The modern building materials market offers a huge range of different linoleum floor coverings. Each of them has its own advantages and disadvantages, which should be taken into account when choosing a particular material. Warm floors for linoleum should be chosen very carefully, since the wrong material can cause certain problems.

Warm floor under linoleum

Electric heated floor: pros and cons

Warm floors are an extremely convenient system. It can be used as the main method of heating a home, which has significant advantages over traditional water heating. But more often, heated floors are installed as an additional source of heat, designed to solve local problems.

For example, it is very good if the floor in the bathroom, on an insulated loggia or in the hallway has a comfortable temperature. Such a project is much cheaper than installing the system throughout the apartment, and installation time will be much less. First you need to decide on the type of floor heating system.

You will have to choose between a water and electric system. In the first case, heating is carried out by hot water circulating through pipes that are laid in a screed under the floor covering. A water heated floor is considered cheaper to operate, since it is like a branch of the heating system of the house.

Alas, such systems are prohibited by building codes for installation in multi-apartment high-rise buildings; they can only be installed in private homes. Electric heated floors are more diverse. A heating cable or special infrared film can be used as a heating element.

This diagram shows the installation of a film heated floor: insulation is laid on the subfloor, then the film is mounted, and covered with a layer of vapor-permeable material on top

This type of flooring is more expensive, but it is easier to install, and the operation of electrical systems can be adjusted more accurately and quickly than with water heating. Therefore, in apartments, and even in private houses, preference is given to electric underfloor heating. But choosing a system is only half the battle. You need to choose the right flooring.

Ceramic tiles combine perfectly with any heated floor, but this type of coating is not acceptable everywhere and not always. Linoleum is distinguished by its availability, low price, and the possibility of quick and easy installation, but it does not combine with heated floors as well as we would like.

Firstly, because this flooring does not conduct heat very well, and this somewhat reduces the efficiency of the heating system. Secondly, because linoleum itself does not tolerate heat very well. Prolonged exposure to high temperatures can cause the following unpleasant phenomena:

- changing the color of the floor covering;

- deformation of its surface and swelling;

- release of phenol fumes into the air, a substance hazardous to health.

And yet, linoleum is quite successfully installed on top of a warm floor. You just need to choose the right flooring. For example, there are types of linoleum with a thick base that protects against the effects of cold.

Such a material with reduced thermal conductivity is not suitable. But too thin linoleum is also not acceptable - it will repeat all the unevenness of the subfloor, and the wear resistance of such a material is usually low.

Marmoleum is a so-called natural linoleum that tolerates heat well and does not emit any hazardous substances.

Modern linoleum has markings indicating whether this material is suitable for heated floors or not. There are good reviews about marmoleum, which is also called natural linoleum.

Marking linoleum for use under heated floors

This coating is made from natural ingredients that do not emit anything harmful. At the same time, marmoleum demonstrates good resistance to heat and wear.

“Unnatural” types of linoleum are also quite acceptable. To prevent the coating from deteriorating, you just need to maintain the correct temperature conditions. The operating temperature of a heated floor usually varies between 25-28 degrees. If this limit is not exceeded, linoleum will withstand even prolonged heating.

Which linoleum is compatible with IR heating systems

When using incompatible brands of linoleum, it may become deformed. Linoleum can warp, stretch, or, conversely, shrink.

Also, when heated, some types release hazardous substances and toxins or have an insulating backing that prevents heat conduction.

When choosing linoleum for laying over an infrared heating system, special attention should be paid to its markings. It must have information about compatibility with warm electric floor systems.

Cable or infrared film?

Heated floor systems that operate on electricity are clearly divided into electric and infrared. Electrical systems consist of a heating cable, which is laid on a special mesh and then covered with a screed. A similar system in which the cable is already laid on special mats may become more convenient for installation. They are laid in strips and connected to each other.

Infrared or film floors are designed fundamentally differently. This is a complex system that looks like a thin, less than one millimeter, dark film. It is actually a graphite heating element sandwiched between two strips of thin polyester. To connect to the electrical network, special copper-silver conductors are used. The degree of heating can be controlled using a thermostat; it is usually supplied with the system. An undoubted “plus” of infrared heated floors is low energy costs for heating.

Infrared film floor

Such a warm floor heats the room using infrared rays and does not require a screed. It is placed on the prepared base, and the floor covering is mounted on top. Film systems are best suited for laying under linoleum. They do not heat up too much, so dangerous overheating of the coating in this case is practically excluded. The film is very thin, it can be laid almost without problems, even if the renovation of the room has long been completed.

To do this, the floor covering is removed, the base is leveled, the film is installed, and then the floor covering is laid again. The floor level will rise only a few millimeters. But it should be remembered that such systems are quite expensive, and also that they require very high quality installation work. For example, the base for an infrared heated floor must be almost perfectly level. Even a small difference in height can damage the film.

Does this mean that you cannot use cable electric flooring with linoleum? Not at all. This decision also has every right to exist. But installation in this case will be more difficult, and the thickness of the so-called floor pie will be greater.

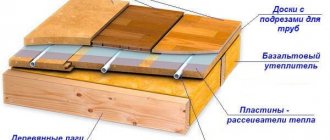

The heated cable floor is laid on a base made of heat-insulating material and secured to a reinforcing mesh, after which it is filled with concrete screed

Due to screed, thermal insulation, vapor barrier and other components, the floor level can increase significantly. An important point is the correct temperature. A heating level of 22-25 degrees is usually enough to make the experience comfortable, and this temperature will not harm the floor covering.

Compliance with thermal conditions

To select a high-quality floor covering, no special knowledge is required, because in the instructions the manufacturer indicates the possibility of using this material in the construction of heated floors. This information can be found near the marking; the permissible heating level is also reflected there; it is 27 degrees.

For your information! If the temperature is exceeded, the floor product will be damaged.

PVC linoleum can withstand +30, but there is no guarantee that the material will not be damaged, and the release of harmful substances is also possible.

To monitor compliance with the temperature regime, you will need a high-quality thermostat, ideally digital. Then, the temperature level will be maintained automatically.

Installation of infrared heated floor

Begin laying the infrared film with a marking plan. This recommendation is especially relevant for spacious rooms, but in small areas it should not be ignored. Film flooring is laid only in open areas; heating is not needed under furniture, it will only create unnecessary stress on the system and can cause its breakdown.

Film strips are usually distributed along the length of the room to minimize the number of connections of individual parts. In this case, it is necessary to maintain a distance of 50 mm from the electrical wiring laid in the floor and 200 mm from any heating sources: oven, fireplace, radiator, etc.

The strips of infrared film are connected to the power supply in parallel, so you need to lay them out along the long wall of the room to reduce the number of contacts

The next stage is preparing the base. It should be thoroughly cleaned of dirt, unevenness should be repaired and leveled using a concrete screed. Installation work can be continued only after the screed has dried. After this, thermal insulation material is laid on the base to increase the efficiency of the system. The joints are taped with special tape. Then you can start laying the infrared film.

A layer of heat-insulating material is laid on the base for infrared heated floors to prevent heat loss. The insulation at the joints is glued with reflective tape

The film must be laid out correctly. It will almost certainly have to be cut into separate pieces to do this. The lines along which this material can be cut are clearly marked on the surface with dotted lines. You cannot cut the film in any other places, so as not to spoil it. After the film is laid in accordance with the previously drawn up plan, it must be secured to the base.

You can cut the infrared film for heated floors only along special dotted lines, so as not to damage the graphite insert heaters

To do this, use tape, staples, or even ordinary furniture nails. But fasteners can only be used on special transparent strips along the edges of the film, so as not to accidentally damage the heating element. Power is supplied to the unfolded strips of infrared film using contact clamps.

Each such clamp must be inserted between the layers of the shell so that its end touches the copper strip located inside. After this, the clamp is fixed with a grommet, which is riveted using a special device. Some craftsmen do this with a regular hammer, but be careful not to damage the graphite inserts.

All connections between the film heated floor and electrical wires must be carefully insulated with special tape. Before turning on the system, you need to make sure the integrity of the insulation

Then a copper wire with a cross-section of 1.5 mm in a protective sheath is connected to the contact clamps using pliers. After this, the cut lines should be protected with a special waterproofing coating. The connection of individual sections of the infrared floor is carried out in parallel, and not in series. The wires are brought out under the baseboard and connected to a power source.

The wires of the infrared heated floor are slightly deeper into the layer of thermal insulation material so that they do not protrude and the surface remains flat

In the form of a description, the process of installing IR film does not look too complicated, but in practice there are several nuances that must be taken into account during the work:

- It is necessary to maintain a certain distance between individual strips of film; overlapping of material is unacceptable; this error will certainly cause overheating of the system and its rapid breakdown, as well as damage to the floor covering.

- It is not recommended to set the thermostat to a temperature above 30 degrees; in the case of laying an infrared floor under linoleum, you can limit it to 25 degrees;

- Before installing a temperature sensor, the electricity in the house should be turned off, installation and connection of the device should be carried out, and only then voltage should be applied to the device and the entire system;

- Before checking the operation of the IR film, you need to carefully inspect all contact connection points to ensure the presence and integrity of the protective insulation.

When installing over large areas, you should monitor the total power of the system. If this figure exceeds 3.5 kW, it is better to allocate a separate power supply line for it to avoid overloads. Since the film is very thin, the contact points will protrude slightly above the surface. To prevent this from affecting the condition of the floor covering, the thermal insulation layer in such places has to be cut off a little in order to equalize the height of the film above the base.

The temperature sensor is installed under the film in an area where there are no heating elements and secured with tape. After this, the system is connected to a thermostat. Now you can start testing the system. The heated floor is turned on, the wire connection points are checked, any identified flaws are eliminated, etc.

Assess the degree of heating of the floor; the heat should be distributed evenly over the area. Now the film needs to be covered with a layer of vapor barrier film, which is also secured with tape. After this, you can begin laying the flooring.

Detailed video instructions for laying film heated floors are presented here:

Conclusions and useful video on the topic

This video demonstrates in detail and clearly the process of laying an infrared floor:

Film heated floors are an excellent choice for laying under linoleum. Installation of such systems does not seem too complicated, but it is deceptively simple.

When laying infrared film, you must strictly adhere to the work technology and strictly follow the manufacturer’s recommendations. This will allow you to avoid mistakes and install the system correctly to ensure a long service life.

Would you like to talk about how you built a floor heating system with your own hands? Would you like to share information that will be useful to site visitors? Please write comments in the block below, post photos related to the topic of the article, and ask questions.

Features of laying the cable system

If preference is still given not to the film, but to the heating cable, you will have to perform the following work:

- Make a heating cable layout plan.

- Clean the base from dirt and level it.

- Lay thermal insulation material.

- Lay out and secure the mounting grid.

- Lay the cable according to the plan.

- Install the temperature sensor.

- Connect the system to the thermostat and power supply.

- Fill the floor with concrete screed and level it.

- Wait until the working surface dries.

- Install the floor covering.

As insulation, you can use polystyrene foam boards or a special material designed specifically for cable heated floors. It looks like a rubber mat with ridges on the surface. These protrusions are specifically designed to fix the heating cable. Then there is no need to lay the mounting grid.

A cable heated floor, which is already fixed to a reinforcing mesh, is much easier to install than a conventional heating cable, but it is a more expensive option

The temperature sensor must be laid at an equal distance from the cable; close contact with the heating element or with the concrete screed is not allowed. Therefore, to protect the temperature sensor, a piece of corrugated pipe is used as a kind of case.

An interesting video on laying electric heated floors can be viewed here:

Possible mistakes

The film floor should be heated evenly. If there is no heat or some areas are colder or hotter than others, it means the installation was done incorrectly. Possible errors should be found and eliminated. Problems usually arise with the following violations:

- Laying film strips overlapping. This position of the heating material is unacceptable.

- Cutting the film too close to the copper bar. This may cause insulation failure. Complete or partial lack of insulation is one of the most common causes of underfloor heating failure.

- Using mastics to fix linoleum. All these compounds are sources of harmful compounds. In addition, during uneven heating they will form swelling on the surface. Removing such defects is difficult and often impossible.

How to lay linoleum on a warm floor?

Laying linoleum is not a very difficult task. Since the flooring comes in rolls, it must first be leveled. To do this, linoleum is spread on the surface without fastening and left for several days to level out. In the case of heated floors, it is recommended to turn on the heating.

The floor covering will become warm and the leveling process will go faster. It is recommended to use plywood or fiberboard as a base for linoleum. When securing the base, make sure that the fasteners do not damage the IR film located below. When using a cable floor, the risk of such damage is much less.

To fix linoleum that is laid over a heated floor, it is better to use a special mastic, this will make the heating of the coating more uniform

After this, the linoleum must be laid on the base and secured using special double-sided tape or glue. It is better to lay laminate flooring on a warm floor using glue. Then the coating will fit more tightly, which promotes uniform heating. After this, all that remains is to install the baseboards, under which the underfloor heating wires will be hidden, and test the operation of the system again to set the appropriate temperature conditions.

The work of installing heated floors and laying linoleum is not particularly difficult. It is important to make a good plan, take into account all the technology requirements and carry out the work as best as possible. Following these simple rules will allow you to get a comfortable and reliable heated floor.

Thermostat sensor

Having decided which heated floor is best to choose for linoleum, you should pay attention to the installation of a thermostat. It controls the heating level. Without it, the system will consume more electricity.

The remote sensor is mounted in the floor next to the film. You don’t have to put it in a corrugated pipe if the system is installed dry. An appropriate recess is made in the lining so that the sensor does not protrude above the floor surface.

Additional equipment

If several wires from different rooms will be supplied to one thermostat, then it is important to determine the entire power consumption by adding the entire power of each heating element. As a result, the wire for connection is selected based on the result obtained. Additionally, you need to purchase a cable through which the underfloor heating system will be connected to electricity. The system must be equipped with an individual 30 mA RCD. The circuit breaker must be of category C and designed to protect a current-carrying branch of 10 A.