Thermal insulation materials from URSA have become very popular recently. They are used for traditional insulation of walls and roofs, and are also used as insulation for ventilation pipes and other communications. Using such materials you can significantly reduce the noise level in the room.

URSA is an insulation material whose technical characteristics are always at the highest level. The service life of the heat-insulating substance is very long. Due to its ability to retain heat efficiently and perfectly absorb noise, URSA insulation is used in absolutely any modern building structure.

Features of Ursa material

Ursa insulation based on fiberglass

Universal Ursa insulation effectively reduces heat loss and creates a comfortable microclimate in the room. Low specific gravity helps reduce the volume of building materials and energy consumption.

The URSA brand produces 2 types of products:

- thermal insulation based on Ursa expanded polystyrene (EPS);

- based on fiberglass.

The first category includes material made using extrusion technology. The foam particles combine with the foam under pressure and heat. The hot mass passes through the extrusion head of the unit and Ursa extruded polystyrene foam is obtained.

Insulation of the second category is produced by combining dolomites, quartz sand and soda. The substances are melted, and additives are added to the mass to glue the components together. The hot composition is forced through the nozzles of the extrusion unit.

Excursion into history

Content

Firstly, Ursa is the name of a company and group of thermal insulation materials. In 2002, it began its journey as a division of the Spanish concern URALITA GROUP, an eminent European leader among suppliers of building materials. Over time, the company's name extended to its products and became the URSA® brand.

Today, 36 manufacturing enterprises operate under the company’s flag, and their products are actively sold in 77 countries around the world. Insulating materials under the URSA® brand are used for roofing and walls; they insulate water pipes, ventilation systems and thermal communications. The structure is effective not only in solving problems of heat conservation, but also in improving sound insulation, which gives materials with Spanish roots the status of universal, and this has always been valued and allowed us to go one step ahead of competitors.

Technical characteristics of mineral insulation

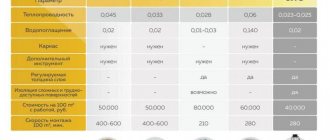

Indicators of the density and size of roll insulation and Ursa boards

The category of mineral insulation includes materials made from natural components, for example, fiberglass. Products are sold in slabs or rolls. The structure does not include phenolic substances to bind the ingredients, so Ursa mineral wool is an environmentally friendly product.

The composition contains sand, soda, and other non-combustible materials, so the insulation is characterized by increased fire safety indicators. The manufacturer indicates a period of 40-50 years of operation without destruction or loss of quality.

Insulation density

The density of a material is determined by the ratio of weight to volume. For glass wool, the indicator is determined on a scale of 15-85 kg/m3, depending on this the area of use is selected. In private houses, material with an index of up to 30 kg/m3 is used, and industrial insulation requires penoplex of higher density.

Thermal conductivity

The characteristic shows the ability of rolled and slab materials to conduct heat from heated to cold layers. Energy transfer occurs due to the movement of elementary particles in the insulation composition. Ursa mineral wool has a low ability to transfer heat, so it provides good insulation of structures and pipelines.

The lower the thermal conductivity coefficient, the better the protection from cold. For mineral wool, the indicator is within the range of 0.031-0.045 W/mK. This amount of energy passes through the thickness, which indicates the high thermal insulation qualities of the layer.

Application temperature

Technical characteristics of flammability and thermal conductivity

The characteristic determines the temperature range at which the insulation retains its specified properties. The manufacturer guarantees that Ursa polystyrene does not change its declared qualities at ambient temperatures down to -60˚C. The upper value is +310˚С.

These indicators relate only to the atmosphere, since the insulation surface can withstand other temperature loads, the limit of which is +100˚С, and some categories retain properties at +180˚С. The insulation belongs to the universal class and is suitable for protecting various structural elements from cold in any climate conditions.

The material is sold in the form of rolls or in the form of slabs. Rolled products are produced in thicknesses of 5-20 cm, width varies in the range of 60-120 cm. The length of mats is 3-18 m, and sheets are produced in sizes of 1.25 m.

URSA insulation: characteristics

All the most common products of the URSA company have their own set of individual and unique characteristics that differ from the rest. To choose for yourself exactly the material that is needed for a specific type of repair, you need to study all the characteristics provided.

GEO fiberglass insulation

Main characteristics of GEO insulation:

- It has a high heat conservation capacity because the fibers are long and elastic. Therefore, a large number of air layers will form between them. When insulating a house with this material, you can expect that the walls will not freeze in winter.

- The thermal conductivity coefficient determines how well this insulation copes with the assigned tasks. The higher the parameter value, the better the material will retain heat. GEO has a coefficient of 0.035 to 0.044 watts per meter per Kelvin. This indicator depends on the type of insulation.

- The insulation also has a high level of noise reduction. Its sound absorption class is “A” or “B”. These indicators have been proven through laboratory studies. By and large, all fiberglass materials can block sound waves. That is why, if you want to create good sound suppression in an apartment or private house, then you can safely choose any URSA heat insulator.

- Environmental friendliness. All components undergo strict testing in laboratory conditions for environmental friendliness. The finished insulation is always checked for safety for nature, as well as for humans. The emission of volatile compounds in this material is 10 or 15 times less than Russian and European requirements. The company guarantees that if insulation is installed, the house will always have a favorable microclimate and the cleanest air. But it is necessary to remember that all fiberglass products will generate a little dust during installation, and therefore it is best to cover the interior parts of the premises with waterproofing material.

- GEO thermal insulator is fire resistant because it is made from quartz sand. Quartz is a natural material that is completely resistant to combustion. If he encounters an open fire, he will not let it into the room. And also the material is completely unaffected by old age. Even after a long period of use, it will not lose its appearance or properties. The manufacturer guarantees a service life of over 50 years.

- Biological resistance. The substance is inorganic, and therefore mice, rats and insects will not try to eat it. Microorganisms such as fungus will not be able to grow in it. There is simply nothing for living creatures to eat there.

PureOne insulation

In production, completely new technologies are used, which were first used in Europe and Russia. Now this development is spreading all over the world. It is used to produce high-quality PureOne material. The essence of the technology lies in the quality of one of the components. We are talking about acrylic - a chemically neutral and safe polymer for humans. It is because of this component that fiberglass will not be as prickly as it is obtained with the standard manufacturing option.

It is also worth noting that less dust will be generated during installation. Acrylic is an inert material, and therefore cannot be dissolved by water or oxidized by air. URSA insulation materials are often used in hospitals and kindergartens .

Noise-absorbing characteristics. All noise absorption tests are carried out by scientists from the Building Physics of the Russian Academy of Sciences. They conducted research and claim that the PureOne tile material has a sound absorption class of “A”, and the insulation in the form of mats has a class “B”.

Acrylic dampens sound waves to a significant extent. Therefore, partitions made of such material will protect against noise effects much better than those made of stone wool or glass fibers. As a result, the difference can be more than 2 decibels.

Elasticity. URSA insulation is more elastic than simple fiberglass. There is a certain springy effect that occurs inside. This allows the material to fit tightly into wall cavities. A particular advantage is that the PureOne form will not lose its original appearance over time.

A line of materials based on mineral components

Mineral wool differs in fiber depending on the initial component underlying it. The structure can be spatial, corrugated, the layers are divided horizontally or vertically.

The manufacturer designates products depending on the raw material composition:

- Fiberglass products are marked with the Geo prefix. The products fall into the category of materials that are safe for humans and environmentally friendly.

- A product with the PureOne index is created on the basis of glass threads. The composition contains acrylic components. This type of insulation is installed to protect against cold in children's institutions and hospitals.

- The non-flammable Terra material is ideal for insulating wooden buildings. The composition includes natural components, the insulation does not harm the environment and humans.

- Thermal insulation based on extruded polystyrene foam is marked with the prefix XPS and is a durable and reliable insulating option for insulation.

Ursa thermal insulation is manufactured in accordance with technological standards that regulate the content of the binder.

Ursa GEO

Material marked Geo is environmentally friendly and does not emit harmful combustion products.

The heat insulator is allowed for use in rooms with a high risk of fire, since the material does not emit harmful components when heated.

Ursa Geo products are available in the following range:

- Light;

- Pitched roof;

- Frame P;

- Mini;

- Facade;

- Noise protection%

- Universal plates.

Mats with one foil side are designated M-11F and M-11, double-sided - M-25F, M-25, M-15. The slabs are marked P-60, P-15, P-45, P-20, P-30.

With a low specific gravity, Geo brand products provide high-quality protection from cold and noise, thanks to the original fibrous structure. The material does not decompose, does not burn, and rodents and insects do not settle in the thickness.

Ursa PureOne

The Pure One material does not emit dust during installation.

The characteristics of Ursa insulation show that the material consists of 95% natural substances, which underwent quality control during the production process. The material is produced in accordance with sanitary international standards and is included in the class of environmentally friendly insulators.

Line names:

- 35QN rolls measuring 1200 mm x 3900 mm;

- slabs 34PN with dimensions 1250 mm x 600 mm);

- rolls 37RN size 1200 mm x 100 mm).

The products are flexible when installed in curved structures due to the thinned fibrous elements in the structure. The material does not emit dust or odor during installation. The white color is obtained through the use of quartz sand.

Ursa TERRA

Terra material is available in the form of slabs.

The products were developed for private buildings, but also meet the requirements of professional construction. Plates of this type are distinguished by their small size and rigidity with sufficient elasticity and flexibility.

The following range of Terra brand insulation is produced:

- slabs 34 PN;

- mats for insulation of highways and ventilation ducts 34 RN.

The sheets are characterized by a good index of thermal and sound conductivity and show moisture-resistant qualities. The production technology involves the use of water-repellent additives.

Popular about the composition

Like all ingenious insulating materials, they arose from something simple. It is based on a structure close to classic glass wool. The difference is technology. Without complicating the story in scientific terms, we will describe the structure of a universal noise- and heat-insulating material.

In proportions, which is a company secret, quartz sand, dolomite mineral and a lot of auxiliary additives are combined in one composition. The mixture is heated to the melting point of the main substances and placed in an extruder, which produces the finest filaments. They are the semi-finished product for the future material. The final product has various forms - carpet, mat, slab, etc., which make it possible to effectively and efficiently carry out certain insulation measures.

Line of materials based on XPS

The materials have a low thermal conductivity (0.028-0.035 W/mK), have increased strength and low specific weight (45 kg/m³), which reduces the weight of the structure. Extruded polystyrene foam is characterized by closed cells in the structure, the diameter of which does not exceed 0.2 mm. This structure ensures moisture resistance in damp conditions.

URSA XPS

The insulation is resistant to loads and chemicals.

Only one type of product is produced in the EPS product category. The material has universal application, but is more often used for insulation work during the construction of railway embankments, runways, lower and underground floors of buildings.

Assortment of the URSA XPS line:

- high strength material NV, sold in slabs 60 x 125 cm;

- N-III sheets are available with straight and stepped side edges;

- N-III-G4 slabs are produced in thicknesses of 3-10 cm, size 60 x 125 cm.

The products do not react to the action of acids, fats, alkalis, lime, bitumen and other caustic substances, but decompose upon contact with tar, hydrocarbons, gasoline and formic acid.

What to choose from

Today, the line of main types of products under the URSA brand consists of:

- GEO insulation;

- Insulation ICS PI ES;

- Thermal insulator Purelan;

- Thermal insulator SEKO;

- Terra insulation (new).

They all have one thing in common - they contain only natural materials, which guarantees environmental and biological purity in the most pedantic understanding of this expression. To confirm these words, we present official data on such an indicator as the emission (volatility) of elements of the main substance. So, the samples of the Spanish manufacturer demonstrated 10-15 times advantages over the far from worse samples of insulation materials produced in the post-Soviet space.

Main advantages

The service life without loss of properties is comparable to the operating time of the structures; the insulator ages simultaneously with them and does not require replacement. The high tensile strength of extruded polystyrene foam is its positive quality, which is why the material performs protective functions and works as additional structural elements that can withstand some loads.

When cutting, fiberglass crumbles, so you need to work with gloves and a mask

Advantages of Ursa materials:

- environmental cleanliness;

- increased noise protection qualities;

- long service life;

- resistance to temperature changes;

- wide range of applications;

- elasticity and resilience;

- fire resistance;

- ease;

- vapor permeability and biostability;

- not subject to decomposition and rotting.

There are some negative points when using it. For example, mineral wool decomposes upon direct contact with alkalis, and small fibers fall out of glass wool during the cutting process.

Areas of application

Ursa slab insulation can be used as a substrate for asphalt.

Ursa universal thermal insulation is used in any construction process. Universal characteristics allow the protection to be used for complex curved surfaces.

Areas of use:

- pitched and flat roofs;

- foundations in damp places;

- walls outside, inside and as an intermediate layer;

- partitions;

- heating lines;

- highways and railway elevations;

- airfield strips;

- extensions, balconies;

- saunas and baths.

Reliable thermal insulation is set to a minimum thickness, which is comparable to thicker layers of other materials. Internal insulation made from Ursa material does not reduce the horizontal and height dimensions of the room.

Installation of Ursa thermal insulation

Installation of roof insulation in wooden logs

Mineral wool is attached to the walls and pressed with 50x50 cm bars so that there is an air space between it and the finishing layer. Wooden elements are mounted at a distance of the width of the roll so that they hold the edges of the canvas. Expanded polystyrene boards are glued to the surface of walls or floors using cement-adhesive solutions or polyurethane composition. Before gluing, walls, ceilings or floors are treated with primer for better adhesion. A screed or starting putty is applied over them using a plaster mesh.

For reliable fastening to vertical surfaces, use special dowels with a large head (up to 10 cm). The ventilation gap between the insulation and the wall of the house ends at the bottom and top with vents - installation holes for normal air flow. Rolls and slabs are stacked tightly next to each other. If the material is placed in 2 layers, the next layer overlaps the joints of the previous one for maximum efficiency.

If a frame is used, a finishing finish is attached to it in the form of sheets of chipboard, fiberboard, OSB, plastic panels or MDF. Ursa insulator works well with all types of building finishes.