In the modern world, an important aspect of a private home is its energy efficiency. That is, the ability to spend a minimum amount of energy to maintain a comfortable climate in the house. To spend less energy, you need to take care of reducing energy losses.

Thermal conductivity of materials is the ability of a material to retain heat in cold weather and keep cool in summer.

Heat capacity is the amount of heat absorbed (released) by a body in the process of heating (cooling) per 1 kelvin.

Density is the ratio of the mass of a body to the volume occupied by this body.

Thermal conductivity of building materials

The design of energy-efficient house technologies should be carried out by specialists, but in real life everything may be different. It happens that home owners, for a number of reasons, are forced to independently select materials for construction. They will also need to calculate thermal parameters on the basis of which thermal insulation and insulation will be carried out. Therefore, you need to have at least a minimal understanding of building heating engineering and its basic concepts, such as thermal conductivity coefficient, in what units it is measured and how it is calculated. Knowing these “basics” will help you properly insulate your home and heat it economically.

What is thermal conductivity

Thermal conductivity of a brick wall: without insulation;

with insulation on the outside; with insulation inside the house; In simple terms, thermal conductivity is the transfer of heat from a hotter body to a less hot one. Without going into details, all physical materials and substances can transmit thermal energy.

Every day, even at the most primitive everyday level, we are faced with thermal conductivity, which manifests itself in each material differently and to a very different extent. For example, if you stir boiling water with a metal spoon, you can get burned very quickly, since the spoon heats up almost instantly. If you use a wooden spatula, it will heat up very slowly. This example clearly shows the difference in thermal conductivity between metal and wood - for metal it is several times higher.

INTERESTING: How to heat a house using electricity economically

Coefficient of thermal conductivity

To evaluate the thermal conductivity of any material, the thermal conductivity coefficient (λ) is used, which is measured in W/(m×℃) or W/(m×K). This coefficient indicates the amount of heat that can be conducted by any material, regardless of its size, per unit time over a certain distance. If we see that some material has a high coefficient value, then it conducts heat very well and can be used as heaters, radiators, and convectors. For example, metal heating radiators in rooms work very efficiently, perfectly transferring heat from the coolant to the internal air masses in the room.

If we talk about the materials used in the construction of walls, partitions, roofs, then high thermal conductivity is an undesirable phenomenon. With a high coefficient, the building loses too much heat, to retain which it will be necessary to build rather thick structures indoors. And this entails additional financial costs.

The thermal conductivity coefficient depends on temperature. For this reason, reference literature indicates several coefficient values that change with increasing temperatures. Operating conditions also affect heat conductivity. First of all, we are talking about humidity, since as the percentage of moisture increases, the coefficient of thermal conductivity also increases. Therefore, when carrying out this kind of calculations, you need to know the real climatic conditions in which the building will be built.

Heat transfer resistance

Thermal conductivity coefficient is an important characteristic of any material. But this value does not accurately describe the thermal conductivity of the structure, since it does not take into account the features of its structure. Therefore, it is more appropriate to calculate the heat transfer resistance, which is essentially the reciprocal of the thermal conductivity coefficient. But unlike the latter, the calculation takes into account the thickness of the material and other important design features.

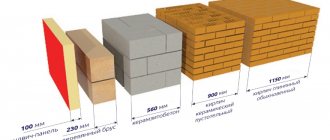

During construction, as a rule, multilayer structures are used, such as frame or SIP houses. One of these layers is an insulating material that maximizes the value of thermal resistance. Each layer of such a structure has its own resistance and must be calculated based on the thermal conductivity coefficient and the thickness of the material. By summing the resistance of all layers, we get the total resistance of the entire structure.

It is important to note that the air gaps that are located in the partition structure and do not communicate with the outside air significantly increase the overall heat transfer resistance.

Modern construction trends include the use of synthetic materials such as EPS PIR boards and Izolon as insulation, which have excellent characteristics, are convenient and easy to install.

INTERESTING: Insulation. Types and characteristics

Thermal conductivity, density and heat capacity coefficients have been calculated for almost all building materials. Below is a table with information about the coefficients for all materials that can be used in the construction of buildings. Even just looking at these data, it becomes clear how different the thermal conductivity of building materials is and how much the coefficient values can differ. To simplify the choice of material for the buyer, manufacturers indicate the value of the thermal conductivity coefficient in the passport for their product.

| Material | Density, kg/m3 | Thermal conductivity, W/(m deg) | Heat capacity, J/(kg deg) |

| ABS (ABS plastic) | 1030…1060 | 0.13…0.22 | 1300…2300 |

| Aggloporite concrete and concrete based on fuel (boiler) slags | 1000…1800 | 0.29…0.7 | 840 |

| Acrylic (acrylic glass, polymethyl methacrylate, plexiglass) GOST 17622-72 | 1100…1200 | 0.21 | — |

| Alfol | 20…40 | 0.118…0.135 | — |

| Aluminum (GOST 22233-83) | 2600 | 221 | 840 |

| Fibrous asbestos | 470 | 0.16 | 1050 |

| Asbestos cement | 1500…1900 | 1.76 | 1500 |

| Asbestos cement sheet | 1600 | 0.4 | 1500 |

| Asbozurite | 400…650 | 0.14…0.19 | — |

| Asbomica | 450…620 | 0.13…0.15 | — |

| Asbotekstolit G (GOST 5-78) | 1500…1700 | — | 1670 |

| Asbothermite | 500 | 0.116…0.14 | — |

| Asbestos slate with high asbestos content | 1800 | 0.17…0.35 | — |

| Asboshifer with 10-50% asbestos | 1800 | 0.64…0.52 | — |

| Felt asbestos cement | 144 | 0.078 | — |

| Asphalt | 1100…2110 | 0.7 | 1700…2100 |

| Asphalt concrete (GOST 9128-84) | 2100 | 1.05 | 1680 |

| Asphalt in floors | — | 0.8 | — |

| Acetal (polyacetal, polyformaldehyde) POM | 1400 | 0.22 | — |

| Airgel (Aspen aerogels) | 110…200 | 0.014…0.021 | 700 |

| Basalt | 2600…3000 | 3.5 | 850 |

| Bakelite | 1250 | 0.23 | — |

| Balsa | 110…140 | 0.043…0.052 | — |

| Birch | 510…770 | 0.15 | 1250 |

| Lightweight concrete with natural pumice | 500…1200 | 0.15…0.44 | — |

| Concrete on gravel or crushed stone from natural stone | 2400 | 1.51 | 840 |

| Concrete on volcanic slag | 800…1600 | 0.2…0.52 | 840 |

| Concrete based on granulated blast furnace slag | 1200…1800 | 0.35…0.58 | 840 |

| Concrete on ash gravel | 1000…1400 | 0.24…0.47 | 840 |

| Concrete on crushed stone | 2200…2500 | 0.9…1.5 | — |

| Concrete on boiler slag | 1400 | 0.56 | 880 |

| Concrete on sand | 1800…2500 | 0.7 | 710 |

| Concrete based on fuel slag | 1000…1800 | 0.3…0.7 | 840 |

| Dense silicate concrete | 1800 | 0.81 | 880 |

| Solid concrete | — | 1.75 | — |

| Thermal insulating concrete | 500 | 0.18 | — |

| Bitumen perlite | 300…400 | 0.09…0.12 | 1130 |

| Petroleum bitumens for construction and roofing (GOST 6617-76, GOST 9548-74) | 1000…1400 | 0.17…0.27 | 1680 |

| Aerated concrete block | 400…800 | 0.15…0.3 | — |

| Porous ceramic block | — | 0.2 | — |

| Bronze | 7500…9300 | 22…105 | 400 |

| Paper | 700…1150 | 0.14 | 1090…1500 |

| Booth | 1800…2000 | 0.73…0.98 | — |

| Light mineral wool | 50 | 0.045 | 920 |

| Heavy mineral wool | 100…150 | 0.055 | 920 |

| Glass wool | 155…200 | 0.03 | 800 |

| Cotton wool | 30…100 | 0.042…0.049 | — |

| Cotton wool | 50…80 | 0.042 | 1700 |

| Slag wool | 200 | 0.05 | 750 |

| Vermiculite (in the form of bulk granules) GOST 12865-67 | 100…200 | 0.064…0.076 | 840 |

| Expanded vermiculite (GOST 12865-67) - backfill | 100…200 | 0.064…0.074 | 840 |

| Vermiculite concrete | 300…800 | 0.08…0.21 | 840 |

| Woolen felt | 150…330 | 0.045…0.052 | 1700 |

| Gas and foam concrete, gas and foam silicate (foam block) | 300…1000 | 0.08…0.21 | 840 |

| Gas and foam ash concrete | 800…1200 | 0.17…0.29 | 840 |

| Getinax | 1350 | 0.23 | 1400 |

| Dry molded gypsum | 1100…1800 | 0.43 | 1050 |

| Drywall | 500…900 | 0.12…0.2 | 950 |

| Gypsum perlite solution | — | 0.14 | — |

| Gypsum slag | 1000…1300 | 0.26…0.36 | — |

| Clay | 1600…2900 | 0.7…0.9 | 750 |

| Fireproof clay | 1800 | 1.04 | 800 |

| Clay gypsum | 800…1800 | 0.25…0.65 | — |

| Alumina | 3100…3900 | 2.33 | 700…840 |

| Gneiss (facing) | 2800 | 3.5 | 880 |

| Gravel (filler) | 1850 | 0.4…0.93 | 850 |

| Expanded clay gravel (GOST 9759-83) - backfill | 200…800 | 0.1…0.18 | 840 |

| Shungizite gravel (GOST 19345-83) - backfill | 400…800 | 0.11…0.16 | 840 |

| Granite (cladding) | 2600…3000 | 3.5 | 880 |

| Soil 10% water | — | 1.75 | — |

| Soil 20% water | 1700 | 2.1 | — |

| Sandy soil | — | 1.16 | 900 |

| The soil is dry | 1500 | 0.4 | 850 |

| Compacted soil | — | 1.05 | — |

| Tar | 950…1030 | 0.3 | — |

| Dense dry dolomite | 2800 | 1.7 | — |

| Oak along the grain (wood) | 700 | 0.23 | 2300 |

| Oak across the grain (GOST 9462-71, GOST 2695-83) | 700 | 0.1 | 2300 |

| Duralumin | 2700…2800 | 120…170 | 920 |

| Iron | 7870 | 70…80 | 450 |

| Reinforced concrete | 2500 | 1.7 | 840 |

| Reinforced concrete | 2400 | 1.55 | 840 |

| Wood ash | 780 | 0.15 | 750 |

| Gold | 19320 | 318 | 129 |

| Limestone (cladding) | 1400…2000 | 0.5…0.93 | 850…920 |

| Products made of expanded perlite with a bitumen binder (GOST 16136-80) | 300…400 | 0.067…0.11 | 1680 |

| Vulcanite products | 350…400 | 0.12 | — |

| Diatomite products | 500…600 | 0.17…0.2 | — |

| Newelite products | 160…370 | 0.11 | — |

| Foam concrete products | 400…500 | 0.19…0.22 | — |

| Perlite phosphogel products | 200…300 | 0.064…0.076 | — |

| Sovelite products | 230…450 | 0.12…0.14 | — |

| Frost | — | 0.47 | — |

| Iporka (foamed resin) | 15 | 0.038 | — |

| Coal dust | 730 | 0.12 | — |

| Hollow-core stones made of lightweight concrete | 500…1200 | 0.29…0.6 | — |

| Solid stones made of lightweight concrete DIN 18152 | 500…2000 | 0.32…0.99 | — |

| Solid stones made from natural tuff or expanded clay | 500…2000 | 0.29…0.99 | — |

| Building stone | 2200 | 1.4 | 920 |

| Carbolite black | 1100 | 0.23 | 1900 |

| Asbestos insulating cardboard | 720…900 | 0.11…0.21 | — |

| Corrugated cardboard | 700 | 0.06…0.07 | 1150 |

| Cardboard facing | 1000 | 0.18 | 2300 |

| Waxed cardboard | — | 0.075 | — |

| Thick cardboard | 600…900 | 0.1…0.23 | 1200 |

| Cork cardboard | 145 | 0.042 | — |

| Multilayer construction cardboard (GOST 4408-75) | 650 | 0.13 | 2390 |

| Thermal insulating cardboard (GOST 20376-74) | 500 | 0.04…0.06 | — |

| Foamed rubber | 82 | 0.033 | — |

| Vulcanized rubber, hard gray | — | 0.23 | — |

| Vulcanized rubber soft gray | 920 | 0.184 | — |

| Natural rubber | 910 | 0.18 | 1400 |

| Solid rubber | — | 0.16 | — |

| Fluorinated rubber | 180 | 0.055…0.06 | — |

| Red cedar | 500…570 | 0.095 | — |

| Lacquered cambric | — | 0.16 | — |

| Expanded clay | 800…1000 | 0.16…0.2 | 750 |

| Expanded clay peas | 900…1500 | 0.17…0.32 | 750 |

| Expanded clay concrete on quartz sand with porosity | 800…1200 | 0.23…0.41 | 840 |

| Lightweight expanded clay concrete | 500…1200 | 0.18…0.46 | — |

| Expanded clay concrete on expanded clay sand and expanded clay foam concrete | 500…1800 | 0.14…0.66 | 840 |

| Expanded clay concrete on perlite sand | 800…1000 | 0.22…0.28 | 840 |

| Ceramics | 1700…2300 | 1.5 | — |

| Warm ceramics | — | 0.12 | — |

| Blast-furnace brick (fire-resistant) | 1000…2000 | 0.5…0.8 | — |

| Diatomaceous brick | 500 | 0.8 | — |

| Insulating brick | — | 0.14 | — |

| Carborundum brick | 1000…1300 | 11…18 | 700 |

| Red dense brick | 1700…2100 | 0.67 | 840…880 |

| Red porous brick | 1500 | 0.44 | — |

| Clinker brick | 1800…2000 | 0.8…1.6 | — |

| Silica brick | — | 0.15 | — |

| Facing brick | 1800 | 0.93 | 880 |

| Hollow brick | — | 0.44 | — |

| Silicate brick | 1000…2200 | 0.5…1.3 | 750…840 |

| Silicate brick from those. voids | — | 0.7 | — |

| Slotted silicate brick | — | 0.4 | — |

| Solid brick | — | 0.67 | — |

| Construction brick | 800…1500 | 0.23…0.3 | 800 |

| Treble brick | 700…1300 | 0.27 | 710 |

| Slag brick | 1100…1400 | 0.58 | — |

| Rubble masonry made of medium-density stones | 2000 | 1.35 | 880 |

| Gas silicate masonry | 630…820 | 0.26…0.34 | 880 |

| Masonry made of gas silicate thermal insulation boards | 540 | 0.24 | 880 |

| Masonry of ordinary clay bricks on cement-perlite mortar | 1600 | 0.47 | 880 |

| Masonry of ordinary clay bricks (GOST 530-80) on cement-sand mortar | 1800 | 0.56 | 880 |

| Masonry of ordinary clay bricks on cement-slag mortar | 1700 | 0.52 | 880 |

| Masonry of ceramic hollow bricks with cement-sand mortar | 1000…1400 | 0.35…0.47 | 880 |

| Small brick masonry | 1730 | 0.8 | 880 |

| Masonry made of hollow wall blocks | 1220…1460 | 0.5…0.65 | 880 |

| Masonry made of 11-hollow silicate bricks with cement-sand mortar | 1500 | 0.64 | 880 |

| Masonry made of 14-hollow silicate bricks with cement-sand mortar | 1400 | 0.52 | 880 |

| Sand-lime brick masonry (GOST 379-79) with cement-sand mortar | 1800 | 0.7 | 880 |

| Triple brick masonry (GOST 648-73) with cement-sand mortar | 1000…1200 | 0.29…0.35 | 880 |

| Cellular brick masonry | 1300 | 0.5 | 880 |

| Slag brick masonry with cement-sand mortar | 1500 | 0.52 | 880 |

| Masonry "Poroton" | 800 | 0.31 | 900 |

| Maple (tree) | 620…750 | 0.19 | — |

| Leather | 800…1000 | 0.14…0.16 | — |

| Technical composites | — | 0.3…2 | — |

| Oil paint (enamel) | 1030…2045 | 0.18…0.4 | 650…2000 |

| Silicon | 2000…2330 | 148 | 714 |

| Organosilicon polymer KM-9 | 1160 | 0.2 | 1150 |

| Brass | 8100…8850 | 70…120 | 400 |

| Ice -60°C | 924 | 2.91 | 1700 |

| Ice -20°С | 920 | 2.44 | 1950 |

| Ice 0°C | 917 | 2.21 | 2150 |

| Polyvinyl chloride multilayer linoleum (GOST 14632-79) | 1600…1800 | 0.33…0.38 | 1470 |

| Polyvinyl chloride linoleum on a fabric base (GOST 7251-77) | 1400…1800 | 0.23…0.35 | 1470 |

| Linden, (15% humidity) | 320…650 | 0.15 | — |

| Larch (tree) | 670 | 0.13 | — |

| Flat asbestos-cement sheets (GOST 18124-75) | 1600…1800 | 0.23…0.35 | 840 |

| Vermiculite sheets | — | 0.1 | — |

| Gypsum cladding sheets (dry plaster) GOST 6266 | 800 | 0.15 | 840 |

| Lightweight cork sheets | 220 | 0.035 | — |

| Heavy cork sheets | 260 | 0.05 | — |

| Magnesia in the form of segments for pipe insulation | 220…300 | 0.073…0.084 | — |

| Asphalt mastic | 2000 | 0.7 | — |

| Basalt mats, canvases | 25…80 | 0.03…0.04 | — |

| Stitched glass fiber mats and strips (TU 21-23-72-75) | 150 | 0.061 | 840 |

| Mineral wool mats stitched (GOST 21880-76) and with a synthetic binder | 50…125 | 0.048…0.056 | 840 |

| (GOST 9573-82) | |||

| MBOR-5, MBOR-5F, MBOR-S-5, MBOR-S2-5, MBOR-B-5 (TU 5769-003-48588528-00) | 100…150 | 0.038 | — |

| Chalk | 1800…2800 | 0.8…2.2 | 800…880 |

| Copper (GOST 859-78) | 8500 | 407 | 420 |

| Mikanite | 2000…2200 | 0.21…0.41 | 250 |

| Mipora | 16…20 | 0.041 | 1420 |

| Morozin | 100…400 | 0.048…0.084 | — |

| Marble (cladding) | 2800 | 2.9 | 880 |

| Boiler scale (rich in lime, at 100°C) | 1000…2500 | 0.15…2.3 | — |

| Boiler scale (rich in silicate, at 100°C) | 300…1200 | 0.08…0.23 | — |

| Deck flooring | 630 | 0.21 | 1100 |

| Nylon | — | 0.53 | — |

| Nylon | 1300 | 0.17…0.24 | 1600 |

| Neoprene | — | 0.21 | 1700 |

| Wood sawdust | 200…400 | 0.07…0.093 | — |

| Tow | 150 | 0.05 | 2300 |

| Gypsum wall panels DIN 1863 | 600…900 | 0.29…0.41 | — |

| Paraffin | 870…920 | 0.27 | — |

| Oak parquet | 1800 | 0.42 | 1100 |

| Piece parquet | 1150 | 0.23 | 880 |

| Panel parquet | 700 | 0.17 | 880 |

| Pumice | 400…700 | 0.11…0.16 | — |

| Pumice concrete | 800…1600 | 0.19…0.52 | 840 |

| Foam concrete | 300…1250 | 0.12…0.35 | 840 |

| Foam gypsum | 300…600 | 0.1…0.15 | — |

| Foam ash concrete | 800…1200 | 0.17…0.29 | — |

| Polystyrene foam PS-1 | 100 | 0.037 | — |

| Polyfoam PS-4 | 70 | 0.04 | — |

| Foam plastic PVC-1 (TU 6-05-1179-75) and PV-1 (TU 6-05-1158-78) | 65…125 | 0.031…0.052 | 1260 |

| Foam resopen FRP-1 | 65…110 | 0.041…0.043 | — |

| Expanded polystyrene (GOST 15588-70) | 40 | 0.038 | 1340 |

| Expanded polystyrene (TU 6-05-11-78-78) | 100…150 | 0.041…0.05 | 1340 |

| Expanded polystyrene "Penoplex" | 35…43 | 0.028…0.03 | 1600 |

| Polyurethane foam (TU V-56-70, TU 67-98-75, TU 67-87-75) | 40…80 | 0.029…0.041 | 1470 |

| Polyurethane foam sheets | 150 | 0.035…0.04 | — |

| Polyethylene foam | — | 0.035…0.05 | — |

| Polyurethane foam panels (PIR) PIR | — | 0.025 | — |

| Penosilalcite | 400…1200 | 0.122…0.32 | — |

| Lightweight foam glass | 100..200 | 0.045…0.07 | — |

| Foam glass or gas glass (TU 21-BSSR-86-73) | 200…400 | 0.07…0.11 | 840 |

| Penofol | 44…74 | 0.037…0.039 | — |

| Parchment | — | 0.071 | — |

| Glassine (GOST 2697-83) | 600 | 0.17 | 1680 |

| Reinforced ceramic ceiling with concrete filling without plaster | 1100…1300 | 0.7 | 850 |

| Flooring made of reinforced concrete elements with plaster | 1550 | 1.2 | 860 |

| Monolithic flat reinforced concrete floor | 2400 | 1.55 | 840 |

| Perlite | 200 | 0.05 | — |

| Expanded perlite | 100 | 0.06 | — |

| Perlite concrete | 600…1200 | 0.12…0.29 | 840 |

| Perlitoplast-concrete (TU 480-1-145-74) | 100…200 | 0.035…0.041 | 1050 |

| Perlite phosphogel products (GOST 21500-76) | 200…300 | 0.064…0.076 | 1050 |

| Sand 0% moisture | 1500 | 0.33 | 800 |

| Sand 10% moisture | — | 0.97 | — |

| Sand 20% humidity | — | 1.33 | — |

| Sand for construction work (GOST 8736-77) | 1600 | 0.35 | 840 |

| Fine river sand | 1500 | 0.3…0.35 | 700…840 |

| Fine river sand (wet) | 1650 | 1.13 | 2090 |

| Burnt sandstone | 1900…2700 | 1.5 | — |

| Fir | 450…550 | 0.1…0.26 | 2700 |

| Pressed paper plate | 600 | 0.07 | — |

| Cork plate | 80…500 | 0.043…0.055 | 1850 |

| Facing tiles, tiles | 2000 | 1.05 | — |

| Thermal insulation tile PMTB-2 | — | 0.04 | — |

| Alabaster slabs | — | 0.47 | 750 |

| Gypsum slabs GOST 6428 | 1000…1200 | 0.23…0.35 | 840 |

| Wood-fiber and particle boards (GOST 4598-74, GOST 10632-77) | 200…1000 | 0.06…0.15 | 2300 |

| Slabs made of expanded clay concrete | 400…600 | 0.23 | — |

| Polystyrene concrete slabs GOST R 51263-99 | 200…300 | 0.082 | — |

| Resol-formaldehyde foam boards (GOST 20916-75) | 40…100 | 0.038…0.047 | 1680 |

| Plates made of glass staple fiber with a synthetic binder (GOST 10499-78) | 50 | 0.056 | 840 |

| Slabs made of cellular concrete GOST 5742-76 | 350…400 | 0.093…0.104 | — |

| Reed slabs | 200…300 | 0.06…0.07 | 2300 |

| Silica slabs | 0.07 | — | |

| Flax insulating slabs | 250 | 0.054 | 2300 |

| Mineral wool slabs with bitumen binder grade 200 GOST 10140-80 | 150…200 | 0.058 | — |

| Mineral wool slabs with synthetic binder grade 200 GOST 9573-96 | 225 | 0.054 | — |

| Mineral wool slabs with synthetic bond (Finland) | 170…230 | 0.042…0.044 | — |

| Mineral wool slabs of increased rigidity GOST 22950-95 | 200 | 0.052 | 840 |

| Mineral wool slabs of increased rigidity with an organophosphate binder | 200 | 0.064 | 840 |

| (TU 21-RSFSR-3-72-76) | |||

| Semi-rigid mineral wool slabs with starch binder | 125…200 | 0.056…0.07 | 840 |

| Mineral wool slabs with synthetic and bitumen binders | — | 0.048…0.091 | — |

| Soft, semi-rigid and hard mineral wool slabs on synthetic | 50…350 | 0.048…0.091 | 840 |

| and bitumen binders (GOST 9573-82, GOST 10140-80, GOST 12394-66) | |||

| Foam plastic boards based on resol phenol-formaldehyde resins GOST 20916-87 | 80…100 | 0.045 | — |

| Expanded polystyrene boards GOST 15588-86 without pressing | 30…35 | 0.038 | — |

| Polystyrene foam plates (extrusion) TU 2244-001-47547616-00 | 32 | 0.029 | — |

| Perlite-bitumen slabs GOST 16136-80 | 300 | 0.087 | — |

| Perlite-fiber slabs | 150 | 0.05 | — |

| Perlite-phosphogel slabs GOST 21500-76 | 250 | 0.076 | — |

| Perlito-1 slabs Plastic concrete TU 480-1-145-74 | 150 | 0.044 | — |

| Perlite cement slabs | — | 0.08 | — |

| Construction slabs made of porous concrete | 500…800 | 0.22…0.29 | — |

| Thermobitumen thermal insulation slabs | 200…300 | 0.065…0.075 | — |

| Peat thermal insulation slabs (GOST 4861-74) | 200…300 | 0.052…0.064 | 2300 |

| Fiberboard slabs (GOST 8928-81) and wood concrete (GOST 19222-84) on Portland cement | 300…800 | 0.07…0.16 | 2300 |

| Carpet covering | 630 | 0.2 | 1100 |

| Synthetic coating (PVC) | 1500 | 0.23 | — |

| Seamless gypsum floor | 750 | 0.22 | 800 |

| Polyvinyl chloride (PVC) | 1400…1600 | 0.15…0.2 | — |

| Polycarbonate (Diflon) | 1200 | 0.16 | 1100 |

| Polypropylene (GOST 26996 – 86) | 900…910 | 0.16…0.22 | 1930 |

| Polystyrene UPP1, PPS | 1025 | 0.09…0.14 | 900 |

| Polystyrene concrete (GOST 51263) | 200…600 | 0.065…0.145 | 1060 |

| Polystyrene concrete modified to | 200…500 | 0.057…0.113 | 1060 |

| activated plasticized Portland slag cement | |||

| Polystyrene concrete modified to | 200…500 | 0.052…0.105 | 1060 |

| composite low-clinker binder in wall blocks and slabs | |||

| Modified monolithic polystyrene concrete based on Portland cement | 250…300 | 0.075…0.085 | 1060 |

| Polystyrene concrete modified to | 200…500 | 0.062…0.121 | 1060 |

| Portland slag cement in wall blocks and slabs | |||

| Polyurethane | 1200 | 0.32 | — |

| Polyvinyl chloride | 1290…1650 | 0.15 | 1130…1200 |

| High Density Polyethylene | 955 | 0.35…0.48 | 1900…2300 |

| Low density polyethylene | 920 | 0.25…0.34 | 1700 |

| Foam rubber | 34 | 0.04 | — |

| Portland cement (mortar) | — | 0.47 | — |

| Pressspan | — | 0.26…0.22 | — |

| Cork granulated | 45 | 0.038 | 1800 |

| Mineral cork based on bitumen | 270…350 | 0.28 | — |

| Technical plug | 50 | 0.037 | 1800 |

| Shell rock | 1000…1800 | 0.27…0.63 | — |

| Gypsum grout mortar | 1200 | 0.5 | 900 |

| Gypsum perlite solution | 600 | 0.14 | 840 |

| Porous gypsum perlite solution | 400…500 | 0.09…0.12 | 840 |

| Lime mortar | 1650 | 0.85 | 920 |

| Lime-sand mortar | 1400…1600 | 0.78 | 840 |

| Light solution LM21, LM36 | 700…1000 | 0.21…0.36 | — |

| Complex mortar (sand, lime, cement) | 1700 | 0.52 | 840 |

| Cement mortar, cement screed | 2000 | 1.4 | — |

| Cement-sand mortar | 1800…2000 | 0.6…1.2 | 840 |

| Cement-perlite mortar | 800…1000 | 0.16…0.21 | 840 |

| Cement-slag mortar | 1200…1400 | 0.35…0.41 | 840 |

| Soft rubber | — | 0.13…0.16 | 1380 |

| Ordinary hard rubber | 900…1200 | 0.16…0.23 | 1350…1400 |

| Porous rubber | 160…580 | 0.05…0.17 | 2050 |

| Ruberoid (GOST 10923-82) | 600 | 0.17 | 1680 |

| Iron ore | — | 2.9 | — |

| Lamp soot | 170 | 0.07…0.12 | — |

| Sulfur rhombic | 2085 | 0.28 | 762 |

| Silver | 10500 | 429 | 235 |

| Expanded clay shale | 400 | 0.16 | — |

| Slate | 2600…3300 | 0.7…4.8 | — |

| Expanded mica | 100 | 0.07 | — |

| Mica across layers | 2600…3200 | 0.46…0.58 | 880 |

| Mica along the layers | 2700…3200 | 3.4 | 880 |

| Epoxy resin | 1260…1390 | 0.13…0.2 | 1100 |

| Freshly fallen snow | 120…200 | 0.1…0.15 | 2090 |

| Stale snow at 0°C | 400…560 | 0.5 | 2100 |

| Pine and spruce along the grain (wood) | 500 | 0.18 | 2300 |

| Pine and spruce across the grain (GOST 8486-66, GOST 9463-72) | 500 | 0.09 | 2300 |

| Resinous pine 15% humidity (wood) | 600…750 | 0.15…0.23 | 2700 |

| Reinforcing rod steel (GOST 10884-81) | 7850 | 58 | 482 |

| Window glass (GOST 111-78) | 2500 | 0.76 | 840 |

| Glass wool | 155…200 | 0.03 | 800 |

| Fiberglass | 1700…2000 | 0.04 | 840 |

| Fiberglass | 1800 | 0.23 | 800 |

| Fiberglass | 1600…1900 | 0.3…0.37 | — |

| Pressed wood shavings | 800 | 0.12…0.15 | 1080 |

| Anhydrite screed | 2100 | 1.2 | — |

| Cast asphalt screed | 2300 | 0.9 | — |

| Textolite | 1300…1400 | 0.23…0.34 | 1470…1510 |

| Termozit | 300…500 | 0.085…0.13 | — |

| Teflon | 2120 | 0.26 | — |

| Linen fabric | — | 0.088 | — |

| Roofing felt (GOST 10999-76) | 600 | 0.17 | 1680 |

| Poplar (tree) | 350…500 | 0.17 | — |

| Peat slabs | 275…350 | 0.1…0.12 | 2100 |

| Tuff (facing) | 1000…2000 | 0.21…0.76 | 750…880 |

| Tufobeton | 1200…1800 | 0.29…0.64 | 840 |

| Lump charcoal (at 80°C) | 190 | 0.074 | — |

| Gas coal | 1420 | 3.6 | — |

| Ordinary hard coal | 1200…1350 | 0.24…0.27 | — |

| Porcelain | 2300…2500 | 0.25…1.6 | 750…950 |

| Glued plywood (GOST 3916-69) | 600 | 0.12…0.18 | 2300…2500 |

| Fiber red | 1290 | 0.46 | — |

| Fibrolite (gray) | 1100 | 0.22 | 1670 |

| Cellophane | — | 0.1 | — |

| Celluloid | 1400 | 0.21 | — |

| Cement boards | — | 1.92 | — |

| Concrete tiles | 2100 | 1.1 | — |

| Clay tiles | 1900 | 0.85 | — |

| PVC asbestos tiles | 2000 | 0.85 | — |

| Cast iron |

| Shevelin | 140…190 | 0.056…0.07 | — |

| Silk | 100 | 0.038…0.05 | — |

| Granulated slag | 500 | 0.15 | 750 |

| Granulated blast furnace slag | 600…800 | 0.13…0.17 | — |

| Boiler slag | 1000 | 0.29 | 700…750 |

| Cinder concrete | 1120…1500 | 0.6…0.7 | 800 |

| Slag pumice concrete (thermosite concrete) | 1000…1800 | 0.23…0.52 | 840 |

| Slag pumice foam and slag pumice gas concrete | 800…1600 | 0.17…0.47 | 840 |

| Gypsum plaster | 800 | 0.3 | 840 |

| Lime plaster | 1600 | 0.7 | 950 |

| Synthetic resin plaster | 1100 | 0.7 | — |

| Lime plaster with stone dust | 1700 | 0.87 | 920 |

| Polystyrene mortar plaster | 300 | 0.1 | 1200 |

| Perlite plaster | 350…800 | 0.13…0.9 | 1130 |

| Dry plaster | — | 0.21 | — |

| Insulating plaster | 500 | 0.2 | — |

| Facade plaster with polymer additives | 1800 | 1 | 880 |

| Cement plaster | — | 0.9 | — |

| Cement-sand plaster | 1800 | 1.2 | — |

| Shungizite concrete | 1000…1400 | 0.27…0.49 | 840 |

| Crushed stone and sand from expanded perlite (GOST 10832-83) - backfill | 200…600 | 0.064…0.11 | 840 |

| Crushed stone from blast furnace slag (GOST 5578-76), slag pumice (GOST 9760-75) | 400…800 | 0.12…0.18 | 840 |

| and agloporite (GOST 11991-83) - backfill | |||

| Ebonite | 1200 | 0.16…0.17 | 1430 |

| Expanded ebonite | 640 | 0.032 | — |

| Ecowool | 35…60 | 0.032…0.041 | 2300 |

| Ensonite (pressed cardboard) | 400…500 | 0.1…0.11 | — |

| Enamel (organosilicon) | — | 0.16…0.27 | — |

Table of thermal conductivity, heat capacity and density of materials

Thermal conductivity of polystyrene foam from 50 mm to 150 mm is considered thermal insulation

Expanded polystyrene boards, colloquially referred to as polystyrene foam, are an insulating material, usually white. It is made from thermally expanded polystyrene. In appearance, the foam is presented in the form of small moisture-resistant granules; during the melting process at high temperatures, it is smelted into one whole, a slab. The sizes of the granule parts are considered to be from 5 to 15 mm. The outstanding thermal conductivity of 150 mm thick foam is achieved due to a unique structure - granules.

Each granule has a huge number of thin-walled micro-cells, which in turn increase the area of contact with air many times over. We can say with confidence that almost all polystyrene foam consists of atmospheric air, approximately 98%, in turn, this fact is their purpose - thermal insulation of buildings both outside and inside.

Everyone knows, even from physics courses, that atmospheric air is the main insulator of heat in all thermal insulation materials; it is in a normal and rarefied state, in the thickness of the material. Heat-saving, the main quality of polystyrene foam.

As mentioned earlier, polystyrene foam is almost 100% air, and this in turn determines the high ability of polystyrene foam to retain heat. This is due to the fact that air has the lowest thermal conductivity. If we look at the numbers, we will see that the thermal conductivity of polystyrene foam is expressed in the range of values from 0.037 W/mK to 0.043 W/mK. This can be compared with the thermal conductivity of air - 0.027 W/mK.

While the thermal conductivity of popular materials such as wood (0.12 W/mK), red brick (0.7 W/mK), expanded clay (0.12 W/mK) and others used for construction is much higher.

Therefore, polystyrene foam is considered to be the most effective material among the few for thermal insulation of external and internal walls of a building. Residential heating and cooling costs are significantly reduced through the use of polystyrene foam in construction.

The excellent qualities of polystyrene foam boards have found their application in other types of protection, for example: polystyrene foam, which also serves to protect underground and external communications from freezing, due to which their service life increases significantly. Polystyrene foam is also used in industrial equipment (refrigerators, refrigerators) and in warehouses.

Necessity of calculations

Why is it necessary to carry out these calculations, is there any benefit from them in practice? Let's take a closer look.

INTERESTING: Polyethylene pipes LDPE HDPE PEX: types, sizes and characteristics

Assessing the effectiveness of thermal insulation

Different climatic regions of Russia have different temperature conditions, so each of them has its own standard indicators of heat transfer resistance. These calculations are carried out for all elements of the structure in contact with the external environment. If the structural resistance is within normal limits, then you don’t have to worry about insulation.

If thermal insulation of the structure is not provided, then you need to make the right choice of insulating material with suitable thermal characteristics.

Heat loss

Heat losses at home

An equally important task is to predict heat losses, without which it is impossible to properly plan a heating system and create ideal thermal insulation. Such calculations may be necessary when choosing the optimal boiler model, the number of radiators required and their correct placement.

To determine heat losses through any structure, you need to know the resistance, which is calculated using the temperature difference and the amount of heat lost from one square meter of the enclosing structure. And so, if we know the area of the structure and its thermal resistance, and also know for what climatic conditions the calculation is being made, then we can accurately determine the heat losses. There is a good calculator for calculating heat loss at home (it can even calculate how much money will be spent on heating, approximately of course).

Such calculations in a building are carried out for all building envelopes interacting with cold air flows, and then summed up to determine the total heat loss. Based on the obtained value, a heating system is designed that should fully compensate for these losses. If the heat losses are too large, they entail additional financial costs, and not everyone can afford this. In this situation, you need to think about improving the thermal insulation system.

Separately, we need to talk about windows, for which the heat transfer resistance is determined by regulatory documents. There is no need to do the calculations yourself. There are ready-made tables in which resistance values are entered for all types of window and balcony door structures. Thermal losses of windows are calculated based on the area, as well as the temperature difference on different sides of the structure.

The calculations above are suitable for beginners who are taking their first steps in designing energy-efficient homes. If a professional gets down to business, then his calculations are more complex, since many correction factors are additionally taken into account - insolation, light absorption, reflection of sunlight, heterogeneity of structures, location of the house on the site, and others.

Why can’t you build a house only from polyurethane foam?

Based on the above, it turns out that houses should be built from materials with small λ. But this is impossible. Because the smaller the lambda, the lower the density and strength of the material. Polyurethane foam with lambda 0.03 W/(m•degC) is a good insulator and even a subjectively durable material, but it can be easily damaged by a knife, hammer, shovel, crowbar, etc. Brick, stone, and concrete have very large lambdas, so they are poor insulators, but they are difficult to damage.

Therefore, building structures alternate layers of materials. The outer shell and supporting frame are made of strong, rigid materials with a large value of the coefficient λ, and between them a low-strength material with a small lambda is laid.

Note that λ = 0.03 W/(m•degC) for polyurethane foam is typical for material with a density of 40...50 kg/m3. There are polyurethane foam with a density of 200 kg/m3. This is a very durable material, it is used to make elements of furniture and building decor. In this case, the thermal conductivity coefficient is much higher. But there is no requirement for furniture that it must store heat. And such heavy-duty insulation, literally like solid wood, is not used to insulate buildings and structures.

Convection in the atmosphere

The importance of atmospheric convection is great, since thanks to it there are such phenomena as winds, cyclones, cloud formation, rain and others. All these processes obey the physical laws of thermodynamics

Among the processes of convection in the atmosphere, the most important is the water cycle. Here we should consider the questions of what the thermal conductivity and heat capacity of water are. The heat capacity of water is a physical quantity that shows how much heat must be transferred to 1 kg of water in order for its temperature to increase by one degree. It is equal to 4220 J.

View gallery

The water cycle is carried out as follows: the sun heats the waters of the World Ocean, and part of the water evaporates into the atmosphere. Due to the process of convection, water vapor rises to a great height, cools, clouds and clouds form, which lead to precipitation in the form of hail or rain.

Advantages and disadvantages

Metallurgical slag is not used in a humid environment due to its tendency to corrosion.

Despite the difference in technical characteristics, all types of slag as insulation materials have similar positive qualities.

The material is different:

- ease of use;

- low cost;

- optimal air exchange;

- resistance to rotting, fungus formation, and mold growth;

- possibility of use in any premises;

- mechanical strength and chemical neutrality;

- inaccessibility to damage by rodents and insects;

- good thermal conductivity compared to monolithic concrete or brick;

- unlimited use time subject to installation technology;

- fire safety.

The structure of the material imposes restrictions on application. High specific gravity is taken into account when designing load-bearing structures.

Slags are less effective compared to modern specialized products for thermal insulation - polystyrene foam, penoizol, mineral boards, etc.

Industrial waste is not used to insulate surfaces exposed to precipitation, or concrete screeds are placed on top of the backfill to protect against waterlogging. Wet slag loses its insulating properties.

The metallurgical type is susceptible to rust in high humidity conditions.

Industrial types of insulation are hidden with a screed or poured into the voids of brickwork to prevent harmful substances from entering the air of residential premises.

How much insulation is needed

With such a high thermal conductivity coefficient - a large 0.1 W/m2C, it is recommended to use a layer no thinner than 30 cm, but better than 40 - 50 cm.

- Expanded clay or slag is poured from a truck under the floor - under wooden joists.

- Expanded clay can be poured onto soil compacted with crushed stone (floors on the ground) and a screed can be made on top.

It is still problematic to use them on the attic floor - the optimal layer for economic feasibility is 40 cm, but dozens of tones need to be raised to the floor level. The question also arises - will the floors withstand it?, and also - is this an extra load on the foundation?

But on the other hand, wood chips or straw, although not so durable, but separated from the housing by a vapor barrier, will not look bad there if you organize a platform for movement on top...

How to determine heat loss

The main elements of the building through which heat escapes:

- doors (5-20%);

- gender (10-20%);

- roof (15-25%);

- walls (15-35%);

- windows (5-15%).

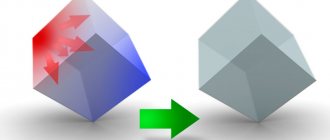

The level of heat loss is determined using a thermal imager. Red indicates the most difficult areas, yellow and green indicate less heat loss. Areas with the least losses are highlighted in blue. The thermal conductivity value is determined in laboratory conditions, and a quality certificate is issued to the material.

The value of thermal conductivity depends on the following parameters:

- Porosity. Pores indicate heterogeneity of the structure. When heat passes through them, cooling will be minimal.

- Humidity. A high level of humidity provokes the displacement of dry air by droplets of liquid from the pores, which is why the value increases many times over.

- Density. Higher density promotes more active interaction between particles. As a result, heat exchange and temperature balancing proceed faster.

Recommendations for thermal insulation

In the process of insulating the floor base, it is necessary to take into account several important nuances. The microclimate in the room will depend on them in the future at any time of the year:

- The height of the thermal insulation layer should be determined by the load on the coating: the greater the load, the thicker the filler layer;

- In the process of thermal insulation of a concrete base, it is advisable to use a reinforcing mesh to improve the strength characteristics of the finishing screed;

- It is advisable to place the slag on waterproofing materials, since when wet, the thermal conductivity of the thermal insulator increases sharply;

- When insulating wooden coverings, the filler is poured in such a way that there is a small air gap of at least 4-5 mm between it and the finishing boards;

- To prevent moisture from getting on the heat insulator, be sure to cover it with a vapor diffusion membrane.

Economical plaster thermal insulation.

Polymer plasters can only be purchased; you cannot make them yourself. But it is more economical to mix solutions with mineral binders yourself.

Hiring hired workers is expensive. But, if you make the mixture yourself, the overall price will drop slightly. Many developers save in this way: they hire plasterers and do the “dirty” work for them. Considering that the help of a helper is paid not per m2, but per day, the savings may not be significant. Approximately 800-1200 rubles/day.

Even cheaper is preparing the wall yourself, placing beacons and rough plastering. The “specialists” will only have to level the coating and apply a decorative solution.

Thermal insulating cheap plaster for exterior use.

Insulating mixtures are more expensive than regular ones because they are more complex.

Moreover, not everything can be done with your own hands. However, the production of cement-based mortar is within the capabilities of any novice builder and can significantly reduce the cost of funds. As a filler, you can use both moisture-resistant bulk materials (foam glass, expanded clay sands) and non-moisture-resistant ones (sawdust, perlite, vermiculite). The latter are only protected with a layer of dense concrete.

For external heat-insulating plaster it is possible to use polystyrene fillers. The most economical filler is crushed polystyrene foam. Its cost is zero, it is free. If you use foam packaging for grinding.

This type of concrete is widely used in Russia and abroad. It is not dense and is not applicable in structures requiring high strength. But it is quite suitable for external insulating plasters.

Do-it-yourself thermal insulation plaster for interior work.

Developers pay less for a square meter of finishing without filler than for a mixture with filler. Therefore, some, especially “enterprising” builders, are trying to add insulating bedding to ready-made mixtures. This is prohibited: such manipulations greatly weaken the solution, reducing its strength and durability.

To reduce the cost per sq. It’s easier to make the batch yourself using inexpensive fillers and binders. Thus, clay-sawdust mortar is practically free, although it is not inferior in strength to gypsum. data-matched-content-ui-type=”image_stacked” data-matched-content-rows-num=”2″ data-matched-content-columns-num=”3″ data-ad-format=”autorelaxed”>

Generalizations of Fourier's law

It should be noted that Fourier’s law does not take into account the inertia of the thermal conduction process, that is, in this model, a change in temperature at some point instantly spreads to the entire body. Fourier's law is not applicable to describe high-frequency processes (and, accordingly, processes whose Fourier series expansion has significant high-frequency harmonics). Examples of such processes are the propagation of ultrasound, shock waves, etc. Maxwell was the first to introduce inertia into the transport equations, and in 1948 Cattaneo proposed a version of Fourier’s law with a relaxation term:

\tau\frac{\partial\mathbf{q}}{\partial t}=-\left(\mathbf{q}+\varkappa\,\nabla T\right).

If the relaxation time \tau is negligible, then this equation becomes Fourier's law.

Definition

Thermal conductivity of a material is the transfer of internal energy from more heated parts to less heated parts. The mechanism of heat transfer differs depending on the state of aggregation of the substance, as well as the temperature distribution over the surface of the material. In other words, the ability of a body to conduct heat is thermal conductivity. It is determined by the amount of heat that is capable of passing through a certain thickness of material in a certain area for a specified time (naturally, for the convenience of calculations, all indicators are equal to one). But plasters differ in the layer of application, which means the indicator will be different

Avoid getting wet

These are porous, vapor-permeable insulation materials; all steam passing through them will condense inside their layer at the dew point. To remove it, you need to ventilate on one side and prevent steam from entering on the other. Therefore, the insulation is separated from the steam source by a vapor barrier.

In floors on joists, the insulation is separated from the ground by a continuous double roofing material flooring - a conventional vapor barrier under the house. First, roofing material is rolled onto the compacted soil, gluing the joints and wrapping it onto the base. Now the humidity of the insulation will always be the same as in the house.

On the attic floor it’s the same thing - first a polypropylene vapor barrier is placed on the floor, and insulation is placed on top of it.

Brief instructions for installing slag wool

Considering that this insulation can react critically to moisture, it is not recommended to install it on the facade of a building. Also, do not attach slag wool to a metal frame. If you plan to insulate vertical or inclined surfaces, then use wooden sheathing. The heat insulator installation diagram is as follows:

- We prepare wooden beams measuring 50x50 or 50x100 millimeters. We select the thickness and width taking into account the width of the insulation.

- We attach the waterproofing to the surface using construction staples, with an overlap of 10 centimeters.

- In order not to unnecessarily cut slag wool and not raise harmful dust from microparticles of fibers, it is recommended to install the lathing in increments to match the width of the mat. Usually it is about 50 centimeters.

- The slabs must fit tightly into the holes between adjacent beams and be laid end-to-end.

- The insulation does not require additional fastening.

- We place a vapor barrier on top of the slag wool. We also attach it with an overlap and glue the joints with special tape.

On top of this structure, you can install additional sheathing for further wall cladding. During work, make sure that the slag wool does not come into contact with metal elements. You also need to be careful and avoid exposed areas of insulation. Firstly, it may get wet. Secondly, slag wool generates dust and will create an unfavorable microclimate in the room. Watch a video about the production of stone wool:

Environmental friendliness of slag

The porous structure of the slag retains heat well.

The material in question is industrial waste. Understanding whether slag is harmful as insulation is important already at the beginning of designing a house.

The insulation technology and places where the backfill is used do not provide for direct contact with humans. Dust and gaseous emissions do not penetrate into the rooms, so they are not able to cause harm to health.

When purchasing, you must require a safety certificate. Some slags emit radioactive background.