Many people call an insulated container the home of the future. The idea of using all-welded metal structures was accepted due to the ease of their transportation over long distances and the possibility of quick installation. Due to their convenient size, they are well suited for garages, basements, cottages and even for the construction of a residential building.

You can stack modules together, stack them on top of each other, connect them. To build a DIY shipping container home on a budget, you need to know how to do it and where you can save money to get the best results. The main work is to insulate the containers inside and out.

View of an uninsulated container inside

How to insulate a container from the inside

For the construction of premises, marine Dry Containers are usually used - these are sealed metal boxes 20 and 40 feet long, i.e. they are roomy enough to comfortably accommodate several people at once. But the problem is that metal is a material with high thermal conductivity, which means that in winter it will be very cold in this iron room, and in summer, on the contrary, it will be too hot. How to insulate a container for housing from the inside?

You can make thermal insulation with expanded polystyrene foam by contacting a specialized company that professionally deals with insulation of various buildings.

This option is the most energy efficient - a layer of polystyrene foam 5 cm is similar in its thermal insulation properties to a one and a half meter brick wall. It does not create dew points, because... the coating is monolithic and integral. Additionally, the effect of a thermos is obtained - heat does not leak out at all, and the room from one heater warms up to a comfortable temperature in just half an hour. In addition, this material is indifferent to moisture, which makes it possible to apply it to the floor of the room. This is especially true if the container stands directly on the ground, without a foundation slab.

The second option is to do the thermal insulation of the container yourself using mineral wool. Its layer should be at least 10-12 cm .

Do not lay the material directly on the floor - it absorbs moisture well, and an accidentally spilled glass of water will gurgle under your feet for a long time.

Instructions for installing sheathing

The lathing technology for all types of walls is standard and consists of the following operations:

- the passage of vertical and horizontal slats is marked. The dimensions of the cells in height and width should be 2-5 cm smaller so that the mats stand upright and stay inside the structure only due to the elasticity of the insulation;

- a vertical frame is attached to the wall. A beam measuring 50x100 mm must be equal to the height of the room;

- horizontal strapping slats are installed. The size of the block is 50x50 mm, the length is equal to the distance between the vertical strapping slats. Attached to a vertical stand using a metal angle. Can be attached directly to the wall;

- Vertical internal racks are installed. The pitch is equal to the width of the insulation minus 2-5 cm. The fastening is carried out either with corners to the horizontal trim, which is easier, or to the wall;

- Horizontal bars are attached between the posts. Do not forget that the distance between them should be slightly less than the size of the insulation boards.

A schematic diagram of the sheathing device is shown below.

Sheathing diagram.

- 1 - sheathing strapping bars;

- 2 - vertical bars;

- 3 - horizontal bars;

- 4 - metal corners on screws or nails;

- 5 - fasteners fixing the harness to the wall.

The process of installing the sheathing is completed by tying the windows and doors.

Preparing the walls from the inside in the apartment

The use of basalt wool for wall insulation minimizes the amount of preparatory work, since there is no need to install lathing for decorative plaster, painting and wallpapering. It is enough to attach a fiberglass reinforcing mesh to the surface of the insulation, and then apply a layer of putty over the dried glue, with the help of which a flat surface will be obtained.

Lathing is only needed for ceramic tiles and PVC panels. You can see how to arrange it correctly using the example of wooden walls. We should not forget that the walls themselves still need to be prepared. In this case, technological operations are performed in the following sequence:

- switches, sockets, lamps, various fasteners, etc. are removed from the walls;

- the old finish is removed, and, if necessary (it’s leaking in many places), the plaster is removed;

- the wall is cleaned of dust and dirt, including smoked areas and oil stains;

- small and large cracks are sealed.

There is no need to carefully level the surface - the cotton wool will hide everything.

Facade preparation

Insulating the outside of a house with basalt wool begins with preparing the facade for thermal insulation work. They are performed according to the following scheme:

- Rainwater drainage systems, doorway and window frames, lanterns, etc. are removed from the walls. As a result, the wall should be completely bare;

- the surface of the walls is cleaned of dirt and dust, deposits of masonry mortar;

- The verticality of the wall is checked. If the slope is more than 1.5 cm for every 3 m, work is carried out to level it (a layer of leveling plaster is applied);

- existing gaps, cracks and holes are sealed with repair mortar. How to properly repair cracks formed due to shrinkage of the building can be found in the work “How to prepare walls for wallpapering”;

- wooden walls are impregnated with fire retardants and antiseptics;

- facade made of brick, concrete, aerated concrete, foam blocks, etc. treated with deep penetration primer in 2 layers;

- Under the sheathing, a vapor barrier membrane (type A) is attached to the walls with the smooth side facing the insulation. For fixation, you can use the staples of a construction stapler. In order for the vapor barrier to be of high quality, the membranes must overlap each other by 15-20 cm (overlapping), the seams are taped with regular tape. Many specialists ignore this operation. But this is the case when “you can’t spoil the porridge with butter”;

Cornice under basalt wool.

Cornice connection at outer corner.

With a wide foundation, you can do without a cornice. Basalt mats are installed directly on the foundation base, previously covered with roofing felt, to prevent moisture from entering the insulation from below.

The sheathing is placed on the fixed membrane.

How to insulate a container from the outside?

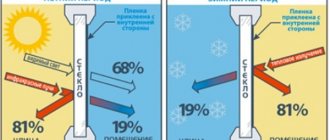

Since metal can easily withstand even 40-degree frost, it is less advisable to insulate the container from the outside than from the inside. The only advantage of this option is the preservation of the internal space of the room.

For external insulation of container walls, you can use foam plastic of considerable thickness, but in this case, when attaching it with “umbrellas,” there is a risk of dew points appearing at the fastening site. By using expanded polystyrene sheets that can be mounted on foam, this problem can easily be avoided.

Experts consider foam polystyrene to be the optimal option for external insulation of containers. It reliably insulates walls, protects metal from aggressive external factors and corrosion.

Is it possible to turn sea containers into full-fledged housing?

Certainly. As mentioned above, the area of one forty-foot Dry Container is 28 m2 . Thus, if you correctly combine only four pieces, you can get a house with an area of 112 m2 - a real full-fledged cottage. Moreover, if the structures are compared vertically, you can get a two-story or three-story building (more than three floors cannot be built, since the metal may not withstand such pressure).

The main advantage of buildings made from sea containers is that the house can be assembled like a construction set - using a grinder we remove unnecessary side or end walls and get the configuration that we need or is convenient for.

Some craftsmen who are particularly demanding in terms of aesthetics manage to cut out shaped (for example, in the form of arches) openings between rooms.

Such a designer house made from a sea container is convenient for living if it is properly insulated. It meets fire and sanitary standards. A building assembled in this way can easily be connected to all necessary communications - water supply and sewerage (both autonomous and centralized), electrical wiring installed and connected, and even centralized heating installed.

Features of external insulation

If it is important to maintain the volume of space, insulation is carried out from the outside

Insulating a house from containers from the outside is in demand in situations where it is important to preserve their internal volume without any changes. For external work, foamed polystyrene is usually used, which protects metal well from corrosion, or thick sheets of foam.

In the second case, special hardware (“umbrellas”) will be required to fasten the material, the use of which poses the threat of the formation of cold bridges. This lack of material must be taken into account when insulating, for which risk areas are additionally treated with liquid heat insulators or sealed with foam.

Pros and cons of container houses

Architects from different parts of the world are experimenting with shipping containers, creating individual designs for their buildings, and offering more and more new ideas.

The popularity of this type of housing is associated with great advantages. Positive sides:

- Relatively low financial costs for construction. This despite the fact that the standard area of such a house is 30 square meters.

- Reliable design that provides maximum protection against unauthorized entry.

- Building a house and insulating it takes a short amount of time.

- You can use a strip foundation, which also seriously reduces construction costs.

- A container house is not susceptible to natural phenomena such as floods or earthquakes.

- Such a building stands out noticeably against the general background.

- Can be used in conditions of heavy snowfall.

- There is a possibility of installation under an inclined plane.

- Suitable not only as temporary housing, but also as a separate permanent home.

Negative sides:

- Containers are intended for sea transportation. To protect cargo from atmospheric agents, a special toxic material was applied to the surface of the containers. Accordingly, before moving into the container, it is necessary to clean it.

- The walls of the container are not intended for habitation. They heat up quite quickly and also cool down quickly at warm and cold temperatures, respectively.

- The structure requires special care, since the walls are susceptible to corrosion.

How does the use of polyurethane foam differ from the use of other insulation materials?

Polyurethane foam (PPU), used for insulation, is a polymer material formed by spraying two components - polyol and isocyanate, mixed together in a special installation. When these two substances interact, a multi-stage reaction occurs, as a result of which a large amount of carbon dioxide is released, forming large or small bubbles. It is to them that the material owes its high level of thermal insulation.

Because polyurethane foam comes in containers rather than in mats or rolls, it is very convenient for this type of insulation. Using the installation and a couple of containers with polyurethane foam components, you can insulate the required number of cars and containers or a container house of a decent area.

Required materials and tools

Penoplex does not allow moisture to pass through, so it is recommended for insulating metal structures.

To organize and implement insulation of a sea container from the inside, you will need to prepare:

- insulation material of the selected type (expanded polystyrene, for example);

- wooden beam 5x5 cm and dowels;

- tape, primer and plastic film;

- mounting foam, paint and sealant.

In addition, it is necessary to purchase plasterboard sheets, as well as chipboard or fiberboard blanks.

Large tools will require a grinder, an electric drill and a screwdriver. In addition, you need to prepare the following toolkit:

- screwdrivers;

- yardstick;

- device for applying polyurethane foam and sealant;

- dowels;

- brush, hammer, sharp knife and building level.

You will also need a pencil or colored felt-tip pen for marking.

When working, you should use protective equipment for the skin of your hands and face - a respiratory mask, gloves and goggles.

Performance

In most cases, polystyrene foam or mineral wool is used as wall insulation from the inside.

The process of insulating a container with your own hands is as follows:

- The selected insulation is attached to a pre-fabricated frame. It is best to use self-tapping screws for this. It is important not to forget to make holes in the lower and upper edges of the walls for condensation to escape.

- After the main thermal insulation work has been carried out, it is necessary to lay a vapor barrier layer. Reinforcing film is perfect for this.

- After the walls are insulated, it is worth moving on to the ceiling and floor. To do this, you can use basalt wool with high density and heat capacity.

Preparing for insulation

Let's consider point by point what work needs to be done to insulate a container for housing:

- Considering that the container is made of perishable materials, it must be prepared in advance. It is necessary to carefully inspect all surfaces for rust, dents and other damage.

- If rust is detected, it is necessary to clean the damaged areas with sandpaper or a grinding machine, if available.

- Before starting the insulation process, it is recommended to prime and paint the walls. If this is not possible, then it is necessary to at least carry out similar work on the damaged areas of the container.

- Before starting insulation work, it is necessary to find and make load-bearing supports for the house. This will require three beams of approximately 50 mm each. They must be made of dry wood. A frame is assembled from blanks around the perimeter of the entire container.

Polyurethane foam

Polyurethane consists of 90% air.

And, as everyone knows, it has low thermal conductivity. That is why this material is good to use as foam insulation. The finish made from it will be vapor and moisture resistant.

But the process of applying polyurethane to walls should only be carried out by a professional. This material must be applied as tightly as possible, and without appropriate experience this will be difficult to do.

For people who like to do everything with their own hands, building a house from a container and insulating it will be an easy and interesting task. Good results can be achieved with modern materials, expert advice and your own creative thought.

Watch the video, which shows in detail the process of insulating a container for housing:

Expanded polystyrene

Expanded polystyrene in slabs is a new generation of foam plastic. It has a higher structure density. Two layers of this material create a seamless vapor barrier, which in turn will prevent the formation of condensation on metal walls.

Insulation with modern foam plastic

How to thermally insulate a container house with polystyrene foam boards? To do this, during the construction of the sheathing, cells are made equal to the width of the foam slab, which is placed in the cells.

Mineral wool

The “pie” of mineral wool insulation is durable and fireproof. Cotton wool has biological and chemical resistance. Metal elements in contact with mineral wool are not subject to corrosion. When installing thermal insulation indoors, mineral wool insulation is covered with a membrane film.

Insulation with mineral wool

This insulation has low vapor permeability, so all condensation will be concentrated in the layers of mineral wool. The film is attached using a construction stapler or expanding anchors.

Advice! If you buy foiled mineral wool, you can do without a vapor barrier film.

If you do not have experience in insulating residential premises, be sure to watch the video on how to properly insulate a container before getting started. After insulation, the house is ready for covering with plasterboard or other materials.

Table of characteristics of materials for thermal insulation of metal containers.

| Name | Properties | Features of insulation |

| Mineral wool | Fungus and mold do not form in the fibers. | You can hide wiring in mineral wool. The installation of these materials begins with the walls, and only then the ceiling is insulated. It is necessary to make holes for condensate to escape. |

| Expanded polystyrene | Has low thermal conductivity. Has the best ratio: price - quality. | |

| Spray polyurethane foam | Durable in use and resistant to wear; | The insulation layer should be continuous. |

How to insulate the ceiling and walls

Liquid polyurethane foam does not leave cracks or air pockets, which extends the service life of steel.

One of the best materials that can be used to insulate surfaces with a wavy structure is polyurethane foam, which hides even large irregularities well. The attractiveness of this insulation is explained by its following advantages:

- ease of installation of the material;

- environmental friendliness;

- tight fit to the walls (without the formation of cracks);

- reliable thermal insulation.

The use of materials of this class reduces convective flows and virtually eliminates the possibility of condensation formation. In addition, extruded polystyrene foam is used to insulate a sea container for living. This material is not inferior in its performance to polyurethane foam, differing from it only in price.

You can also insulate a container for housing with ordinary mineral wool, but its use is limited in conditions of high humidity (in sea containers, for example). In the presence of moisture vapor, this insulating material quickly becomes saturated and begins to rot over time.

Insulation of floors

Logs are installed on the floor, into which insulation is laid - mineral wool, penoplex.

To insulate the floor in a residential container, you need to carry out the following work:

- A dense polyethylene film is laid on the base, providing complete vapor insulation.

- A thermal insulation layer is placed on top, formed on the basis of foam plastic, for example.

- Before laying it, a frame is made of beams (logs), laid across the container in increments of approximately 60-70 cm.

- To fasten the beams, a set of self-tapping screws is used, screwed into each board in at least 3-4 places.

- The insulation is placed in the spaces between the joists so that it fills them to the entire height of the beam and is distributed as densely as possible.

- The remaining gaps must be sealed with polyurethane foam.

The material is covered on top with multi-layer moisture-resistant plywood 10 mm thick, which protects the heat insulator from deformation and damage.

Before installing the baseboards, all gaps around the perimeter of the floor base are treated with sealant or polyurethane foam.

Work order

Purple coral for removing rust before insulation

The procedure for turning an ordinary steel box into a warm container includes several stages. Before insulating a container for permanent residence, you will need to carry out preparatory measures. You should decide in advance on the method of insulation (outside or inside).

Preparatory stage

The essence of preparation is to carefully examine the container for traces of dirt and rust on its surfaces. The former are simply washed off with water, and traces of corrosion, if possible, are cleaned in any convenient way. Typically, a grinder with a metal brush attachment is used for this. Traces of rust are removed from the outside and inside, after which they proceed to coating the metal with a layer of protective primer.

After the primer has dried (after about 2 hours), you can proceed to painting the surfaces, which will reliably protect the metal from moisture and damage. A second layer is applied over the dried paint. Upon completion of these procedures, they proceed to the main insulation operations.

Stages of interior work

To reflect heat, you can use penofol before laying mineral wool.

Insulating a container from the inside is possible when the loss of part of the volume of the internal space does not matter. The work carried out in this case is divided into two stages: finishing of the side surfaces and thermal insulation of the ceiling. When carrying out them, the walls should be insulated first. To do this, a wooden sheathing consisting of bars of a suitable size is attached to them. Then, plates of the selected heat insulator (expanded polystyrene, for example) are placed in the spaces between them. To enhance the insulation effect from cold air masses, it is additionally covered with a layer of penofol.

The ceilings are insulated in the same way as the walls, after which everything is sheathed with plasterboard sheets.

If you plan to install a stove inside the structure, it should be taken into account that polystyrene foam and polyurethane foam do not tolerate high temperatures. Therefore, the areas of their contact with heated surfaces will need to be insulated with glass wool gaskets.

What else determines the price of a container house?

- the number of containers used – a building made from one container unit will cost less, but if you buy several at once you can get a good discount;

- condition - the price varies greatly depending on whether you are purchasing a new container or a previously used one;

- the need for additional services - whether you insulate the container yourself, as well as carry out all the necessary communications (electricity, plumbing and sanitation, heating) or contact a specialized company, its final cost will also depend.

The only disadvantages of container construction include the fact that it is impossible to build a tall (more than three floors) house from containers and its urban character - it is difficult to beat the rectangular shape. Although such a strict geometric appearance is precisely what attracts those who decide to build a house from containers.

Where else can you use insulated containers?

The scope of application of marine packaging is very wide - from a seasonal summer cottage shed for storing garden tools to permanent housing. In Europe, budget hotels, fast food establishments and even public transport stops are built from it. And as cabins on construction sites, staff and residential trailers on shifts, etc. they are simply irreplaceable. This is due to the fact that corrugated steel is a very durable, weatherproof material. The container, even without additional external finishing, can last for decades.

One of the most popular is block container bcode 01. It is a container made of galvanized metal, insulated and lined with chipboard. It can be used as living quarters for shift workers or as a change house for security at a checkpoint.

The container is well insulated, the inside is lined with particle boards that are pleasant to the touch, and is cozy and comfortable.

Fire protection of metal structures of two different types

Structural fire protection system for metal structures ET Profile

A system of structural fire protection for metal structures with different fire resistance limits.

Provides for the use of basalt fire-retardant foil material (MBOR) in combination with the fire-retardant adhesive composition "Plazas".

It is used for protection against exposure to open flames and high temperatures in the event of a fire in buildings and structures of any type and purpose.

To learn more

Structural fire protection system for metal structures ET-Metal

A system of structural fire protection for metal structures with different fire resistance limits.

Provides for the use of basalt mineral fire-resistant board EURO-LIT in combination with fire-retardant adhesive composition "Plazas".

It is used for protection against exposure to open flames and high temperatures in the event of a fire in buildings and structures of any type and purpose.

To learn more

Environmental cleanliness, radiation safety

Basalt insulation Tizol, which is used as the main material for fire protection of metal structures, is made from natural, environmentally friendly raw materials - basalt.

It is absolutely safe for use in residential and industrial premises, does not contain adhesive or binding elements, and therefore does not emit harmful substances even when exposed to high temperatures or during prolonged use.

EFFICIENT FIRE PROTECTION

Due to the fact that basalt fiber can withstand temperatures up to 1000˚C, material made from it can significantly enhance the fire-resistant properties of metal structures protected by it.

Vibration resistance, moisture resistance

Even in conditions of increased vibration, all the unique properties of Tizol basalt insulation remain unchanged. Pressure, bending and compaction of the material do not lead to a deterioration in its physical and mechanical properties, since basalt fiber can withstand high static and vibration loads.

Low load on the structure

The material used for fire protection is basalt mineral wool.

In the material for fire protection of metal structures, this wool is formed in the form of a canvas or plate and has different thicknesses and densities, which makes it possible to optimally calculate the fire resistance threshold and the consumption of the required amount of material with a minimum load on the structure.

Aesthetic appearance

The surface of metal structures, coated with fire-retardant material MBOR, looks aesthetically pleasing and finished. In this regard, there is no need to use additional decorative means.

The surface of metal elements, covered with a fire-resistant basalt slab, can be plastered or covered with various non-combustible building materials, which will give it a completely aesthetic appearance while maintaining all fire-resistant characteristics.

Is a sea container suitable for arranging a cellar?

The container is a sealed container. If you insulate it correctly, you will get a thermos. Therefore, some summer residents and owners of private houses have a question: is it possible to adapt the structure to a cellar?

It is difficult to give a definite answer to this question. It all depends on the type of soil and the depth of soil freezing. Experts are inclined to believe that in areas where light sandy and sandy loam soils predominate, this is quite possible, but only if the container is well anchored (and it does not “float” to the surface). Naturally, in this case it will be necessary to take care of additional thermal insulation of the structure. For heavy loams, it is not recommended to use a container for arranging a cellar - lateral soil pressure can deform it. This, in turn, is fraught with a violation of the integrity of the structure and deterioration of its thermal insulation.

Insulation of wooden and refrigerator cars

To insulate wooden cars, a beam is hammered onto their inner surface, between which foam is foamed. Spraying is carried out in such a way that there is a small space between the edge of the polymer and the sheathing for air ventilation. The hardened foam is covered with any finishing material - boards, plywood. After insulation and refurbishment, such trailers can be used as residential and technical premises.

When insulating isothermal (refrigerated) cars and tanks, a layer of polyurethane foam is placed in the enclosing structures located between the inner and outer casing by pouring, which forms a kind of thick shell that does not let heat and cold in.

The use of polyurethane foam makes it possible to do without protective films, as well as laying asbestos and other fiberglass fire-retardant materials, which creates good savings.

Table of contents:

- How does the use of polyurethane foam differ from the use of other insulation materials?

- Insulation of wagons and containers for transportation

- How metal cars and containers are insulated using polyurethane foam

- Insulation of wooden and refrigerator cars

- Insulation of containers for living

- Technology of spraying polyurethane foam onto a converted container

Recently, this service has become increasingly in demand, since wagons and containers are used not only for transporting goods, but also as mobile warehouses, mobile dormitories, workshops, and cabins. Shipping containers are often purchased for conversion into cheap housing. A variety of buildings are built from them - from garden houses and tire shops to student dormitories and shopping centers. Naturally, you need to keep it warm inside the container.

How to calculate the approximate area of a container

Since the cost of the work carried out depends on the area of the surface being sprayed, to insulate container buildings you need to know the dimensions of the modules

| Dimensions | Container type | ||||||

| standard 20 feet | high 20 feet | standard 40 feet | high 40 feet | tall, wide 40 feet | tall, wide 45 ft 2.75 m | high, wide 45 ft 2.90 m | |

| external dimensions | |||||||

| height, mm | 2591,00 | 2896,00 | 2591,00 | 2896,00 | 2750,00 | 2896,00 | |

| length, mm | 6058,00 | 12192,00 | 13716,00 | ||||

| width, mm | 2438,00 | 2500,00 | |||||

| inner dimensions | |||||||

| height, mm | 2381,00 | 2693,00 | 2372,00 | 2693,00 | 2549,00 | 2670,00 | |

| length, mm | 5905,00 | 12039,00 | 13513,00 | ||||

| width, mm | 2350,00 | 2432,00 | 2444,00 | ||||

By multiplying these data yourself, you can calculate the area of the container and, using the attached price list, calculate the cost of the work. When insulating large areas, organizations that carry out such work give a discount.

Possible problems

When insulating a room from the inside, problems may arise. They can be avoided using the following recommendations:

- When insulating internally, it is very important to lay the materials in a continuous layer, avoiding any gaps. It is easier to achieve this effect when using polyurethane foam.

- It is important to prevent contact of materials with high thermal conductivity with the interior of the room. If isolated rooms are planned in the house, and a metal partition is needed, it is prohibited to weld it to the walls of the container.

If you take these two points into account and do everything correctly, heat will not escape from the room through the walls. Containers with a constant temperature are called isothermal.

Methods of fastening plates

There are two methods of attaching slabs for thermal insulation, which are suitable for internal and external insulation. In the first option, a sheathing with cells is made into which the slabs are laid. The process goes like this:

- Markings are made on the surface of the wall so that the size of the resulting cells is equal to the size of the slabs.

- The wooden frame is securely fastened to the metal walls of the cabin.

- The slabs are packed tightly into cells.

The second method is to attach the insulating sheathing directly to the metal surface. To do this, the metal is thoroughly cleaned of dust and dirt, and then moistened with water so that the polyurethane foam adheres better. Then foam is applied along the contour of the slabs, applied to the wall and held for several minutes.

The material needs a day to dry completely. At the end the walls are finished with plaster. You can determine the water resistance of an insulated container by watering the walls and roof with water.

Preparation

The sea container is an all-metal structure. Therefore, the thermal circuit should be made on all surfaces at once. The insulation of the container inside begins from the walls, then the heat-insulating material is laid on the floor, under the ceiling lining. For external insulation, the thermal insulation technology may vary depending on the roof design of the modular building:

- exploitable roof - insulation is carried out before laying the membrane, heat-insulating material is attached to the walls after the roof is installed;

- flat roof - insulated from the inside, under the ceiling lining;

- pitched roof - insulation is laid from the inside of the attic on top of the ceiling, attached to the facades.

Rice. 4 Container house with flat roof

Depending on the design of the foundation, the following insulation method is used:

- MZLF tape, slab - the insulation layer passes from the wall to the base vertically, then continues horizontally under the blind area;

- columnar, pile grillage - it is necessary to make a fence, which does not make sense to insulate.

The fence imitates a plinth and protects against the penetration of dirt, rodents, and animals under the building. Inside it there are communication input nodes, which also need to be covered with thermal insulation materials in the air and to a depth of 1.5 m to protect against freezing.

Rice. 5 Comprehensive insulation of walls, blind area and basement

Preparation for insulation of the walls and ceiling of a sea container involves the manufacture of a frame structure, taking into account the following nuances:

- racks and lintels are mounted on brackets;

- the length of the brackets is equal to the thickness of the soya thermal insulation plus a ventilated gap of 3 cm minimum.

Rice. 6 The sheathing on the brackets should not be adjacent to the walls

Metal surfaces are additionally degreased to increase adhesion to adhesives on which thermal insulation materials will be attached.

What affects the value of a home

The most affordable option is to purchase a house made from one container. Such buildings are suitable for country houses for temporary residence. To build a permanent home, you will need several containers, due to which the cost of materials will increase several times depending on the size of the future home.

Affects the final price and number of floors of the house. If you want to make a 2nd floor by adding 2-3 containers on top, construction costs will at least double. A noticeable increase in the cost of future housing is ensured by turning to contractor firms that build houses from sea containers. Additionally, costs are greatly influenced by the territory and conditions under which construction will take place, as well as the type and quality of finishing, soil characteristics, and others.

Container house project

Shipping containers are popular with architects. People with a creative streak are converting trailers into incredibly beautiful residential structures. Some use such houses as change houses, while others build full-fledged two-story cottages with balconies from containers with their own hands. For construction, blocks 6 meters long and weighing 2200 kg are most often used.

The layout of container housing varies; it is developed for each individual individually. For such buildings, it is important to accurately calculate the possible load. First, future residents must decide on the number of rooms, the floor plan and decide whether the house will have a shower and toilet. To avoid errors in calculations, you can contact specialized companies that develop container house projects. They will take into account the nuances and calculate the amount of materials. The internal part of the block can be divided into compartments of different sizes with the installation of additional doors, windows, hatches.

Housing built according to the project will be reliable, durable and beautiful. Sometimes combined plans are made, in which other materials are additionally used during construction. After completing the project drawing, it is sent to production, where blanks are made - windows, doors, floors and others. They are then brought to the construction site, the house is assembled, ventilation is installed and a roof is erected, since containers with a tarpaulin top are often found.