The technology of insulating the floor on a balcony is a process in the implementation of which it is important not to make mistakes. At the stage of repairing a balcony room, it is imperative to correctly resolve the issue of thermal insulation. This determines whether mold will appear and whether condensation will accumulate on surfaces during the cold season. In today’s article we will consider every aspect of organizing insulation, and will also tell you which materials to choose for this purpose and, accordingly, how to work with them.

Insulation of the floor on the balcony between the boards Source build-experts.ru

Foamed polyethylene

This is one of the most affordable and easy-to-use materials. Its distinctive feature is its small thickness; therefore, it is not recommended to use it for insulation without an additional insulator. This is due to the fact that the coating will not perform its function properly.

Thermal insulation layer with polyethylene foam on the balcony Source samsebemaster.net

An alternative to simple foam insulation is foil foam. Such sheets cope quite well with thermal insulation properties. Even despite the presence of a reflective layer, this insulation is well ventilated, so the accumulation of condensation in it is minimized. Foil polyethylene can have a mirror coating on one or both sides. The latter will be more effective and more expensive.

It is important to install such material correctly, since the insulation must be overlapped or end-to-end. Foamed polyethylene is laid with the reflective surface facing up.

Foamed foil polyethylene is placed both on the floor and on the walls Source oknosnz.ru

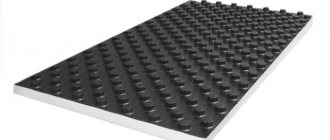

Expanded polystyrene

Expanded polystyrene or polystyrene foam for insulating the floor on the balcony is available in the form of slabs of different thicknesses. They are convenient to lay on a concrete base. As for the important properties, the material is poorly thermally conductive, has low weight, and as a result, can be installed without much effort. The foam is also moisture resistant. It should also be noted that it is vapor tight.

One of the disadvantages of this is its fragility, so work on laying it on the floor must be carried out carefully.

Expanded polystyrene sheets for insulating the concrete base on the balcony Source russian.alibaba.com

No. 2. Mineral wool

Mineral wool is a whole class of materials, the production of which is carried out from mineral raw materials by heating it until it melts, drawing it into separate threads and forming fibers. If blast furnace waste was used as a raw material, then the result is slag wool , if the basis was glass waste or silicon-containing rocks, then glass wool . Often, mineral wool is understood as stone wool , which is produced from basalt rocks. It has the best performance properties, and that is what we will talk about.

Stone wool is produced in slabs and rolls, but can also be in granular form and directed with a special installation onto the insulated surface to fill all the cracks. Whatever the form of mineral wool, its main advantages are:

- good thermal insulation properties. The thermal conductivity coefficient is approximately on the same level as polystyrene foam, so the material will provide excellent protection and will not release valuable heat;

- ability to pass air - the microclimate of the balcony will be in perfect order;

- non-flammability;

- noise insulation properties;

- resistance to mechanical damage;

- rock wool is not touched by rodents;

- durability;

- affordable price.

The combination of all these advantages explains the wide distribution of the material. It is worth noting that glass wool and slag wool will be cheaper, but they are more fragile, and all work will need to be carried out in protective equipment.

Preparing for floor insulation

Having decided on the type of alternative insulation, you can begin its installation, but first we recommend that you carefully study this section dedicated to preparatory work. It will consist of several step-by-step actions:

- A general assessment of the condition of the floor is carried out; if there are visible defects on the surface, they are removed by concreting; large potholes are eliminated using rubble and concrete screed.

- If there are old tiles on the floor, it is not necessary to remove them, unless the factor that the height of the floor will rise by several centimeters plays a role.

- Fill small cracks. It is a mistake to believe that nothing will happen to them under a layer of insulation. Such defects will begin to quickly deteriorate, and moisture will certainly settle in them. If a crack appears on the old tile masonry, then it is dismantled, and then a smooth concrete screed is poured into the old place.

- After removing all defects, clean the surface from dust and then prime it. Then the areas that were defective are treated with a sealant.

- The next stage is waterproofing. After laying the rolled sheet or tile, check each joint for gaps. Only then is a thermal insulation layer applied.

Preparing the floor on the balcony for thermal insulation Source obustroeno.club

How to cover a wooden frame with insulation

The floor on the frame can be made of any durable, moisture- and frost-resistant material. These can be OSB boards, planed boards 2.5-4 cm thick, plywood 5-8 mm thick, parquet boards of suitable size.

The wood is pre-treated with any antiseptic solution.

A floor made of boards can be left as is if you are confident in its moisture resistance and the quality of wood processing. If the frame is covered with OSB or plywood, any floor covering must be laid on the floor. You can lay laminate, linoleum, parquet, carpet. This will make your stay on the balcony more comfortable, and the space of this room cozy. Senezh, decorating impregnations for wood, and fire-bioprotective compounds are used as an antiseptic.

YOU MAY ALSO BE INTERESTED

Methods for laying insulation on the floor

To lay the insulation layer on a small balcony floor, two methods can be used. About them below:

- on wooden racks (logs). The construction of such a structure is necessary to pre-level the coating before further laying. The logs are raised to a height equal to the thickness of the insulation layer. The structure can be supported on metal corners or special brackets;

- insulation of the floor using the heating function. Its role will be played by a heating cable or infrared film. It can also be a water structure, which is connected to stationary heating.

Knocking off beacons for installing logs on the balcony under insulation Source transkribator.guru

Below in this section we will talk about methods for arranging each of these two options.

Materials and tools

Before starting work, you need to buy basic and auxiliary materials and prepare a set of tools. Materials you will need:

- insulation (its quantity is equal to the insulated area);

- Chipboard, plywood or OSB (chipboard is better, since it only exhibits linear expansion during fluctuations in humidity and temperature);

- waterproofing material (the specific choice of waterproofing agents will be discussed in a separate work);

- vapor barrier film (needed when using soft insulation);

- primer;

- wooden beam (specific dimensions depend on the thickness of the insulation);

- metal U-shaped supports for attaching timber or studs;

- polyurethane foam;

- self-tapping dowels for fixing supports to the base of the balcony;

- electrical tape (painting tape) for gluing insulation joints;

- wood screws for connecting the timber to the supports.

Attention: the tiles are laid on a screed, which requires completely different materials and tools, which you can read about in the material “Technology of wet floor screed with expanded clay.”

The tools you need to have on hand are:

- electric drill or powerful screwdriver;

- hammer drill (needed only for leveling the base of the balcony and removing the plaster layer from the bottom of the walls to the thickness of the thermal insulation);

- jigsaw or wood saw;

- construction knife with replaceable blade;

- roulette;

- construction pencil.

Video description

Do-it-yourself insulation of the floor on the loggia.

How to make thermal insulation on joists

Thermal insulation on joists requires not only the insulation material itself, but also wooden beams and a metal profile. The entire insulation process in this way is carried out according to the following algorithm:

- Cleaning the base and making it functional (filling holes and leveling the concrete screed.

- Marking the surface for the racks. Marks are placed every 50 cm, at these points the longitudinal joists will be attached.

- Installation of racks for each jumper. To do this, a mark is made every five centimeters, starting from the wall.

- Finding the zero line on the wall. Here they use a laser or a water level. This parallel is used to level the height of each joist.

- They install racks or brackets that are securely fastened to the concrete base, put the logs in place, and correct them.

- Insulation is laid between the installed beams, rolls or slabs are cut so that a small margin remains. This is necessary for compaction, which will help hide all voids in the structure.

- A diffuse membrane is laid on top, which will provide vapor and waterproofing, then sheets of plywood are laid and secured to the joists.

- At the end, they make sure that there is a correct slope (or lack thereof), and then they make the finishing touch - laying the floor covering.

When laying the thermal insulation layer, you need to ensure that there are no gaps or holes. Otherwise, the insulator will not fulfill its direct tasks.

The principle of thermal insulation under logs Source eco-kotly.ru

How to install insulation in combination with underfloor heating

It is often practiced to combine insulation with electric or other type of heating. The effect of this is much higher, but it is also more difficult to install in this way. The whole process is based on the following steps:

- First of all, the floor on the balcony is insulated according to the scheme described in the previous paragraph.

- Next, lay the foil backing so that the reflective layer is on top. If the fragments are not solid, then they are laid strictly at the joint and secured with adhesive tape with a reflector.

- The film heater or underfloor heating pipes are laid out along the length of the floor. Each element is monitored so that there are no kinks and the heater sheets do not overlap each other.

- If the heaters are electric, then they are covered with thick plastic film so that they do not come into contact with moisture.

- The final step is to apply the finishing trim.

Installation of the insulating coating can be done by hand. The main thing is to follow the steps so as not to miss laying this or that material.

Installation of thermal insulation and heated floors on the balcony Source drive2.ru

Insulating the balcony floor from the outside

Since the structure of the balcony slab is porous, it tends to accumulate flags and, accordingly, will penetrate the internal thermal insulation and disrupt its properties. Therefore, it is necessary to install external insulation. Only for this you need to purchase a special adhesive base.

A destroyed balcony slab in need of repair and thermal insulation from the outside Source remontnik.ru

How to insulate a balcony floor from the street

Insulation of a balcony slab is carried out according to the following instructions:

- Initially, inspection work is carried out on the outer part of the balcony slab, eliminating defects, chips, and cracks. There are many of these if the screed is old. Be sure to strengthen the edges of the structure with cement mortar. It is unacceptable for the reinforcement to be visible and for the concrete to crumble in these places.

- Afterwards, cobwebs, dust and debris are removed from the outer surface. For this purpose it is better to use a special soft brush.

- Then the structure is measured and determined with a sufficient amount of external insulation. It is cut in accordance with the specified dimensions and shapes of the concrete slab. Be sure to make fragments 10-20 cm wide. They will be necessary to reach the lower part of the walls.

- Then the concrete base is primed, then glue is applied to the heat-insulating layer and attached to the balcony base. An assistant will be required for this manipulation, since it is necessary to hold each edge of the insulation pressed against the concrete screed for several minutes. Gluing the insulation begins from the wall of the house. Finally, the parapet is edged using pre-cut fragments of thermal insulation and placed on the same glue.

- The entire surface is sealed in the same way, and after complete drying, the seams are coated with Tilit or special mounting tape that is suitable for the selected thermal insulation material.

- Upon completion of the insulation work, the heat insulator is hidden under the finishing coating. This can be a special plaster with waterproofing.

On a note! It is better to entrust the work of gluing the balcony base from the outside to specialists, especially if it is at a sufficient height. Also, in case of high climate humidity, before attaching the insulation, it is recommended to cover the concrete slab with a liquid waterproofing agent.

Balcony slab that needs external repairs and thermal insulation Source troitsk.okna-servise.com

What needs to be done before work begins?

It is no secret that the balcony slab is subject to atmospheric influences and has regular “contact” with precipitation. In an “elderly” house, it can become completely unusable - then it will not be a question of insulation at all, but rather a major overhaul or even demolition of the structure. Although, it is worth noting that particularly advanced cases are immediately visible. It is best to dispel all doubts about the strength and reliability of the slab in dialogue with the management company. Information about the maximum permissible load will also be useful.

If the balcony is not in danger of being demolished and its condition is more than satisfactory, then you can, armed with a level and a ruler, go to find out the curvature of the slab and the desired level of floor elevation. All desired values should be correlated with real possibilities.

It is unreasonable to make the floor level of a balcony or loggia higher than in the room - and this is obvious. It should either be level with him or slightly lower.

Important! It is dangerous to pour a “ton” of screed on the balcony to raise the level.

The next important step should be general insulation of the balcony. After all, the cold comes not only from the floor - bare walls and roof also do their job. If you do not insulate them, then “exercises” with the floor will be of little use.

Types of adhesive for attaching thermal insulation

To lay external thermal insulation material, especially on a horizontal surface, it is necessary to use reliable compounds. These include:

- MV-40 or T-Avangard-K. These products are moisture-resistant, so they reliably glue any heat insulator, and over time it will not come off even when used in outdoor conditions;

- assembly glue or liquid nails. These adhesive base options are ideal for insulating a concrete floor on a balcony outside. They are distinguished by reliable fixation and are moisture resistant. They perform well when installing complex structures. One of the best branded options is “Moment Montage”;

- glue titanium. It is considered an excellent product for concrete bases. It thickens quickly after application and adheres to the surface. Requires preliminary priming of the coating;

- Neoprene-2136. A convenient product sold in spray form. It is easily applied to the coating and creates reliable adhesion of the insulation to the concrete base. It is considered a convenient composition for attaching penoplex.

Ideally, the adhesive composition is chosen together with the purchase of insulation. Usually, construction stores recommend a special adhesive that is compatible with the thermal insulation material.

Mixing glue for attaching thermal insulation of a balcony from the outside Source materik-m.ru

What if the balcony floor faces the neighbors?

It also happens that even with proper insulation of the floor on the balcony, mold spots appear, fungus develops and dampness in the corners. In this situation, the problem must be sought from the neighbors. Often such consequences arise due to the fact that their ceilings and walls are not insulated.

You may even need to insulate not only your floor on the balcony, but their ceiling at your own expense, if they refuse to resolve this issue on their own. Such a problem is always easily solved through a special housing commission. For this you need to provide all the evidence.

Thermal insulation of the ceiling surface on the balcony from neighbors Source m.nn.ru

“Good old” polystyrene foam

Polystyrene foam is produced on the basis of the same polystyrene as materials such as penoplex. However, foam plastics are inferior to extruded boards in terms of strength and hygroscopicity. The relatively low price is the only reason why foam plastics have not yet been displaced from the construction market by more modern insulation materials.

Balcony floor insulated with foam plastic

Due to low strength, floor insulation with foam plastic is done using wooden logs, as is the case with mineral wool. There are 2 differences in installing foam plastic on the floor instead of cotton wool:

- The wooden beam must be higher than the layer of material being laid.

- The joints between polystyrene foam and wood must be foamed.

Why is thermal insulation needed?

The thermal insulation function is very important on balconies and loggias. It helps get rid of dampness and constant formation of condensation, especially when there are temperature changes outside. Insulate the room; it can be used for personal purposes: organize a leisure area, make it a storage room or an additional mini-room.

Insulating the floor will allow building materials to retain their attractive appearance longer, so the regularity of repair work is eliminated.

No. 5. Foam glass

For loggias and balconies, the number of possible insulation materials is greatly reduced due to specific conditions. We have to refuse, for example, ecowool, but foam glass can be used. In terms of its composition, the material is ordinary silicate glass, but the production method allows it to add unique properties. Glass waste is crushed into powder, melted, and due to the action of a gas-forming agent in the form of coke or coal, the mass increases tens of times and acquires a porous structure. Not only is this material much lighter than glass, but it also has many other advantages :

- good heat and sound insulation properties. A 10 cm thick slab reduces noise levels by 56 dB;

- durability. The material can retain all its basic properties for 100 years;

- tolerates cold and heat, temperature changes well, does not change geometric dimensions;

- does not burn, because it is based on glass, which melts at a temperature of 10000C and does not ignite;

- strength;

- the material is not afraid of water, but allows air to pass through.

Due to its high cost, foam glass is not so often used for insulating residential buildings and, especially, loggias and balconies. In terms of its overall performance qualities, it is an ideal insulation material.