ATTENTION! Maintenance operations and repairs of geysers associated with dismantling its gas or water communications must be carried out by qualified craftsmen. Self-repair can have the opposite effect before purchasing a new device.

Error E1 - no flame

The ignition clicks for about a minute, the burner does not ignite.

The electronic control unit does not see the presence of a flame and the column goes into emergency mode. Reason #1.

Presence of air in communications. If the column is idle for a long time, or after its installation, the pilot burner will operate only after air has been removed. The system should be purged by constantly turning on the column. Since ignition lasts no more than a minute, after completion you should reopen the water tap until ignition occurs.

Reason #2.

There is no gas in the cylinders or the tap on the descent to the column is closed. Fully open the shut-off valve. Check LPG gas cylinders. Replace them if necessary.

Reason #3.

There is no contact between the block and the flame sensor. The contacts coming out of the electronic unit should be serviced, if necessary, cleaned, pressed for a good connection, and worn ones should be replaced.

Reason #4.

Flame sensor outside the flame zone. Adjust the position of the flame sensor so that its electrode is in the gas combustion zone. Make sure that the electrode does not touch other metal components. Clean the electrode from carbon deposits.

Reason #5.

The gap between the spark plug and the igniter is broken. Due to constant heating and cooling, the ignition burner nozzle is deformed, which increases the gap to the spark plug. Once every two years, or during regulated maintenance, the gap should be adjusted to 4...5 mm.

Error E7 - lack of gas

The speaker goes out after switching on. Unsuccessful ignition attempt. Process: the igniter lights up, then the main burner, then everything goes out and the process repeats again.

Reason #1. Low gas pressure. Open the gas valve on the downstream side of the column. Invite a specialist to your home to measure the gas pressure in the system and further configure the column. You should also blow out and clean the gas filter.

Reason #2. The flame ionization sensor is not located in the fire zone of the main burner. Adjust the sensor. Install the electrode so that the fire of the main burner washes on both sides. It is possible that carbon deposits have formed on the sensor, which makes heating weak - clean and adjust the sensor.

Reason #3. The mechanism in the water unit is stuck. Increased deposition of salts on moving mechanisms leads to jamming and stopping. A stuck rod of the water unit leads to a permanent short circuit of the flow sensor. In this case, you should dismantle the water part and carry out preventive work: lubricate the rod, replace rubber gaskets.

e1

Error e1. This malfunction indicates low fluid pressure in the heating circuit.

The reasons may be as follows:

- The heating circuit has become airy or the pressure has dropped to its minimum point. Increase the fluid pressure in the system, remove air from the heating circuit.

- The bypass valve is installed incorrectly or is faulty; to check, follow these steps: set the boiler to heating mode, then close the shut-off valve to the heating circuit.

The bypass should redirect the liquid not into the heating circuit, but pass it through the bypass line (at the same time it will heat up). And, if it is faulty, replace it with a new one, installing all the taps in the position in which they were before the check. - Pump failure. It is necessary to remove it from the device, disassemble it, wash it, and clean it of accumulated deposits. If this does not work, replace it.

- There is a breakdown in the electrical circuit of the pressure sensor.

Using a multimeter, test the circuit for an open; if found, repair it. DHW sensor Visually check all contacts and connectors. If this does not give the expected result, replace it with a working device. Occurs often in Neva Lux 2073. - A slow-moving rod or sticking of the measuring device rod in the heating circuit, the cause could be a failure of the membrane on the flow sensor.

To begin, remove this sensor from the device, turn the boiler (pump) on and off, in a similar way you can remove the boiled rod. If this does not work, check the condition of the membrane; if it is worn or deformed, replace it. - There is a malfunction in the flow sensor, or the integrity of the connecting wire is broken. Perform an electrical circuit check and also check the connections of the controller board connectors. If the problem persists, replace the flow sensor. Typical for the Neva Lux 2083 model.

- Failure in the electric motor of the three-way valve. Repair is not possible, complete replacement is necessary.

User's Guide.

User Guide

Thank you for choosing our product. You purchased

heating gas double-circuit wall-mounted boiler with forced circulation of coolant “NEVALUX”.

When purchasing a boiler, check: completeness of delivery (see section 23, page 50) and the presentation of the boiler; compliance of the type of gas (natural or liquefied) you use with the type of gas,

20 and 21 (page 48) of this manual and on the plate on the boiler casing.

Also require the sales organization to fill out warranty repair coupons. When purchasing a boiler using a loan, a payment schedule must be drawn up with

indicating the full amount to be paid. The payment schedule must be signed by the Buyer, indicating the date and deciphering the signature.

The boiler and this manual are two integral parts of the proposed

goods. The manual contains information about the procedure for installing the boiler, the rules of its operation and maintenance, compliance with which will ensure long-term trouble-free and safe operation of the boiler. Please read this manual carefully before putting the boiler into operation, follow the instructions contained therein and store it carefully for future use.

Unified Technical Support Service telephone number

(the call is free in Russia, service hours: from Mon to Fri from 9.00 to 17.00 (Moscow time))

Installation of the boiler is allowed only in non-residential premises with a temperature not lower than +5 0C in

strict compliance with the Gasification Project, SP 62.13330.2011 “Gas distribution systems. Updated version of SNiP 42−01−2002", SP 41−108−2004 "Apartment heat supply of residential buildings with gas-fuelled heat generators", SNiP 41−01−2003 "Heating, ventilation and air conditioning" and Fire Safety Rules (PPB 01-03 ).

All installation work, installation, owner instruction, preventive maintenance,

Troubleshooting and repairs are carried out only by a specialized service organization.

The boiler is not intended for use by persons (including children) with reduced mental

abilities or lack of life experience.

Responsibility for the safe operation of the boiler and its maintenance in proper condition

is borne by its owner. Failure to comply with the safety measures and installation, use and maintenance rules set out in the Manual can lead to boiler failure, fire, burns, gas or carbon monoxide (CO) poisoning and electric shock.

Armavir Gas Equipment Plant LLC is constantly working to improve

manufactured products and reserves the right to make necessary changes to the design

boiler These changes may not be reflected in this Guide.

History of the Neva company

Russian users are well aware of the single-circuit and double-circuit wall-mounted gas boiler Neva Lux. But not everyone knows that the company producing such equipment appeared on the market more than 50 years ago.

The original enterprise was called "Gazapparat". It specialized in the production of any gas equipment, including water heaters, boilers, and heaters. Currently, the company belongs to the largest concern “Baltic Gas Company”.

Thanks to this alliance, models such as the Neva Lux and a new product on the market - the Turbo model - appeared. The shortcomings in the work of the first models were taken into account and were eliminated in subsequent ones. As a result, the consumer receives a product of European quality.

User manual

If the instructions are lost, you can download them from the company’s official website

Instructions are included with the equipment. It can also be downloaded from the official website of the manufacturer - NEVA (Russia) in PDF format.

The document stipulates: technical characteristics of devices, safety parameters, requirements for installation and installation of the boiler. Also given are diagrams of the device and control panel, recommendations for igniting the boiler and methods for connecting it. Methods for seasonal inspections, maintenance, and care of the unit are described. The table provides lists of errors and methods for eliminating them. At the end there are marks about the acceptance of the device, warranty statements, and a list of service centers.

When working with equipment, the instructions should be at hand. If you cannot fix the error yourself, you should call the service center and call a technician.

Gas wall-mounted boiler Neva Lux 8224

Gas boiler NEVALUX-8224 is a wall-mounted double-circuit gas boiler with an open combustion chamber and an LCD display designed for apartment heating and hot water supply in multi-storey buildings, as well as in private cottages with an area of up to 240 m2. The use of one bithermic heat exchanger for heating and hot water supply allows reducing the cost of the device while maintaining all consumer functions.

The NEVALUX-8224 gas boiler is significantly different from the previous generation NEVALUX boilers. The combustion chamber is water-cooled, which increases the service life and increases the reliability of the boiler. The primary heat exchanger, responsible for heating the water, is designed on the basis of pipes of increased diameter, which significantly slows down the process of scale formation, extends the service life and reduces the frequency of service.

The external cladding of the boiler is made of metal-plastic with a triple degree of corrosion protection, consisting of primer, galvanization and enamel coating. The metal-plastic cladding ensures reliable operation of the boiler for several decades.

There has been another improvement in the appearance of the boiler - a new control panel. Boiler control has reached a modern level, has become intuitive and more informative. The function of connecting a remote control, an external street sensor, and a personal computer has been added. An outdoor temperature sensor will provide information to the boiler for more economical operation, and connection to a PC will simplify service and diagnostics of the boiler. The Italian-made electronic board that organizes all these functions is optimized for Russian operating conditions. These innovations will allow the boiler to ensure stable operation and increased safety.

Distinctive features of the gas boiler NEVALUX-8224:

- Two separate heat exchangers for heating and domestic hot water circuits

- Stainless steel plate heat exchanger for DHW circuit

- Closed combustion chamber

- Continuous electronic flame modulation in heating and domestic hot water modes

- Multi-level security system

- Electronic control and self-diagnosis system

- Possibility of connecting a remote control, thermostat and outdoor temperature sensor

- LCD display

- Stable operation at low water and gas pressures

- Modern ergonomic design

- Possibility of working on liquefied gas

- European components

- NEVALUX boilers are designed for Russian operating conditions and are ideal for apartment heating of houses of any number of floors, as well as for country houses and cottages.

- Two separate heat exchangers: the main one, which ensures the operation of the heating circuit and the secondary (plate) one, which functions as part of the hot water supply circuit;

- The plate heat exchanger of the DHW circuit, made of stainless steel, reduces the intensity of the scale formation process and eliminates the danger of “coking”;

- Automatic maintenance of the set temperature of hot water and heating with an accuracy of one degree;

- Closed combustion chamber with water cooling and forced smoke removal;

- Electronic board, made in Italy, optimized for Russian operating conditions.

Piping for heating equipment

Gas boiler Neva

Popular gas equipment - heaters, water heaters, gas stoves and boilers - have been produced in St. Petersburg for more than 50 years. After the creation of the Baltic Gas Company concern, the enterprise became part of it, maintaining its production capacity and specialization. Current name. It is rapidly developing and produces high-tech boilers equipped with modern automation. For example, a popular and sought-after series is Neva Lux gas boilers, which is presented in two categories.

Review of the Neva Lux boiler range

The range of popular gas boilers produced by the Neva company includes two basic series: Lux and Turbo. In this article we will consider the most famous and popular Lux series, which is divided into two categories:

- Single-circuit gas boilers Neva Lux, designed for individual homes. The series is characterized by ease of maintenance, low cost and energy independence.

- Double-circuit wall-mounted gas boilers of the Neva Lux series are equipped with open or closed combustion chambers; the boilers include a bithermic heat exchanger. The chimney can be coaxial or classic. The series is equipped with high-precision automation. It is possible to connect two heating systems to the Neva Lux series boiler, and some models have outlets for organizing heated floors.

The most popular boilers of the Neva Lux series

Under the Neva brand, modern luxury class gas boilers are produced, which eliminate the shortcomings of previously produced models. The design has been changed, modern automation has been installed, but the price of the products is less than models of Western companies with similar parameters. Other models of domestically produced gas boilers can be found in our article “Russian-made gas boilers: varieties and properties.”

Model Neva luxury 8618

For Neva Lux gas boilers, the price depends on the model. Single-circuit models are cheaper, double-circuit models are more expensive. For example, one of the most popular models in this series, the gas boiler NevaLux 8618, is in demand due to its low price and the following qualities and capabilities:

- small dimensions;

- all models are adapted to Russian conditions;

- the boiler is equipped with a circulation pump manufactured by the Neva company, which facilitates the installation of the boiler into the installed heating system;

- DHW is organized by connecting an indirect heating boiler;

- if necessary, a fan is connected for forced smoke removal;

- connection to a room thermostat is provided.

The popular single-circuit gas boiler Neva Lux 8618 for wall installation is intended only for heating, but if necessary, organizing hot water supply is possible using an indirect heating boiler. The model has the simplest possible design with non-volatile automation. The price of this boiler is the lowest of the entire model range.

Model Neva luxury 8224

The wall-mounted gas boiler Neva Lux 8224 is designed for heating rooms up to 250 m2. The boiler is equipped with a unique water-cooled combustion chamber. High accuracy of temperature setting is ensured by a special microprocessor. In terms of their parameters, Neva boilers are not inferior to foreign models, the only difference that the gas boiler Neva Lux 8224 has is the price, reviews of many owners confirm this.

This model has two heat exchangers. A plate heat exchanger is used for hot water supply, and a copper heat exchanger built into the Neva Lux gas boiler of this series is used for the heating circuit.

The model can use a PC for diagnostics and configuration, as well as remote control.

For the popular gas boiler Neva Lux 8224, reviews found on the Internet fully confirm the excellent consumer qualities of the device. Many reviews emphasize that the Neva Lux 8224 gas boiler has a relatively low price and high performance. This is a wall-mounted double-circuit model, which is designed to heat rooms up to 240 m2. The unit provides hot water supply (DHW).

Structural components

From a technical point of view, the Neva wall-mounted gas boiler is impeccable. It implements all the technical advances in heating engineering, as well as developments in the field of electronic control of heating circuits.

Structurally, the Neva double-circuit gas boiler consists of the following interconnected systems:

- a control system consisting of an electronic unit that controls the operation of the boiler and ensures safety, and an electrical harness that connects sensors, an electronic board and other devices into a single system;

- hydraulic system, including a pump for forced circulation, an automatic valve for removing air, a heat exchanger for heating the coolant, a secondary heat exchanger for the hot water system;

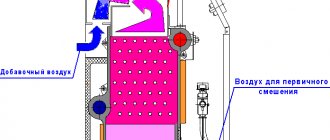

- the gas system includes a burner unit, which ensures uniform and complete combustion of the gas-air mixture in the combustion chamber, and an ignition transformer to create a spark on the spark plug, which automatically ignites the gas mixture;

- smoke removal system, which includes a fan for forced removal of combustion products and a chimney;

- a setup and adjustment system consisting of a gas supply regulator to the burner block, a heating circuit temperature sensor, a DHW temperature sensor, and a DHW circuit flow sensor.

Advertising on the Internet and on television encourages you to buy a Neva Lux double-circuit wall-mounted gas boiler as the most economical, cheapest, most convenient, etc. Can you trust this advertising and reviews on the web pages of online stores?

How to buy a gas boiler and not make a mistake?

A buyer, choosing, for example, a wall-mounted gas boiler Neva Lux 8224 reviews for which may be false and written to order, must understand that they cannot be relied on. After all, it often happens that the design is ideal, the equipment is the most modern, but poor-quality assembly worsens all the advantages. For example, in 2014, reviews characterized the wall-mounted gas boiler Neva Lux 8224 as a naturally raw product, which is called “finish it with a file.”

This review appeared due to poor quality assembly, as well as due to unstable operation of the boiler due to a defect in the coaxial chimney, which was not specified in the instructions. Of course, the Neva company has now taken certain measures and eliminated shortcomings in the assembly of the product. There are practically no complaints about the Lux 8618 model and you can buy a single-circuit wall-mounted gas boiler Neva Lux, with delivery to any region, in specialized stores.

Prices for mounted gas boilers depend on their power, type, configuration and demand for the device. For example, the Neva Lux gas double-circuit wall-mounted boiler offered by many online stores, the price of which with a power of 24 kW, but with different configurations, ranges from 31,800 to 35,600 rubles.

The most expensive boiler, Nevalux 8224, is equipped with a built-in storage boiler. When choosing a boiler for heating, if you are satisfied with the gas boiler Neva Lux 8224 price, it is best to get reviews from real owners or gas equipment specialists.

Malfunctions of the gas boiler Neva Lux

The simplest single-circuit and non-volatile model Neva Lux 8618. It completely lacks electronics. A simple Neva gas boiler is very reliable.

The most common faults characteristic of this boiler are the following:

- very low level of gas pressure in the line;

- low pressure due to the presence of air in the circuit;

- burner flame goes out;

- mechanical damage to the boiler or heating circuit.

The presence of a control unit with a microprocessor in the Neva Lux 8224 model allows for self-diagnosis of faults that arise during the operation of the gas boiler. The electronics installed on the Neva Lux double-circuit gas boiler displays faults on the display in the form of an error code.

Error codes displayed on the display

Any technical device can break down. The Neva Lux boiler of any model is no exception. Its stop may be due to the failure of any element in the control system or their incorrect operation. The control system displays the error code on the display, and knowing the error code makes it easier to detect a malfunction.

The following error codes are displayed:

Error 01. This error indicates unsuccessful ignition. The boiler does not turn on:

- gas supply failure;

- the spark plug has failed;

- loss of contact or disruption of the voltage supply circuit to the spark plug;

- increased gap between the spark plug and the burner body;

- spark plug contamination.

Error 02. Coolant overheating. The boiler does not work:

- system clogging;

- thermal relay malfunction;

- air lock in the circuit;

- filter clogging;

- the bypass valve is installed incorrectly;

- pump malfunction;

- pump activation relay malfunction;

- malfunction of the gas supply regulator;

- failure of the thermal relay (overheating sensor).

Error 03. Lack of traction:

- The fan or its circuits are faulty.

- the chimney or air supply channel is clogged;

- depressurization of pressure switch tubes;

- presence of condensate in the pressure switch tubes;

Error 04. Low water pressure in the circuit:

- pressure sensor malfunction;

- low water pressure in the circuit;

- airlock;

- the automatic air release valve or pump is faulty;

- open circuit from the pressure sensor.

Error 05. Heating system temperature sensor failure:

- the malfunction is eliminated by replacing the sensor;

- open or short circuit of the sensor electrical circuit;

Error 06. DHW temperature sensor failure:

- sensor malfunction;

- open or short circuit in the electrical circuit between the sensor and the electronic board.

Other faults that cannot be displayed. For example, if there is no electricity, the boiler will not turn on and will not work. Of course, if you install an uninterruptible power supply, then such a problem can be avoided.

The fuse has blown. It is rare for a fuse to blow for no reason. If, after replacing it with a similar fuse, it blows again, then you need to find the reason. Under no circumstances should you install “bugs” that can damage the entire electronics of the boiler.

If the electronic board was accidentally flooded with water. You need to turn off the boiler from the network and dry the board with warm air from a hairdryer. Sometimes there may be an electronic malfunction. To reset to its original position, press the RESET button. If this does not help, then unplug the boiler for a few minutes and turn it on again.

If you smell gas, you must immediately find and repair the leak.

If you cannot fix the leak yourself, it is recommended to call the gas service by emergency number 104.

Design and principle of operation of Neva and NevaLux speakers

The BaltGaz line includes several instantaneous gas boilers, differing in their operating principles and internal design features. All manufactured equipment can be divided into several groups:

- Type of ignition - there are semi-automatic and automatic models. The first ones (4011, 5111) during operation use a constantly burning wick, ignited by a piezoelectric element. The second, with automatic ignition, runs on batteries. The gas is ignited by a spark supplied to the burner device.

Using modulation - gas instantaneous water heaters Neva and Neva Lux operate using hydraulic (5111, 5611) and electronic (6011,6014) changes in water heating power. There are models without automatic adjustment of combustion intensity.

The design of Neva and NevaLux geysers is constantly being modified and modified. New models are being produced, the design of which is adjusted taking into account the wishes of consumers.

The technical characteristics of water heaters manufactured by Baltgaz are described in detail in the following table:

| Technical characteristics of instantaneous gas water heaters BaltGas | |||||||||||

| NEVA 4011 | NEVALUX 5111 | NEVA 4510 | NEVA 4510M | NEVA 4511 | NEVA 4610 | NEVALUX 5514 | NEVALUX 5611 | NEVALUX 6011 | NEVALUX 6014 | ||

| Power, kWt) | 21 | 21 | 17 | 17,9 | 21 | 20 | 28 | 21 | 21 | 28 | |

| Heating capacity (kW) | 18 | 18 | 15 | 15,5 | 18 | 17,5 | 24 | 18 | 18 | 24 | |

| Efficiency, not less (%) | 87 | 84 | 85 | 87 | 87,5 | 87 | |||||

| Combustion modulation on the burner | — | continuous hydraulic | — | continuous hydraulic | continuous electronic | ||||||

| Ignition | piezoelectric | electronic | |||||||||

| Gas type | natural/liquefied | natural | natural / liquefied | ||||||||

| Gas pressure (natural/liquefied) (kPa) | 1,3;2,0/2,9 | 1,3/— | 1,3;2,0/2,9 | ||||||||

| Gas consumption (natural/liquefied) (m³/h / kg/h) | 2,22/1,66 | 1,80/— | 1,89/1,41 | 2,22/1,66 | 2,11/1,57 | 2,96/2,21 | 2,22/1,66 | 2,22/1,66 | 2,96/2,21 | ||

| Chimney diameter (mm) | 110 ÷ 125 | 120÷ 125 | 110 ÷ 125 | 103 ÷ 110 | 125 ÷ 155 | 110 ÷ 125 | 125 ÷ 155 | ||||

| Required vacuum in the chimney, not less (Pa) | 2,0 | ||||||||||

| Max. pressure water (kPa) | 1000 | ||||||||||

| Min. water flow (l/min) | 2,5 | 2,0 | 2,5 | ||||||||

| Min. pressure water (kPa) | 15 | ||||||||||

| Water consumption when heating at ∆t=25℃ (l/min) | 11 | 11 | 10 | 10 | 11 | 10 | 14 | 11 | 11 | 14 | |

| Number of water points | 1-2 | 1-2 | 1 | 1 | 1-2 | 1 | 2 | 1-2 | 1-2 | 2 | |

| Dimensions (mm) | Height | 565 | 565 | 624 | 565 | 565 | 610 | 650 | 565 | 565 | 650 |

| Width | 290 | 290 | 356 | 290 | 290 | 350 | 350 | 290 | 290 | 350 | |

| Depth | 221 | 221 | 186 | 221 | 221 | 185 | 239 | 221 | 221 | 239 | |

| Net weight | 9,5 | 9,5 | 10,4 | 9,0 | 10,0 | 10,5 | 12,5 | 10,0 | 10,0 | 12,5 | |

| Case color | white, silver | white | white, silver | white | white, silver |

Download: instructions for the speaker NEVA 4510.pdfDownload: instructions for the speakers NEVA Lux 5111, 5611.pdfDownload: instructions for the speakers NEVA Lux 6011, 5514, 6014.pdf

This code means that the water temperature has exceeded the permissible value

It is strictly recommended to connect heating boilers through a stabilizer (for the boiler) or a UPS; this will save you from unnecessary costs for replacing the control board.

Checking the polarity in the plug-socket connection: turn the plug 90 degrees and insert it back into the socket or stabilizer.

Check grounding: the main cause of errors installed in apartments.

In the private sector, circuit testing is carried out with a device - a megger; when measuring resistance, R should show no more than 4 ohms.

The simplest testing of a pump is performed by turning its shaft manually and assessing the condition of the mechanical part based on how easily the shaft turns.

Low coolant pressure in the system: if the boiler pressure gauge needle leaves the green sector and turns to red), it is necessary to increase the pressure to the minimum threshold of 1 Bar

The make-up valve is located at the bottom of the heating installation, next to the connection pipe for the cold water pipe.

It opens counterclockwise until the characteristic noise of the incoming liquid appears; do not forget to close the tap in the reverse order, otherwise the pressure will creep into the reverse red zone and the relief valve will begin to operate (water will flow).

Leakage: easy to identify by walking around the house, looking at puddles on the floor

Focus on pipe connections, heating radiators, mounted appliances

The water supply tap in the system is closed: you need to check the position of the controls of the taps, valves on the main line and bypass. Most likely, the heating circuit pipe is blocked in some area.

The coarse filter on the main line is clogged: it gradually becomes clogged with sediment from the heating system, and if the mesh has not been washed for a long time, dirt can cause an error.

The pressure switch is faulty: the sensor is initially set to a value of 0.45 bar. and when the pressure in the heating circuit increases, its contacts close, a switch-on permission signal is sent to the board, a drop in pressure leads to a break in the circuit, and an error is generated - blocking the operation of the boiler in emergency mode.

The safety valve has failed.

Failures in the gas supply to the house: often the gas supply pressure on the main line decreases and the boiler does not return to operating mode. The check comes down to igniting all the burners on the stove at maximum mode. Flames with a characteristic shade will indicate the absence of problems with the fuel supply, and their intensity and stability will indicate the constancy of the pressure and its normal value.

You also need to check:

- The position of the shut-off valve controls: the gas supply valve to the house may have been accidentally turned off or the shut-off valve was activated during a power outage.

- Serviceability, condition of technical devices: meter, reducer (with autonomous gas supply), main filter, filling level of the tank (gas tank, cylinder group).

Resistance between pins 1 and 3 – 6.5; 1 and 4 – 7.4 (for SIT SIGMA 845048 block).

If there is a discrepancy, the gas valve is replaced (turn-to-turn short circuit). If R = ∞ – open circuit, R = 0 – short circuit.

The electronic board is faulty: a fault in the electronic circuit also causes an error to appear in the boiler.

Defects are identified by inspection for deformation, melting, breaks, condensation, etc.

The new board may not be configured correctly.

If the cause of equipment failure is the board, contact the service center indicating the alphanumeric marking of the node.

Typical faults

Boiler error codes can be found in the operating instructions

Any complex equipment fails after prolonged use. The main indicator of reliability is quick commissioning through repairs with the elimination of typical faults. A warranty card is issued for any heating equipment and installation work. Therefore, calling a technician during the warranty period will be free - the manufacturer’s warranty will cover equipment malfunctions, and the installer company will eliminate installation defects.

A list of major equipment errors can be found on a special display.

Error 01

In the Neva Lux boiler, this type of error means that the device cannot be ignited.

- Check valve opening and gas supply. If necessary, call the gas service.

- The gap between the spark plug and the burner should be 5 mm. Adjust.

- Isolate the breakdown site when the candle is broken.

- Clean the dirty spark plug.

- Ring the ignition transformer circuit.

Error 03

An uninsulated chimney allows condensation to accumulate, which impedes operation.

Accumulation of condensate in pipes causes error type 03.

- The chimney is clogged or its structure is damaged.

- Depressurization of the pressure switch tube or disruption of its electrical network.

- Fan failure.

Error 04

Error 4 indicates insufficient pressure in the heating circuit. This interferes with the functioning of the components and contributes to overheating of the boiler.

- Increase the pressure in the circuit.

- Remove the air lock using the air bleed valve.

- Check the pressure sensor.

- Clean the pump and inspect the connections.

Installation and connection

Installation and piping of the Neva Lux floor-standing boiler

Neva Lux boilers are installed as follows:

- The equipment is hung on the wall with special strips.

- Ball valves are installed at the inlet and outlet of the boiler to facilitate operation and repair.

- Filters are placed using squeegees.

- The hot water supply and heating system is supplied, or the boiler is connected to the existing water supply.

The boiler must be connected and configured by certified employees of the gas company. Neva Lux is usually located in the kitchen or utility room with a ventilation system. When choosing an installation location, you should take into account the locations of water and gas pipes.

Design and principle of operation of Neva Lux boilers

Neva Lux gas boilers are presented in two variations - wall-mounted and floor-mounted; let's look at their design using the example of some models. Neva Lux 8618 is a single-circuit heating boiler, wall-mounted, has low energy consumption, a fairly high efficiency of 91%, power 18 kW. Can heat a room with an area of 30 to 180 square meters.

Powered by both natural and liquefied gas. It has small dimensions, is equipped with a combustion chamber that is cooled with water, and can also be connected to a room thermostat, which is convenient for use. Equipped with a protection device against overheating (boiling), a thermostat against overheating of the gas exhaust device. Can be connected to both the chimney and the turbo nozzle.

Neva Lux 8224 is a double-circuit gas boiler designed for heating a room up to 240 meters2, as well as for heating water for household needs, with a throughput capacity of 14 liters per minute. Its power is 24 kW, equipped with a closed combustion chamber.

The installation method is wall-mounted, equipped with a built-in 6-liter expansion tank, this makes it possible to connect the boiler to a 70-liter heating circuit. The design provides two heat exchangers, a copper one for the heating circuit, and a second one made of stainless steel for hot water supply.

Powered by natural or liquefied gas, for ease of use it has a display that reflects the current and set temperature in the coolant.

Neva Lux 7224 - installation method: wall-mounted, double-circuit device designed for heating a room up to 240 m2, water throughput for domestic needs is 14 liters per minute. Can run on natural gas and liquefied gas, efficiency 92%.

Boiler Neva Lux 7224

Equipped with a bithermal heat exchanger, thanks to which it is possible to reduce the final cost of heat. It is equipped with an electronic self-diagnosis system, and a small display is installed on the body to indicate readings.

Neva Lux 7023 - wall mounting, designed for heating a room up to 250 meters2, as well as heating process water 13 liters per minute. It runs not only on natural gas, but also on liquefied gas; for ease of operation, you can connect a room controller.

Smoke is removed forcibly using a built-in fan; combustion air is pumped from the street. It is equipped with a closed combustion chamber, has a coaxial heat exchanger, and an expansion tank with a capacity of 6 liters.

Neva Lux 8023 is a double-circuit wall-mounted boiler that can provide heat to a room whose area does not exceed 240 m2. Liquid circulation in the system is forced, using a pump, equipped with a closed combustion chamber.

Smoke removal occurs thanks to an exhaust fan. The power of the device is 23 kW, there are two heat exchangers, the heating circuit is paramount, made of high-alloy stainless steel.

Specifications

Wall-mounted gas double-circuit boilers Neva Lux

Various modifications of Neva Lux gas boilers are suitable for heating homes, industrial and administrative buildings. Their modifications heat rooms of varying sizes. High reliability and “smart” automation have brought these boilers to a leading position among Russian manufacturers.

Specifications:

- Thanks to the powerful gas supply pump, they can work in low pressure systems. The pump itself will create the necessary conditions, depending on the settings.

- Copper heat exchangers have higher efficiency than cast iron and steel models.

- All the most important mechanisms are made in Italy. Localization of production is limited to the manufacture of the body and unimportant parts. Cooperation with foreign partners and the use of European technologies have a beneficial effect on the quality and cost-effectiveness of the product.

- Foreign technologies provide a 100% level of security.

- Easily adapt to specific operating conditions.

- The efficiency reaches up to 98%.

Thanks to the interaction of European manufacturers, the consumer is provided with a technologically advanced and reliable device of high quality.

The company's new product is the Turbo boiler

As the Lux models were used, both negative and positive consumer reviews accumulated. Over time, all the necessary adjustments resulted in the production of a separate series of heating equipment.

Neva Turbo boilers are, in fact, a modified version of the already familiar Lux modification, taking into account the shortcomings of previous versions. The models have the following technical characteristics:

- Closed combustion chamber - forced air supply is carried out using fans. Smoke removal occurs using a special device through a coaxial chimney.

Automation - gas double-circuit mounted boiler Neva Turbo, a station completely ready for operation. Heating control and safety are achieved using a multi-level system of sensors and valves. There is a self-diagnosis system that automatically performs tests and displays fault messages on the LCD display.

Controls: Simple push-button controls. Using a simple regulator, you can set the required temperature, provided that the programmer is installed, you can set operating conditions for several days or a week. A room thermostat is supplied as an additional package. The sensor sends a signal to turn off the heating when the room is heated to the required temperature.

Turbo boilers are energy-dependent. The boiler is powered by connecting to a regular 220 V mains voltage. For stable operation, you will need to install a UPS and a generator.

Ease of maintenance and operation

Regardless of the chosen model, installation of a mounted boiler is quick and without the need for additional costs. The manufacturer places the main emphasis on ease of installation and subsequent operation. Therefore, the company’s boilers, in fact, represent a station ready for operation.

It is enough to connect the installation to the heating and power supply system and start heating your house or apartment. In practice, provided the heating system is already ready, all work takes about 3-4 hours.

After installation, there is no need to worry about the safety of the station. The sequence of operation of the automation completely eliminates the possibility of gas leakage and the creation of an emergency situation, even if an unplanned power outage occurs.

Download: NEVA Lux - installation, configuration and maintenance instructions.pdf

The main differences between Neva boilers

Simple design and operation make it possible to distinguish Neva boilers among all domestic heating equipment. Today, in terms of their characteristics, boilers are in no way inferior to foreign equipment and have a more attractive price.

The Turbo modification provides economical gas consumption and, subject to proper operation, fully pays for itself within a few years.

Neva gas boilers: technical characteristics, range overview and maintenance

Currently, many people install gas boilers in their homes. These products are widely represented in heating equipment stores. Today we will talk about such devices from Neva.

Design features

Neva gas boilers are single-circuit or double-circuit equipment that has an open or closed combustion chamber. Each of these devices has a built-in thermostat. It controls the temperature of the coolant.

The operation of such units can be generated with a thermostat , which will make it possible to accurately set the temperature regime. The burner of this device has automatic equipment used to control the flame.

Such devices boast a multi-stage security system that increases the service life of heating equipment.

Each Neva boiler is equipped with a pressure gauge (a device for measuring gas and liquid pressure). Install it on the device panel. With a significant increase in temperature, the pressure in the system increases. Heating appliances from this company can operate stably even at low water and gas pressure.

These gas boilers have a screen with which you can set the required temperature. Thanks to the display, the operation of blocks and nodes is monitored. It comes with a special control panel. In one set with the device itself there is an expansion tank, a circulation pump and a detailed diagram that contains a complete description of how to install the device.

Other faults

If the device does not turn on:

- There is no power, contact the supply company.

- The fuse has burned out, you need to replace it, it is located on the board.

- A leak inside the boiler, which led to liquid getting onto the board and causing a short circuit. Dry the board on the battery or with a hairdryer and let it dry for two days.

Popping sounds during operation:

- Adjust gas pressure.

- Poor air flow in the room, clean the chimney duct, open the window or door while the boiler is operating.

- Accumulation of a large amount of soot in the burner group.

There is a smell of gas:

- If there is a gas leak, you must immediately contact the gas service.

- Low fluid pressure, contact water supply.

- If the heat exchanger is clogged, clean it using special chemicals.

Error E8 no traction

The column turns off after 2..5 minutes of operation. Restarting becomes possible only after cooling down - 2..3 minutes.

Reason #1.

Lack of draft in the chimney. Clean the chimney.

Reason #2.

Soot on the heat exchanger. Increased accumulation of soot on the heat exchanger, which prevents the passage of carbon monoxide into the chimney. To resolve the problem, the column must be serviced.

Reason #3.

The traction sensor is faulty. The traction sensor works to break. Over time, the sensor becomes very sensitive to vibrations and may turn off the column during heating. Therefore, if this error occurs, the sensor will be checked for functionality.

Air supply and flue gas removal (errors 6**)

The system for supplying air and removing flue gases generated during the operation of a gas boiler can be natural or forced. Therefore, some errors may not occur for different devices. But we'll look at them all.

Error No. 601. The draft thermostat is triggered when the contact is broken or the smoke exhaust thermostat is internally damaged. It is also possible that the air vent system is clogged.

Error No. 602. The same thing, only for VMC type combustion chambers.

Error No. 604. The Hall sensor is faulty (it needs to be replaced) or the speed of the fan blades is low (it needs to be cleaned or also replaced).

Error No. 607. The contacts of the controlling pneumatic relay were closed before the fan turned on. This detail confirms that there is sufficient draft before ignition. To eliminate early closure, you need to carefully remove the pneumatic relay and blow out its tubes, removing dirt or condensation. If this does not help, the part will have to be replaced.

The air relay is connected to the exhaust chamber with a silicone tube. Sometimes there is a condensate trap there. If the problem is with the pressure switch, then first you need to check the integrity of the tube

Error No. 610. Thermal fuse contacts are open. This part needs to be replaced.

Error No. 612. Same as error No. 604, but on early Ariston models.

Main technical characteristics and features of Neva company equipment

Please note that wall-mounted gas boilers on the market are available with open and closed combustion chambers. What does it mean? In the first case, combustion products are removed naturally, through the chimney to which the device is connected. The air required for normal gas combustion is taken from the room.

In the second case, the gas boiler is connected to a coaxial chimney, the design of which is made according to the “pipe-in-pipe” principle. Through the inner pipe, combustion products are forced out, thanks to the built-in fan, and air is supplied through the outer pipe, which comes from outside the room.

Wall-mounted double-circuit gas equipment is capable of performing two tasks aimed at heating the coolant and sanitary water. Heat exchangers are installed separately, one is designed to heat the coolant, the second is designed to heat sanitary water.

Household appliances of this type are distinguished by a wide power range, which allows you to select a unit for installation in an autonomous heating system for a house of any size

When choosing a device, it is important to consider that 1 kW is needed to normally heat 10 m2. So, if a house, for example, has an area of 200 m2

in which there is a need for hot water supply, then for the system to operate stably, efficiently and economically, you will need to buy a Neva double-circuit gas boiler of any model with a capacity of 24 kW.

How to turn on the Neva column

Automatic water heaters turn on independently. When the water supply tap is opened, the ignition unit sends a signal to produce a spark. The gas supplied to the burner ignites. After closing the water consumption tap, the column turns off.

Semi-automatic instantaneous boilers are distinguished by the fact that a pilot burner is used for ignition. To bring the column into working condition, you need to light the wick. For this purpose, a piezoelectric element is provided in the internal device. After igniting the pilot burner, the water heater continues to operate in automatic mode.

You can adjust the Neva column using water flow and gas pressure regulators. If the device has a modulating burner, the consumer sets the heating temperature, after which the electronics changes the combustion intensity depending on the pressure in the pipeline and other operating parameters.

Error H1 - insufficient heating

The column does not heat the water to the set temperature.

Reason #1. The temperature is set to high and the pressure is high. The column cannot heat the amount of water that passes through the column. Reduce pressure.

Reason #2 . The burner is clogged with dust. If you notice that the gas is burning orange and the flame is sluggish and elongated, then it’s time to clean the burner. If you neglect cleaning, this error will appear constantly. The column efficiency will decrease by half. A lot of soot will appear.

|

|

Model range of boilers Neva Lux

The luxury series, well known to consumers, is divided into two categories:

- For heating an apartment or house, a wall-mounted single-circuit Neva boiler is best suited. Instead of a DHW circuit, you can install an indirect heating boiler. The modulation burner installed in such boilers, thanks to automatically changing combustion intensity, makes it possible to achieve high efficiency of the equipment. The 8618 single-circuit gas boiler attracts buyers with its low cost and simplicity of design, as well as the absence of complex energy-dependent automation.

- The double-circuit boiler 7218 luxury series from the Neva company has extremely positive reviews due to its practicality and efficiency. Modern automation allows you to accurately monitor the temperature of the coolant and water in the DHW circuit. In addition, some models provide additional outlets for the underfloor heating system. The installed automation is capable of controlling each circuit separately. The most popular models are 7218 and 8224.

Overview of the boiler line

Model 8224 Turbo is suitable for heating an apartment up to 250 sq. m.

m The Lux model line has been updated with a new Turbo modification. This is a separate series of equipment. It was made taking into account the advantages and disadvantages of the previous modification.

Widely used models:

- For heating an apartment or house, a single-circuit wall-mounted boiler is suitable. Instead of a water circuit, you can install an indirect heating boiler. The modulation burner allows you to effectively save fuel. The 8618 boiler is attractive due to its simplicity of design and low cost. It does not contain volatile, complex electronics. Compact dimensions allow installation in small spaces. The circulation pump in the boiler makes it possible to connect to existing heating systems. It is possible to connect an indirect heating boiler, a forced smoke removal fan, or a room thermostat.

- The 7218 and 8224 Lux series are very popular among dual-circuit models. Modern automation monitors the temperature in the hot water supply and at the same time energizes the heated floor outlets. To reduce heating costs, a separate thermostat is installed to monitor the room temperature - it turns on the boiler only when the set temperature drops. Neva Lux 7218 is suitable for heating an area of 180 sq.m. The bithermic heat exchanger reduces equipment costs while maintaining user-specific features. The efficiency is 90%. The device can be converted to liquefied gas. It has a closed combustion chamber. The coolant temperature is 30-85 degrees. An electronic safety unit with permanent flame monitoring constantly checks the burner.

- Neva Lux 8224 heats 250 sq. m. of residential premises. Water cooling of the combustion chamber doubles the operating life. The microprocessor maintains the temperature level of the working environment with an accuracy of 1 degree. A copper heat exchanger is used for the heating circuit; a stainless steel one is used for the hot water supply. The ability to connect a computer has been added to the control to simplify diagnostics and equipment configuration. The digital display displays self-diagnosis information with parameters and errors.

The operation of the boiler is based on the “set it and forget it” principle. Once you set the parameters, you don't have to worry even when you turn off the power. During a long business trip or trip, the equipment is set to minimum mode and saves gas. When the gas supply stops, the boiler switches to circulation mode and circulates water around the circuit, preventing it from freezing.