Thermal insulating materials help to save on heating in winter, maintain a comfortable temperature in summer, prevent the appearance of mold and mildew, and provide sound insulation. Mineral wool has been used for this purpose for a long time, and it has not lost its relevance in the modern world.

Facade wall insulation with mineral wool is in great demand among owners of private houses

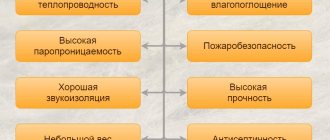

Basic properties of mineral wool

Mineral wool is used to insulate walls indoors and outdoors. This became possible thanks to the following insulation properties:

- Low level of thermal conductivity , due to which heat loss is minimal, and in the hot season, the air temperature outside has virtually no effect on the atmosphere inside the room.

- Non-flammability . Withstands high temperatures and does not ignite. When smoking, no toxic substances are released.

- Vapor permeability . The material is capable of releasing absorbed steam into the atmosphere, thereby preventing the proliferation of pathogenic microorganisms.

- Soundproofing . The fibrous structure of mineral wool perfectly retains extraneous noise, preventing it from penetrating into the building.

- Chemical passivity . Thanks to this, corrosion does not develop when the metal comes into contact with the insulation.

Mineral wool is absolutely fireproof, has high vapor permeability and good water-repellent properties.

Before insulating a house with mineral wool, it is worth studying all its pros and cons, and determining whether it is rational to use it specifically in your case.

Advantages

The advantages of thermal insulation material are obvious, as they arise from the technical characteristics:

- high level of thermal insulation due to low thermal conductivity coefficient;

- safety for human health due to fire safety and resistance to aggressive substances;

- durability due to high strength;

- ease of installation due to the flexibility of the material;

- versatility - suitable for all types of surfaces (wood, aerated concrete, etc.), in addition, mineral wool is used not only for facades, but also for attics and floors.

When choosing a thermal insulation material for your future building, you need to familiarize yourself with all its advantages and disadvantages.

Based on the listed advantages, insulating facades with mineral wool is a fairly effective method of thermal insulation, which helps to save significantly.

Flaws

Along with the visible positive aspects, mineral wool also has certain disadvantages that limit its range of use:

- during installation, you must strictly adhere to the recommendations of the material manufacturer;

- despite the low level of hygroscopicity, cotton wool is capable of absorbing moisture, which negatively affects its quality characteristics, so it is necessary to take additional care of waterproofing;

- the abundance of offers on the market creates the risk of purchasing low-quality products that can be toxic and therefore dangerous to human life;

- Due to the peculiarities of the structure, it is important to carry out insulation work in special clothing in order to protect the mucous membranes and skin.

- the price of mineral wool is higher than that of polystyrene foam, but the cost is justified because its quality and strength characteristics are higher.

Mineral wool is often used to insulate floors and roofing structures.

The disadvantages are very conditional and by choosing high-quality mineral wool, as well as following the technology for its installation, you can achieve excellent results.

Stone wool Green Guard Universal

There is a large selection of various thermal insulation on the market, including stone wool in a wide range, so why should you choose Green Guard Universal?

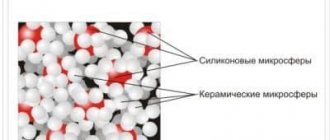

These non-flammable basalt fiber slabs combine minimal thermal conductivity with a high sound insulation coefficient, which is achieved by a special arrangement of fibers and a density of 35-40 kg/m³. Low density in this case means lightness, a large amount of air inside and water resistance. The insulation is designed for use in non-load-bearing structures, which includes ventilated facades, and is capable of maintaining its performance properties for a hundred years. The latter is proven by the results of tests carried out according to the GOST method.

Another important indicator is the environmental friendliness of the boards; they are produced using a biopolymer binder and meet all domestic and European environmental standards.

That is, when using this universal thermal insulation, the house will be protected from both heat loss and extraneous noise, which is often no less important. Both during installation and during operation, the material does not emit harmful substances into the air. And thanks to the light weight, there is no need for additional fixation - it is enough to maintain the correct step between the lags to install the slabs sideways.

Specifications

- Thermal conductivity coefficient is 0.035-0.037 W/(m·C).

- Compressibility (based on volume) – no more than 30%.

- Vapor permeability – not less than 0.3 mg (m·h·Pa).

- Density – 35-40 kg/m³

- The content of organic substances (by weight) is no more than 2.5%.

- Flammability – non-flammable (NG).

- Service life – up to 100 years.

Types of mineral wool

Mineral wool is divided into separate types, depending on the raw materials that were used in the production process:

- slag;

- fiberglass;

- rocks.

Many people are concerned about the question of what is better: basalt wool or mineral wool. In fact, the first is a subtype of mineral insulation. It is important to understand the difference between basalt and basalt wool. The difference is that the first is a rock, which is only one of the components of the thermal insulation material, and the second is the insulation itself.

A comparative table will help you to clearly see how basalt wool differs from mineral wool in properties and operation.

| Minvata | Basalt wool |

| The density of mineral wool is low, which affects the moisture absorption coefficient, therefore, to maintain the thermal insulation characteristics, it is necessary to additionally lay special membranes. | The difference between basalt wool in this aspect is significant. High density increases thermal insulation characteristics and also extends the service life of the insulation. |

| Due to the pliability of the material, it is easy to transport and quickly restores its original shape. | This insulation is produced in the form of slabs, so the conditions for its use are limited. |

| It is very easy to install, since the long, soft fibers do not break or fall off. | Basalt - inelastic, mineral wool can crumble during installation and cause irritation of mucous membranes. |

Before starting insulation work, you need to decide on the choice of insulation: choose basalt or mineral wool. When

choosing which is better: basalt or mineral wool, you must take into account the operating conditions, the required degree of thermal insulation, and the characteristics of the room to be insulated.

The best manufacturers

There are a large number of mineral wool manufacturers represented on the construction market. At the end of the year, the most popular brands were named:

- ROCKWOOL insulation . The manufacturer's products have a high level of thermal insulation and sound absorption. It is absolutely safe for humans, which makes it possible to use it even for insulation of public institutions. The high quality characteristics of the material made it preferred, which influenced the cost. According to experts, the technical characteristics of Light Butts from Rockwool rightfully allow it to be called one of the best.

- TechnoNIKOL is a leading manufacturer of inexpensive mineral wool. It is very convenient to install, but if installation rules are not followed, the sheets may break. Basalt wool from the manufacturer has excellent vapor permeability.

- The ISOVER brand is also well known on the building materials market . The manufacturer offers stone and glass wool, which are environmentally friendly and safe. The insulation properties of the materials are excellent, and the price is quite reasonable.

Thermal insulation basalt wool Rockwool Light Butts Scandic

Also, experts highlight such manufacturers as PAROC, KNAUF, URSA. Products from these brands are often used to insulate log houses and other buildings.

The listed heat insulators retain heat well and are easy to install. These are quite expensive materials, but their price is consistent with the quality.

Experts highlight the Beltep brand among mineral wool for facades in the mid-price category. Fire safety, excellent level of vapor permeability, good rigidity and ease of installation, combined with an affordable price, have made the Belarusian manufacturer very popular.

Work order

Preparing for insulation

For stone buildings (made of brick or foam blocks), you need to inspect the facades, remove mortar build-ups, and repair cracks, significant chips or potholes with a repair compound.

A log house, especially an older one, requires more careful preparation. First, you should check the condition of the gaps between the logs or beams, remove debris from there, and, if necessary, remnants of tow, replacing it with a special cord for filling the seams and sealant. Having cleaned the facade of mold, moss and rot, you can treat it with antiseptic impregnation.

If there is no ventilation system, it is recommended to install ventilation valves near the windows before insulation. Unlike those found in city apartments, they must work in both directions, i.e., ensure both the supply of fresh air and the removal of exhaust air (and along with it, excess moisture). They are needed only in houses with year-round living: in the summer there is no particular need for them (you can get by with ventilation through the windows). However, if you have an air conditioner installed, adjustable valves for air inlet and outlet will be needed during the warm season.

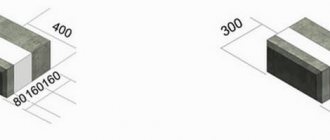

Installation of sheathing

The frame of the ventilation facade is usually made of timber 50 x 50 or 100 x 50 mm, it is mounted vertically to the wall at a distance of 600 mm (in the clear). The guides are fastened with galvanized or yellow-passivated self-tapping screws (into wood or dowels, depending on the wall material) with a pitch of 400 mm. When installing on a dowel, holes are pre-drilled in timber or masonry (aerated concrete, brick, etc.).

Insulation

Between the bars, installed at intervals of 600 mm (in the clear), IZOVER Warm Walls Strong mineral wool slabs fit perfectly without fasteners. If the pitch of the sheathing is non-standard, the insulation must be cut, leaving an extra 10–15 mm on the sides for installation by surprise (the allowance is added after measuring at the widest point). For cutting, take a knife with a blade length of at least 150 mm. The best option is a special ISOVER knife.

If two layers of insulation are required, the guides of the second are attached horizontally to the bars of the first. Such a need may arise, for example, if the calculated thickness of the insulation is insufficient to achieve maximum energy efficiency (if the heating is electric) or during construction in the northern regions, for which the thermal calculator gives a mineral wool layer of more than 100 mm. Sometimes two layers are installed instead of one (for example, 50 + 50 instead of 100 mm) in order to increase the efficiency of insulation: horizontal slabs cover the wooden frame, minimizing the number of cold bridges.

Hydrowind protection

The ISOVER Vetranet membrane (vapor-permeable, i.e. “breathable”) is mounted close to the insulation and secured to the guides with a construction stapler. The roll should be rolled out horizontally, from left to right. Installation proceeds from the bottom up to create an overlap between the sheets, protecting the insulation from drops of condensation flowing down. The membrane sheets are slightly stretched, preventing the formation of waves. The overlap between adjacent sheets should not exceed 150 mm, otherwise vapor permeability may decrease. It is important to ensure that the logo marking is always facing the street, since the membrane is maximum vapor-permeable only in one direction. In addition, the outer side is more resistant to ultraviolet radiation.

Ventilated gap

Its width should be 40–50 mm. To install a ventilation gap, a series of vertical counter-lattice bars of the appropriate cross-section are attached on top of the hydro-windproof membrane.

To remove water from entering the gap, a drip tray is installed below, and to protect against mice, rats, and other small animals, a galvanized mesh with a cell of 5 x 5 mm is installed.

Facing

Features of its installation depend on the type: at this stage you need to follow the instructions from the instructions supplied by the manufacturer. So, wooden lining or vinyl siding is nailed with galvanized nails directly to the guides.

Corrugated sheeting or steel siding is mounted on a metal substructure, which is attached to the load-bearing walls with special brackets. They are installed first, then a wooden sheathing is installed using the method described above, mineral wool is inserted, and the membrane is pulled. Finally, galvanized steel guides are hung on the brackets and the steel cladding is attached to them. The length of the brackets is selected so that it is enough for the ventilation gap.

A ventilated facade is the most modern and technologically advanced method of insulation in private and industrial construction. It provides effective, reliable thermal protection for the house without significantly increasing the thickness and weight of supporting structures. The system can be installed at any time of the year, since the technology does not contain wet processes and frosts do not affect the result. The mineral wool used inside the ventilation facade lasts for decades without collapsing or losing its properties.

When is insulation necessary?

Insulation of warehouses, houses outside with mineral wool or industrial premises is relevant in a region with any climate. Installation of thermal insulation material will not only maintain a comfortable temperature, but will also provide excellent sound insulation. Insulating walls from the outside with mineral wool can be done under plaster, siding or other methods. The main thing is to follow the installation rules in order to achieve the desired result and avoid shrinkage.

Installation of insulation under siding

Tools for work

Before you start insulating facades with mineral slabs or roll material, you need to prepare all the tools for the job:

- timber or metal profile;

- level and tape measure;

- hardware: screws, dowels, self-tapping screws;

- metallized tape and knife;

- membrane materials;

- primer;

- finishing material;

- hammer drill or drill;

- screwdriver or screwdriver;

- hammer.

Having everything you need at hand, having chosen the insulation of the required thickness, you should choose an option for finishing the facade of the house.

Types of facade finishing using mineral wool

Insulation of the building facade with mineral wool is carried out for various finishing options. The choice will depend on the features of the structure, as well as the personal preferences of the owner.

Wet facade

For a wet facade, mineral wool is ideal as insulation.

The most common finishing method is plastering, or the so-called wet facade. Insulating a residential building with mineral wool in this way ensures contact of the insulation with the walls. Additionally, by using dowels, you can guarantee the strength of the material. After plastering, the surface can be subjected to additional finishing.

Ventilated facade

Insulation of a ventilated facade with mineral wool

Insulation of a building facade with mineral wool using a pre-prepared metal profile frame is called a ventilated facade. This method provides for the presence of air space between the wall and the insulation, which ensures drying of the walls, that is, natural ventilation. This option significantly extends the service life of the heat-insulating material. The peculiarity of the process is that the procedure should be carried out exclusively on flat walls.

Facade cladding with siding

Insulating the outside of a house with mineral wool for siding

Insulating the outside of a log house with mineral wool is almost always accompanied by finishing with siding. This allows you to significantly extend the service life of the timber while maintaining the external attractiveness of the building and aesthetics. Any type of panel can be used for this:

- vinyl;

- metal;

- acrylic.

They perfectly resist exposure to ultraviolet radiation, precipitation, and pathogens.

Paroc is a Finnish brand with a rich history

One of the leading European manufacturers of stone wool is Paroc, which has been producing products of the same name for about 80 years. The company itself is part of the large concern Owens Corning. Paroc's head office is in Finland, with other offices in 13 other countries.

The main types of products are insulating and fireproof materials for buildings under construction and reconstruction, various types of insulation for repairs, acoustics, insulation of ships and industrial premises. The brand colors of the packaging are bright red and white, which is recognizable in the 40 countries where their products are sold.

Paroc basalt slabs have a long service life and low thermal conductivity, but for each specific location of use you should choose a product from a specific category. The manufacturer has specialized lines of basalt insulation for facades, roofs, foundations and general thermal insulation.

General building thermal insulation made of stone wool

When reconstructing part of a house or building a new one, you have to insulate many parts at once: the floor, roof, facade, attic. If the region is cold, then additional insulation will be required on the interior walls. Buying a lot of specialized materials for a specific installation location is sometimes unprofitable. Sometimes it is better to choose among universal insulation materials that have average performance and characteristics that allow them to be used anywhere.

Paroc has four types of wool in this insulation category:

- eXtra - Great for walls, roofs and floors. Does not burn and is easy to install at any angle. Features low shrinkage.

- eXtra light - similar in properties to the previous one, but is distinguished by its lightweight mass, which is well suited for insulating various parts of frame houses, so as not to increase the weight of the structure. This does not reduce its thermal conductivity and is 0.038 when exposed to a temperature of 10 degrees.

- eXtra plus is a more expensive premium insulation option. In addition to fire protection and sound insulation, it inhibits the transmission of low temperatures even better thanks to a thermal conductivity of 0.034.

- eXtra Smart - has the same properties as other universal boards in this category, but also has increased flexibility without losing elasticity. This type of stone wool is best for insulation in hard-to-reach places.

Paroc eXtra.

Paroc thermal insulation for plaster facades

If the building is planned to be decorated with a layer of plaster on the outside, then the façade must be insulated with cotton wool, which will withstand the subsequent load from the applied mortar. For this purpose, Paroc produces basalt slabs of a separate category called Fatio and Linio.

These materials are resistant to the alkaline environment inherent in plaster mortar, and therefore are not subject to shrinkage or corrosion. Installation is carried out using steel reinforcing mesh, which increases the strength of the facade and the reliability of fixation of facing materials.

The Linio line of stone wool is available with indexes from 10 to 80, which implies the tensile strength of the external surface. The value is measured in kPa and determines which layer of plaster can be applied to the slab. The thicker the decorative finishing with cap materials, the higher the number in the name of basalt wool of this category should be. The surface of the insulation is specially made especially smooth to make it easier to level the subsequent layer of plaster on it.

Paroc Linio.

Paroc thermal insulation for flat roofs

A flat roof has its own characteristics - it needs reliable insulation that can withstand both the pressure of water and snow, as well as waterproofing materials and users passing over it to perform work or other technical purposes. For this purpose, Paroc produces a special category of stone wool in the ROB and ROS series. Plates and rolls of insulation have a height of 60 to 180 mm.

They can withstand temperatures up to 200 degrees without losing useful properties, which is optimal for roofs exposed to direct sunlight. After 200 degrees, the binders begin to evaporate, but the cotton wool retains its integrity even up to 1000 degrees.

To withstand the weight of various materials and sediments, this type of product is produced with a digital designation. For example, ROS 30 can withstand up to 3000 kg of weight per square meter. The top layer of the basalt slab is specially designed to be more rigid and well suited for covering with subsequent building materials. Cotton wool is completely non-flammable and remains stable in size at different temperatures, not prone to drying out and forming cold bridges. ROS 60 and 80 can withstand top layer loads between 6000 and 8000 kg/m2.

Paroc R.O.B.

Paroc thermal insulation for foundations and ground floors

When insulating foundations and floors on the ground, you need insulation that protects not only cold, but also dampness, and the insulation layer itself should not collapse in such an environment during long-term use. Paroc GRS 20 stone wool is specially designed to meet these conditions. It is hydrophobic and exposure to water does not affect it in any way.

Excellent for insulating various foundations or floors, both the basement and the first floor. Stone wool is quite durable and can withstand up to 2000 kg/m2. Thermal conductivity at the level of 0.042 W/(m*K) provides decent insulation from negative temperatures.

Paroc thermal insulation for walls

For thermal insulation of walls, the manufacturer has two series of stone wool: WAS and WAB. The first has a thickness from 40 to 200 mm with a density of up to 30 kg/m3. It maintains dimensional stability and is completely non-flammable. Thermal conductivity is within 0.039 W/(m*K).

There are some modifications with particular strength, for example WAS 50t and WAS 30 tb, which are equipped with fiberglass lining. This protects the fibers from delamination. WAS 35 is well suited for two-layer insulation with the creation of an air gap, or can act as an outer layer in combination with thick brick walls. On the contrary, the WAB 10t basalt slab is produced as thin as 20 mm and does not create a load on the light frame. Moreover, it can withstand temperatures up to 750 degrees.

PAROC WAS.

Insulation installation technology

In order for the thermal insulation to be of high quality, it is necessary to insulate the facade with mineral wool strictly according to technology. It is important to carry out all processes in a clear sequence and use high quality materials for this. A detailed diagram of insulating a frame house with mineral wool is as follows:

Priming the wall

The primer will help ensure better adhesion, protect the surface from mold and mildew, and also prevent steam from getting into the wall and insulation. It must be applied in a thick layer, and further processes must be carried out only after complete drying, the duration of which depends on the brand of the composition.

Marking

When insulating the walls of a frame house using mineral wool, you should first carry out markings. This will allow you to fix the insulation as evenly as possible. For marking, you must use a rule and a level. It should be carried out vertically and horizontally.

Installation of the base profile

This process removes excess load, protects the material from getting wet and ensures its reliable fastening. For installation you will need fasteners, a level, a drill or a screwdriver. The procedure must be carried out clearly according to the markings, since the entire insulation of the frame house with mineral wool will depend on how smoothly the strips are secured.

Installation of slabs using dowels

When insulating, it is necessary to use hardware. They will be needed at different stages. With their help, you can directly insulate the walls of a building with mineral wool, securing insulation boards with dowels. You should first make holes in the wall for the dowels. First you need to fasten the outer part of the hardware, and then the central one. The hat should sink slightly into the mineral wool, and the resulting depression should be hidden with glue.

When fixing the slabs, it is necessary to use driven dowels

Installation of slabs with adhesive mortar

Insulating walls with mineral wool from the outside can be done using glue. The diluted solution must be applied over the entire surface of the sheet, additionally covering the corners. The lower part should rest tightly against the profile to prevent displacement. After fastening each one, the horizontal and vertical positions should be checked.

Wind and water protection device

Insulation of frame walls from the outside with mineral wool must be accompanied by wind and water protection. If a vapor barrier film is sufficient for internal thermal insulation, then for external insulation it is better to purchase a special construction membrane. It does not retard evaporation, and at the same time it perfectly resists strong gusts of wind. You can attach the film to the slabs using staples or liquid nails.

A hydro- and windproof membrane, it will reliably protect the walls from drafts and raindrops getting inside

Installation of thermal panels for the facade of a house

The easiest way is to install insulated tiles for the facade, and this can be done at any time of the year, which is a definite advantage. There are four holes in the concrete surface through which the panels are secured to the wall with anchors. It is advisable to first apply glue to the mineral wool. It is needed not so much for fixation, but to prevent air from flowing under the panels. Then the seams and fastening points are rubbed with concrete mixture. Due to the fact that the surface of the panel is porous (the structure of concrete resembles a sponge), it has good adhesion to all types of paints for exterior use.

Safety precautions when working

To protect mucous membranes and skin from the harmful effects of fibers and dust, which can cause irritation, it is necessary to carry out work in special clothing. Gloves are required. To protect your eyes, you can use a mask or special glasses. At the end of all procedures, you must immediately remove your clothes, wash your hands thoroughly, and only then proceed to your face.

Strict adherence to technology, the use of proven materials, and compliance with safety precautions will allow mineral wool insulation to be carried out absolutely safely and to obtain maximum thermal insulation effect.