home

> Roofing materials > Heat - waterproofing > Waterproofing, vapor barrier Price from 15 rubles per m2 Price may be lower under certain order conditions Buy

Price list

Today, in any modern construction site, when installing roofs, walls, facades and ceilings, polypropylene roll materials are used for waterproofing and vapor barrier of the interior of the building being built. Vapor barrier films are needed to cut off moisture and steam from the internal space into the external insulation of the roof or facade.

Waterproofing films are necessary to prevent penetration into the interior of the building (including under the roof) and into the thermal insulation. Accordingly, when constructing insulated pitched roofs (attics) or insulated frame walls of houses, both films are used: waterproofing and vapor barrier.

A diffusion membrane is a high-quality waterproofing microperforated film with vapor-permeable properties. Its fundamental difference from conventional waterproofing is precisely its ability to allow steam to pass from the insulation to the outside and at the same time not to allow moisture from the atmospheric outdoor space to enter the insulation. The term “superdiffusion membrane” means a membrane of very high quality and the presence of excellent vapor permeability of the film. Almost all manufacturers of waterproofing and vapor barrier films (including roofing films) produce all types of hydro-vapor barrier for the construction of roofs, facades and walls. On the additional pages on the left you can familiarize yourself with the range of insulating films of the most popular imported and Russian manufacturers.

Purpose of vapor barrier

Many home craftsmen ask whether a vapor barrier is needed on the ceiling. Living in any room leads to a constant increase in humidity levels. This fact is explained by the regular use of water and cooking. As a result of such events, moist steam, which is much lighter than air, rises. If there were no ceilings in the way, the moisture would easily leave the room.

However, this cannot be, therefore excess moisture settles and has a destructive effect on wood, metal, fibrous and porous materials that are directly included in the multilayer structure of any floor. As a result, dampness appears between the materials, which inevitably causes the formation of mold, mildew and rot. Such processes reduce the main operational characteristics of the floor: strength and durability. In addition, the microclimate in the room worsens, unpleasant odors appear, which negatively affects human health.

However, moisture in the room can also form for other reasons. In particular, we are talking about violations of construction technology or mistakes made at the design stage. In this case, the problem is solved using forced ventilation.

The use of vapor barrier membranes helps prevent premature destruction of construction, finishing and thermal insulation materials. The membrane is a material consisting of several layers, each of which is assigned a specific function. Such protection will be quite expensive, so if there is a budget deficit, you can look for other options.

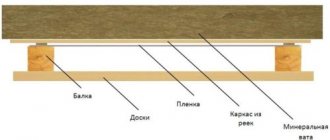

The right insulation pie

There is no need to reinvent the wheel; the vapor barrier in the house has long been thought out to the smallest detail - the correct roofing pie for a mansard-type roof is as follows:

- Interior decoration;

- A gap of 20-30 mm for air circulation (usually formed by a counter-lattice);

- Vapor barrier;

- Thermal insulation (the thickness of the insulation is the calculated value, depending on its thermal conductivity and the region of residence);

- Diffusion membrane;

- Ventilation gap 50 mm (in extreme cases, no less than 40 mm, formed by a counter-lattice);

- Lathing;

- Roofing covering.

The ventilation gaps themselves do not solve anything; air must circulate through them, keeping the structures dry. Ventilation is carried out through overhangs, covered with soffits and ridge aeration, or through dormer windows and a ridge, when installing a cold triangle.

It is impossible to lock steam in a room, set it in the desired direction and ventilate it through the vents or force it out - vapor barrier only works in tandem with ventilation of the under-roof space.

KabykiFORUMHOUSE Member

In practice, it is impossible to create an absolutely airtight structure, and this is not required - there will always be an unglued hole, cracks, and leaks. It is unrealistic to stop the phenomenon of the transition of a substance (in this case water) from one state to another (liquid, solid, gaseous). The condensation plane, also known as the dew point, is always located in the structure, from here you take a number of measures to prevent moisture accumulation - limit the flow of steam (vapor barrier) on the one hand, and ventilate the structure on the other. At the moment this is the most effective solution.

You can make a single-layer structure, you can heat it, you can install forced ventilation, but the classic vapor barrier/insulation/vent gap pie is definitely cheaper and easier to implement. I repeat - we insulate on one side and ventilate on the other. At the same time, the problem of the materials’ own moisture content is solved, which is important in our construction conditions.

When it comes to the attic floor and the cold attic, there are no fundamental differences in the insulation scheme.

- Finishing.

- Gap.

- Vapor barrier.

- Thermal insulation.

- Diffusion membrane.

- Ventilation gap.

- Sparse flooring for free movement (not always installed).

It is recommended to use a diffusion membrane over the insulation even in the case of a cold attic, as it protects against convective heat transfer, which minimizes heat loss. And in case of leakage or precipitation in the form of rain and snow, the membrane is very useful, as it will prevent the insulation from getting wet even in direct contact with water. When insulating the interfloor ceiling, both film and diffusion membrane are used. The film cuts off steam, albeit in a minimal amount, but entering the insulation through the ceiling when warm air rises upward. And the membrane will prevent particles of thermal insulation from entering the air, which inevitably occurs over time, and will protect the insulation if the floor leaks.

Types of materials

Vapor barrier and waterproofing are completely different concepts, so it is important to understand how ceiling vapor barrier works. It is a mistaken belief that the problem of excess moisture can be solved by ordinary polyethylene film. This material reliably protects walls and ceilings from the penetration of steam and water. However, condensation will accumulate on the surface of the polyethylene, which will certainly fall on the facing material covering the plastic film. As a result, the cladding is deformed and destroyed, which affects the appearance of the room.

Modern vapor barrier materials are capable of transmitting a certain amount of moisture; as a result, walls and ceilings do not suffer from this negative effect. The ability to control the release of steam from the room gives such materials a great advantage over other analogues.

Among the large number of vapor barrier material manufacturers, it is difficult to determine which vapor barrier is best for the ceiling of a wooden house. There are several popular brands: TechnoNIKOL, Nanoizol, Izospan, Penofol, Tyvek.

Modern vapor barrier is represented by several types:

- Multilayer membrane.

- Foil material.

- Perforated reinforced polyethylene film.

- Polypropylene film.

- Liquid mastic.

You can protect wooden floors with any of the listed materials. All of them have been tested in practice and have many positive reviews. However, it is better not to use coating vapor barrier for residential premises; it is the best option for outdoor structures made of concrete and brick, as well as for industrial premises.

The vapor barrier of a wooden ceiling has some features, in particular we are talking about the following:

- It is recommended to lay insulation between floor beams, and materials in slabs or rolls can be used.

- The vapor barrier material is installed in several ways: directly in front of the thermal insulation material, after it, or on both sides. The choice is determined by the characteristics of the selected vapor barrier.

- The entire surface of the ceiling, including beams, is covered with vapor barrier material.

- The steam protection must form a continuous sheet. When using several pieces, the joints are securely glued together.

- The edges of the vapor barrier material must be pressed tightly and fixed to the walls, and not to the ceiling.

Windproof waterproofing materials for facades and walls

Classic wind protection (moisture protection) is a high-density waterproofing, vapor-permeable film, which is installed under the external cladding when installing frame walls of a house or an insulated facade (ventilated facade, insulation must be on the outside). In this case, the walls can be made of any material: wood, brick, blocks, etc.

The purpose of wind and moisture protection is to protect the insulation and all internal structures of the house from the penetration of moisture, condensation and cold from the outside. Some builders also use wind protection for waterproofing insulated attics with a large roof slope (more than 35 degrees), which corresponds to the manufacturers' recommendations. However, our 10 years of experience in sales and construction of roofs and facades shows that a superdiffusion membrane with higher vapor permeability and waterproofing is still better suited for an insulated attic. Wind-moisture-proof films for facades and walls are available in the range of almost all manufacturers of waterproofing and vapor barrier materials.

| Installation of wind protection (waterproofing) of an insulated facade (ventilated facade) | Installation of wind protection (waterproofing) in frame walls |

Polypropylene and polyethylene film

The cheapest option of all the above materials are thin polyethylene and polypropylene films. However, low cost does not mean poor quality and low efficiency; such materials provide controlled release of steam from the room.

Reinforced polyethylene film can be of two types: perforated and multilayer foil. Both options are used with great success to create a vapor barrier layer in houses with wooden ceilings. The foil material simultaneously performs a heat-reflecting function. As a result, heat remains in the room, which allows for some savings on heating costs.

Polypropylene film contains hygroscopic fibers, so it simultaneously allows steam to pass through and absorbs moisture. Thus, moisture penetrates the fibers and, gradually evaporating, comes out.

Films made of polyethylene and polypropylene are presented to the consumer in roll form, which determines the method of their installation. Solving the question of how to make a ceiling vapor barrier involves performing the following steps:

- The film is cut into pieces of a certain length.

- Lay the canvases on the ceiling, making an overlap of about 15 cm.

- The joints are hermetically sealed with wide self-adhesive tape.

- Fix the edges of the vapor barrier material using a metal profile or construction staples.

Izospan V has the best vapor barrier characteristics in this group of materials. However, despite the excellent vapor permeability, this isospan for the ceiling in a wooden house has a rather significant drawback - the lowest strength characteristics. This property greatly complicates installation work. When using Izospan B, you should be careful and careful.

The material “Izospan B” is a two-layer polypropylene non-woven fabric. Its top layer has a smooth surface, the bottom layer is fibrous and rough. It is the villi that prevent condensation from penetrating into the insulation and the ceiling. When choosing this material for arranging a vapor barrier layer, you should know one feature: its installation is carried out before the insulation. When vaporizing a ceiling in a wooden house, first of all, lay the Izospan B film, pointing its smooth side down.

The process looks like this:

- The roll is unpacked and the canvas is rolled out. Measure and cut pieces of a certain size.

- The strips are laid with an overlap of 15-20 cm in the horizontal and vertical directions.

- Elements for fixing the canvas are selected depending on the material from which the decorative ceiling will be made. For example, for a plasterboard ceiling, metal profiles are used, for a ceiling covered with clapboard, wooden slats are used.

- Regardless of the material used, it is recommended to purchase self-tapping screws with an anti-corrosion coating.

- The joints of the canvases are sealed with adhesive tape, and this must be done tightly enough.

- The insulation is attached to the ceiling using plastic disc dowels or galvanized self-tapping screws.

- Another layer of Izospan V vapor barrier is installed on top of the thermal insulation.

- Finally, the finishing material is installed. In this case, a free space of about 4 mm should be left between the vapor barrier material and the decorative structure.

Technology of installation of waterproofing and vapor barrier of the roof

| Insulated roof | Uninsulated roof |

Another important point: the service life of the roof and facade directly depends on the quality of their installation. Therefore, it is essential that the seller’s company has its own construction teams and licensed practice in installing roofs and facades.

Our Company offers its customers professional installation of the roofing and facade systems of your home. When ordering roofing and facade work in full (rafter system, substructure, insulation, insulation, roofing or facade covering, gutters, etc.), all materials are provided to the customer at wholesale prices.

Foil vapor barrier

Foil vapor barrier materials consist of several layers, which ensure that several functions are performed simultaneously to create a comfortable microclimate in a living space. In particular, we are talking about vapor barrier, insulation and sound absorption.

When choosing such a material to protect against moisture and a pair of wooden floors, the consumer receives a fairly economical solution. Popular brands in this area are Alucraft, Armofol and Penofol. To understand which vapor barrier is best for the ceiling, you should take a closer look at the main brands.

About misconceptions. Differences between vapor barrier and waterproofing

The most common misconception is the use of the term “vapor barrier membrane for roofing.” An even bigger mistake is when superdiffusion membranes are classified as vapor barrier materials.

Important! Both “regular” and “superdiffusion” membranes are classified as waterproofing materials. But not to vapor barrier.

This is what the structure of insulation and the relative arrangement of insulating materials throughout the house looks like. Source guru220v.ru

The very concept of “membrane” for woven and non-woven materials means breathable properties. If a vapor barrier should prevent steam from penetrating into the insulation from the room, then waterproofing should only protect it from the penetration of water from the roof, and remove water vapor outside.

Although there are waterproofing materials with limited ability for vapor diffusion - vapor permeability.

Remember! To put it briefly, any vapor barrier does not allow water and steam to pass through, and a waterproofing membrane cannot serve as a vapor barrier for a roof.

This difference in properties determines the position in the composition of the roofing pie:

- Waterproofing is located “on top” of the insulation - on the rafters or counter-lattice (distance strip) under the roof. It protects mineral wool from condensation and leaks through leaky roof joints or its attachment points to the sheathing.

- The vapor barrier is located “bottom” of the insulation . It is attached to the inside of the rafter legs.

Classic roof vapor barrier scheme Source stroytec.org

There is only one case when a vapor barrier film is used as waterproofing - metal roofing.

Important! The peculiarity of metal tiles or corrugated sheets is that with daily temperature fluctuations, a fairly large amount of condensate forms on the inner surface of the roof almost every day.

An example is Izospan C or Izospan DM films, which the Hexa company positions as a vapor barrier - they are laid instead of a waterproofing membrane. And the Utah company produces for this case a special vapor-proof waterproofing Yutakon - a four-layer material with reinforcement and an anti-condensation coating.

And at the end of the section. If we talk about the differences between waterproofing and vapor barrier, then they can most clearly be seen using the example of Utah materials. The labeling of the main products of this and “Vapor Barrier” differs only in one letter. And the structural difference comes down to the presence or absence of a layer with microperforation.

This is what a vapor-permeable membrane looks like when magnified Source kristan.org.ua

See also: Catalog of popular plots in the Moscow region for the construction of a country house

Main characteristics and advantages of Alucraft vapor barrier

One of the best options is the Alucraft vapor barrier material with a three-layer structure. The top layer is aluminum foil, the bottom layer is kraft paper, and the connecting link between them is molten polyethylene. A special feature of aluminum foil in this material is its high tensile strength, which is ensured by the paper base. In this case, the material allows vapor to pass through and at the same time reflects the heat flow, therefore, the heat returns to the room.

The material of this brand can be called an excellent option for creating a vapor barrier layer in a bathhouse and sauna, with brick, concrete and wooden walls. As for the ceiling of a private house with wooden floors, Alucraft is the best option in this case.

All materials with a foil layer do not pose a risk to human health. They do not tend to emit harmful substances when heated or exposed to solar radiation. In addition, foil vapor barrier for the ceiling is characterized by a very reasonable cost. The material is rolled into rolls, which simplifies transportation to the site and installation work.

How to attach a vapor barrier to the ceiling

Ceiling installation includes 3 stages: waterproofing, insulation and vapor barrier. This is the last layer before finishing. Its installation is determined by the type of material used, as well as the design of the ceiling.

Fasteners for proper installation of vapor barrier on the ceiling

Construction staples are preferable for fastening the covering. They are much thinner, provide the same reliable fixation of the film, but do not violate the vapor barrier properties of the coating. Thick cardboard or other similar material should be placed under the staples.

It is allowed to use nails with wide heads. It is better to choose galvanized ones, as they are resistant to moisture and will last much longer.

Scotch tape also serves as a fastening element. It is used both for attaching film to joists and for vapor barrier of joints. In special cases, a profile is also used to connect sheets to each other.

How to install and secure different types of vapor barrier on the ceiling

In order for the vapor barrier to effectively perform its functions, it is necessary to follow all the rules for waterproofing during installation:

- during installation, it is allowed to use vapor barrier materials that are less resistant to water than waterproofing materials;

- it is very important to achieve a solid surface; for this, the film is laid overlapping, the sheets are glued with tape, and so on;

- it is necessary to exclude moisture in the vapor barrier coating; work cannot be carried out during snowfall, rain, or fog;

- when laying rolled vapor barrier, the material must first be kept in a warm room for at least 20 hours;

- The film should not be stretched too much, it should sag slightly;

- When vapor barrier corners, be sure to use solid material.

Important! When choosing different types of coatings, the list of rules is supplemented with recommendations from the manufacturer.

Description of the ceiling vapor barrier "Armofol"

Materials of this brand are divided into two types, some have one-sided foil, others have foil on both sides.

Vapor barrier "Armofol A" is a roll material with one foil layer based on a fiberglass mesh. The main purpose is vapor barrier and thermal insulation of rooms with high levels of humidity and high temperature values. Such premises include baths, saunas and catering establishments. In addition, “Armofol A” can be used to create a vapor barrier layer in private houses with wooden ceilings.

“Armofol V” is a roll-type material consisting of three layers, two of which are made using foil, the third layer is glass mesh. High efficiency was noted for vapor barrier and thermal insulation of attic spaces, as well as on wooden ceilings.

A distinctive feature of the Armofol S roll material with one foil layer is the presence of a self-adhesive base. The disadvantage of such a vapor barrier for a wooden ceiling is a decrease in efficiency when installed on uneven surfaces.

Other brands of this brand have a higher cost, so they are used quite rarely in the private sector. They are more suitable for industrial premises in which the air space is filled with vapors of acids, alkalis and other aggressive chemicals.

Features of roof vapor barrier depending on the device and the nature of its operation

There are three types of roofs:

- uninsulated;

- insulated;

- combined.

The first type does not require roof vapor barrier. Only the ceiling is insulated, so the vapor barrier is laid on the surface of the “rough” ceiling of the upper floor on the side of the heated room.

Vapor barrier of a cold attic is carried out in any case, regardless of the floor materials Source mfc04.ru

If the cold roof is not covered with a metal roof, then in some cases you can even do without waterproofing. For example, when using slate or ondulin, which has a rough (fibrous) texture - a kind of anti-condensation surface.

Insulated roofs, the internal volume of which is completely occupied by attics or occupied attics with engineering equipment, have a “continuous” roof vapor barrier device. That is, a vapor-proof film is installed from below the insulation along the rafters in a continuous and continuous layer over the entire inner surface of the roof.

If the “height” of the rafter section is not sufficient to accommodate mineral wool of the calculated thickness, a counter-lattice is installed from the inside, between which an additional layer of insulation is laid. In this case, the vapor barrier is attached to the counter-lattice.

If there is an additional layer of roof insulation, a vapor barrier is attached to its sheathing Source archi.ru

Combined roofs have a dedicated “warm” contour. It can take different forms:

- Cut off any part of the attic at a vertical level from the side of the slope or gable. In this case, the walls of such an attic space are insulated according to the principle of a frame house. And the vapor-proof film of the walls is overlapped and hermetically sealed with tape to the vapor barrier of the roof in its insulated part.

- Cut off part of the attic along the horizon . In this case, the attic has “its own” cold attic, which is insulated along its ceiling. And the vapor barrier is sewn from below to its ceiling (or false ceiling) and connected with tape to the vapor-proof film of the insulated part of the slope.

The vapor barrier of the attic roof is carried out along the insulation contour Source prorab.help

Characteristics and advantages of Penofol vapor barrier

The materials of this brand are very popular for creating a vapor barrier on the ceiling in a wooden house. The structure of such vapor barrier materials contains a thin aluminum film and polyethylene foam. Modification “A” has one foil layer, materials of group “B” have two layers of durable foil, models of group “C” have an additional adhesive base.

To solve the problem of how to properly make a ceiling vapor barrier, you must follow the following rules:

- The foil layer should be facing indoors towards sources of heat and moist steam.

- It is recommended to lay the panels end-to-end, trying to avoid gaps.

- The joints are hermetically sealed with adhesive aluminum tape.

- To create additional thermal insulation, the sheets are laid with an overlap of 10 cm.

- When using materials with double-sided foil, care should be taken when dealing with low-quality electrical wiring close together. It is important to remember that foil is an excellent conductor of electricity.

Delta-Duo Tape for vapor barrier

When installing vapor barrier films on the ceiling, all joints and overlaps must be taped. Reinforced polyacrylic tape Delta-Duo Tape allows you to hermetically connect overlapping panels of vapor barrier films. Delta-Duo Tape is also used for reliable connection of waterproofing films and membranes. The tape has a high adhesive force, has longitudinal-transverse reinforcement and a width of 38 mm.

Delta-Duo Tape for vapor barrier

The scope of application of this tape is the connection of various roofing membranes: vapor barrier, waterproofing and wind protection. Can be glued to smooth wood, OSB or metal surfaces at temperatures above +5° C.

Vapor barrier membrane for wooden ceilings

The most effective and at the same time expensive solution to the question of which vapor barrier to choose for a wooden ceiling can be called a diffuse membrane. This material is available in two types: single-sided and double-sided. When using the first option, you should carefully perform the installation, since such material allows wet vapor to pass through only in one direction. Therefore, one should not confuse which side should be adjacent to the load-bearing surface and which should be adjacent to the insulation. Double-sided material allows steam to pass in both directions, so installation work is not particularly difficult.

When deciding which vapor barrier to choose for the ceiling, you should know that membranes can be single-layer or double-layer. In the first case, the distinctive feature is low cost and simple operating principle. The second option is characterized by the ability to accumulate moisture inside the canvas and gradually remove it outside.

The “smart” membrane attracts special attention in this product category. This material simultaneously absorbs steam and serves as a kind of hydrobarrier, regulating the level of humidity in the room. This is the best option for vapor barrier of wooden ceilings of private houses, however, their cost is at a fairly high level, so most consumers cannot afford such materials.

Application of varnishes and mastics

Mastics and varnishes are applied to concrete floor slabs. Their purpose is the same as that of rolled materials, i.e. they protect the insulation from moisture getting into it. The application technology is simple: using a brush or spatula.

Before starting work, you should carefully read the attached instructions, paying special attention to the temperature conditions for the work. Solvents used in varnishes and mastics are fire hazards, so special attention should be paid to preventing fires.

Membrane "TechnoNikol" for the ceiling

The leading position among vapor barrier materials is occupied by the TechnoNikol membrane. Her brand “Optima” is excellent for vapor barrier of the ceiling in a house with wooden floors. The structure of this material contains three layers, two of which are made of polypropylene, the middle layer between them is a high-tech functional vapor-permeable film. Membranes of this brand are in most cases presented in roll form up to 1.5 meters wide and 50 meters long. The material is the best option when creating a vapor barrier layer on any type of floor. Can be used both indoors and to protect the external surfaces of a building.

Installation of a vapor barrier on a wooden ceiling is carried out according to the following scheme:

- The membrane should be laid on top of the thermal insulation, with the smooth side facing the inside of the room.

- The stripes can be located in a parallel or perpendicular direction relative to each other.

- The strips are installed with an overlap of 10-15 cm.

- To fasten the membrane, it is recommended to use galvanized self-tapping screws with a wide head or special brackets that have an anti-corrosion coating.

- The joints of the canvases are hermetically sealed with mounting tape with a self-adhesive side.

- The edges of the membrane sheet must be placed on the wall by 15-20 cm and secured with a wooden strip or metal profile.

- The perimeter of the vapor barrier layer is also taped with mounting tape.

- In areas where the membrane will come into contact with beams, pipes and ventilation ducts, care and attention should be exercised. It is important that the vapor barrier does not have folds or sagging.

- A gap of about 3-4 cm should be left between the vapor barrier membrane and the decorative ceiling for ventilation.

In addition to the main listed brands, there are other materials on the market for ceiling vapor barrier. Their quality characteristics and efficiency are also at a high level.

Manufacturers

There is a huge selection of films from different manufacturers on sale. At the same time, high-quality vapor barriers can be found not only in time-tested brands. This means that when choosing a little-known supplier, there is a risk of receiving material that is not of the same quality as planned.

No, not a marriage, but a combination of characteristics. The conclusion is simple: either you need to have a recommendation from acquaintances, friends or professional builders regarding an unpromoted brand, or you still need to buy a product from a well-known company.

Promoted brands include:

"Izospan" - produces polypropylene films of all types (A, B, C, D, F). Products:

- elastic;

- UV resistant;

- with a wide range of operating temperatures;

- environmentally friendly.

You can buy "Izospan" DM for 44 rubles/m2, "Izospan" C - 25 rubles/m2, "Izospan" FB - 35 rubles/m2.

"URSA SECO" (). Under the URSA SECO brand, membranes of type A and AM, films B and D are produced. These are high quality products designed to protect various structural elements of a building from steam. Effectively performs its assigned functions throughout the entire service life of the insulation.

Membranes can be purchased from 110 rubles/m2, films in the range of 11-19 rubles/m2 (depending on the density of the material).

"TechnoNIKOL". For the ceiling, a universal film is used, consisting of 3 layers, the top and bottom of which are polypropylene. Price 1 m2 - about 20 rubles.

"Axton" is a trademark of the French company Leroy Merlin. Membranes (type A) and films of types B, C and D are produced. For the ceiling you need to buy membranes (price starts from 21 rubles/m2) and film type B for 15-17 rubles/m2.

In addition, the following companies should be noted:

- "Ecolife";

- Tyvek;

- "Utah";

- "Ondytis".

Sometimes they talk about such criteria as resistance to ultraviolet radiation and the possibility of leaks under the weight of rainwater. Such characteristics have nothing to do with the ceiling.

Laying waterproofing

Places of application: insulated roofs, structures with external insulation, suspended ventilated facades, attic floors.

How to lay: in the middle between the insulation and the outer cladding, the rough side towards the thermal insulation, the smooth side out. Often there is a manufacturer’s logo on the waterproofing; such a film should be attached with the logo facing out.

Characteristics: water resistance - from 300 to 1000 mm water column, vapor permeability - from 800 to 2000 g/m2 per day, tensile load - from 160 to 190 N/50 mm.

What do errors in terms lead to?

Manufacturers' marketers are interested in increasing sales of vapor barrier films and waterproof vapor-permeable membranes. They advertise their properties in every possible way, coming up with various names. Thus, the complex word vapor-waterproofing was created, which led to confusion of the characteristics of two completely different materials used to solve opposing problems.

Due to this, building owners can allow the installation of vapor barriers on both sides of the wall structure, when moisture cannot escape from the building elements and will create increased dampness and their destruction.

An even worse situation with moisture occurs when the location of the vapor barrier, which was installed outside the wall, is confused with the vapor-permeable membrane installed inside the room.

Then all the moisture from the room is directed into the wall, and its exit is blocked. As a result, mold, fungi, and dirt form.

The installation of protective film coverings must not be interchanged. They perform different, opposing functions.

Advantages and disadvantages of ceiling insulation with penofol

Today the product is very popular due to its versatility and easy installation. Masters also appreciate it for the following qualities:

- The material is lightweight, making it ideal for work performed at heights.

- To lay penofol on the ceiling, no special equipment is needed.

- The metal coating does not allow steam and water to pass through, does not absorb liquid and is not destroyed under its influence, so it is indispensable in damp rooms, for example, in baths. It does not require additional protection with hydro- and vapor barrier membranes.

- The material performs several functions. Once attached to the ceiling, it not only retains heat in the apartment, but also dampens sounds transmitted through the air or through the ceiling. It is often used with other products to increase thermal insulation properties. For example, in saunas it additionally maintains the temperature by reflecting heat.

- When heated, it does not emit harmful substances. In its production, the same polyethylene and foil are used that are used in the food industry.

- After installation, the distance between the floor and the ceiling decreases slightly. A 1 cm thick canvas can be used instead of 8 cm thick mineral wool or 4 cm thick polystyrene foam, so insulation is often used in rooms with low ceilings.

- The sheets are sold rolled up, which makes installation work easier.

- The product does not burn and is often used in fire hazardous areas.

- Rodents don't like him.

Penofol has few disadvantages. Negative factors include the high cost of the material and the need to use other insulation materials to improve the result. It is also glued to the surface to ensure the integrity of the coating, which increases financial costs. The material is soft, so it cannot be used if plastering or wallpapering is planned.

How to properly install a vapor barrier on the ceiling: step-by-step instructions

The finished vapor barrier in appearance resembles a pallet with sides. The coating should cover not only the insulation on the ceiling, but also the gap between the heat insulation and the walls. In addition, the film must cover each beam.

The first stages of finishing the ceiling are carried out as usual. The wooden surface is cleaned, treated with antiseptics and fire retardants, and communications are installed. Then the ceiling is waterproofed and insulation is laid on it.

- Laying begins from any wall. The roll or sheets are cut to size and secured to wooden beams with staples. In this case, a gap must be maintained between the heat insulator and the vapor barrier. If necessary, pre-attach the sheathing.

- The film or membrane must cover each beam. There are two ways to do this. A simpler option involves fastening the material around the beams. In this case, the canvases are laid perpendicular to the beams, taking into account some recess into the interblock space. If the length of the film is not enough, gluing the vapor barrier is allowed.

- Another option: cut the film into fragments of the appropriate size; you need to wrap each compartment separately. All seams and joints are additionally taped with tape. As a rule, this method is used for vapor barrier of panel-box ceilings. Laying is done with an overlap. The tolerance on walls is 10–15 cm.

- The joints are sealed with tape according to the following scheme. First, glue the seams between the canvases. To do this, bend the overlap, secure the edge of the vapor barrier with tape, then remove the protective strip from the adhesive tape and attach the overlap on top. The joints with the wall are sealed in the same way. In this case, you cannot stretch the film; it should sag by about 2 cm.

- Then the second and third layers of vapor barrier are laid, following the same rules. Make sure that the joint of the next layer does not coincide with the seam on the first layer. The displacement should be at least 30–40 cm.

Foil material, especially sheet material, is mounted according to a different scheme.