The popularity and high demand for Buderus gas boilers is partly based on the relatively low cost of the equipment.

But the main factor determining preference among users is the high level of design and assembly, traditional German quality of components, precision and thoroughness of development.

Most owners, after purchasing a boiler, are not ready to operate such equipment due to an outdated approach to the operation of heating products.

The prevailing idea in people’s minds is that it is enough to turn on the boiler and no additional measures will be needed.

However, complex technology requires an understanding of the developers’ logic and design features, otherwise it will not be possible to achieve high efficiency and long service life.

How to set up a Buderus gas boiler

The basic adjustment of Buderus boilers is carried out at the manufacturer. After purchase, you only need to make some adjustments necessary for the most efficient operation of the unit under the given conditions .

As a rule, it is necessary to set operating limits for gas pressure and heating water temperature.

Gas supply parameters are adjusted using the adjusting screws of the gas fittings, while simultaneously monitoring the result of the actions on the control panel. A U-shaped pressure gauge is connected to the measuring fitting, with which the gas pressure limits are determined.

At this time, you need to start service mode 1.2.F (maximum performance).

Temperature setting is done from the control panel . By pressing the “-” button, winter mode is called up (the heating circuit is turned on).

Then press the “OK” button, the temperature of the extract air (direct or supply line) will then appear on the display.

Using the “+” or “-” buttons, enter the required values and press the “OK” button again.

To set the summer mode, the same steps are performed, only when setting the value, press the “-” button until dots appear on the display. Then press “OK”, the crossed out radiator icon will be constantly lit on the display, indicating that the coolant heating is not functioning .

Manual recharge scheme

The easiest way to replenish the heating circuit with water is to refill it manually. In order to fulfill it, it is necessary to stretch a pipeline from the city water supply and connect it to the return line of the heating network. A shut-off valve and a water purification filter are installed in this area.

The scheme functions perfectly in simple heat supply systems for one-story small-area households. The line is connected to the return line before the circulation electric pump, since this section has the lowest pressure and temperature of the network water.

For open heating networks, the make-up system organizes the supply of water not to the return, but directly to the expansion tank. To do this, you do not need to go into the attic to check the recharge level. According to the diagram, the expansion tank is connected with 3 independent terminals: make-up, supply and return pipelines.

The level in the tank is controlled by opening the valve on the control pipe directed to the sewer. When water flows after opening the valve, this means that the system is full; if not, the make-up valve opens, which is kept open until there is overflow from the control pipe.

How to start the device correctly

The first start is made after connecting all pipelines:

- Direct (left) and return (right) lines of the heating circuit.

- Hot water supply.

- Gas pipeline.

In addition, you need to connect the power supply using a special socket with a grounding electrode.

The boiler electronics are very sensitive to voltage surges or surges, so it is important to protect the control board from them.

You must use a standard voltage stabilizer manufactured by Buderus, or something similar (which is somewhat worse).

The boiler is started either when it is first turned on or after the summer break.

In both cases, you must first fill the system with water . Checking the pressure gauge readings, fill the system to a value of 0.8 bar. The standard operating pressure is from 1 to 2 Bar, but it must be taken into account that when heated, the volume of water will increase, which will cause a rise in pressure.

After this, set the required coolant temperature on the control panel, which will cause the burner to start and the boiler to start operating.

Before turning on, it is necessary to bleed the air from the radiators using Mayevsky taps, otherwise an error will appear during startup. It is reset by pressing and holding the “OK” button, after which attempts are repeated until a positive result is obtained .

It is impossible to fill a hot heat exchanger with water, as this can lead to cracks and failure of the unit. Before filling, you must wait until the boiler has cooled down, and only then fill the system.

What functions does it have?

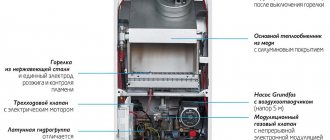

Wall-mounted boilers Buderus Logamax u072 24k are double-circuit models of gas units.

They are capable of simultaneously heating the house (preparing coolant for the heating circuit) and preparing hot water for domestic needs. The letter “K” in the boiler marking means “Combined”, i.e. double-circuit.

The range of boiler functions is quite wide:

- The ability to independently detect problems using a self-diagnosis system.

- There is protection against freezing of the system.

- All models are adapted to Russian technological conditions.

- The electronic ignition function makes using the boiler much more convenient.

- The flame is constantly monitored; if it disappears, the boiler operation is immediately blocked.

- When installing additional devices, it is possible to control the operation of the boiler via a smartphone.

The functionality of boilers is abundant; according to some owners, it is even somewhat redundant.

All capabilities are implemented through a control board, the operation of which is similar to the actions of the brain of a living organism.

A system of sensors distributed across all units of the unit constantly monitors the operation and immediately signals the occurrence of malfunctions, failures or breakdowns.

IMPORTANT! Buderus Logamax u072 24k boilers are sensitive to power fluctuations, which can cause the control board to malfunction and cause a series of errors. To eliminate this possibility, you should use a voltage stabilizer that ensures that the power supply remains constant.

How to turn on after shutdown

The boiler is turned on by pressing the corresponding button . If the shutdown occurred due to external reasons (lack of gas in the main line, water or electricity outage), then you must first make sure that the supply of the necessary resources is restored.

If any components or parts fail, causing the boiler to shut down, the cause must first be eliminated - replace or repair the problematic component or part, restore oxidized contacts, etc. Otherwise, the boiler will not start, and the installation will immediately be blocked by the self-diagnosis system .

Basic faults

The design of Buderus boilers was created on the basis of the most advanced technical developments.

They are stable in operation, but no insurance has yet been invented against the occurrence of malfunctions . Buderus boilers are equipped with a self-diagnosis system, which is a network of sensors connected to the most important and critical components or parts of the boiler.

The operation of all elements is constantly monitored by these sensors; if any inconsistencies or changes in the normal mode occur, an alphanumeric code for a particular error appears on the display. In addition, other malfunctions are possible.

Let's look at the most common:

- The burner does not light. The reasons for this may be disconnected starters of heating or control systems, failure of circuit breakers, failure of the boiler regulator or temperature limiter. The boiler may be blocked due to problems with the flue gas control equipment.

- The burner turns on, but immediately gives an error. Most often, the problem is a closed gas valve, or the presence of air in the gas pipeline. In both cases, you need to open the valve and let out the air.

- After the burner starts, a signal indicating the absence of ionization current appears. Usually the problems are oxidation of the contacts or mixed-up connections of the “N” and “L” electrodes. It is also possible that the ionization electrode is shorted to the housing or the burner automatic is broken.

- After ignition, the burner gives an error - the current is less than 1.5 mA. Here the cause may be oxidation or the appearance of soot on the ionization electrode, which should be cleaned.

- Boiling sounds are heard from the heat exchanger. This is a sign of the appearance of a thick layer of scale, or an insufficient amount of coolant in the system.

IMPORTANT!

Troubleshooting should be carried out by service center employees. Solving problems on your own can increase them many times over.

Familiarization with technical characteristics

Below we discuss the main parameters of the products of the most popular “Logano” series. The information is provided in the form of a comparative table to make it easier to make a choice. All models are made of steel or cast iron, as these materials have the most suitable properties.

Logano G221 products presented.

Having made preliminary calculations of the heating system for the building, you can familiarize yourself with the technical data of the boilers.

| Products | Power in kilowatts | Efficiency in percent | Pressure in bars | Material |

| S111-2 | 12-45 | 86 | 2,5 | Steel |

| S121-2 | 21-38 | 85 | 2 | Steel |

| G221 | 20-40 | 78 | 3 | Cast iron |

| G221A | 25-30 | 80 | 4 | Cast iron |

The Logano S121-2 boiler is demonstrated.

Recommendation! When operating boilers operating on solid fuel, it is necessary to use firewood whose humidity does not exceed 20 percent. Otherwise, the power of the devices will be noticeably reduced.

All main error codes and their interpretation

Let's look at the main error codes for Buderus boilers:

| Code | Decoding | Ways to fix the problem |

| H11 | Problems with the DHW temperature sensor | Check the contact group, determine the functionality of the sensor, and replace if necessary |

| 2P | Coolant overheating | Check the contacts, determine the condition of the circulation pump |

| 3A | Fan stop | Check the contacts, replace the fan with a new one |

| 4C | Heat exchanger overheating | Stop the boiler, check the functionality of the circulation pump and the extract air temperature sensor, call a technician |

| 4U, 4Y | Short circuit or break in the forward line (supply) temperature sensor | Check the condition of the sensor and contacts, clean and reconnect them, if necessary, replace the sensor |

| 6A | No flame | Check the presence of gas in the system and in the boiler equipment, call specialists |

| 3C, 3L, 3P, 3Y | Fan failure | Check connection and functionality, replace |

| 6C | The system sees a flame on an idle burner | Moisture on contacts or control board, poor ground contact |

How to start a boiler

To turn on the boiler, use the “On” button located on the control panel.

For normal operation of the unit, it is necessary to correctly connect all power supply electrodes, it is especially important to have a connected grounding electrode.

NOTE!

If it is not there, the operation of the ignition equipment and control board will become impossible, which is why the boiler will either simply not start, or will immediately generate an error and be blocked. The use of conventional sockets for connecting is excluded; special samples with an active neutral are required.

User manual

Operating the boiler is not particularly difficult . The user is not required to perform any special actions other than the current temperature setting or switching the boiler to winter or summer mode.

In addition, in the summer you need to drain the water from the heating system, and at the beginning of the next season you need to fill the system again. This is also performed by the user, guided by the readings of the pressure gauge on the unit body .

If an error appears on the display, you must reset it by pressing the “OK” button and holding it in this position until the error disappears.

This is done because the control panel often perceives voltage surges as signals from the corresponding self-diagnosis sensors. If it appears again when you restart it, you need to call a technician.

Download instructions

Download instructions for Boderus gas boilers.

Positive qualities of the device

Products of this type are produced by the German company of the same name, which began its activities back in 1731 with the production of cast iron for its subsequent processing. At the end of the 19th century, the company began producing sectional boilers for heating systems. Such a long period of existence indicates the seriousness of intentions in the field of thermal technology.

If we talk about the advantages of devices for heating coolant, then first of all we should highlight the most basic of them.

- A long period of operation is ensured by the design itself, which assumes low tension in the base unit.

- The high efficiency of the units makes it possible to organize the most efficient heating systems for homes and technical premises.

- The high quality of the equipment is explained by the accumulated experience in the field of heating devices.

- Due to the wide range, you can choose the right product for a specific situation without much difficulty..

- The price of products varies in a fairly decent range , due to which the number of consumers is large.

- A high level of safety makes it possible to avoid situations that could lead to a fire.

- Due to the ease of installation, all work can be done with your own hands , thereby saving financial resources.

- Long-lasting combustion is achieved due to the design features of the devices.

This is how the boiler looks in a modern interior.

Note! An additional advantage that Buderus solid fuel heating boilers have is their ease of maintenance. All details of the device are thought out to the smallest detail.

Service

Buderus boilers are serviced by specialists from service organizations.

It must be done annually; the necessary procedures include cleaning the heat exchanger, removing soot from the chimney, inspecting and adjusting the contacts of the control board.

It is not recommended to perform independent maintenance of the boiler; you can only clean the body of dust or soot that appears on it during operation.

IMPORTANT!

Carrying out any work on your own is regarded as termination of the warranty agreement by the owner, therefore, for repairs or maintenance, you must use the services of technicians from the warranty workshop.

Cost of work for YouDo performers

Engineers in Moscow, registered on YouDo, provide a full range of services for the installation of electric boilers. When designing, specialists take into account the specifics of the heating system, equipment design, and room features.

Our technicians strive to ensure that you are satisfied with both the quality and price of the installation. That is why YouDo performers offer favorable rates, which in some cases are set by agreement. The cost of installing electric boilers depends on parameters such as:

- complexity of work

- installation duration

- price for equipment and components (all materials are paid separately)

Installation prices may depend on the type and model of the electric boiler. Often the master needs to carry out additional communications in order to connect to the network. A specialist can also remove old equipment for replacement. In these cases, the total cost of the work will be higher.

Before ordering the help of a YouDo performer, you can find out how much their services cost. You can ask a specialist questions about prices and terms in a chat on YouDo, as well as compare the prices of several specialists to choose the right contractor.

There are no intermediaries between you and the private master, so the tariff can be set by agreement, this allows you to save money. Contact the YouDo contractor to install an electric boiler inexpensively and enjoy a comfortable room temperature. The specialist will perform all the necessary work at a high professional level.