In the process of assembling a heating system, a wide variety of components are used, and one of the most common and in demand are the fittings, with their help the radiator is connected to the pipelines, therefore special requirements are imposed on this group of components.

Let's consider what products are used in the work and how the assembly process should be organized in order to achieve the best result and strength of all resulting connections.

In the photo: there is not a single unit in the design without which it can work, all elements are necessary and important

Metal mounting

At a time when you need to assemble a new water supply instead of a dilapidated one, you need to connect the metal to the new pipes.

Sometimes it is polypropylene, sometimes it is steel. What needs to be done in order to carry out the installation correctly? First, you need to turn off all the risers to be replaced and drain the water from them. After this, you need to unscrew the old valves, which are still made of cast iron and are very unreliable. They change to more modern ball ones with a flag. Later, using a plumbing cable, a section of the water supply system is cleared of debris (various deposits and rust). The valve itself (new) and the filter are mounted - it is needed to extend the life of the faucet or bathroom equipment, for example, a washing machine. For sealed seams, linen thread is used, which is wrapped around the thread as the nut rotates. At the end of the filter, the required fitting of the appropriate size is installed, and a polypropylene coupling is attached to its other end. After this, the new pipeline is entirely planned.

Radiator piping

The sectional radiator itself is a “semi-finished product” that cannot be connected to the system. Especially considering that it has a right-hand thread on one side and a left-hand thread on the other. This feature is dictated by the way individual sections are connected into a battery through a nipple, which has two sections with multidirectional threads and a gasket between them.

To connect the battery to the system, you need special fittings (futures) and plugs.

The minimum set of additional elements for connecting a cast iron battery includes two fittings and two plugs. Depending on the characteristics of the heating system and the side from which the connections are fitted, the external thread of the plugs and fittings can be left-handed or right-handed. And the internal thread of footwear is always right-handed.

If a cast-iron battery needs to be equipped with a Mayevsky valve or an automatic radiator air vent, then instead of the top plug, another fitting is screwed in.

For aluminum and bimetallic radiators, they sell ready-made kits that consist of four fittings (in pairs with left and right external threads), one plug to match the size of the internal thread of the fitting and one Mayevsky tap (plus a key for it).

Of course, a Mayevsky tap or an automatic air vent is optional, but they make it possible to release the air lock that has formed in the battery.

Another recommended piping element for the central heating system battery is ball valves for supply and return. They make it possible to repair or replace the battery without stopping the system if a leak appears in it, as well as increase the number of sections if there is insufficient thermal power to heat the room.

For an autonomous heating system, instead of a ball valve for the supply, it is better to install a manual or automatic thermostat.

Taps and thermostats are connected to the battery through an “American” connection, and the method of connecting them to the supply line depends on the material of the pipes.

Review of the radiator connection kit (future)

Good afternoon, dear readers. Today we will look at a rather easy, but no less important topic: “Review of the aluminum radiator connection kit (futor)”

I won’t write anything in the introduction, and it’s better to get straight to the point...

We have an almost complete connection (except for taps).

Here we see:

— mounting radiators with dowels

— connection kit for 4 pcs., air vent (Mayevsky tap), plug, key for air vent

Radiator mounting with dowel.

The metal mount is coated with white paint, which will allow it not to stand out against the background of the radiator. First, we drill a hole in the wall, hammer in a dowel, and screw the fastener into the dowel. The radiator fits into the mounting recess. To install the radiator for better fixation, you will need 4 pcs. fastenings

Futorka (right)

The set includes 2 pieces. footers with gaskets. They are also painted white so as not to stand out. They screw onto the radiator without much difficulty. If you look closely, you can see the letter “D” on the fitting - this means which side the fitting is screwed into. in this case "to the right".

Futorka (left)

Everything is the same with the coating and application as the previous futorka, only here there is already the letter “S” and, accordingly, the connection is “on the left”.

Stub

The plug is screwed into the foot simply to plug it if there is no connection on that side. The plug screws into absolutely all the fittings, be it the left or right fitting. The color of the plug is white, complete with gasket.

Air vent or Mayevsky tap

The function of the air vent is to remove the air that has formed in the heating system, or more precisely in the radiator. The vent is mounted in such a way that the drain (small thin hole) is down. When all the air is bled from the radiator, you need to drain a couple more liters of water and, accordingly, so that the water does not splash in all directions, but the direction should be straight down. Pay attention to this installation detail as the direction of the air vent hole. The color of the vent is white, the gasket is included.

Air vent key

You can open the air vent using a special key for this purpose. If you don’t have the key or you’ve lost it, you can use a regular flat-head screwdriver, just don’t go to construction markets specifically to get it. There were such cases when this key was sold)))

Fitting with plug assembly (left), fitting with air vent assembly (right)

This is what the assembled fitting looks like, whether it’s a plug or an air vent, or it’s a continuation of the pipe leading to the radiator.

?

Connecting an aluminum or bimetallic radiator.

Here is a schematic diagram of how the radiator (battery) is connected. I think it’s unnecessary to explain anything. Everything is beautifully shown. In the fitting we connect either a ball valve with an extension with a pipe, or a plug, or an air vent. But in any case, we will have a supply pipe to the radiator, a return pipe from the radiator, an air vent (always placed in the upper part of the radiator, and a plug.

The upper part of the aluminum radiator in section with the liner

This is what a screwed-in liner into a radiator looks like. As you can see, the fitting is screwed into the radiator quite well and deeply, which is quite reliable.

The fitting is screwed into the radiator (connection from below)

Here we screwed the fitting (“D” - right) into a solid aluminum radiator. to show what she looks like from this side.

Futorki at first glance are very simple and insignificant, but select even these spare parts wisely. And remember, it is always better to entrust the matter to professionals, both in terms of sales and installation.

Thank you for your attention, we will soon prepare more useful and interesting articles for you.

Best regards, 100kotlov.by company

Types of fittings

Fitin products are classified depending on the configuration:

- Adapter. Allows you to bring the pipeline system to modern standards. The adapter is easy to install and dismantle and can be used repeatedly.

- Barrel. Equipped with threads on the outside.

- Water socket. Used when connecting a tap or mixer.

- Knee. Used for drainage of sewage in horizontal or vertical direction.

- Plug (stopper). Allows you to shut off the pipeline at the right time, ensuring the tightness of the pipeline.

- Collector. Necessary for uniform supply of water from the water supply channel to plumbing fixtures.

- Straight coupling or fitting. Corresponds to the material and design of the pipes connected with it.

- Compensator. This is a curved loop that protects the pipeline from strong pressures of the working fluid and its temperature fluctuations.

- Cross. Used to connect four pipes located at right angles.

- Retraction. Allows you to change the direction of the pipeline by a given angle.

- Pipe branch. Secures the end of the pipe with shut-off valves.

- Revision. Used to provide access to the inside of the pipe in order to eliminate blockages that occur in it.

- Connecting press. Necessary for connecting threaded pipes.

- Demountable connection. Joins pipes of different types.

- Sgon. Used to connect plumbing fixtures and fittings.

- Siphon. Connects plumbing points to sewer outlets.

- Tee. Allows you to fix three pipes at one point.

- Extension.

- Flange. Necessary for connecting the pipeline with other structures.

- Futorka. Has external and internal threads.

- Union. Required for connection to a flexible hose.

Fittings are made of stainless steel, bronze, cast iron, brass, metal-plastic, polyethylene. In rare cases, copper may be used.

Siphon (Photo: Instagram / metallplast)

CAST IRON futorka

In our assortment, you can find:

welded thread 1 1 4, cast iron American, American cast -iron galvanized to buy an American cast -iron, cast -iron American, an American cast -iron 32 gasket of a cast -iron American, a bully footer, a cast -iron radiator, a set of footsteps for a cast -iron radiator to buy , cast iron plug for a cast iron pipe, cast iron threaded plug, size of a cast iron battery plug Articles on the topic CAST IRON futor:

- CAST IRON futorka.

- Pipeline installation.

Cast iron futor

A cast iron fitting is a connecting element of plumbing, which is intended to connect two pipes of different diameters. On one side there is an internal thread, on the other there is an external thread. The element can be used to connect gas and water pipes, as well as heating; operation is possible only in non-aggressive environments. The fittings are made from KChZObf cast iron. In our online store you can purchase footwear of various sizes in bulk at competitive prices. High quality guaranteed.

Technical documentation:

Download catalog

CAST IRON fittings Fittex

- on request.

Description in detail:

Characteristics of the material Cast iron:

The uniqueness of malleable cast iron is represented in

alloy grade ,

by the addition of certain components to increase the service life of the product.

Products

- American cast iron straight angular and combined, cast iron plugs, cast iron lock nuts, cast iron crosses, adapter couplings, nipples, bends, tees and cast iron fittings.

Material characteristics Steel:

The steel alloy chosen was an analogue of the Russian St45, but with the help of additional components it was achieved - an increase in ductility, resistance to deformation, spectral analysis of the display, the structure of the crystal lattice did not change the configuration during long-term operation in aggressive environments, with a subsequent increase in anti-corrosion properties (lack of scale).

Products

- Bochata, CAST IRON futor, steel locknuts, steel threads

Basic configurations of cast iron fittings:

All presented cast iron fittings are made according to the Russian thread standard and comply with GOST standards for the height and number of pipe turns (G thread - pipe, cylindrical), the thread is made as external (Male, Fitting) or internal (Female, nut), threading is carried out on highly productive machines.

Therma static properties:

When forming the technological map of cast iron fittings, the load on the parts was taken into account up to 100 kg/cm, the parts were placed in an aggressive environment with increased acid and oxygen components, the test temperature was chosen at 110 degrees Celsius - all tests were successful.

Quality control, rejection of cast iron castings and pipe fittings:

For each part, the weight was selected by measuring and calculating the department, an analogue of the quality control department, to increase productivity and reduce the human factor, elements were inserted into the conveyor for electronic reading of the parameters of the cast iron fitting - which led to an additional increase in the quality of cast iron fittings, with a subsequent reduction in defects (1 - 1.5%), for comparison, the closest competitor to us gives 10,000 pieces per batch (5-9% defective).

*if you see an inaccuracy, please write in a letter.

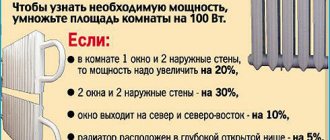

Rules for choosing the diameter of heating pipes

The cross-sectional size affects the circulation rate of the coolant. If the diameter is chosen incorrectly, the transportation of the heated liquid will be slow, and the devices will heat up unevenly. Coolant fluid flow speed standards are 0.4–0.6 m/sec. Reducing movement to 0.2 m/sec. causes water stagnation and air pockets form. Provided the coolant circulates at a speed of 0.7 m/sec. Energy consumption increases and noise is heard. The optimal parameter for the speed of water movement in the system is 0.3–0.7 m/sec. From this calculation, the diameter of the heating pipe is selected.

Recommendations from experts on product selection:

- if no more than 2 radiators are connected in the network, the cross-sectional size is up to 16 mm;

- when integrating 1 battery with a capacity of 7 kW or several radiators with a capacity of up to 2 kW (in total, the total power should not exceed 7 kW) - the permissible circuit cross-section is 20 mm;

- with a total power of a group of radiators in the main line of 11 kW, a pipe with a diameter of 25 mm is needed;

- supplying heat to a dead-end distribution, for example, to a distant wing of a house, requires the installation of elements with a cross-section of 25 mm;

- parts with a diameter of 32 mm are mounted into a network with 12 batteries with a total power rating of up to 19 kW;

- if the house system has more than 20 radiators, the total power of which is not higher than 30 kW, products measuring 40 mm will be required.

It is also important to consider the capacity of the pipeline. If the water speed in the main line is no more than 0.4 m/sec, the polypropylene circuit ensures the transfer of the required amount of heat. Table of thermal energy release depending on the pipe cross-section:

Table of thermal energy release depending on the pipe cross-section:

| Thermal energy (kW) | Outer diameter (mm) | Inner diameter (mm) |

| 4,1 | 13,2 | 20 |

| 6,3 | 16,6 | 25 |

| 11,5 | 21,2 | 32 |

| 17 | 26,6 | 40 |

How to choose the right wallpaper depending on the type of room

You need to choose one or another type of wallpaper based on the room in which it will be hung.

For a bedroom, living room or nursery, you can choose any type of wallpaper at your discretion. Unless for the bedroom and nursery it is recommended to choose canvases made from natural materials. Kitchen and bathroom – rooms with high humidity levels

Therefore, when choosing wallpaper, you need to pay attention to moisture-resistant models. Corridor. Outerwear (sometimes after rain) or dirty shoes are often left in the hallway

Dust or dirt from jackets and boots can get onto the wallpaper - so choose a canvas that can be wet cleaned.

Let's take a closer look at which rooms the above materials are suitable for:

| Types of wallpaper | Bedroom | Living room | Children's | Kitchen | Bathroom | Corridor |

| Paper | Allowed | Allowed | Allowed | Not recommended | Forbidden | Not recommended |

| Non-woven | Allowed | Allowed | Allowed | Allowed | Allowed | Allowed |

| Vinyl | Allowed | Allowed | Forbidden | Allowed | Allowed | Allowed |

| Textile | Allowed | Allowed | Allowed | Not recommended | Forbidden | Allowed |

| Glass wallpaper | Allowed | Allowed | Allowed | Allowed | Allowed | Allowed |

| Liquid | Allowed | Allowed | Allowed | Forbidden | Forbidden | Allowed |

| Bamboo | Allowed | Allowed | Allowed | Allowed | Not recommended | Allowed |

| Photo wallpaper | Allowed | Allowed | Allowed | Allowed | Allowed | Allowed |

How and what to seal pipe joints with

Types of seals, sealing methods

To prevent leakage of the pipeline working fluid, it is necessary to properly seal the pipe twists.

When threading steel pipes, the following are used as seals:

- gasket This method of sealing a threaded connection requires relatively thick end pipe cuts. The presence of smooth pipe ends can never ensure tightness. When using a rubber or plastic gasket, this problem is successfully solved. This option is ideal in case of articulation using a union nut;

- winding The materials can be linen strands, polymer threads, FUM tapes in combination with hardening sealants, paints, pastes.

When installing plastic risers, a sealing method is used based on the deformation properties of the material. The essence of this method is that a plastic pipe with an external thread is screwed into a riser with an internal thread. During deformation, plastic contributes to excellent filling of the intermediate space, eliminating the appearance of gaps.

When it comes to pipeline structures with high pressure, cylindrical threaded pipe connections are not entirely appropriate here. In such cases, a conical type connection is used. The principle of connection is that when screwing in, the pipes are tightly pressed until the gap completely disappears.

Materials for sealing joints

To make the joint impenetrable, the following are used as seals:

- flax (tow);

- asbestos;

- FUM tape;

- natural drying oil;

- whitewash;

- minium;

- graphite lubricant, etc.

A reliable sealant when twisting steel pipes onto threads is strands of flax impregnated with red lead or white lead. This connection is easy to install and reliable in terms of sealing. The seal has been used for a very long time and does not lose its popularity today, despite the emergence of artificial analogues.

For those who have little experience in installing fittings and pipes, we suggest that under no circumstances use flax without paint.

At first, the joint will not allow moisture to pass through. But several months will pass, the flax fibers will get wet and begin to decompose. Therefore, the quality of all connections will deteriorate, and in another month or two, water will leak at the junction.

Many people use FUM tape, which is in no way inferior to old traditional materials - tow with paint.

Sometimes there is no tightness at the junction of the risers. To eliminate this defect, you need to replace the sealing material, and clean the threaded area from dirt and sealant residues. After this, rewind the linen thread, FUM tape or other sealant, and assemble the structure.

Pastes and sealants of chemical origin are used as additional sealants, which will help strengthen this section of the pipeline.

Recommendations for choosing components

First, let's look at what criteria you should pay attention to when choosing components for assembling a heating system; these recommendations will apply not only to the footers, but also to all other necessary elements:

| True to size | If you do not know the parameters of the equipment, then it is unlikely that you will be able to purchase components; in extreme cases, if you decide to do the work yourself for the first time, take documentation for radiators and other equipment included in the system so that the seller can figure out what you need |

| Availability of a heating system plan | This is much more important than you think, so you must make a sketch; perfect accuracy is not required from you. The main thing is a clear definition of the location of all nodes in the system and the features of their location relative to each other. This will greatly help in determining the exact quantity of certain components, you will not miss important nuances |

| Thread matching | Another important factor, since the type of connection and its pitch may vary. Moreover, differences can be both in the measurement system (inch or metric) and in the thread pitch. Of course, most manufacturers try to produce products according to certain standards, but nevertheless, some features still occur, and it is important to know about them in advance (again, the instructions included with the equipment will help) |

| Product quality | You can determine how well a particular product is made by eye - the carvings inside and outside must be smooth without flaws or damage, other surfaces must be smooth and well-finished. If we are talking about components for aluminum and bimetallic radiators, then the products are most often painted white, since most radiators have exactly this color |

| Material of manufacture | The liner for a cast iron radiator must be made of the same material as the main element; as for bimetallic and aluminum radiators, the optimal solution for them is products made of galvanized steel, they are quite reliable and durable, and their price is affordable |

| Checking elements | It is best to check how well the element screws onto the thread; if you are purchasing many units, then check at least a few of them to choose from. The parts should screw on fairly easily without any effort on your part. If resistance is felt, then the thread on one of the elements is damaged. |

Advice! We recommend purchasing components from the same company as the main components. In general, the easiest way is to buy everything you need in one store, then specialists will assemble the entire set for you, and you will save a lot of time, since you don’t have to figure everything out yourself, everything will be explained right on the spot.

When carrying out work, you may need a variety of components and components.

What is futorka

The fitting is a specially designed adapter, which is characterized by both external and internal threads.

Very often their diameter differs significantly. In the language of plumbers, they have their own “names”.

So, the internal thread is usually called a nut, but the external thread is called a fitting. There are also pipe and metric threads.

Each product can have its own thread diameter. This indicator is measured in inches or millimeters. The tool with which you can make such calculations is a caliper or ruler.

The accuracy of measurements in this matter is quite important. Even one inch of threaded connection mismatch can cause problems with the normal functioning of the heating or plumbing system.

Based on the purpose and fittings used, the fittings are divided into two groups: those used for cast iron products and for adapters for bimetallic and aluminum objects.

First class characteristics include:

- Products designed for connecting cast iron batteries to pipelines and shut-off valves. The guiding factor is the design of the heating system itself.

- Cast iron parts. Despite their low cost and lack of external coating, they have earned their place due to their high level of reliability.

- Brass elements. Due to its ability to tightly adhere to a cast iron product, it is not so popular among consumers. This type of product has a slightly higher price and is not reusable.

- Thread direction. The radiator can be connected from different sides - right or left. The direction of twist at the foot will also change.

- Possibility for better clamping when using various devices. Frequently used tools are open-end wrenches, plumbing wrenches and socket wrenches.

- Products are characterized by a certain number of characteristics, namely maximum pressure, temperature, type of working environment. The adapter can operate using steam, air, oil, gas and water. The pressure can reach 25 Bar, the maximum temperature will be 300 degrees. Based on these indicators, not every material is able to cope with its work in such conditions.

Technician's note: it is not recommended to use FUM tape to seal the threads of the radiator liner. This is due to the fact that it does not tolerate high temperatures well. The best option would be the classic type using flax.

The second group of products, namely adapters for aluminum and bimetal, include the following characteristics:

- Such parts are often made of high-strength galvanized steel. This material provides a high level of reliability, as well as resistance to corrosive processes.

- Coating of the element with epoxy powder enamel. It gives the product strength, resistance to deformation, and attractiveness.

- There are also left-hand and right-hand threads.

- In order not to compromise the integrity of the components, a special key is used during the installation process to tighten them. It will help to secure the connections well when assembling the system, and also not to damage the surface of the pipes.

- Operating pressure. The maximum value of this indicator in the system is 16 Bar, and the coolant temperature is 110 degrees.

- Paronite or silicone rings are best suited for sealing joints. Their effectiveness is due to their good resistance to high temperatures, as well as their ability to be elastic for a long time.

- To ensure the comfort of customers, manufacturers produce ready-made kits, which include 4 fittings and gaskets, one plug and tap, and a key.

There may also be adapters with a flange, which in essence are also a futor. The internal thread of such conductors is always larger than the external one.

Features of the type of product under consideration and recommendations for work

We will analyze in detail the design and purpose of the liner and tell you how to install it correctly during the installation of radiators in the heating system.

What is futorka

Let's consider the features of this type of product, first of all, let's voice the scientific definition: a fitting is a special adapter that has internal and external threads, and the diameter of the external threaded part is always larger than the internal one.

As an example, we will give a version of the product ½ by ¾, this marking means that we have an adapter with an internal thread diameter of ½ and an external thread diameter of 3/4, everything is quite simple and clear.

The location of the element in the structure is indicated by number 2

If we consider this group of products, we can easily notice that it is divided into two large groups: liners for cast iron radiators and adapters intended for bimetallic and aluminum products. Let's consider each of the options in more detail and detail.

Units for cast iron radiators

Products intended for use on cast iron radiators have the following features:

- Adapters are specially designed for connecting cast iron batteries to pipelines or shut-off valves (depending on the design of the heating system).

- The most common options are cast from cast iron ; they do not have any external coating, so their cost is very low; this option can rightfully be considered the most budget-friendly, while its reliability is very, very high.

A cast iron radiator liner costs little, which is why its popularity is so high among buyers

- Brass products can also be used for work , but they are much more expensive than the first option, moreover, during use, brass tends to stick tightly to cast iron, and it will be almost impossible to remove such a connection. That is why this solution is less popular among specialists.

Brass units are much more expensive, but there are practically no differences in quality

- Remember that depending on which side of the radiator the connection will be made, the element may have both right-handed and left-handed threads . It is better to check the direction of twisting in advance in order to know exactly how many and what elements will be required during the work process.

A pipe wrench is the most convenient device for securely tightening fittings

- The design of the adapters is such that they can be clamped using a variety of devices - an open-end wrench, a spanner wrench, a plumbing wrench. It all depends on what you have on hand, the result will be excellent in any case.

Advice! You should not use FUM tape to seal the threads on the futorka, as it does not tolerate high temperatures; it is better to use the classic version with flax or modern sealing compounds.

Linen is a time-tested option that supports millions of connections in heating systems

- The products meet the following characteristics : maximum pressure in the system is up to 25 Bar, maximum temperature is 300 degrees, adapters are suitable for working with media such as steam, water, gas, oil, air and special coolants.

Adapters for aluminum and bimetal

This group of products is used quite often and has differences from the option described above:

- The manufacturing material is most often high-strength galvanized steel , which is resistant to corrosion processes and ensures high reliability of all connections.

- In order for the element to look more attractive and be protected even more reliably, it is coated on the outside with epoxy powder enamel , which is highly durable and resistant to deformation.

This is what a steel frame looks like

- Depending on the side of the location, there are options with right-hand and left-hand threads , you choose which of them and in what quantity you need.

- To avoid damaging the surface of the product when screwing, it is recommended to use a special key , which is most often made of plastic. With its help, you can properly tighten the connection without damaging the metal surface, and you won’t overtighten the connection, as the plastic will simply break.

Such a key can be purchased without any problems at any specialized plumbing store.

- The characteristics of the products are as follows : the operating pressure should not exceed 16 Bar, and the maximum temperature of the coolant in the system should not rise above 110 degrees for a long period of time.

- As for seals, paronite or silicone rings are most often used ; they retain elasticity for a long time and are resistant to high temperatures.

- For the convenience of buyers, ready-made kits are sold , which include 4 fittings and 4 gaskets, one plug and one Mayevsky tap, as well as a key for carrying out work, this is very convenient.

The ready-made kit will allow you to easily attach the radiator

Problems and solutions

Dripping water and puddles on the floor mean that the integrity of the pipeline has been depressurized at the joints. There are several typical problems and ways to solve them:

- Leaking locknuts at water supply connections. Usually the reason is unsuitable winding.

- Heating radiator lock nut is leaking. Leaks occur due to displacement of the heating battery at the point of connection to the heating line. The problem can be solved by additional winding of the locknut or restoration of the fitting with damaged threads.

- Leakage thread length. This occurs due to too thin pipe walls or destruction of the anti-corrosion coating on the outer surface of the fitting. The defect that has arisen is eliminated by replacing the fitting.

Radiator valves

In any modern apartment or private house, the heating system plays an important role. And today there are a sufficient number of functional devices and solutions that make it much more energy efficient and adjustable. After all, it’s no secret that heating in our homes does not always work as we would like.

In this material we will look at why control valves for heating radiators are needed and how they will help improve the heating of a house or apartment.

So, radiator valves (valves) are a type of pipeline shut-off and control valves. And they are designed to regulate (control) the coolant flow in the radiator in manual mode. Depending on the design, straight and angular ones are distinguished. Most often they are made from brass or bronze. As a rule, valves are distinguished by their low price, tightness and often stylish design.

Unlike conventional ball valves (shut-off type), a manual regulating valve for radiators allows you to more smoothly change the amount of coolant, i.e. liquids into batteries. This means that at any time you can adjust the temperature in the room as you wish. For example, if the room is already warm, then the heating is clearly excessive, then using a valve you can reduce the heat transfer from the radiator. But it is worth remembering that an angle valve for a radiator can only reduce the heat transfer of the battery!

Features of the type of product under consideration and tips for carrying out work

We will analyze in detail the design and purpose of the liner and tell you how to install it correctly during the installation of radiators in the heating system.

What is futorka

Let's look at the highlight of this type of product, first of all let's voice the scientific definition: a fitting is a special adapter that has internal and external threads, and the diameter of the external threaded part is invariably larger than the internal one.

How can we give an example of a product variant? to ?, this marking means that we have an adapter with an internal thread diameter of ? and the outer diameter is 3/4, everything is quite simple and clear.

If you look at this group of products, you can easily notice that it is divided into two numerous groups: liners for cast iron radiators and adapters intended for bimetallic and aluminum products. Let's consider any of the options in more detail and detail.

Units for cast iron radiators

Products intended for use on cast iron radiators have the following features:

- Adapters are specially designed for connecting cast iron batteries to pipelines or shut-off valves (depending on the design of the heating system).

- Much more often you see options cast from cast iron ; they do not have any external coating, so their price is low, this option can rightfully be considered the most budget-friendly, and at the same time its reliability is very, very high.

- In addition, brass products can be used for the purpose of carrying out work , but they are much more expensive than the first option, moreover, during use, brass tends to stick tightly to cast iron, and it will be virtually impossible to remove such a connection. It is precisely on this basis that this solution is less popular among experts.

- Do not forget that depending on which side of the radiator the connection will be made, the element may have both right-handed and left-handed threads . It is better to check the direction of twisting in advance in order to know exactly what quantity and what elements will be required during the work.

- The design of the adapters is such that they can be clamped using a variety of devices - an open-end wrench, a socket wrench, a plumbing wrench. It all depends on what you have on hand, the result will be good in any case.

Advice! You should not use FUM tape to seal the threads on the futorka, since it does not tolerate high temperatures well; it is better to use the classic version with flax or modern sealing compounds.

- The products meet the following features : high pressure in the system up to 25 Bar, high temperature - 300 degrees, adapters are suitable for working with these media such as steam, water, gas, oil, air space and special coolants.

Adapters for aluminum and bimetal

This group of products is used quite often and has differences from the option described above:

- The material of manufacture is much more often high-strength galvanized steel , which is resistant to corrosion processes and ensures high reliability of all connections.

- To make the element look more attractive and be protected even more reliably, it is coated on the outside with epoxy powder enamel , which is highly durable and resistant to deformation.

- Depending on the side of placement, there are options with right-hand and left-hand threads ; you choose which ones and in what quantity you need.

- In order not to damage the surface of the product when tightening, it is recommended to use a special key , which is much more often made of plastic. With its help, you can properly tighten the connection, at the same time, the iron surface will not be damaged, and you will not overtighten the connection too much, since plastic.

- The characteristics of the products are as follows : the operating pressure should not exceed 16 Bar, and the high temperature of the coolant in the system should not rise above 110 degrees for a long time.

- As for seals, paronite or silicone rings are used much more often ; they retain elasticity for a long time and are resistant to high temperatures.

- For the convenience of customers, ready-made kits are sold , which include 4 fittings and 4 gaskets, one plug and one Mayevsky tap, and a key for the purpose of carrying out work, this is very convenient.

Pros and cons of aluminum heaters

Aluminum radiators have become frequent “guests” of private houses and apartments in houses with centralized heating.

This was made possible thanks to the qualities that have won the hearts of consumers around the world:

- Aluminum is one of the best heat conductors. releasing it into the surrounding space in two ways: radiation and thermal convection. This feature is especially in demand in heating systems with unstable media pressure.

- Assembly of aluminum radiator sections is possible without the use of additional forces. Since their light weight allows you to do everything yourself. They are easy to both transport and install.

- These batteries can withstand pressure from 16 to 25 atmospheres. which makes them desirable in the places that were occupied by cast iron “accordions”. There are 2 types of aluminum radiators. One of them is suitable for autonomous heating systems, where the load rarely exceeds 10 atmospheres. The second is for batteries connected to central heating, where differences of up to 15 atmospheres occur.

- Aluminum radiators are much lower in price than their steel or bimetallic counterparts. This is one of the most important factors that attracts consumers.

- They are easily adjustable. which allows you to create the necessary microclimate in the room and save money on heating.

- They have an attractive design. which easily fits into any interior.

These qualities have made aluminum batteries in demand all over the world, despite the fact that they have minor disadvantages:

- Aluminum is not resistant to corrosion, but modern radiators are treated with special means that prevent its occurrence. But even after treatment, it is better to keep such heaters filled with coolant, which is difficult to do in a centralized heating system, where water is discharged after each end of the season. This is why aluminum batteries are more in demand in autonomous systems where there are no such discharges.

- Batteries of this type are prone to air condensation. therefore, at the beginning of the heating season, excess air must be vented from them.

- The threaded connection in aluminum models is weak and if there is a strong water hammer, a leak may appear at the joint. This defect can be eliminated only by knowing how to assemble an aluminum heating radiator using additional gaskets.

This type of radiator is available in two types: solid and sectional. The second is most common in private houses and apartments.

Find out useful information about aluminum batteries on our website:

Sealing the liner on a heating radiator is an issue that is relevant both when installing new equipment and when urgently replacing a connection that has leaked. In order to install the system efficiently and protect your home from flooding for the next 20 years, you need to approach the choice of sealant with all responsibility. Let's see what the plumbing market offers for sealing threaded connections in heating radiators.

What are we compacting?

A fitting or threaded fitting is a connecting element between the battery and heating pipes. It is the futorka, despite its insignificant appearance, that is the key link in the heating system of a house or apartment. The comfort and safety of your home will depend on how you seal the threaded connection with the fitting.

A fitting is a nut or bushing with external and external threads for connecting to pipes of different diameters.

When do we compact?

Typically, footers are sold together with gaskets - rubber, paper, paronite, silicone. In theory, the gaskets should help seal the threads and protect against leaks. In fact, they are practically useless. So, only a professional can make a seal with a silicone gasket. When tightened, this material tends to “come out” of the thread and you have to unscrew and reassemble the connection several times. Rubber gaskets work until the first pressure surge; they often tear and, as a result, allow water to pass through.

Our advice is to get rid of the gaskets that come with the footer and replace them with a stronger “product”. Forewarned is forearmed. Make a connection immediately and forever.

What do we seal with?

To seal the battery casing, materials of different generations are available on the market. Until now, flax is considered the most common. Linen winding is a classic of the genre, and this is the first thing that a plumbing store can recommend to you. But don't rush to be charmed by the low price. The combination with flax tow is a thing of the past. And not only because today the market offers much more civilized tools. The system itself has changed. If earlier the pressure in pipes reached a maximum of 8 atmospheres and connections on flax had nothing to fear, then in modern high-rise buildings when crimping pipes, the pressure reaches 16 atmospheres. Is it possible to talk about protection here? Flax, moreover, requires additional impregnation in the form of paint or a special composition (red lead on drying oil, for example). The paint that held tow tightly in the Soviet years can no longer be found, and red lead is not sold on every corner.

Linen is a natural material that swells, rots and causes corrosion inside the thread. The connection on the tow will have to be changed every 2-3 years.

Another option from the past is fum tape. It’s easier to work with than flax strands, but that’s where all the advantages end. Firstly, fum tape has the ability to tear when winding and crumble when drying. This means that leakage is 100% unavoidable. Secondly, if fum tape is suitable, it is only for cold water supply and discharge systems. This material cannot withstand multidirectional loads, obvious for heating systems. Thirdly, fum tape is capricious and requires the thread to be in perfect condition when winding. This is not only about cleanliness, but also about the design of the foot itself. If the manufacturer applied the notches carelessly, the tape will tear very quickly and will not have time to last even a couple of weeks.

For a long-lasting seal of the battery casing, pay attention to modern sealants - anaerobic gels and plumbing threads. A 20-year leakage guarantee is a serious claim to victory and consumer trust.

Anaerobic gels are a new generation of sealants that are easy to apply, completely fill the threads and form a super-strong connection inside. Suitable for sealing threaded and flanged metal connections in heating systems, including heating antifreeze, water supply, sewerage and even drinking water.

Application technology

If only an experienced craftsman can work with flax and fum tape without any problems, then even the most ordinary consumer, an amateur, can apply an anaerobic sealant and seal the futor. But this is important when it comes to eliminating an unexpected leak.

Anaerobic gels are produced in a convenient tube with a brush. The gel is applied directly from the tube to the thread - a narrow neck is provided for this - and distributed evenly. The viscous gel does not flow or roll off. Then the connection is tightened without any effort, and the excess gel is either removed or transferred with a brush to the next thread. The waiting time for the gel to polymerize will take from 5 to 20 minutes.

It is important that, if necessary, the connection can be dismantled at any time, regardless of when it was assembled. When dismantled, the gel breaks up into fractions of different sizes - from crumbs to small granules. It is enough to remove them, clean the threads and reassemble them.

Anaerobic gel sealants:

• protect threads from corrosion • do not shrink or expand • are resistant to mechanical stress, pressure and temperature changes

Plumbing thread, unlike anaerobic gels, is also suitable for plastic pipes. It starts working instantly, without waiting for polymerization.

Wind the thread crosswise along the thread, starting from the first turn. The layers are made thinner at the edges, thicker in the middle. This is necessary for easy assembly of the connection. The number of turns depends on the diameter of the pipe. The maximum figure is 15 turns for DN 30. Considering the length of the thread is 50 meters, we can safely talk about the economical consumption of material. One coil will last for several years for occasional household work.

Advantages of plumbing pipe winding

• instant sealing • contains no plant components, the product is completely synthetic • can be used on wet and dirty threads • works in the range from -60 to +120 °C

When preparing for the heating season, when replacing a radiator or after fixing a leak, think about choosing a high-quality sealant. Anaerobic gels SantekhMaster Gel and pipe winder Record are guaranteed to last for several decades and protect your apartment or cottage from emergencies and unplanned expensive repairs.

If you need to do this work efficiently and without special expenses, choose modern sealants. You can buy them directly from ]on our website.[/anchor]

Pipeline assembly technology

To assemble the pipeline, you must perform the following sequence of actions:

- First, screw the coupling onto the pipe.

- Then the side with the short thread is screwed into the coupling (sometimes it is connected directly). The parts should be screwed all the way, then the connection will be reliable.

- A locknut is screwed onto the long side of the drive.

- Next comes the connecting fitting.

- Then the end of the drive is applied to the pipe and the coupling is screwed together so that it goes onto the pipe. The connection will be easier to complete if the axes of the parts coincide as much as possible.

- The fitting must then be secured with a locknut. To do this, it should be screwed to the coupling so that there is a distance of 2-3 cm between the parts. This space must be filled with strands of flax. They should be wound in the direction of rotation of the nut. Then the locknut should be tightened until it stops. This must be done to seal the connection and prevent water leakage through it. You should use a wrench to tighten the locknut because its edges are narrow.

Types of couplings depending on the type of connection

In this case, what is meant is that all adapters, despite the fact that they perform the same function, their method of fixation may be different. Let's look at everything in detail in the table below.

| Mounting method: | Highlights: |

| This is essentially the soldering of elements and this technology is used for plastic systems. The advantage of this method is that the connection is very tight and reliable. If the master does everything as expected, then under no circumstances will any leaks appear at the joints. As for the shortcomings, it is possible to single out such a moment as incorrect soldering. If the melting temperature of the plastic is exceeded by at least a couple of seconds, then after installation of the fitting is completed, the possibility of cracks appearing is enormous. Well, what if the soldering iron affects the part less than necessary, then the strength of the connection will be low. |

| Well, everything is quite clear here - the fitting is made of metal, in most cases. The part is simply screwed onto the end of the iron pipe. The advantage of technology is the low price of similar work and its simplicity. It is completely possible to do everything yourself without involving experts and without purchasing expensive tools. Well, the disadvantages of the method are that such seams will have to be constantly monitored, since there is a huge risk of their depressurization. Based on this, a threaded pipe coupling should never be embedded inside a wall, for example. |

| For the most part, it is used to connect lines through which water or some air currents pass. The essence of the connection is that the connector is snapped onto the ends of the pipes using special carbine-type nuts. Such a seam can be made quickly, but its tightness and strength are not very good. |

| The principle of operation is that the pipe is, as it were, put on a special pipe in the connector. The fitting itself, in most cases, has a nut that clamps and fixes the coupling on the pipe. These connectors can withstand enormous pressure, you just need to ensure that there is a high-quality coupling for the pipe - the metal hose, by the way, and the pipe itself must also be strong . |

The couplings may contain rubber seals, which are very sensitive to temperature changes. If the rubber in the product is of poor quality, then as the temperature changes, an increasing number of microcracks will slowly appear on it. And this, of course, will affect (in a bad way) the tightness of the connection of the pipeline elements.

As for the scope of application of couplings, they are now actively used to connect the following systems:

- For water pipes.

- For gas lines.

- For heating mains.

- For oil pipelines, etc.

Of course, in a private house or apartment, fittings are much more often used to connect heating pipes or water supply/drainage

Let's look at how such parts are mounted in most cases and what is fundamentally important to take into account

Tips for choosing components

First, let's look at what specific criteria to pay attention to when choosing components for assembling a heating system; these tips will apply not only to footers, but also to all other necessary elements:

| True to size | If you do not understand the parameters of the equipment, then it is unlikely that you will be able to buy components; in extreme cases, if you decide to do the work yourself for the first time, take documentation for radiators and other equipment included in the system so that the seller has the opportunity to understand what you need |

| Availability of heating system design | This is much more serious than you think, based on this, you must make a sketch; you are not required to be completely accurate. The main thing is a clear definition of the placement of all nodes in the system and the features of their placement relative to each other. This will greatly help in determining the correct quantity of certain components, you will not miss important nuances |

| Thread matching | Another serious factor, since the type of connection and its progress may vary. Moreover, there can be differences both in the measurement system (inch or metric) and in the thread pitch. It goes without saying that most manufacturers try to produce products according to certain standards, but some features are still visible, and it is fundamentally important to know about them in advance (again, the instructions included with the equipment will help) |

| Product quality level | It is possible to find out how well a particular product is made by eye - the threads inside and outside must be smooth without flaws or damage, other surfaces must be smooth and properly processed. When it comes to components for aluminum and bimetallic radiators, the products are much more often painted white, since most radiators have just this color |

| Material of manufacture | The liner for a cast iron radiator must be made of the same material as the main element; as for bimetallic and aluminum radiators, products made from galvanized steel are a good solution for them; they are quite reliable and durable, and at the same time their price is affordable |

| Checking elements | It’s best to check how well the element screws onto the thread; if you receive a large number of units, then make sure that at least a couple of them are reliable. The parts should screw on fairly easily without any effort on your part. If resistance is felt, then the thread on one of the elements is damaged |

Advice! We recommend purchasing components from the same company as the main components. By and large, the easiest way is to purchase everything you need in one store, then the experts will put together a whole kit for you, and you will save a lot of time, since you will not need to figure everything out yourself, everything will be explained right on the spot.

What specific fittings are there?

The differences between fittings can be determined by several parameters. For example, their size and shape may depend on the following indicators:

- pipe diameter,

- pipe material,

- where they will be used.

Now more details. The diameter of the pipes also affects the diameter (internal or external) of the fittings; therefore, when taking fittings, it is necessary to first determine the size of the pipes with which to work. Otherwise, you will not be able to answer the seller’s question about what diameter fittings are needed. Speaking of diameter, it is meant that both fittings with uniform diameters of outlet holes can be used, when the size of the pipes is the same, and adapters, if you need to connect a large pipe with a smaller one.

When it comes to what material should be used, there are a few things to consider. For example, if threaded types are used, the connection must be sealed with a strand of flax, FUM tape or something similar for greater tightness. When welding, tightness is determined by how carefully the seam is made.

Fittings for flanges are sealed only with rubber gaskets, and when using crimp fittings, O-rings pre-lubricated with sealant are used. In addition, there are mixed fittings (a combined version, where one side is welded to the pipe, and the other has a thread).

Compression fittings are used much more often, because it is thanks to them that reliable tightness is optimally ensured, and welding and threading are not necessary.

They are easy to install, they can be removed without any trouble, and the process can be carried out several times. Date: September 25, 2022