Today, underfloor heating has become a very popular way to heat interior space. Before installing a heated floor under a parquet board, it is necessary to take into account some nuances, especially when wood materials are used as flooring. To make it pleasant to stay in a house or apartment, and for the cladding to last a long time, it is important to choose and install the heated floor structure correctly.

Warm floor under parquet boards: features of the device

The feasibility of choosing a heated floor

The parquet looks very aesthetically pleasing. It is pleasant to the touch. But for many, the natural warmth of wood is not enough and they want to install additional heating. I would like to dwell on this point in more detail. There are plenty of opponents to installing heated floors under parquet. Several arguments are given in support of this position:

- Wooden finishing materials are sensitive to climatic factors. As a result, they can dry out, begin to creak and become covered with cracks. Warm floors can also have a negative effect on wood.

- Many people do not see much point in installing additional heating, due to the fact that parquet flooring, which is installed correctly, saves heat in the room well.

- Installing an underfloor heating system at the same time as parquet is a rather difficult task, since any miscalculations can lead to damage to the heating elements.

But there are enough supporters of installing a warm structure. They justify their position by the fact that if certain recommendations are taken into account, the performance characteristics of wooden cladding will not be harmed. And parquet manufacturers admit that the material they produce is compatible with floor heating. But on the packaging of the material there must be a marking that allows the installation of heated floors under parquet. In the absence of such a sign, the risk of damage to the floor covering is very high.

The packaging of the material must contain a marking allowing the installation of heated floors under parquet

Of course, heated floors will be an excellent solution in children's rooms and bedrooms. When choosing parquet for a heated floor , it is recommended to take into account some nuances:

- Due to their low thermal conductivity, wooden materials do not readily transmit heat from heaters. Therefore, parquet or parquet boards for heated floors have some limitations in size. The thickness of the coating should vary between 12-15 mm (very thin planks are deformed by temperature).

- More preferable are materials made from wood species that are less susceptible to deformation as a result of external influences, for example, walnut, ash or oak.

- The temperature on the floor surface should be less than 26 degrees. In this case, heating should be carried out evenly.

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

In order for the heated coating to function for a long time and reliably, it is equally important to be responsible for the installation of the structure. Thus, attaching a plywood backing to a concrete screed (it often acts as an underlay for parquet) should not be done with self-tapping screws. For installation, you can use glue (most often a two-component composition based on polyurethane is chosen), despite the fact that the reliability of this design is lower than when using hardware. Floating fixation of the boards, compensating for thermal expansion and contraction, will help prevent possible deformations of the wood.

It is best to attach a plywood backing to a concrete screed using glue.

Installation of a water floor

A water-based floor is a good solution that is often adopted when it is necessary to lay a wooden floor. Thanks to this, heating the room occurs without problems, and an additional heating system is not required. The advantages of systems of this type:

- a minimum amount of electricity is consumed;

- they are safe and environmentally friendly;

- the base heats up evenly.

However, water heating elements also have their disadvantages. It’s also worth learning more about them:

- temperature control is much easier than with infrared or electric floors;

- in the process of laying plastic pipes, the floor level rises by 10 cm;

- when laying a water floor, it is impossible to completely eliminate leaks;

Due to the disadvantages of a water floor, it should not be installed in apartments of multi-storey buildings. If a leak occurs, several problems will arise - the coating material will warp and the wiring will short out.

Types of heated floors

| Photo | Name | Rating | Price | |

| #1 | Infrared | ⭐ 99 / 100 | More details | |

| #2 | Cable | ⭐ 98 / 100 | More details | |

| #3 | Water | ⭐ 97 / 100 | More details |

Infrared

This design is called film, as it consists of a film made of polymer with graphite heaters sewn into it. Infrared heated floors under parquet boards are distinguished by their simplicity of design. The film is placed on the base and the heater is connected to the power supply. Operating principle: converting the energy of electric current into infrared radiation.

Infrared heated floor

pros

- high heating rate of the floor covering;

- due to its flexibility, the film can be installed on bases of any shape, including steps;

- when using heated floors, the risk of harm to human health is eliminated;

- the system continues to operate even if some part of it is damaged;

- the film can be easily cut if necessary;

- the thinness of the heated floor allows it to be used in any room;

- The service life of a heated floor is 2-3 decades.

Minuses

- If the film is laid under varnished parquet, the temperature on its surface should not exceed 21 degrees Celsius, otherwise deformation of the cladding is possible.

- The disadvantage of infrared heated floors is some limitation on the permissible pressure. In this regard, the film should not be placed where massive interior items will subsequently be installed.

Tips for installing infrared heated floors

Prices for infrared heated floors

infrared heated floor

Cable

Today, floor-mounted electrical systems are in great demand among consumers. The heating element in it is a special heat cable. However, laying parquet on a heated floor of this type is done quite rarely.

pros

- affordable price;

- long service life;

- setting and maintaining the required temperature;

- easy installation.

Minuses

- heavy load on the wooden covering;

- significant electricity consumption;

- the difficulty of carrying out repair work in case of system breakdowns.

Cable floor electrical system

Prices for cable heated floors

cable heated floor

Water

Such heating systems are installed no less often. It consists of flexible plastic tubes filled with water supplied from a boiler or central water supply. How a water heated floor under a parquet board : when the heating is turned on, the liquid heats up, but the temperature rises gradually. As a result, sudden temperature changes that lead to wood deformation are eliminated. But installing a water heated floor is labor-intensive.

pros

- uniform heat distribution;

- saving energy consumption;

- does not dry out the air in the room.

Minuses

- complexity of installation;

- high initial costs;

- the likelihood of a leak and the difficulty of eliminating it;

- cannot be installed in apartments.

Water heated floor installation

When deciding which heated floor under a parquet board is better, you have to keep in mind that both cable and water heated floors are filled with a concrete screed, which protects the system from damage and increases the efficiency of its operation. In this regard, any shortcomings made in the work may affect the functioning of the entire heating. When using infrared heated floors, screeding is not required. It can only be used as a base for placing the film.

Prices for water heated floors

water heated floor

All of the listed heating systems operate on the same principle: at the first stage, the floor covering is heated. Already from it comes thermal energy that spreads throughout the room.

Options for floor heating systems: features

Warm floors, which are abundantly available on the market, are actually divided into three main groups. Actively used:

- film heated floor (infrared);

- water;

- electric.

Each system has special operational characteristics, pros and cons. Their analysis with a forecast of interaction with the parquet board will allow you to make the right choice.

Example of a water heated floor

Installation instructions for infrared heated floors and parquet boards

Work technology:

Step 1 . First, a warm floor is installed under the parquet board . A foiled polyethylene foam backing (which also plays the role of thermal insulation) 3 mm thick is laid out on the floor. The foil will reflect IR rays in the required direction.

Lay out the foil polyethylene foam backing

Step 2 . The film heater is spread out. Such a warm floor can be very easily adjusted to the size of the room (using scissors). Clamping electrical contacts with wiring are installed along the edges. They are isolated.

We spread the film heater and adjust it to the size of the room

Step 3 . The film strips are connected to each other (in parallel) and brought to the thermostat.

We connect the film strips together

Step 4 . A vapor-waterproofing membrane is placed on the heater.

We lay a vapor-waterproofing membrane

Step 5 . Now you can begin installing the parquet flooring. An expansion gap of 10 mm must be left around the entire perimeter. This will allow the coating to slightly change its size under the influence of temperature. For convenience, wedges are installed.

Important! It is recommended to lay the parquet board along the direction of the sun's rays (perpendicular to the window opening).

Laying is carried out using the floating method, without the use of adhesives.

You can calculate the number of rows of boards by measuring the width of the room, subtracting the size of the gaps (20 mm) from the resulting value and dividing the remainder by the width of one board. At the same time, it will become clear to what width the boards of the last row will have to be cut. If after trimming they become narrower than 70 mm, it is recommended to trim both the first and last rows.

The tenon of the boards of the first row is cut off.

Cut off the tenon from the boards of the first row

Step 6 . The parquet board is laid taking into account the compensation gap. To form it, wedges are installed between the wall and the covering.

Laying parquet boards

Step 7 . When installing the second row, it is necessary to offset (by about a third) the lamellas. To do this, you will have to cut the outer boards to width. The elements are fixed using a locking connection. Using a hammer and a block, the connection is tapped (first the end, then the longitudinal).

Step 8 . The same sequence is performed before installing the last row. The tamping of these boards (cut to accommodate the expansion gap) is carried out with a mounting bracket.

Parquet boards are installed on the heated floor. When the coating is installed taking into account all the requirements, it will serve for a long time.

Primary requirements

If it has been decided to lay a wooden covering on a warm floor, then, in order to avoid possible problems, the following number of features of this combination should be taken into account:

- The most suitable type of parquet for laying on a warm floor is parquet boards, since this floor covering is better able to withstand changes in humidity and temperature than others.

- To prevent the board from drying out too much when heated, its factory humidity should not be higher than 6..7%.

- It is best to choose a board with the smallest possible width of the plank, because the size of the gap, all other things being equal, is directly proportional to the transverse size of the plank.

- Parquet boards on a warm water floor must be laid either by professionals, or at least under their direct supervision.

- The maximum permissible temperature of the parquet surface is 26°C, and it is strictly not recommended to exceed it. Any excess can cause drying out and deformation of the parquet planks.

- Any change in floor temperature during its operation should be gradual.

- When using a warm water floor system, a waterproofing layer should be installed.

- When choosing a parquet board, you should focus on one that is made from wood that is resistant to deformation. The most commonly used wood is oak. At the same time, maple or beech wood is the most undesirable choice, since these are the species that are most sensitive to changes in humidity levels.

- To prevent humidity levels from falling below 40%, use a humidifier.

laying parquet boards on heated floors

Installing a water system under parquet boards

Since this design has one significant drawback - the possibility of leaks cannot be completely excluded, its installation must be taken with great responsibility.

Stages of work:

Step 1 . Insulation - polyethylene film - is laid on a flat base.

Lay down plastic film

Step 2 . To minimize heat loss downwards, thermal insulation is laid. For this purpose, it is better to use polystyrene foam with a thickness of 5-10 mm.

Installing expanded polystyrene

Step 3 . To compensate for the thermal expansion of the screed (which can cause it to crack), a damper tape made of foam polyethylene is attached around the perimeter of the room.

Installing a damper tape made of foamed polyethylene

Despite the fact that the tape is self-adhesive, it is recommended to secure it with mushroom dowels (you can attach it to drywall or wood with a stapler).

Step 4 . A reinforcing mesh (metal thickness - 4 mm) must be laid on the thermal insulation. It will be needed not only to strengthen the structure, but also to secure the pipe.

Laying the reinforcing mesh

Step 5 . Pipes are being laid. To install a heated floor, a pipeline with a diameter of 1.6 cm is sufficient. The most popular methods of laying out the pipe are spiral or loop.

Laying pipes

Laying in a spiral allows for uniform heating of the floor. That's why it is used more often. Process diagram: first, the pipes are laid out around the perimeter, and gradually, in a spiral (in increments of 30 cm), they are wrapped towards the center. Having reached the center, work continues in the opposite direction. The pipe must be returned to its original point. As a result, there will be 15 cm between the pipes.

To fasten the pipes to the mesh, nylon ties are used (if mats with bosses are used as insulation, then the pipes are fixed between these protrusions).

Layout options for heated floor pipes

Important! The length of one pipeline circuit should not exceed 120 linear meters.

Step 6 . The pipes are connected to the collector. The system must be checked for operability and tightness. Before pouring the screed and installing the floor covering, testing (pressure testing) is carried out for two days.

Connecting the pipes to the collector

Step 7 . A cement-sand screed is made (on the beacons). For greater reliability of the structure, it is recommended to lay another reinforcing mesh on the pipes. The screed is made of concrete grades M200 or M300. Its thickness should be such that there is a distance of at least 5-8 cm from the pipes to the surface of the new floor.

Making a cement-sand screed

Step 8 . Installation of the floor covering can be carried out 4 weeks after the concrete has gained strength.

Step 9 . Plywood is laid on the concrete base. For fastening, it is better to use polyurethane glue rather than self-tapping screws, so as not to accidentally damage the pipeline.

Polyurethane adhesive for fastening plywood and parquet

Step 10. The parquet boards are laid using a floating method.

Why wood flooring is not suitable for heated floors

There is no worse covering for heated floors than natural wood. No matter how you look at it, this solution has some disadvantages. Let's look at the problem from two points of view: heating and finishing.

Heating problem

The entire structure of a heated floor in a room: pipes with coolant circulating through them, a concrete screed or a lath or flooring system that replaces it, and a coating - this is one large heating device

For a heating device, it is important that the maximum possible part of the thermal energy enters the room without encountering obstacles along the way. The cast iron battery releases heat to the environment without any problems

Also, a warm floor, where the pipes are filled with a layer of concrete about 4 cm thick, and ceramic tiles are laid on top, transfers thermal energy well into the room. This is because metal, concrete and ceramics have high thermal conductivity.

You can conduct an experiment: in winter, wrap a radiator located in a room under a window in a warm blanket. After a while we will feel that the room has become noticeably colder. The blanket prevents heat transfer; the coolant returns to the system at almost the same temperature as it entered the battery. If we wrap all the radiators in the house in blankets, the rooms will become cold, and the boiler may overheat.

Natural wood has low heat transfer and acts like a blanket, reducing heating efficiency. In addition, thermal energy, encountering an obstacle to its spread from above, will tend downwards into the ceiling or subfloor. In order not to lose a significant part of the heat, you will have to additionally insulate the floor structure from below. And these are financial costs and reducing the height of the room due to increasing the thickness of the insulation. The above indicates that using natural wood for underfloor heating is not economically feasible.

Coating problem

Natural wood is a “living” finishing material. Wood fibers easily absorb and release moisture, and the geometric dimensions of the products noticeably change. Wet wood swells; when it loses moisture, it shrinks; the changes are especially great across the grain. The relative air humidity in the room in summer is 40-65%; at these values, wooden furniture and floors “feel” good. During the heating season, with radiator heating and the absence of humidifiers, humidity can drop to 20-35% or lower. At the same time, wooden floors dry out: gaps appear between the parquet floors and the closer to the radiators, the wider the gaps in the floor. Let's imagine that the entire floor is a large radiator, constantly heating the entire surface of the wooden floor. Under the influence of heat, the wood will dry out, the parquet flooring or boards will decrease in size and noticeable gaps will appear between them over the entire surface area. The higher the temperature of the heated floor, the more the wood will dry out over the winter.

A multilayer parquet board will behave a little more stable. Due to the fact that it consists of several layers of wood, the fibers of which are located perpendicularly, the humidity-temperature deformations of glued parquet boards are not as great as those of solid parquet and floorboards.

But here a different danger awaits the consumer. When making parquet boards, glue containing formaldehyde is used. Up to a temperature of 26 ºC it is bound in glue and the parquet board is safe. When the specified temperature is exceeded, harmful formaldehyde vapors begin to be released and enter the air. At the same time, the operating temperature of the coolant in the heated water floor system, which is provided by standard equipment, is 40ºC. The floor surface can heat up to 35 ºC.

Instructions for installing cable heating under parquet boards

An electric heated floor can act as an independent heat source or be used as additional heating.

System installation technology:

Step 1 . On a flat floor (the quality of the surface in this case is of great importance, since kinks in the cable provoke its breakdown) hydro- and thermal insulation (polyethylene film and polystyrene foam) are laid. A damper tape is attached around the perimeter of the room (as in the previous paragraph).

Laying thermal insulation

Step 2 . A reinforcing mesh is laid on the insulation.

Step 3 . A thermostat is mounted on the wall (at a height of 30-50 cm from the floor). A groove is cut down from it for laying the cable.

Attaching the thermostat

Step 4 . A heating cable can be used as the main element of the heating system, but it is more convenient to lay mats, which are a fiberglass sheet with a cable fixed on it at a certain pitch. If you still choose a separate cable, its installation can be done on a special tape secured in the screed with self-tapping screws, but in our case it is attached to the reinforcing mesh using clips.

Laying the cable

The table will help you correctly calculate the heating system:

Heating system calculation table

Step 5 . A thermostat is placed in a corrugated pipe between the heating lines at a distance of 50 cm from the wall.

Place the thermostat at a distance of 50 cm from the wall

Step 6 . The heated floor is connected to the electrical network, and the design is tested.

Step 7 . If the system is functioning normally, a concrete screed 5-6 cm thick is poured and leveled.

Filling the floor with concrete screed

The result is a pie like this:

Installation of heated floors

Step 8 . After the concrete has hardened (after 28 days), a topcoat of parquet boards can be installed (on a substrate made of foam, cork or plywood). Again the floating method should be used.

The “warm floor + parquet board” system has the right to be used. With proper design, an optimal microclimate will be created in the room.

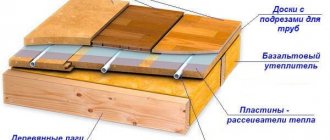

Installation of a floor heating system

When laying a flooring system, you get a kind of multi-layer cake; let’s look at each layer in more detail.

Requirements for the foundation for the structure

The first layer of the cake is a properly prepared base. This can be any overlap that is pre-leveled. SNiPs regulate the absence of significant differences in heights, protrusions and roughness. The wooden floor must be level, without protruding boards.

Each board should be well secured and should not bend. The maximum permissible limit of deviation from the horizontal is 2 mm, distributed over 2 m of area in any of the existing directions.

Construction of the insulating layer

To prevent heat loss, it is necessary to install an insulating layer. The material for its implementation is selected individually, based on operating conditions. It must be moisture-resistant, fire-resistant and compatible with other building materials.

It is desirable that additional sound insulation be provided. If possible, the thinnest but most effective material is selected.

Pipe fixation option

The actual flooring under the pipes is laid on top of the insulation. There are many options here. These can be polystyrene mats with special bosses for pipes. Such mats are produced single and doubled with insulation.

In the latter case, the insulating layer may be superfluous. Sheets of lumber with cut grooves for pipes can be used as flooring. They are also produced industrially. There are also homemade floorings made from slats, bars, etc.

Pipe for moving coolant

Next, the heat pipe is laid into the prepared fasteners and grooves. To ensure a tight fit and create a heat shield, the parts are placed inside a special aluminum profile.

If there is none, you can make similar elements from galvanized steel or wrap each part in thick foil. It is optimal to lay an additional layer of foil on top of the mounted pipes.

Construction of the foundation for finishing

A base must be laid on top of the pipes under the floor covering. It is selected depending on what kind of finishing coating will be laid.

If you plan to install tiles, ceramic or PVC, as well as linoleum or carpet, moisture-resistant plasterboard is laid on the metal elements of the wooden flooring. If polystyrene mats were used to construct the flooring, GVL is laid in two layers.

The decking structure is usually covered with a base for the finishing coating. It is selected depending on the material that is preferred as a coating. For example, a moisture-absorbing substrate is placed under the laminate; moisture-resistant plasterboard or chipboard is placed under the tiles.

Drywall is not laid under laminate on wooden flooring. Instead, foamed polyethylene or a cardboard backing is placed on aluminum plates to absorb excess moisture.

Instead of GVL, you can use moisture-resistant types of chipboard or plywood. A good solution is glass-magnesium sheets, which also conduct heat well, which is absolutely not superfluous when arranging a heated floor.