Electric underfloor heating brings comfort and coziness to your home. It fits under different floor coverings. Laminate plus electric heating is an ideal combination, since the product is cold and walking on it without additional heating is not comfortable.

Laminate can be laid on electromats and infrared film heated floors. The floor covering must have a special marking stating that the material is compatible with heating.

After reading this article, you will become familiar with the types of electric heated floors and will be able to understand which one is most suitable for a bathroom or living room finished with laminate. In addition, you will learn how to lay warm floors under laminate with your own hands.

Infrared film

Infrared heated floor is a thermal film with heating carbon elements that emits infrared waves. The width of the product varies from 30 to 100 mm, and is available in different capacities. The model has been on the market for several years and is popular as it saves up to 20% of electricity.

Advantages of infrared electric film:

- ease of installation and operation;

- does not affect the height of the ceilings, since the film thickness is only 1 mm;

- does not harm human health, since it practically does not emit electromagnetic waves;

- is not afraid of mechanical loads, so it can be installed under furniture.

This type of electric heating does not contribute to the release of formaldehyde, which is contained in the glue of the lamellas, since it is heated by infrared rays.

Almost the only drawback is the high price. But due to the ease of installation and savings during operation, the total cost of the device is not much different from other types.

Installation

You need to start installing an electric warm infrared floor under a laminate by preparing the project and purchasing the material.

Warm flooring under laminate is easy.

Step by step process:

- Installation of a thermostat - the device is mounted at the planned location, a cable placed in a corrugation is laid from it to the film.

- Preparation of the rough base - leveling and cleaning.

- Laying hydro- and heat-insulating material - polyethylene film is placed over the walls, and heat-insulating sheets are glued together with tape.

- Placement of thermal film - copper contacts should be directed downwards, the strips are connected using clamps. The film must be laid carefully so as not to damage it. Cutting should be done strictly along special lines.

- Connection - the cable is connected to the heating elements with terminals, the connection points are insulated with bitumen tape, so that the contacts do not protrude into the heat-insulating material, recesses are made for them.

- Installation of a temperature sensor - it is placed in a corrugation on graphite strips and connected to the thermostat.

- System testing - the heating of each film is checked.

- Film protection - covered with a special material such as “Izospan”, it protects it from abrasion.

- Laying the final finish - laminate.

Film installation

Film installation has a number of features. This is due to its design and technical characteristics. There are several stages when installing film under laminate:

- preparatory. They include leveling the surface, and it is not necessary to fill the screed. If the base does not have obvious unevenness, it is enough to clean it from dirt and dust;

- isolation. The prepared surface should be covered with waterproofing and thermal insulation. It is important to know that the use of aluminum foil rolls for these purposes is strictly prohibited;

- laying heating material. First, you need to lay a heat-reflective film over the entire surface, fastening the individual pieces with tape. Then the infrared film is installed with parallel connection and connection. Copper strips are connected using contacts and insulated with bitumen fixative;

- testing. Connecting a network cable to the system, connecting a temperature sensor, testing in different modes;

- final. At this stage, the entire structure is covered with polyethylene, a substrate is placed and the laminate is assembled.

Carbon rod

Carbon rod TP is a device consisting of self-adjusting carbon rods, they are located in parallel. It is able to regulate the heating level in the room, depending on the ambient temperature.

Powered by current, when it is supplied, infrared waves are emitted, they release heat and heat the room.

Advantages and disadvantages

Thanks to the parallel connection of the rods, when one comes out of standing, the entire structure continues to function. In addition, the core heated floor tolerates moisture well.

This model can be installed under laminate, either with or without a screed. The main disadvantage of screed installation is the complexity and duration of the work.

Installation

Laying a rod electric heated floor under a laminate is similar to installing a film system. You need to start by installing the thermostat and punching grooves (grooves) for the wire on the wall.

Rod carbon heated floor gtmat Caleo – installation from Master Tiler

Next, the rough coating is prepared - leveled and cleaned. A heat-insulating two-layer substrate is spread over it - foam material and lavsan film.

The next step is to lay the rod mats, they are fixed to the insulation, then the device is connected. That is, a temperature sensor is installed, the wires from it and the mat are connected to the regulator.

Filling the rods with concrete or tile adhesive is carried out after testing the system; the screed layer is made no more than 3 cm.

Only after the solution has dried can you begin installing the laminate.

Materials and tools

To install an electric “warm floor” under a laminate, you need to buy materials and assemble a set of equipment. Materials you will need:

For heated floors:

- heating cable - you can calculate the power yourself using an online calculator (located here), or look at the ready-made table given in the work “Do-it-yourself warm floor on the balcony”;

- temperature sensor with electrical wiring for connection to the thermostat;

- thermostat with a set of power wires;

- mounting tape;

- special clamps for fastening the power cable;

- dowels for fastening the tape;

- plastic corrugated tube ⌀20mm.

Ties:

- deep penetration primer;

- waterproofing materials, rolled or coating;

- insulation 50 mm thick under the screed;

- scotch;

- plastic or metal reinforcing mesh;

- damper tape;

- metal profile for installing beacons;

- Portland cement M300 or M400;

- sand;

- fiberglass;

- plasticizers TsPR.

For flooring:

- underlay for laminate;

- laminate (quantity calculation is given here).

The set of tools and accessories includes:

- electrical tester;

- grinder or wall chaser (can be rented, which will speed up the work;

- hammer drill (electric drill) with mixer and crown;

- jigsaw or wood saw;

- container for the solution (if there is a large volume of work, it is economically justifiable to rent a small concrete mixer);

- bucket for carrying the solution;

- rule;

- grinding machine (rented);

- chisel;

- hammer;

- Screwdriver Set;

- construction knife;

- felt-tip pen or colored tape;

- roulette;

- construction square;

- block for closing the laminate with a lock;

- corner for fixing the technological gap;

- construction pencil.

Most of the listed tools can be found in almost every home. As a last resort, you can borrow it from friends, acquaintances or rent it from specialized companies.

Carbon solid

Solid carbon heated floors are a new model of the heating system. A continuous layer of carbon will be applied to the film. The mats consist of 13 layers - 3 for work and 10 for safety, 5 on each side.

HOW TO MAKE A CARBON WARM FLOOR WITH YOUR OWN HANDS?

This type is safer, more environmentally friendly, and energy consumption is significantly lower. But since it appeared on the construction market recently, it is not used often. Disadvantage: short service life, about 15 years.

The construction process is similar to laying any carbon mats, but it is easier to do the installation yourself, since it is done without pouring a screed.

After preparing the base and laying the insulation, the film is laid. The strips are connected by soldering, which is much more reliable than conventional fasteners.

In addition, it is possible to cut the film anywhere and place it under furniture. Laminate flooring is installed using a floating method.

Operating rules

The hardest part is over, you installed the floor yourself, and so that your efforts are not in vain, read the operating rules. At the end of August, do the following:

- Heat the floor. When the thermometer reaches the optimal value, stop. Do this gradually: 1 step per 5 C.

- Then after 4 days, start reducing the temperature to 15 degrees.

The easiest way to lay laminate flooring and make the floor of your house warm is to use an infrared film floor heater. In addition to ease of installation, it has a lot of positive characteristics. And only strict adherence to the rules will allow you to reveal all its possibilities. We hope that the installation instructions given in this article will be a complete and understandable guide to action for you.

Amorphous metallic

The basis of this design is an amorphous-metal alloy, which has:

- high efficiency;

- increased resistance to moisture and corrosion;

- strength and flexibility;

- electromagnetic safety;

- good level of thermal conductivity.

These properties make the floor universal; it can be installed under different surfaces, including laminate.

Advantages of a device based on metal alloys:

- uniform heating of the room;

- easy installation;

- efficiency in energy consumption;

- Possibility of installation under furniture;

- warranty period up to 25 years.

Installation

Installing an amorphous metal floor is much easier than installing other systems.

A substrate is laid on the prepared concrete base, on which heating mats are placed; a laminate is placed on top; a concrete screed is not required.

Connects to a thermostat that is installed on the wall.

Warm floor made of amorphous metal. Why is it better than analogues?

Additional insulation

Before you start laying a heated floor, you need to lay a special underlay; it will improve the insulating properties and reduce heat loss. There are several options for lining materials; it is better to choose taking into account what type of system is used:

- Under the water. The substrate in this design can perform two functions at once: insulation and fixation of pipes. For this purpose, special polystyrene foam plates with protrusions are used. An alternative option is to use even insulating mats with a foil coating; they are also effective, but installation will be complicated by the use of additional fixing elements.

Underlay with guide elements

- Under cable. For electric heating, pads made of polystyrene foam or propylene are suitable. These materials are sold in the form of slabs; they are laid on top of the screed, and only then the cable is laid. An alternative to slabs would be insulating materials in rolls with a reflective surface.

- Under infrared. A substrate with a metallized tape and a special lavsan coating will be safe. You can also use liquid insulators, for example, keramoizol.

Keramoizol will provide reliable thermal insulation

Installation of sensors: temperature, thermostat

Thermostat is a device for controlling the heating of a room and for adjusting the temperature level. The device can be mechanical or electronic.

How to connect a heated floor to a thermostat

If the regulator is installed on the wall, then the wires from it are covered with a plastic box. For internal installation, a recess is made into which the box is placed, and grooves are punched for the wires.

It is placed on the wall 1 - 1.5 meters from the floor, preferably near sockets, and also away from windows.

The temperature sensor is the main element of the heating system. It is small in size and has two wires that connect to the regulator.

The operation of the device depends on how accurate the temperature sensor readings are. Therefore, the choice of location for its installation must be taken seriously.

It should be placed with a distance from the wall of no less than 60 cm, and preferably 1 meter, in the middle of the film or between the cable loops. In cases with a cable floor that is filled with screed, the temperature sensor is placed in a corrugated hose; it will protect it from the solution and simplify the process of replacing it.

This device is very vulnerable and often breaks. But it is not expensive, so the costs are not significant.

The cable is heating up

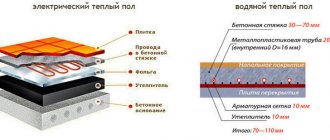

Cable heating is often used with laminate flooring as an option with maximum heat transfer. The effectiveness of this method is associated with heating the screed, and, accordingly, the floor covering in record time.

The most important point in installing a cable system in the case of a laminate is the procedure for connecting it. It is well known that when bodies heat up, they increase their linear dimensions. The heating cable, which is “tightened” into a screed, is no exception. Since it cannot particularly elongate, therefore, when heated, it fills any void in the screed. No one can say for sure what their behavior will be like under cover, so it is recommended to “train” it. The system must be turned on to full heat about five times for three to four hours within 48 hours. Each time, taking into account complete subsequent cooling and checking the functionality of the system.

This approach will avoid warping and swelling of the material, and the formation of cracks in the joints. However, this option is associated with high energy consumption. That is why such floors are often used under ceramic tiles.

Comparison of electric floors, which one to choose?

The first step when choosing an electric heating device is to calculate the level of floor elevation when laying each model. If the ceilings are not high, or you do not want to raise the floor, then it is better to opt for models that do not require screeding - infrared systems or thin cable mats.

If the ceiling height allows, then you can use the cable type under the screed. In such a “pie” the cable is thicker than in mats, the insulation is at least 20 mm, and the screed is at least 30 mm. Pouring concrete mortar up to 50 mm is allowed; the strength of such a structure is higher, but the warm-up time increases significantly.

It is necessary to choose a heating system together with the laminate, as they must fit together. After all, when heated, the product can release formaldehyde, so you definitely need to check whether the model is compatible with heated floors. In this regard, infrared structures benefit, since heating is produced by infrared rays.

Are all underfloor heating systems suitable for laminate flooring?

If we take it in general, then all types of heating are suitable for such material. But there are nuances regarding the choice of materials, compliance with installation and operation instructions. Each option has its own characteristics.

Water

Laminate is a very demanding floor covering that does not tolerate sudden temperature changes and constant overheating. Therefore, a water heating system will only be relevant with autonomous heating, because with a centralized heating system the owner will not be able to control temperature conditions.

heating system

A water heated floor is installed on a well-insulated base, otherwise there will be too much heat loss. Different materials are used for insulation; it is most convenient to take special mats with protrusions that help lay the pipe in the shape of a snail or spiral. On top of the insulation with pipes, a concrete screed with a thickness of at least 30 mm is required. On top of it you can already lay a substrate and a finishing layer in the form of a laminate.

Electric with heating cable

The cable type option is universal and can be used in different rooms. Additionally, the system is equipped with a temperature control function, the owner will be able to control the heating and set it in such a way that the coating is not damaged

Heating cable in ready-made rolls

As in the case of a water circuit, you first need to lay insulation. You can use foil-coated materials that will reflect heat from the base. They also attach special profiles along which the electrical cable will be fixed. The maximum permissible distance between its loops is 30 cm; if this is observed, uniform heating is obtained. A screed is poured over the fixed cable and a lining is mounted.

It is important to make the screed correctly. It should level the surface, cover the wires, but not block the passage of heat. The optimal screed thickness is up to 30 mm. If it is thicker, then heating costs will increase significantly.

Application of cement-sand mortar

Infrared

Infrared floor heating technology goes well with a laminate finish. When arranging, you can do everything without pouring a screed; there is also no need to install thick insulation; even thin polyethylene foam will suffice. When the system operates, the coating quickly heats up to a set temperature, after which the infrared radiation “goes” further, heating other objects. Film heating is often used as an independent heating system.

IR film can be easily cut.

Thin film options can also be used as a substrate. The intensity of the system after installation can be adjusted by setting any temperature conditions.

How to choose a laminate?

Laminate is an MDF product, the front side of which is made of polymer. When choosing it for heated floors, you need to consider:

- The presence of an icon indicating that the product is not afraid of high temperatures and meets the standards of the European Union.

- The amount of harmful substances - they should not be more than normal, otherwise when heated the material will release harmful substances.

- Thermal resistance - the higher the better.

- The thickness of the lamellas - the thicker they are, the less heat enters the room.

In addition, the method of fastening the panels is important; if there is glue, then they are not suitable for heated floors. There is no need to take very cheap products - they are of low quality.

Laying laminate

The principle of laying laminate depends on the type of heated floor:

- Cable - you can lay the finishing coating only after the screed has completely dried. A substrate is placed on it - polystyrene sheets of small thickness, or a special insulator. It is possible to lay laminate directly on concrete, but then the level of sound insulation will be reduced.

- Film - since it is laid without a screed, dense polyethylene is laid to protect the conductive product from mechanical damage and moisture. The laminate is already placed on it.

Laying laminate flooring on a warm floor. Making the right substrate.

In all cases, the finishing coating is assembled in a standard way - the panels are attached to each other by snapping locking connections.

Preparing the base

There are three main requirements for the base under a heated floor: it must be level, clean and dry:

- Repair and alignment. Small chips can be repaired with cement mortar or special repair mixtures. It is better to sand the tubercles so that they do not protrude. If there are many irregularities or they are too large, you will have to make a rough screed; self-leveling mixtures are well suited for this.

- Cleaning. After leveling, all large debris is removed from the surface, then the floor is swept. It should also be vacuumed.

Cleaning the rough foundation

- Drying. If for some reason the floor is wet, then all work should be postponed until it dries. Ventilation in the warm season and heating in winter can speed up the process.

Top manufacturers

When choosing an electric heated floor, you should give preference to manufacturers who have been producing products for several years.

Teplolux

Technolux is a Russian company that produces economical, efficient devices for additional and main heating of premises. There are different types of models - cable, mats, rugs. They are inexpensive and easy to install. However, in these systems the thermostat quickly fails.

Unimat

Unimat (Korea) - produces infrared rod floors with increased resistance to moisture. The systems are economical, prices are not high, and the warranty period is 20 years. But this heating cannot be used as the main one at high sub-zero temperatures.

Devi

Devi is a Danish manufacturer. The company produces high-quality cable products at an affordable cost. Heating devices from this manufacturer are easy to install, they do not dry out the air, and the warranty period is more than 20 years. The disadvantage is high energy consumption.

ReXva

ReXva (South Korea) - produces infrared self-regulating floors. The kit includes a thermostat and sensor. A special feature of the devices is the ability to automatically lower the temperature in overheated areas. The advantages include cost-effectiveness, moisture resistance, they extend the life of the laminate. The price is high, but it is justified by the quality. The downside is that it attracts dust.

Caleo

Caleo is an infrared floor made in South Korea, designed for quick dry installation. It has good heat dissipation and is equipped with all elements for installation. The only negative is fragility.

Heat Plus

Heat Plus (South Korea) - flexible infrared film with carbon stripes. The device emits long-wave infrared rays that are not dangerous to humans. The film is universal - suitable for both floors and walls, durable, used without a thermostat. The disadvantage is the high cost.

Rehau

Rehau (Germany) - the company produces two-core self-regulating electrical cable of a certain length. It has increased resistance and a double insulating coating on the outside. The price of this product is high, but it is justified by its quality.

Having decided to install not a water, but an electric heated floor under a laminate in your home, you should familiarize yourself with the characteristics not only of each brand of heating system, but also with the description of each laminate model. After comparing all the pros and cons, making sure that the heating device is combined with the finished product, you can choose the right model for your apartment.

Additional Tips

Laminate in combination with TP is a good solution for residential buildings. To improve its effectiveness, you need to follow these recommendations:

- Installation of the system will be more effective if it is installed in all rooms at once.

- When caring for the coating, you should try to use as little water as possible, even if the coating is moisture resistant.

It is important to properly care for the coating

- Using underfloor heating instead of traditional heating will help avoid uneven heating of the air and raising dust.

- You need to choose only those laminate models that are allowed by the manufacturer to be installed on top of a heated floor.