepare the necessary tools. To install roll-type materials, you will need carpentry tools: a hacksaw, hammer, scissors, knife, stapler. On a large site, it is useful to supplement this list with power tools: a hand-held circular saw, the design of which would allow for attachment to a workbench, a screwdriver, a pneumatic stapler. The latter will entail the need for a compressor.

Varnishes and mastics are applied to concrete surfaces using brushes and spatulas. Work must be carried out in strict accordance with the attached instructions. To wash the instrument, you will need appropriate containers in the form of cuvettes and glass or plastic jars. Plastic ones are preferable because they do not break and do not pose a risk of injury to workers. In addition to tools, performing work on the ceiling surface requires the presence of stepladders and scaffolding of appropriate height.

You can make scaffolding yourself from suitable boards. It is simpler and easier to use purchased prefabricated scaffolding made from square pipes. At an affordable price, they are very convenient to use. They are light in weight. Quickly assembled and disassembled. Allows you to vary the working height within a wide range. They have wheels for moving around the premises.

How to lay a vapor barrier on a ceiling

Vapor barrier materials are very diverse. To install them correctly for maximum efficiency, the following factors should be considered:

- side of laying the vapor barrier - for some materials this does not matter, but if, for example, a double-sided membrane is used, attention should be paid to this issue, such a film does not allow water to pass through only on one side;

- docking - the vapor barrier coating must be solid; for this, different techniques are used;

- ventilation gaps - vapor barriers cannot be laid close to the ceiling insulation.

The purpose of the room and the nature of the wooden ceiling are also important: it separates the heated rooms or living room and attic.

Which side to put the vapor barrier on the ceiling

Which side to lay the vapor barrier on the ceiling depends on the type of vapor barrier chosen. The exception is coated and painted material, since in this case the functionality is ensured by the vapor barrier composition.

For all other options, the following recommendations apply:

- with a double-sided film, one side is rough and the other is smooth; the material is laid with the rough side outward and the smooth side inward; the outer layer retains moisture but allows it to evaporate; the smooth layer is impenetrable to steam and does not allow moisture to pass into the insulation;

- one-sided polypropylene film with a laminated layer is mounted according to the same principle: the smooth side inward, towards the insulation, and the regular side outward;

- ordinary plastic film has both smooth sides, so how exactly it is laid does not matter;

- foil sheets are laid with a metal layer outward, this option is designed to retain heat in the room, and it is the foil layer that reflects thermal radiation back into the room.

Important! There are always exceptions. For example, Izospan film is laid contrary to generally accepted recommendations: with the rough side inward and the smooth side outward.

How to install a vapor barrier on the ceiling

The vapor barrier coating must be a solid structure. Even fastening with nails can disrupt its vapor barrier properties:

- if a coating vapor barrier is used, then make sure that there are no untreated areas left; it is necessary to also cover the upper section of the wall in order to isolate the joints between the ceiling and the walls;

- films and membranes are laid with an overlap of 8–15 cm and the joints are taped, the sheets are laid as closely as possible to each other, the seams are taped.

If a sheet vapor barrier is performed, then a special profile can be used. The latter can be done with your own hands.

Ventilation gap when installing ceiling vapor barrier

There should be a ventilation gap of 50 mm between the layer of insulation and the vapor barrier on the ceiling. If the height of the logs is greater than the thickness of the insulation, such a gap is formed automatically. If the values coincide, then a wooden sheathing 50 mm high is first attached to the logs, and then a vapor barrier is laid on top.

A ventilation gap should also be maintained between the vapor barrier coating and the finishing of the ceiling. They use the same technique for this: install a sheathing of thin slats.

Review of offers from vapor barrier manufacturers

Izospan

Trusted manufacturer

A domestic manufacturer offering a wide selection of hydro, wind and vapor barrier films. The vapor barrier segment is represented by the following materials: Izospan RS, Izospan FS, Izospan B, Izospan B fix. Izospan materials are of excellent quality.

Izospan B and Izospan B fix (with adhesive tapes) – a two-layer polypropylene sheet that is smooth on one side and rough on the other. During installation, the smooth side is located towards the insulation, the rough side - inside the room. Temperature range from – 60 to + 80 °C. The width of the rolls is 1.6 m. Price is 18 rubles/m2.

Izospan RS is made of polypropylene and additionally reinforced with reinforcing mesh. Application temperature from – 60 to + 80 °C. Can also be used as waterproofing. Width 1.6 m. Cost – 56 rubles/m2.

Izospan FS differs from Izospan B by having a metallized layer applied on one side, which reflects heat (infrared radiation) into the room. Suitable for use in ordinary rooms at temperatures from – 60 to + 80 °C. Cost 37 rub/m2.

Vapor barrier for wooden houses Tyvek (DuPont)

Premium segment

Tyvek AirGuard® SD5 is a two-layer polyolefin membrane with the highest price in the selection at RUB 113/m2. The material is intended for internal use at temperatures from – 40 to + 80 ° C. During installation, the material is placed with an inscription inside the room. Material width 1.5 m.

The manufacturer’s line also includes the AirGuard® Reflective product, which consists of four layers and has increased vapor resistance.

Isover

High quality material

Two-layer vapor barrier from a well-known manufacturer of insulating materials. Temperature range from – 60 to + 80 °C. Width 1.5 m. Cost 26 rubles/m2.

TechnoNIKOL vapor barrier film

Proven quality

Another well-known domestic manufacturer that produces high-quality roofing and facade materials. Its vapor protection is represented by three films.

TechnoNIKOL Alfabarrier 2.0 is a two-layer film for use in insulated pitched roofs, attics and walls. Limits steam from entering the insulation. Able to accumulate excess moisture and then remove it. Film width 1.5 m.

TechnoNIKOL Alfabarrier 3.0 is a three-layer translucent material reinforced with reinforcing mesh. Has increased vapor permeability. Material width 1.5 m.

TechnoNIKOL Alphabarrier 4.0 - consists of four layers, including a layer of foil to reflect IR radiation back into the room. Absolutely no steam leaks. Roll width 1.5 m.

Vapor barrier for roofing Yutafol

Vapor barrier films Yutafol N 110 Standard and Yutafol N 110 Special consist of three layers: external polyethylene, internal - polyethylene reinforcing mesh. In the production of Special film, a self-extinguishing reagent is used. The film is sold in rolls 1.5 m wide.

Yutafol Thermo reflective film is produced for baths and saunas.

Vapor barrier membrane Ondutis (Ondutis)

Professional polypropylene vapor barrier films for the protection of insulated walls, ceilings and roofs. The material is mounted with the smooth side to the insulation. The width of the rolls is 1.5 m.

Ondutis B passes less than 10 g of steam per m2 per day. Operates at temperatures from -40 to + 80 °C. Price 17 rub/m2.

Ondutis Smart B is distinguished by the presence of adhesive strips applied to it to seal the joints, which simplifies installation. Cost 19 rub/m2.

Polinet

Polinet Lux 2x50 is a three-layer reinforced transparent film made of high-pressure polyethylene. Application temperature from -40 to + 80 °C. The roll width is 2 m to speed up installation. Price 21 rub/m2.

Vapor barrier Izobond

The vapor barrier from this manufacturer is similar in markings and technical characteristics to Izospan. For ordinary rooms, you can use material with the index “B”.

For the bathhouse, Izobond FB 1x12 is offered - this is a vapor barrier based on kraft paper with aluminum foil. Temperature from -10 to + 140 °C. Cost 41 rub/m2.

Vapor barrier for bath Isobox (Isobox)

Isobox Thermo 70 is also more suitable for use in steam rooms, due to its high heat resistance from -40 to + 130 ° C. However, thanks to the standard roll width of 1.5 m, it can be conveniently used in any room. The material consists of three layers with a polypropylene base and reflective foil. Cost 26 rub/m2.

TDStels (TDStels)

Reinforced three-layer high-pressure polyethylene film 2 m wide with a temperature range of use -40 to + 80 °C. Cost 28 rub/m2.

Kolotek

Vapor barrier film at an extremely low price - only from 8 rubles/m2. Judging by the information on the packaging, the manufacturer’s films are similar in labeling and purpose to Izospan.

Unispun (Unispan)

For vapor barrier, the manufacturer offers polymer material Unispun B. The width of the rolls is 1.6 m. The cost starts from 10 rubles/m2.

Technohaut

The materials are mainly represented by three-layer reinforced vapor-waterproofing films: Technohaut B70, Technohaut C90, Technohaut D90, Technohaut H110. The price starts from 17 rubles/m2.

There is also a material with a reflective layer Technohaut FS150, which can also be used in a bathhouse.

At the end of the review, we note that when choosing vapor barrier films, it is better to give preference to trusted manufacturers, whose products have been used on the market for a long time and have proven themselves positively.

The use of films and membranes with a reflective metal layer will reduce heating costs, since such films will reflect part of the infrared radiation back into the room, reducing heat loss.

How to attach a vapor barrier to the ceiling

Ceiling installation includes 3 stages: waterproofing, insulation and vapor barrier. This is the last layer before finishing. Its installation is determined by the type of material used, as well as the design of the ceiling.

Fasteners for proper installation of vapor barrier on the ceiling

Construction staples are preferable for fastening the covering. They are much thinner, provide the same reliable fixation of the film, but do not violate the vapor barrier properties of the coating. Thick cardboard or other similar material should be placed under the staples.

It is allowed to use nails with wide heads. It is better to choose galvanized ones, as they are resistant to moisture and will last much longer.

Scotch tape also serves as a fastening element. It is used both for attaching film to joists and for vapor barrier of joints. In special cases, a profile is also used to connect sheets to each other.

How to install and secure different types of vapor barrier on the ceiling

In order for the vapor barrier to effectively perform its functions, it is necessary to follow all the rules for waterproofing during installation:

- during installation, it is allowed to use vapor barrier materials that are less resistant to water than waterproofing materials;

- it is very important to achieve a solid surface; for this, the film is laid overlapping, the sheets are glued with tape, and so on;

- it is necessary to exclude moisture in the vapor barrier coating; work cannot be carried out during snowfall, rain, or fog;

- when laying rolled vapor barrier, the material must first be kept in a warm room for at least 20 hours;

- The film should not be stretched too much, it should sag slightly;

- When vapor barrier corners, be sure to use solid material.

Important! When choosing different types of coatings, the list of rules is supplemented with recommendations from the manufacturer.

What tools and fasteners will be required?

For successful work and compliance with the sequence of steps, it is recommended to prepare the entire tool in advance. When working with vapor barrier, the following materials are used:

- Roulette.

- Hacksaw.

- Construction glasses.

- Knife with replaceable blades.

- Stationery knife.

- Hammer.

- Side cutters.

- Scissors.

- Pliers.

- Level.

- Construction stapler.

- Construction wide tape (tape).

To fasten materials, thin and always reliable staples are used. Experts with many years of experience claim that this is an ideal film fixer, and moreover, it does not interfere with the vapor barrier functions of the coating.

It is recommended to place any thin sealant such as cardboard under the staples. For proper installation, the materials of the ceiling covering, the side of installation, joints and ventilation gaps play an important role.

How to properly install a vapor barrier on the ceiling: step-by-step instructions

The finished vapor barrier in appearance resembles a pallet with sides. The coating should cover not only the insulation on the ceiling, but also the gap between the heat insulation and the walls. In addition, the film must cover each beam.

The first stages of finishing the ceiling are carried out as usual. The wooden surface is cleaned, treated with antiseptics and fire retardants, and communications are installed. Then the ceiling is waterproofed and insulation is laid on it.

- Laying begins from any wall. The roll or sheets are cut to size and secured to wooden beams with staples. In this case, a gap must be maintained between the heat insulator and the vapor barrier. If necessary, pre-attach the sheathing.

- The film or membrane must cover each beam. There are two ways to do this. A simpler option involves fastening the material around the beams. In this case, the canvases are laid perpendicular to the beams, taking into account some recess into the interblock space. If the length of the film is not enough, gluing the vapor barrier is allowed.

- Another option: cut the film into fragments of the appropriate size; you need to wrap each compartment separately. All seams and joints are additionally taped with tape. As a rule, this method is used for vapor barrier of panel-box ceilings. Laying is done with an overlap. The tolerance on walls is 10–15 cm.

- The joints are sealed with tape according to the following scheme. First, glue the seams between the canvases. To do this, bend the overlap, secure the edge of the vapor barrier with tape, then remove the protective strip from the adhesive tape and attach the overlap on top. The joints with the wall are sealed in the same way. In this case, you cannot stretch the film; it should sag by about 2 cm.

- Then the second and third layers of vapor barrier are laid, following the same rules. Make sure that the joint of the next layer does not coincide with the seam on the first layer. The displacement should be at least 30–40 cm.

Foil material, especially sheet material, is mounted according to a different scheme.

Possible difficulties and errors in the process

The biggest difficulty when creating multi-layer interfloor slabs of a residential building is to correctly calculate the number of layers and choose an effective vapor and waterproofing material. Since such a calculation must cover many parameters, ranging from the climatic characteristics of the area, wall and roofing materials and the number of storeys of the house, it is better to order it from a specialist designer.

Modern design firms use complex software systems for such calculations, but the results are very accurate.

Technologically, the process of installing a “multilayer cake” is not complicated; it is important to follow the design technology and recommendations of the manufacturer of the protective membranes. However, developers often make the following mistakes when installing film insulation :

- The steam and waterproof film was laid on the wrong side.

- Poor quality membranes were selected.

- The vapor barrier membrane was confused with the waterproof membrane.

- The film is not tightly connected, there is no overlap of 10 cm, which is not sealed with construction tape.

- The thin heat-protective layer was incorrectly selected, the “dew point” was located in the insulation with the formation of condensation.

- There is no ventilation gap.

- The membrane was stretched very tightly, and during operation it burst due to overload.