Insulation of the attic floor is carried out in order to retain heat inside the room and prevent the penetration of cold air from the roof.

There is no universal method of thermal insulation for all types of floors. For concrete slabs and wooden ceilings, insulation technologies differ, as does the choice of the insulation material itself.

How to choose the right insulation, and what points to pay attention to when purchasing a product, later in the article.

Insulating the attic with mineral wool: technology for amateurs

There are dozens of ways to insulate attic floors, using hundreds of insulation models, but mineral wool is still the most popular material.

Insulating the ceiling with mineral wool from the attic side is considered the best option

The only problem is that not all amateurs know how to properly insulate an attic with mineral wool in a private home. Therefore, next we will analyze the technology and important nuances of the process.

Preparatory part

Before you insulate the floors in the attic of your home, you need to be well prepared.

- selection of wool and related materials;

- calculation of the required amount of material;

Selection of mineral wool

Stone or mineral wool is the name of a whole direction, in which there are dozens of different models. Based on the name, this includes all soft insulation materials made from rocks; the most famous option is basalt wool.

A number of sources include glass wool and slag wool here. In the first case, glass is used as the basis, and slag wool is made from blast furnace slag (a by-product of blast furnace production).

All materials are good, but which one is better is a moot point. I’ll say right away that if you take material from a well-promoted brand, there is not much difference in quality.

Mineral wool on any base is suitable for a cold attic

It is much more important to choose the type of material.

There are 2 types of such insulation:

- Soft mats , which are sold rolled into rolls.

- Dense slabs.

Theoretically, insulating the ceiling from the cold attic side can be done using both options, but from experience, it is better to give preference to dense slabs.

The price of the slabs is slightly higher, but this material does not shrink over time, plus, when wet, some models of slabs can be dried without loss of volume and quality.

As for soft mats, here you are buying a “pig in a poke”; well-known manufacturers make good products, but it is not a fact that you will not buy a fake.

Such mats are inexpensive, but in an attic they lose volume in a couple of years.

It is better to insulate the ceiling of a cold attic using slabs

Related materials

This is the case with related materials. Any cotton wool is afraid of moisture; to protect it, a vapor barrier membrane is needed.

It is a fabric that allows steam to pass through only in one direction; neither steam nor moisture passes through from the other side.

Important! Steam moves from the room to the street or to the attic, so the membrane is laid with a vapor-permeable side towards the room, i.e. down.

Material calculation

To calculate the amount of wool, you need the area of the attic and the thickness of the insulation:

- With the area of the attic floor, everything is simple - the length is multiplied by the width. Plus 5% for shrinkage and trimming.

- The thickness of the material depends on the climate zone. In central Russia, to insulate an attic floor with mineral wool, the thickness of the slabs is 100 mm, the mats are taken 150 mm. Accordingly, the further north, the thicker the layer.

Advice! If you expect to lay slabs, for example, to a thickness of 100 mm, then it is better to take 2 slabs 50 mm thick and lay them offset. This way the joints overlap and there will be no cold bridges.

Ecowool

As the name suggests, this is a more environmentally friendly material than mineral wool. It is most often used for walls, but is also suitable for ceilings as a healthier alternative. Since this type of cotton insulation consists of small crumbly particles, it is possible to carry out both “dry” and “wet” installation.

The “dry” option is simpler. Essentially, you just need to pour the insulation into the space between the beams. For the “wet” method, cotton wool is mixed with an adhesive base and sprayed under air pressure through a special pneumatic tube.

Ecowool prevents the appearance of mold and mildew. It is difficult to ignite due to fireproof impregnation, but even if it does catch fire, it emits a minimum of harmless smoke. It does not retain moisture. Ecowool does not lose its beneficial properties for many years.

How thick should this type of insulation be on the ceiling?

The size of the ecowool layer is not particularly important, since it is compressed to a minimum thickness of a few millimeters and will not load the attic floor. Thanks to the ability to lay wool in one layer, you can save a lot, but due to these features, there are no specific standards for the ecowool layer, and you will have to calculate the thickness of the insulation yourself.

So, let's consider what the thickness of the insulation for the ceiling of a cold attic should be if it is made of ecowool?

In this case, a 25 cm layer will be enough for full functionality. Since under these conditions the insulation dries out and evaporates over time, the layer should be increased by 25 percent of the total thickness. Over the course of a month, the insulation will slowly harden until it turns into one large monolithic surface.

Insulating the attic of a house with mineral wool

In a private house, the ceiling can be concrete and wood (on beams). The insulation technology of these options is similar, but there are still differences.

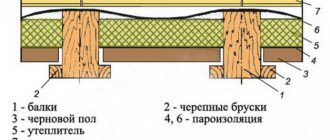

Insulating the attic using beams

The instructions for insulating a beam floor are similar to arranging roofs with an inclined rafter system, so if you wish, you can completely insulate the attic using this technology.

- The first layer is laid with a vapor barrier membrane (rough side down). The rolls are rolled out across the beams and overlapped by 100 mm; with such an overlap, it is not necessary to tape the joint of the sheets with tape. The material is fixed with a stapler.

When arranging an attic with mineral wool, a vapor barrier is laid first

- A slab or roll of mineral wool is cut 20 mm wider than the distance between the beams. This tolerance will allow the material to be laid without gaps. As already mentioned, it is advisable to lay the insulation at intervals to cover the joints.

- When insulating with stone wool, a gap of 30–50 mm is left from the top edge of the material to the edge of the beam. It is necessary for arranging ventilation ducts.

- The next layer is a vapor barrier ; it is placed in the same way as the bottom one (with the vapor-permeable layer down). If you mix it up, condensation will accumulate under the membrane and wet the insulation. The membrane is attached with a slight sag between the beams.

Photo of the arrangement of the ventilation duct under the vapor barrier

- A counter-rail is placed on top of the beams and the floor is mounted on it. Often, the subfloor in the attic is built directly onto the joists.

The video shows the process of insulation along beams:

Insulating the attic using floor slabs

Insulating the attic floor over a concrete floor is somewhat similar to the previous option.

Only the choice of materials differs slightly:

- Liquid waterproofing. The concrete floor is cold and condensation can settle here. To prevent the wool from drawing moisture from the concrete, instead of a vapor barrier, the slab is covered with waterproofing.

I recommend using liquid penetrating waterproofing like Penetron.

- Lags. Next, wooden logs are attached to the floor slab. Select the thickness of the timber according to the thickness of the insulation, plus a ventilation gap.

- Insulation. After this, insulation is laid between the joists, just like on the beams.

- Vapor barrier. The top of the wool is covered with a vapor barrier - it is needed so that excess moisture can escape upward.

- Rough floor. Now you can lay a subfloor on the joists.

Pie of insulation of floor slabs with mineral wool

What shouldn't happen

Do you know how a greenhouse works? To explain it in a primitive way, a film is stretched over the frame, providing insulation of the space from the external environment. We noticed that with a sealed shell, drops of water condense on the film. In the absence of ventilation, high humidity has a detrimental effect on plant growth and the condition of retaining structures. Therefore, the greenhouse must be equipped with ventilation, which allows maintaining the necessary microclimate. To eliminate the greenhouse effect when insulating the attic, it is necessary to use hydro- and vapor barrier in conjunction with thermal insulation.

How to insulate the ceiling and attic floor

In a heated private house, a large amount of heat will escape through the roof if measures are not taken and the ceiling of the upper floor is not properly insulated. The physics of the process is known: heated and lighter air is forced into the upper zone of the room, bordering the cold attic, where it gives off heat to the uninsulated ceiling. To prevent this from happening, a barrier in the form of a layer of thermal insulation must be placed in the path of the heat flow. This material will discuss how to properly insulate a ceiling or attic floor with your own hands and the best way to insulate this horizontal structure.

Popular materials for energy saving work at home

Mineral wool

Mineral wool in the form of sheets or rolls is widely used in construction work. The characteristics of the insulation meet the technical requirements of thermal insulation. Use in residential premises is dictated by the absence of toxic substances in the composition and excellent thermal insulation properties. Mineral wool has components of limestone, basalt, diabase and dolomite.

Rocks endow the material with valuable qualities:

- low degree of thermal conductivity;

- resistance to temperature changes;

- lack of flammability;

- environmental characteristics.

Still, the material has disadvantages:

- ability to absorb moisture;

- When installing, be sure to use a waterproofing film;

- additionally treat the joint seams with polyurethane foam for better sealing;

- to attach the insulation, a lathing is made of wooden beams or profiles;

- relatively short service life (10-15 years).

Penofol

Penofol consists of layers of foamed polyethylene and aluminum foil. Combines the properties of several insulating materials with a fairly wide range of applications. It represents the basis for innovative finishing of balconies and loggias.

It has low thermal conductivity, which will save energy resources. Protective qualities will prevent the penetration of cold air, draft and radon into the room. In summer, penofol will help keep the house cool and create a comfortable microclimate.

The light weight of the material makes installation convenient, and the structure of the building does not become heavier. To work with penofol, you will need a minimum amount of available tools: a construction knife, tape and liquid nails.

Along with the advantages, there are also disadvantages:

- a flexible surface involves finishing the ceiling with a suspended structure with a frame;

- It is problematic to attach the material to some surfaces;

- To increase thermal protection, it is recommended to use mineral wool.

Expanded polystyrene

Expanded polystyrene is better known to many as polystyrene foam. The material, easy to use, creates strong heat protection in the room without harming the health of household members. When installed correctly, it fully justifies the cost and retains its quality for a long time.

The advantages are:

- moisture resistance;

- good thermal conductivity;

- light weight, eliminating structural reinforcement;

- easy installation.

Disadvantages include:

- easy flammability;

- instability to ultraviolet rays and solvents;

- low resistance to mechanical damage.

Penoizol

Penoizol is a liquid foam plastic. To insulate the ceiling from the outside, it is necessary to use special equipment to apply a binder to the surface.

Advantages of the material:

- affordable price;

- thermal insulation qualities;

- flammability resistance;

- Easily fills hard-to-reach places;

- safe operation.

Flaws:

- the lack of special equipment precludes independent installation;

- weak resistance to mechanical stress;

- the first 2-3 weeks after installation, a small amount of toxic substance evaporates;

- ability to absorb moisture.

What is the best way to insulate a ceiling?

When choosing insulation for a ceiling located under a cold roof, you should take into account regulatory fire safety requirements. The fact is that for all types of floors these requirements are quite stringent, which makes it impossible to use combustible materials for thermal insulation. To put it briefly and in simple words, the insulation layer should not reduce the standard fire resistance of the structure. That is, ceilings under a cold attic, hemmed to wooden beams, as well as interfloor wooden floors and the same ceilings above the basement cannot be insulated with flammable materials.

For reference. According to the requirements of regulatory documents, wooden floor beams and other load-bearing structures must be impregnated with a special fire-fighting compound, and the spaces between them must be filled with non-combustible materials.

Accordingly, the answer to the frequently asked question, whether it is possible to insulate the ceiling with foam plastic from the inside over wooden beams, is quite clear - it is not possible. This also applies to the use of extruded polystyrene foam and penoplex. It turns out that the list of insulation materials suitable for thermal insulation of wooden structures is quite limited:

- non-flammable basalt (stone) wool, sold in slabs and rolls;

- bulk fire-resistant insulation – expanded clay, perlite;

- traditional folk material - sawdust mixed with clay.

Note. Polyurethane foam coating applied by spraying also resists open fire well. But the resistance time is limited; with prolonged exposure, the insulation changes its structure and collapses.

Mineral wool made from fiberglass is not suitable, as it can withstand temperatures no higher than 200 °C. The same applies to actively advertised ecowool. Although it does not burn, ecowool cannot serve as both ceiling insulation and a fire barrier. Judging by the degree of popularity among homeowners, the best insulation option in this case is basalt mineral wool. The other listed materials have too high thermal conductivity in comparison.

Of course, you can violate fire safety requirements and insulate your private home with anything; there are no sanctions for this. But it should be remembered that as a result of such actions, the danger of rapid collapse of the ceilings in a fire increases, which leads to very negative consequences.

Another thing is the insulation of concrete floors, which themselves have a high degree of fire resistance. Here it is possible to use any polymer insulation - polystyrene foam, polystyrene foam and penoplex. At the same time, it is strongly recommended to insulate the ceiling not from the inside, but from the outside; such a solution will be the most correct in all respects.

Calculation example

Let’s say the house is located in the city of Anadyr with the required room temperature of 20 °C. Then, according to the table “Thermal resistance for large cities of Russia”, in the column “For coatings”, the average R value will be 6.4 m2⋅°C/W (rounded 6.39 to 6.4).

When calculating the thermal resistance of a structure, it is necessary to add up the indicators of each layer: R = R1 + R2 + R3, etc. The thickness of the insulation depends on the building material and its size: the lower the thermal resistance of the ceiling, the larger the insulation layer should be.

The ceiling is made of cement-based aerated concrete, 0.8 m thick. Mineral wool is used as insulation. According to SP 50.13330.2012, thermal conductivity (λ) of reinforced concrete = 0.38 W/(m⋅°C). Based on the above data, the formula for the thermal resistance of the ceiling will look like this:

- Rп = 0.8 / 0.38 = 2.1;

- Ry = R - Rп = 6, 4 - 2.1 = 4.3.

When the coefficient of thermal resistance of the insulation layer (Ry) for a ceiling made of a given material has become known, it remains to calculate the thickness of the layer of this insulation (p), in this case mineral wool. To do this, it is necessary to calculate the thermal conductivity coefficient of mineral wool (k). Different manufacturers will have different thermal conductivity.

Let's take as an example the minimum coefficient - 0.045 W/m*k, according to the table above.

p = Ry ⋅ k = 4.3 ⋅ 0.045 = 0.19 m.

Accordingly, with such input data, the thickness of the insulation on the ceiling in the house will be 19 cm. Below are examples of calculations for the attic.

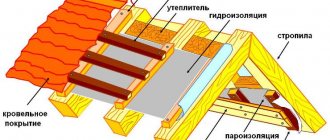

Insulation of wooden floors

As a rule, the ceiling located under a cold roof is insulated from the attic side. To do this, the first step is to hem the ceilings from below so that mineral wool or expanded clay can be safely laid between the beams. The filing will serve as a support for it, which means it must be designed for the appropriate load. This is especially true for expanded clay or clay with sawdust, whose weight is quite significant.

The second important stage is laying a vapor barrier layer. It is well known that mineral wool absorbs moisture well, so do-it-yourself attic insulation should include a protective layer of film and an air gap for ventilation. Due to this, water vapor from living quarters will not get inside the insulation, and those that condense on the vapor barrier will erode through the air gap. The general layout of the thermal insulation layer on the ceiling under the roof is shown in the figure:

The film sheets should be laid with an overlap of at least 10 cm on each other, after which the joint is carefully taped with construction tape. The organization of the air opening is carried out by installing an internal sheathing of bars up to 50 mm wide, to which the finishing coating of the ceilings is nailed. On the roof side, the insulation is covered with a diffusion membrane, which protects from wind and water droplets, but allows steam to pass through.

Advice. A vapor barrier can be installed using thin foil insulation - isolon or penofol. Then the canvases are laid end-to-end, and the seams are sealed with special aluminum tape.

The moisture that forms in the thickness of the material due to the occurrence of a dew point will be removed using ventilation from the attic, so that the thermal insulation will work correctly and last for a long time. It should be noted that often the height of the beams is not enough to lay insulation of the calculated thickness between them. That is why the diagram below with suspended ceilings shows the laying of mineral wool in 2 layers: one between the beams, the other on top of them. Expanded clay is simply poured into the openings on top of the vapor barrier.

Note. The attic ceiling, that is, its horizontal part, is insulated in the same way. The composition of the heat-insulating “pie” is the same as for the ceiling, the thickness of the insulation is the same as on the walls of the attic.

Installation of ceiling insulation can be done in the reverse order - from below, from the side of the room. There is not much difference, only it is not so convenient to carry out the work, and even the vapor barrier must be done with an outlet of 15-20 cm on the walls, otherwise moisture will be able to penetrate along the edges of the “pie”. This is especially true for wet areas, such as the bathroom. More details on this topic are described in the video:

As for the insulation of interfloor wooden floors, it often makes no sense to do it. It appears only when you plan to isolate the second floor from the first and heat them separately in order to save money.

In such a situation, the insulation between floors will have to be protected from vapors on both sides, as shown in the diagram:

Types of insulation

Thermal insulation materials are used both for insulating external enclosing structures and in multi-layer “pies” indoors or on the roof.

The thermal insulation layer, depending on the type and density of the products used, can be:

- single-layer – based on thermal insulation products of the same type and thickness;

- multilayer - based on two or more heat-insulating products of different densities and types;

- combined - based on multilayer thermal insulation products of the same type, made of layers of different densities, interconnected due to both chemical and physical adhesion.

In order to choose the right insulation for your home, you need to take into account several important criteria: environmental friendliness of the material, susceptibility of thermal insulation to fire, reaction to moisture.

Insulation of concrete floors

It is best to insulate the concrete ceiling of the upper floor from the outside, but this is convenient to do during the construction process. After all, a roofing covering must be laid on top of the insulation to protect the house from precipitation. The sequence of work is as follows:

- cleaning and leveling the concrete surface;

- organization of inclined surfaces for water drainage using a monolithic screed;

- laying waterproofing with outlet along the edges;

- laying insulation in 1 or 2 layers;

- installation of cement-sand screed up to 5 cm thick;

- spreading and sealing the roof covering.

The “pie” for proper insulation of a concrete ceiling from the outside is shown in the diagram:

If the roofing covering is already available, then it is not practical to open it to organize thermal insulation; instead, you can insulate the ceiling from the inside. The easiest way for this purpose is to take polystyrene foam or penoplex, which do not need to be protected from moisture. Plates of material are attached to the concrete surface in 2 ways:

- first, wooden logs are installed, insulation is inserted between them, and the gaps are sealed with foam;

- Penoplex slabs are attached directly to the ceiling using umbrella-shaped dowels.

Advice. When installing joists or fastening polystyrene foam, be careful when drilling holes so that the dowel does not fall into the void.

When there are logs, it is convenient to install any finishing coating.

At the same time, installing insulation on dowels is practiced when installing suspended ceilings. When mineral wool is used as an insulator, the organization of a vapor barrier and an air gap is mandatory, so you can’t do without logs and counter-lattice. The concrete floor above an unheated basement also needs insulation, since in this situation a lot of heat will escape through the floors of the first floor. There are 2 options: insulate the basement ceiling or the floors on the first floor.

The choice often falls on the second option, since it is more convenient to insulate the floors of the first floor. There are also two methods of thermal insulation: on joists and under screed, both of them are reflected in the diagrams:

Features of installation of different materials

The tactics of action depend on the chosen material and the location of its placement - from inside the room or from the attic.

Laying mineral wool

Installation of insulation is carried out along the attic floor.

When constructing a thermal insulation cake, it is important to meet two conditions:

- ensure protection of mineral wool from water vapor coming from inside a warm room;

- arrange ventilation of the outer surface to ventilate moisture from the insulation.

Mineral wool slabs are laid between beams or strips of prepared sheathing. Can be mounted on the ceiling surface.

Before starting work, it is necessary to check the boards for rot and treat the wooden elements with an antiseptic. Make sure the roof is not leaking

The surface is cleared of debris, and if necessary, a wooden frame is constructed.

Further actions:

- Install a vapor barrier membrane.

- Roll out rolls or place mats between beams.

- Install a wooden base, maintaining a ventilation gap between the insulation and the hard floor.

The last step can be missed. However, it will not be possible to walk in the attic or store things there, since mineral wool cannot be pressed.

Internal lining with expanded polystyrene

This thermal insulation option is suitable for concrete ceilings. Expanded polystyrene slabs are fixed to the surface with glue and secured with “fungi”.

At the preparatory stage, the ceiling is cleared of debris and old finishing, holes, cracks and gaps between the slabs are sealed.

Before installing the insulation, the ceiling is treated with an antifungal compound and primer.

The procedure for attaching polystyrene foam boards:

- Apply glue to the insulation, apply and press it to the ceiling.

- Cover the entire area with slabs, leaving no gaps between the elements.

- Use a hammer drill to drill holes for fasteners.

- Kill the fungi.

- Foam the joints and gaps between the plates.

- Cut off the remaining foam and fix the reinforcing mesh with adhesive.

- The surface should be primed and plastered.

After the layer has dried, clean the ceiling and apply the final decorative coating.

Filling the attic with expanded clay

The minimum layer of bulk insulation is 20 cm. To adjust the height of the backfill, you need to prepare a beacon - make the necessary mark on a piece of reinforcement, securing a piece of electrical tape.

If a wooden base is insulated with expanded clay, then the floor must first be covered with waterproofing extending onto the walls. Polyethylene film will do

There is no need to lay a water barrier on a concrete base.

Sequence of work:

- Pour in expanded clay and distribute the granules evenly.

- Check the thickness of the insulating layer. Its height should be 3-4 cm below the level of the flooring. If this norm is neglected, then when walking through the attic the sound of granules rubbing will be heard.

- Lay a layer of vapor barrier membrane and seal the joints of the panels with tape.

- Install a rigid base. Boards, fiberboard or OSB panels are suitable.

The floor on top of expanded clay makes it easier to move around the attic and increases the effectiveness of the insulation cake.

Application of Spray Insulation

It will not be possible to carry out the work yourself, since spraying will require expensive equipment - a high-pressure apparatus. In addition, skills in working with equipment are required to evenly distribute polyurethane foam.

To start the device, a voltage of 380 V is required. If there is a two-phase network in the house, a generator is connected that produces the required value of the electric field.

It is better to entrust the work to a specialized company and conclude an agreement with them for the provision of services. At the appointed time, a team arrives and extends a hose with a gun into the house.

Recommended work order:

- Install wooden joists on the attic floor. They will be needed for subsequent fastening of the flooring.

- Fill the device with components in the required proportions.

- Set the gun to the minimum foam supply force.

- Apply polyurethane foam between the joists in an even layer.

- Wait for the composition to dry. If the thickness of one layer is not enough, then the treatment must be repeated.

- Level the cured coating by cutting off the excess to the level of the joist.

- Mount on boards on a rigid base.

To insulate a small ceiling yourself, you can use a disposable foam spray kit.

The kit contains everything you need: cylinders with components for preparing foam insulation, a spray gun, hoses, personal protective equipment

Assembly and preparation takes a couple of minutes, no power supplies are needed - the device operates autonomously.

Insulation of a cold attic with mineral wool

A vapor barrier is placed under the mineral wool.

To insulate the ceiling of a cold attic with mineral wool, you can take material of any density, from low to high. At the same time, it is still preferable to choose lighter materials so as not to create additional loads on the beams. Some experts are inclined to believe that glass wool is better suited for insulating an attic with mineral wool than stone wool. The latter is too brittle, and it weighs a lot. Also read: “Which insulation to choose for walls and ceilings.”

As you already understand, insulation of a cold attic of a private house with mineral wool is carried out by laying thermal insulation between the load-bearing beams directly on the rough ceiling of the first floor. Due to the high hygroscopicity of mineral wool, it is necessary to use a vapor barrier film. In principle, even simple polyethylene can be used. There will be no special loads on the film and if installed carefully it will not tear. To be completely confident in the reliability of the protective layer, you need to use a polypropylene vapor barrier reinforced with fiberglass mesh.

Insulating the attic with mineral wool, technology:

- the supporting beams are sewn up from below - this is the rough ceiling of the first floor;

- on the attic side, a vapor barrier is laid on the rough covering;

- Mineral wool is placed on top of the film.

Vapor barrier tapes should be laid overlapping, the joints should be taped with double-sided tape. The mineral wool is placed outward so that there are no cold bridges at the junction of the insulation with the beams.

Insulating a cold attic with mineral wool is always preceded by calculating the thickness of the thermal insulation. In any case, the layer will be at least 10 cm. Mineral wool is available in a thickness of 5 cm. It is better to lay thermal insulation in two layers with offset joints. This will eliminate the possibility of heat loss through the joints of the mineral wool sheets.

After insulating the attic floor with mineral wool, you can immediately lay the floor on top of the beams. It is advisable to first cover the insulation with waterproofing - a material that does not allow water to pass through, but at the same time allows steam to pass through, but only in one direction. It is important not to confuse which side to lay the waterproofing on, otherwise moisture will accumulate in the mineral wool, as a result of which the thermal conductivity of the material will increase significantly.

It is quite possible to use a fireplace to heat a country house. To do this, a heat exchanger is built above the firebox.

Read about how to choose the size of brackets for radiators here.

Expanded clay

Now let’s look at how thick the insulation on an expanded clay ceiling should be. This is the most wear-resistant material of all of the above, and at the same time environmentally friendly and inexpensive. It is characterized by high resistance to fire and good water absorption.

If you use expanded clay as ceiling insulation, the thickness should be maximum: 10 cm and above. To create a dense insulating layer, it is better to use a mixture of several types of expanded clay to insulate the ceiling. A 20-centimeter layer insulates heat better than a half-meter thick wooden wall.

Quite often it is used in baths. What thickness should the ceiling insulation be in this case? It all depends on the insulating layer.

The ceiling is first lined with waterproofing material, and then a layer of expanded clay is poured. The thickness of the ceiling insulation in a bathhouse made of blocks in this case will be about 25 cm. Waterproofing material is laid on top of it, just like on mineral wool.

Let's consider what the thickness of the insulation for the ceiling of a cold attic should be.

For the walls of attic structures, it is better to lay expanded clay in large blocks of 20-40 cm. Expanded clay particles are very light, so they will not significantly increase the load and are well suited for insulating roofs and attics. The downside is that for the most effective insulation of the ceiling, the thickness of the roof insulation must be at least half a meter.

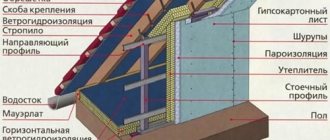

Insulation of a heated attic with mineral wool

If the attic is heated and it belongs to the living space, then it is already an attic. Naturally, it also needs insulation. In this case, the thermal insulation is not laid between the floor beams, but between the roof rafters. At the same time, there are two methods for insulating an attic with mineral wool.

Let's consider the first option - laying thermal insulation between the rafters from the roof ridge to the ceiling of the first floor. In Fig. 1 the area where the insulation is applied is marked in red. Remember that you need to insulate not only the attic, but also a small section of the first floor, which is marked in green. As you can see, this option solves both problems at once. Installation method (layers from the inside):

- vapor barrier - stapled to the rafters. It is laid with overlap and tension. The joints are sealed;

- mineral wool - placed by surprise. You can use glass wool of any configuration (mats, slabs, rolls) or basalt wool in slabs with a soft end;

- waterproofing – three-layer polypropylene diffusion membrane. The tapes are laid horizontally and overlapping, starting from the edge of the roof;

- counter-lattice - the cross-section of the bars depends on the length of the roof slopes;

- finishing coating.

In terms of functionality, vertical tubular heating radiators are no different from horizontal ones.

In this article you will find information about plate heating radiators: characteristics, types, installation methods, operation and maintenance.

The second method of how to insulate an attic in a private house with mineral wool is somewhat different (see Fig. 2). The insulation is installed on the attic floor. Next, the wall is insulated according to the principle of thermal insulation of a frame house. Also, the insulation is laid on the ceiling of the first floor from the attic wall to the end of the building. It is important that the insulation lays down without breaks, that is, it should move from one surface to another and preferably without joints. If there is a connection point, then the thermal insulation must be pressed tightly against each other.

With such an installation, undoubtedly, more material will be used, but in the long term there is a benefit. You will not have to heat square meters unused for housing, so the cost of heating your house will be somewhat lower.

Special cases

Let's look at a few special cases

In an apartment building

Apartments on the top floors of apartment buildings are known to be cold. Especially if the builders performed thermal insulation of the ceiling in violation of the technology. Any independent work in the attic of an apartment building is illegal; it is better to spend time complaining to the construction or operating organization and forcing them to fulfill their obligations to ensure normal temperatures. But the claim process is not a quick process, and the rooms are already cold today.

However, you can quickly and inexpensively insulate the ceiling from the inside and do it yourself. You will have to “please” your neighbors by drilling numerous holes in the ceiling for dowels, but the result is worth it.

Ceiling insulation in an apartment building

Another drawback will be a reduction in the height of the rooms by 4-5 cm, and around the perimeter of the ceiling - up to 40 cm. But heat is more expensive.

A system of guides made of wooden slats or a metal profile 4 cm high is installed on the warm ceiling. Sheets of foam plastic 30 mm thick are laid between them and attached to the ceiling with disc-shaped dowels.

After this, a foil vapor barrier is attached along the lower edges of the guides. Slopes with a radius of 40-40 cm are made along the perimeter, ensuring a smooth connection between the planes of the lines of the false ceiling and walls. At the last stage, sheets of moisture-resistant drywall are attached. Curvilinear slopes are covered with foam chips, starting from the short sides of the room. Ecowool is also suitable for this.

Attic

A residential attic must be insulated. Insulation of a non-residential attic will not hurt either - this will be an additional barrier to the cold on the residential floors. How to reliably insulate the ceiling in a residential attic? The most common scheme is insulation with mineral wool or polyurethane foam slabs laid between the rafters. For vertical walls, you will need to take special cotton wool with a low shrinkage coefficient.

Attic thermal insulation diagram

Particular attention will need to be paid to vapor barrier. In an already built house, the space under the ridge is not always available. In this case, ecowool can help out - it can be blown through temporary technological holes, which are then sealed with polyurethane foam.

Garage and bathhouse

The roof of a garage is often supported by metal I-beams. When installing guides for insulation, drilling holes from bottom to top in a steel beam is inconvenient, so the method shown in the figure is used. Thermal insulation boards are laid in two overlapping layers. Instead of fibrous materials, you can try ecowool. In this case, you can do without foil insulation, and instead lay kraft paper on the false ceiling.

Results

Today we figured out how to properly insulate an attic with mineral wool and came to the following conclusions. If the attic is unheated (cold), then the insulation is placed between the floor beams. If the attic is heated, then thermal insulation is placed between the roof rafters. There is a method of laying thermal insulation on the attic floor, then the wall itself is insulated and then a section of the first floor floor from the wall to the edge of the building. This approach will slightly reduce heating costs, since there is no need to heat extra square meters.

For work, it is better to use glass wool, since it does not break and, after compression, restores its previous shape. It is lightweight and does not overload the load-bearing floor beams and rafter system. If you use stone wool, then you need to take slabs with a soft end so that they can be inserted between the guides at random. A vapor barrier is laid between the heated room and the insulation. When laying thermal insulation on the roof, you also need waterproofing, which is placed on the outside. There must be a ventilated gap between the waterproofing and the finishing.