Regardless of the appearance on the market of completely new, high-tech building materials, modern developers quite often use natural wood - logs or beams. This is understandable, such materials are environmentally friendly, relatively cheap, easy to process, and houses made from them can be built quickly.

However, houses in temperate and northern climate zones must be insulated. Insulation of a house made of timber or logs can be internal or external, and for this purpose several types of modern thermal insulation are used.

To insulate or not?

Insulation of houses for permanent residence is always necessary, except in cases where the owner has unlimited access to any type of fuel, or if the house is operated in positive temperatures. If fuel has to be purchased for a fee, then in most cases the one-time costs of insulating a house will quickly pay off by reducing heating costs.

In central Russia, where negative temperatures are observed for at least 4-5 months a year, houses made of wood simply cannot meet the necessary standards for human habitation.

The thickest wall made of timber with natural moisture can be no more than 200 mm at reasonable costs. You can cut timber even thicker, but its price will increase several times. A beam thickness of 200 mm according to modern building standards is not enough for most regions.

A way out of this situation, which partially simplifies the solution, is the use of laminated veneer lumber, the thickness of which can be any.

Just like a house made of timber, a log house in which people will permanently live cannot do without insulation. The logs can be very thick, but between the crowns, at the joints, in the corners, the wall thickness will still be no more than 100 mm. For insulation, the log house is caulked using tow, jute or the oldest material for wall insulation - moss. To make the corners of a wooden structure warmer, special technologies called “warm corners” are used even at the construction stage.

However, insulation of wooden buildings is not always required. Sometimes they are used periodically as bathhouses, sheds, and other auxiliary premises. Even residential houses made of timber are often used as country houses, which the owners visit two to three times a month. During a week's absence of a person, the rooms inside the house will still cool down, and insulating such buildings will simply be economically unprofitable.

Time-tested

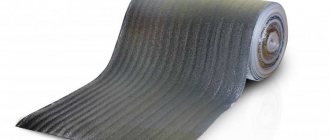

Photo: today the traditional material for timber and rounded logs is jute inter-crown tape.

Even today, experts are in no hurry to part with materials that have been proven over the years for laying between the crowns of a log house; only now manufacturers have given these materials a convenient form for their intended use. So a jute tape was made from jute, rolled into a roll, and the rolls were given different widths of 10 cm, 12 cm, 15 cm, 20 cm. A roller of jute tape was placed on a log bowl, unrolled and secured with a construction stapler. Agree, it is very convenient to use such insulation. If you are building a bathhouse, then we advise you to choose moss - cuckoo flax - as a gasket between the logs. Moss absorbs all unnecessary odors and moisture well. But keep in mind that laying with moss requires a lot of experience and knowledge in this matter, so choose specialists wisely. Tow is also a good spacer between logs. Typically, tow for laying is made in the form of a tape, which is rolled into rolls. There is no other form of tow, for example, in bales or bales, for laying; such construction tow is not suitable for these purposes. Tow usually consists of a mixture of jute and flax fibers. Also, tow has a wide range of prices, from cheap to the most expensive, the main thing is that the price-quality ratio suits you.

Which side to insulate?

From a constructive point of view, there are two options for insulating house structures:

- internal;

- external or external.

Both options have both positive and negative sides. To decide on which side to insulate the walls, you need to take into account the purpose of the building, the type of heating, the frequency of use, and the material of the enclosing structures.

From the inside

When internally insulating a house made of timber, the insulation is located inside the structure. This is convenient if the building is heated periodically. As soon as the heat source starts working in the room, the air quickly heats up, and the insulation slows down the transfer of heat to the walls. This means that it will take longer for the timber itself to heat up. Thus, the house will warm up very quickly from the inside.

It is advisable to use internal insulation in bathhouses and temporary shelters. But with such insulation of wooden houses many difficulties arise.

Firstly, installing an insulating layer with subsequent fastening of facing materials will significantly reduce the area of the house.

Secondly, almost any insulation has the property of absorbing moisture. The air inside a room is more humid than the air outside. Therefore, moisture will tend to pass through the thermal insulation and timber to the street. Since the vapor permeability of wooden walls is lower than the vapor permeability of insulation, the latter, having absorbed moisture, will largely lose its thermal insulation properties.

Over time, the moisture in the insulation will freeze, and if there is insufficient ventilation, fungus and mold will begin to multiply. To prevent this from happening, a good vapor barrier of the insulation on the room side is necessary. It is clear that with such sealing, ventilation of the premises must be organized, otherwise the increased humidity inside will not meet the standards for comfortable and safe living.

Outside

External insulation of a house made of logs or timber involves the location of the insulation on the street side, which prevents rapid heating of the interior volume of the premises, since a significant amount of heat is spent on heating the wooden wall itself. But heated walls take longer to cool down. In the case when the heat source does not work, for example, during a break in the furnace fire or a forced shutdown of the electric boiler, the wooden walls will cool down for some time, giving off heat inside the room.

In addition, the insulation located outside protects the wall material from premature destruction. The thing is that any wall material works at different temperatures. They are positive on the inside and negative on the outside. Depending on the density of the material and the internal and external temperatures, at a certain distance from the surface there will be a point with a temperature of 0 ° C. This is the notorious dew point.

At this point there will always be water in a changing state of aggregation. With repeated freezing and thawing, the material in this place will be destroyed, and the wooden walls will also be susceptible to the formation of fungus and mold, and it will be impossible to control this condition. If there is insulation on the outside of the beam, the dew point will shift into the array of insulating material, and the wood will be in positive temperatures.

Despite the fact that the technology for insulating the inside or outside of the wall will not differ very much, it will be possible to better insulate the corners from the outside, since in this case it is more convenient to install the frame for the insulation. External work will not in any way affect the daily use of the interior space. You will only have to adapt to weather conditions.

What is the best gasket for logs in a log house? Expert opinion

A variety of building materials are used to build houses, bricks, concrete panels, cinder blocks, but the highest quality and most durable material is wood. Houses built from wood are warm, durable and very beautiful. Such houses can be built from either timber or logs, but it is the second version of the material that is being used more and more often, due to its most optimal cost and at the same time its excellent characteristics. In the construction of a log house, the main thing is its insulation and the correct choice of insulation material, of which there are many.

Materials

There are many different materials for thermal insulation, but not all are suitable for insulating houses made of timber. Some can only be used under certain conditions. Most often, the following materials are used for insulation:

- mineral wool;

- glass wool;

- slag;

- Styrofoam;

- extruded polystyrene foam;

- penofol;

- warm plaster;

- thermal insulation paint.

Mineral, glass wool and slag wool are very similar materials and differ only in the type of feedstock. These materials have been used for a very long time, and when insulating a facade or ceiling, you can safely choose them as the most economical and reliable insulation option. They are produced in the form of slabs and rolled mats. Plates are usually used for insulating walls, and rolls are used for insulating ceilings and roofs in houses made of timber.

Polystyrene foam is produced in a factory from plastics. To do this, the mass is melted and then foamed. As a result, a material with a huge number of closed pores is formed.

Note! Polystyrene foam is water- and vapor-proof, so insulating a timber or log house with it from the outside is unacceptable.

It is recommended to use it only indoors. However, when burned, this material releases a lot of toxic substances. Another unpleasant property of polystyrene foam is that rodents love it very much. They not only make holes in them, but also happily eat the material itself.

Extruded polystyrene foam is a foamed polymer composition into which carbon dioxide is added during the process of pressing (extrusion) through a special mold. This material has very low thermal conductivity, high resistance to deformation, and can operate at temperatures from -50 to +75 °C. It is very durable. Due to the fact that polystyrene foam has a low coefficient of vapor permeability, it is also not recommended to be used for insulating a log house from the outside.

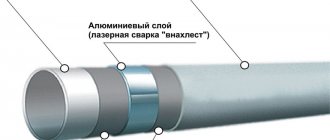

Penofol is a thin foamed mass of polyethylene. Its thermal conductivity is so low that it is possible to successfully use plates and rolls with a thickness of only 1 cm. To give this material reflective properties, aluminum foil is glued to one or both surfaces. In some cases, penofol is produced, foil-coated on one side, and on the other side it has an adhesive layer that facilitates the installation of such a heat insulator. Penofol is water- and vapor-proof, inedible for rodents.

New materials for insulating timber houses are heat-insulating plasters and paints, which contain substances that are activated upon application and create a porous coating with a very low thermal conductivity coefficient. They are used like ordinary plaster or paint, covering the surfaces in several layers.

Insulating the roof of a log house

The roof is insulated using a vapor barrier film.

The largest amount of steam collects at the top, so when insulating the roof, special attention is paid to protecting the thermal insulation from it. The concept of a log house is constant air circulation, but there is no question that the roof should breathe. As always, let's start with our favorite liquid thermal insulation, which is applied by simple spraying. In addition to all its advantages, it also does not burn, fire safety is at the highest level.

With mineral wool, things are somewhat more complicated. Some craftsmen get confused about the concepts of waterproofing and vapor barrier, and also forget about the gaps between materials. These reasons most often lead to problems. In order to avoid unnecessary troubles and hassles with their elimination, we tell you the correct technique, the layers from the inside:

- vapor barrier - a film that does not allow moisture to pass through in any form;

- insulation;

- waterproofing is a diffusion membrane that allows steam to pass in one direction, but does not allow water to pass through at all;

- counter-lattice - thanks to it, a ventilation gap is formed where moisture will evaporate;

- roof finishing.

The vapor barrier can be laid on either side, there is no difference. The diffusion membrane is placed with the advertising side facing the sky, and the soft side facing the insulation. Manufacturers wind the rolls so that when unwinding, the material lies on the correct side.

Jute insulation

The insulating material made from the fibers of the jute plant is modern and of high quality. Jute insulation is produced in the form of tow for caulking, tape, rope and even rope. The last two types are used mainly for decorative purposes. And tow and tape are used to insulate the log house.

Jute tow is most suitable for caulking, but jute tape insulation is ideal for laying a log frame. Jute tape is easy to work with, it is easy to lay and is fixed using a simple construction stapler. The tape will fill all the gaps in the crown groove well. It protects the seam from excess moisture, mold, and fungi. It will provide good thermal insulation and at the same time breathability, allowing the logs to breathe.

Tools for the procedure

The basic tools for caulking seams are special blades called caulking tools and a mallet.

The first ones can be either wooden or steel. Here it is important to follow the rule that the caulking material is softer than that of logs, since otherwise marks will begin to form on the walls.

Over time, the working plane of the wooden spatula becomes frayed, in which case it will need to be replaced with a new one. Metal caulks , where it is very important to caulk the inner area of the bowl.

To carry out heat-protection operations during the construction of a log home, conventional or type-set caulking is used. The dimensions of a traditional spatula range from 16 to 25 cm in length, 5 cm in width and 5 mm in thickness. Its shape is flat and ends in a wedge shape.

It is designed for sealing ordinary seams of various thicknesses and makes it possible to easily push the protective material into a narrow gap. Based on the volume of the surface being treated, it is divided according to its dimensions into large, ordinary and narrowed.

The main types of tools for caulking a log house:

- The standard spatula is used for gaps of various sizes and additionally in corners and roundings of joints. The width of the working blade is from 5 to 6 cm and the thickness is 5 mm. It is preferable to use an iron spatula for processing fillet welds.

- A wedge-shaped or split blade allows you to move apart the inter-crown gaps to facilitate the installation of insulation. The width of its working blade is 3 cm.

- The road worker is a spatula with a wide working blade of 17 cm, up to 15 mm thick, has a longitudinal groove 1 cm wide. As a result, it twists the fibers well into a roller when sealing cracks using the “stretch” method. In the retail chain there are such blades in 3 sizes - for wide, medium and narrow cracks.

- A steel caulking chisel is produced with different working blade sizes, so it can be used for different types of wooden walls.

- A mallet or mushel - with a rubber or wooden working tip, promotes deeper penetration of the insulation into the inter-crown cracks.

Before choosing a caulk in a retail chain, the buyer should pay attention to the fact that the working blade of the tool is smooth and does not catch the insulation. Metal tools are more productive .

Despite the fact that steel blades have the highest wear resistance, an overly sharpened blade can damage the fiber of the log, leaving harmful marks on it.

Attention! For ease of use, the handle of the spatula is made of corrugated rubber. In order to cover all the uniform seams in a log building, three types of caulk are purchased: two with a wide working blade, and one with a narrow one.

During the caulking process, consumable materials include the insulation itself and various impregnations, usually antiseptics. Currently, artificial insulation for caulking is becoming increasingly popular : inter-crown sealants, mineral wool fiber and polyurethane foam.

They have high elasticity, good heat-shielding characteristics, as well as moisture and bioresistance. The use of self-expanding sealing cords can perfectly seal the seam.

Description of methods and technology

For those developers who are faced with the need to caulk log houses for the first time, experts advise choosing the right method and following these simple recommendations :

- Compaction always begins from the bottom, from the 1st crown.

- First, carefully compact the 1st layer along the entire contour and only after that move on to the 2nd crown.

- They rise gradually upward, without breaking the order. Otherwise, distortions may form in the wall structures.

- You cannot apply great force, otherwise you can split the log, thereby damaging the thermal insulation of the object.

There are two methods of caulking: “in a set” and “in a stretch”, in addition, according to a separate procedure in log houses, the inter-crown corner joints are sealed.

Stretch

With this method of thermal protection of seams, the material stretches along the logs. After this, the resulting bundles of insulation are pushed into the inter-crown holes using a special tool.

Important. It is of great importance that the gap between the logs is densely filled with material, and from the external and internal positions of the building wall its parts are additionally marked by at least 50 mm.

Afterwards, pre-prepared heat insulating rolls are placed into these remaining pieces, rolled together, and pushed into the cracks.

For this purpose, you need to push them with caulk, tapping it gently with a mallet to ensure the compaction is effective.

Gradually grab adjacent parts of the building material, stretching the roller and pressing it into the depth of the gaps between the logs.

Included in the set

This method is used for fairly large cracks using insulation previously wound into a ball. For this option, strands with a diameter of 20 mm are formed from the material, twisted into a rope and wound into a ball.

Next, you will need to gradually unravel the tangle, forming loops and driving them into the inter-crown cracks, compacting it with a spatula and mallet. In areas where the gaps are particularly wide, make several layers of loops of the required size and also push them into the gap.

The tourniquet needs to be pushed with a spatula according to the pattern: from above, then from below and only then in the center. To simplify the movement of the sealant deep into the crack, tap the caulk with a mallet. The caulking process proceeds from the bottom up, the entire seam of one crown is passed and only then the next one begins .

Despite the fact that theoretically this method of sealing wall seams in wooden households is not complicated, the work does not allow errors that could lead to significant distortion and deformation of the log walls.

Important! It is impossible to carry out uneven caulking outside and inside the building, since this option leads to a violation of the vertical angle of inclination of the walls.

If, during caulking, the log house is raised onto the crown, then the log may fall out of the lock or dowels. Therefore, when performing work, the contractor must constantly monitor the vertical and horizontal lines of the log house. The permissible level of lifting of the log house during caulking should not exceed 15 cm.

How to caulk the corners of a wooden building?

This operation is carried out only after sealing work with the walls has been completed. The tool is a curved caulk, since the corner joints have a semicircular shape, and it is best to use tape insulation.

Technology using tape caulking:

- The tape is placed vertically. Grab it by the edge, applying it to the corner seam and pressing it into the depth with caulk. They move down a little and again push the tape into the gap.

- After securing the tape, they begin tucking the protruding parts, driving them deep into the cracks.

- After compacting and smoothing the high-lying seam, they begin to compact the lower-lying tape.

- The tape needs to be periodically straightened and stretched a little so that it fits as evenly as possible.

- Seams should not be left protruding more than 5mm, otherwise the house will look untidy.

Possible difficulties and errors

Low-quality caulk leads to cracks and distortion of door and window structures.

In this case, gaps appear between the box and the canvas, or they will fit extremely tightly into the box; great effort will be required to open/close them.

Glass can generally crack from stress initiated by misalignment.

Errors in this process are easier to prevent than to eliminate. For example, the same distortion of a log house, created as a result of an erroneous sequence of processes, is extremely difficult to correct. Even if you go through the entire procedure again, you will not be able to recreate the perfect geometry.

It will be easier to eliminate distortions in technological openings and adjust windows and doors during the hanging process. Very experienced craftsmen can correct the misalignment by installing caulk on one side of the wall enough to lift the logs to the required height.

Note! The most radical way to correct errors is to completely dismantle the low-quality caulking and install a new one.

The insulation will have to be removed entirely so that the adhesion of the new seal to the log is not disrupted. Removal is performed with a hook made from a file, sharpening and bending its tip. Dismantling is carried out only in a circular manner.

In order to avoid mistakes when caulking with traditional seals, today they use the “warm seam” technology. First, an elastic polyethylene cord is placed into the hole, acting as a compressor and heat insulator, after which the seam is sealed with a special acrylic sealant for log walls.

Beforehand, the seam is thoroughly cleaned of dirt, old caulk and other layers on the wood.

Common mistakes when caulking log walls:

- Unprofessional choice of heat-shielding material. A common mistake among inexperienced developers. This can lead to rotting of the walls, mold and dampness in the room.

- Incorrect calculation of insulation, replacement with another type, which can lead to distortion of the log house.

- Poor waterproofing properties of the building materials used.

- Violation of the order of the process.

- Laying an extremely large cover of compaction, which can cause the building to warp.

Moss insulation

Moss is an ancient insulation material that has been used for a long time. Over the years it has proven its ideal quality, excellent thermal insulation, and durability. Moss also has properties that are not inherent in all insulation materials - bactericidal. In the premises of a log house, it is able to destroy all harmful microorganisms, people living in a wooden house with insulated moss, their well-being will noticeably improve, headaches will stop, etc.

Moss absorbs moisture surprisingly well; it is capable of absorbing water 20 times more than its weight. And if the air is not humid enough, it will evenly and without problems release moisture into the air, thereby regulating the level of humidity in the room. It allows air into the room well. No one has yet come up with better thermal insulation properties than moss.

Photo: this is cuckoo flax moss. It has green tops and red-brown roots.

Many experts consider moss the best inter-crown insulation.

Photo: above, this is sphagnum bog moss. In our opinion, this is one of the best natural cushioning materials for chopped logs of wooden log houses, saunas and baths.

Performance characteristics

High-quality insulation, which is laid between the crowns of logs or beams, must meet high standards of quality and safety of use. Therefore, the main performance characteristics of the material include:

- High elasticity and density, maintaining properties throughout the entire period of operation. Thanks to its elasticity, the insulation is able to take the desired shape, and its density is able to fill existing gaps between the crowns.

- Low thermal conductivity for effective protection of walls from heat loss.

- High moisture and vapor permeability.

- Resistance to mold, fungi and harmful microorganisms that arise when exposed to increased moisture and heat.

- Resistant to ultraviolet exposure and adverse weather conditions.

How to insulate the foundation of a wooden house from the outside

The foundation of a wooden house can be insulated during construction. Lay thermal and waterproofing between the foundation and the frame of the house. If this is not possible, insulation should be carried out outside along the foundation. This will help to properly insulate the house.

The concrete base must be checked for cracks and chips and repaired with cement-polymer compounds. You can insulate the foundation by installing a brick box, polystyrene foam, or polyurethane foam. In the first case, you need to make an indent of 30 centimeters from the base and build a brick wall equal in height to the foundation. Place expanded clay between it and the base, cover the surface with waterproofing and mineral wool. Another way is to cover the base walls with polystyrene foam or spray foam. First prepare the concrete base, install a waterproofing membrane, insulation, reinforcing mesh and plaster.