Attic spaces, the frame of which is presented in the form of wooden trusses, are correctly called “cold”. These objects are not particularly durable compared to reinforced concrete structures, but they have their advantages.

Basically they come down to the great possibilities of using thermal insulation materials. A classic attic floor on wooden beams is equipped with insulation using ordinary carpentry tools, unlike reinforced concrete, where special equipment is required.

Insulation of the attic floor, in addition to insulation, requires the installation of proper vapor barriers and exhaust hoods that prevent the formation of mold and mildew. And if you correctly follow the technology when installing insulating material, then air exchange will be guaranteed.

Options for insulating an attic floor using wooden beams

The design of the attic directly depends on the parameters of the building and the purposes intended for the use of this room. The under-roof space plays the role of a kind of air gap separating warm heated rooms from the cold roof.

In this case, the floor in the attic performs two tasks:

Isolating. In the attic of a house, the air temperature is almost no different from the street temperature. In this case, the floors have an insulating function, thereby preventing the penetration of cold air into the living spaces.

Carrier. In most cases, the ceiling on wooden beams between the attic space and the upper floor of the house, like the walls, has a load-bearing function. In this regard, it must be reliable and durable, since people move along it, utensils are stored or any equipment is placed.

Therefore, in order to know the permissible load on the attic floors, it is necessary to make a calculation. Then, based on their results, draw up a project that will show how to properly insulate the attic floor of a building.

Step by step guide

Before you start laying a vapor barrier on the rough ceiling, you need to understand what this part of the room is like. According to its purpose, a rough ceiling is a special ceiling that is installed during the construction of a building. Depending on the material of manufacture, the structure takes on a number of loads. For example, wood products differ significantly from concrete products, having their own characteristics and properties. At their base is a wooden beam.

When choosing vapor barrier materials for the ceiling, it is necessary to clearly understand what tasks and loads it will encounter.

We advise you not to neglect the installation of vapor barrier materials

And at the stage of finishing the rough ceiling, it is recommended to adhere to the following instructions:

- The vapor barrier layer is fixed directly to the beams.

- An unedged board is stuffed in compliance with a certain step.

- After this, they begin laying thermal insulation.

- Next, they arrange the floor on the second floor using boards.

- The finished structure is leveled and decorated with a decorative layer.

When arranging wooden houses, various methods of insulating the ceiling from moisture are used. The simplest one looks like this: a boardwalk is placed at the bottom of the beams, and a layer of vapor barrier is laid on top of the structure. In the second option, cranial bars are fixed to the ceiling, and a rough coating is placed on top of them. In this case, the vapor barrier can be placed in both the lower and upper parts.

Selection of material for insulation

The technique for insulating an attic is simple, since the material is laid directly on the floor, in the gap between the rafters and wooden floor beams. If you plan to use the attic space as an attic, then you also need to insulate the roof.

To insulate the floor between the beams in the attic, several types of insulation are used:

- Mineral wool.

- Styrofoam.

- Expanded polystyrene.

- Sawdust.

- Expanded clay.

- Foam.

Let's take a closer look at each insulating product.

Thermal insulation from inside the living room

Installing a ceiling in a private house with a cold attic and insulation from the inside is done much less frequently, since the work is accompanied by a number of disadvantages:

- the ceiling level decreases;

- Carrying out thermal insulation work disrupts the finishing, if it has already been completed, and requires subsequent repairs;

- not all thermal insulation materials are useful and environmentally friendly, which leads either to an increase in the cost of work or to a decrease in living comfort. For this reason, the use of mineral wool is not recommended. In addition, it is always recommended to leave a ventilation gap between the thermal insulation material and the finishing material.

Mineral wool insulation

In order to save heat, the material must be placed between steam and waterproofing films. Vapor barrier protects against moist air masses that form in living spaces near the ceiling, especially at the junction with the walls. The second layer protects the wool from water entering from the roof through microcracks and holes in the roof.

The attic space of a house is insulated most often from the floor rather than from the ceiling of the lower floor. For this purpose, mineral wool is a reliable, inexpensive insulating material with high compression, allowing it to cover the surface of not only the floor, but also beams of various shapes. This insulation is sold in rolls or slabs of different thicknesses.

At the same time, it has the following advantages:

- Budget cost.

- Easy to install.

- Rodents do not grow in such insulation.

- High fire safety of the material.

- Ability to isolate any uneven surface.

At the same time, when working with mineral wool, it is necessary to take protective measures: wear thick clothing, work in goggles and protective gloves, and it is also advisable to use a respirator.

Insulating the attic with mineral wool

The best and most sought after

If we talk about the most popular insulation on the market, then 2/3 of all houses are insulated using mineral wool , both for concrete floors and beams.

It is chosen for its moisture resistance, thickness, fire resistance and elasticity.

At the moment, this is the best option in terms of price and quality. It is easy to install and requires no further maintenance. It is used for both warm and cold attics.

However, foam, polystyrene insulation, although not as malleable in shape, does not require the use of a vapor barrier. They are not picky in installation because they do not crumble and do not get under the skin or into the respiratory tract. But they are more flammable, and this indicator reduces the scores for this material.

Natural insulation materials provide an advantage only from an environmental point of view; otherwise, they burn great and serve as a home for mice and parasites.

Granular insulation creates a truly warm atmosphere, but it is incredibly heavy and some types require the use of expensive equipment.

The best thermal insulators for warm and cold attics are those that are sprayed , filling all cavities, relief and cracks. They do not burn or ignite, do not require vapor or waterproofing, do not decompose over time and are not attractive to rodents and bacteria.

But since spraying work costs several times more than installing tile or matte insulation yourself, foam insulation is still left out.

Styrofoam

Insulating an attic space with polystyrene foam is a good option for converting it into an attic, suitable for year-round use. This material has low thermal conductivity, as it is produced in the form of foamed air granules pressed into slabs.

During installation, the foam must be cut so that the plates fit tightly between the attic floors. Any gaps and cracks become “bridges” for the penetration of cold, and thereby significantly worsen the quality of insulation.

In this case, it is necessary to maintain a distance between the foam board and the waterproofing film of at least 2-3 cm. It is recommended to use it as insulation with a thickness of 70 mm, and in regions with a harsh climate - 100 mm.

Attention! When installing a vapor barrier film, you need to pay attention to the fact that it faces the insulation with the required layer, according to the instructions. Otherwise, the opposite effect will be produced: all the steam will be directed towards the insulating material.

Roof insulation from the inside with foam plastic

Polyurethane foam

Its parameters are almost identical to polystyrene foam. It has higher mechanical strength and low toxicity. Available in yellow and orange slabs measuring 120/60 cm. Marked with the letters PPU. This information should be taken into account due to the fact that in trade organizations it is also often called expanded polystyrene, and when ordering by phone, it is worth clarifying what they are selling PPU or PSB-S.

Insulation using polyurethane foam

It’s just as easy to install with your own hands as polystyrene foam. The simplest operations of cutting to size and laying between beams or rafters do not create any difficulties. Laying a vapor barrier layer is not required.

Note

One significant disadvantage of these materials is their low fire resistance. Therefore, it is worth taking a responsible approach to the installation of electrical wiring when insulating the attic floor, so as not to start a future fire in the walls with your own hands.

Special corrugated non-flammable insulation of the electrical wire should be used. When using the attic as a non-residential space, it is enough to apply a fire-retardant coating to the insulation and enjoy the warmth in the house for at least 30 years, proud that it was created with your own hands.

Cost of materials

- Name

- Foam plastic PSB-S-25

- Polyurethane foam Polimer

- Mineral wool ISOVER

- Unit

- sheet

- balloon

- m2

- Price, rubles

- 100

- 400

- 33

The first layer of vapor barrier is spread over the ceiling and attached to the beams in such a way as to form a tray into which the insulation will be laid.

Before laying, the mineral wool should be allowed to rest after opening the package.

After the material has increased in volume, you can begin work. You can cut the insulation with a regular knife. The size of the sheets should be 7/10 centimeters larger than the inter-rafter pitch. This will ensure that the material adheres tightly to the beams.

It would be useful to lay additional vapor barrier between the layers of the material being laid. It will significantly increase the thermal insulation properties of the material.

Extruded polystyrene foam

When insulating the ceiling of a living space over attic floors, this material is considered the best option for many builders. This insulation does not cause any difficulties during installation; it can be laid under any beam ceiling.

It also saves space, since you can get by with two to three times less thickness than using the same mineral wool. Extruded polystyrene foam comes in different types, as it is produced by different manufacturers. To insulate attic floors, the density of such material should be about 32-34 kg/m, and its thickness should be from 40 to 100 mm.

Manufacturers also produce shaped elements from expanded polystyrene, which are used to lay out complex fragments in the attic ceiling. It is convenient to install this insulation in two layers: the first layer is laid between the attic floors, and the second layer is applied end-to-end along the bottom row, covering the wooden beams as well.

The main disadvantage of such insulation is that it is flammable. To reduce the fire hazard, you can lay mineral wool with expanded polystyrene, or add antipyrine.

Insulation of the attic with polystyrene foam

How can you isolate?

To insulate floors, materials are selected that are most suitable for a particular climate and the structure of the floors.

When purchasing thermal insulation material, you should make the following requirements for it :

- lowest thermal conductivity;

- environmental friendliness (no toxic substances released);

- fire resistance;

- thickness appropriate to the climate;

- resistance to moisture accumulation;

- sufficient strength, resistance to shrinkage;

- ease of installation.

Insulation materials can also be divided according to their release form. There are both fairly dense options that you can walk on, as well as loose ones, such as sawdust or foam. The entire process of installing thermal insulation, including the structure of the ceiling itself (the pitch between the beams and the presence of sheathing), depends on the form of release.

The thickness of the insulation is of great importance; it is calculated using a certain formula:

q=R*k

Where:

- q – required material thickness;

- R – thermal resistance;

- k is the thermal conductivity of the insulation.

Table 1 shows the thermal resistance for each region:

Table 2 shows the thermal conductivity for each material:

For example , to calculate the required thickness of mineral wool for a wooden floor in Voronezh, you need 3.8*0.035=0.133. 13 cm is the required insulation thickness. But since the cotton wool will shrink over time, this figure can be rounded to 15-17 cm.

Minvata

For interfloor wooden floors, mineral wool and its varieties are most often chosen. This choice is due to the ease of installation, sufficient thickness, as well as excellent resistance to fire and smoldering. Basalt wool begins to melt only at a temperature of +600 degrees.

This is the highest figure among all known insulation materials. But it has a significant disadvantage - it easily accumulates moisture, as a result of which it becomes moldy. It is for this that the highest quality waterproofing is needed.

Polystyrene

There are 2 options for polystyrene:

- extruded;

- non-extruded.

They differ only in the degree of density. Non-extruded polystyrene is ordinary foam plastic, it is quite brittle and flammable material. Extruded polystyrene foam (EPS) is more durable and monolithic.

In terms of thermal conductivity and other indicators, they are almost the same. This insulation does not require water insulation; insects and bacteria are not interested in it.

Polyurethane foam

This type of insulation is considered the highest quality.

It has the required thermal conductivity, does not absorb moisture at all, does not shrink or decompose. Apply to any surface using a special sprayer .

As it dries, it swells, creating the desired thickness. It can be sprayed both on the floor and on the ceiling, insulating the ceiling on either side. During installation, polyurethane foam gets into all the cracks without creating gaps.

The only negative is that insulation services are quite expensive, so they are not yet so popular.

Wood sawdust

If there are no other options, you can insulate the ceiling with sawdust and shavings. The process is not simple, but it is cheap. To mix the composition, take cement, lime and water, mix and lay out a layer in the cells between the beams .

The insulation is heavy due to cement, and flammable due to sawdust. Therefore, the chips must also be treated with fire retardants. There are many disadvantages - mice love it, mold, it burns, it is afraid of moisture. One of the advantages is that it is cheap, you can buy a machine of sawdust for 3-5 thousand rubles and use it to insulate all floors from the basement to the attic.

Expanded clay

Expanded clay is produced in granules, similar in diameter to sand, crushed stone or gravel. These names are used for classification. For wooden flooring, coarse expanded clay is used. It is laid on a vapor barrier because it is able to absorb moisture because, in fact, it is fractional clay.

In terms of thermal conductivity, it is inferior to all of the listed insulation materials, and it is also quite heavy, because the insulation layer for it to work requires a large one, about 20 cm or more. It is quite popular on the market due to its low cost.

Expanded clay

Expanded clay for the attic of a house is a traditional method of thermal insulation of a technical floor. This material is poured between wooden floors with a layer thickness of at least 150 mm. This mass is a universal means that can insulate floor structures, and it can also be used as thermal insulation together with other bulk materials.

Attention! Expanded clay is a fairly light insulation material, but when a thick layer is applied, the load-bearing surface of the ceiling will bear a large load.

Thermal insulation is best carried out at the construction stage of the building, since it is easy to waterproof the ceilings of the rooms under the attic and provide for an exhaust hood.

To do this, cover the ceiling with a vapor barrier film to protect the expanded clay layer from getting wet. It is not recommended to pour it directly onto the floorboards for another reason: during operation and operation of the room, a lot of dust is released, which penetrates into the living rooms.

Expanded clay insulation layer

How to insulate a cold attic: a few more nuances

Insulation of reinforced concrete floors

For even surfaces, it is recommended to insulate with EPS (Extruded Polystyrene Foam). Between the slabs it is necessary to putty, apply waterproofing, and lay EPS in several layers. If there is a need for a screed, then reinforce it with mesh and pour the solution along the beacons. If desired, lay several layers of board material, such as plywood or OSB, staggered.

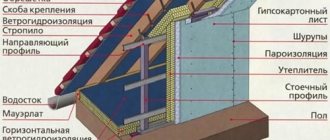

Ceiling insulation

In most cases, a rafter system is used as the ceiling of the attic. The construction of a work scheme for insulating rafters is similar to insulating an attic using beams. A vapor-permeable membrane that protects from wind is mounted across the rafters (from above) using a counter-batten with a thickness of 0.5 cm. Next is the flooring or sheathing for the roof covering, and below, between the rafters, insulation (in those regions of Russia where low temperatures reach their maximum, a double layer is required). A vapor barrier is nailed on top of the insulation (a gap for ventilation is not needed). Then again the counter-rail and the material on which the attic ceiling will be mounted.

Insulation of communications

In cases where there are no plans to install an attic in the attic, we carry out work to insulate the ventilation ducts. The easiest way is to wrap the pipes in mineral wool and secure the roofing material on top using ordinary wire. To achieve aesthetic perfection, use a special design for communications, the so-called fan “shell” made of polystyrene foam, polyurethane foam and other modern materials. The installation method for these structures is simple; just snap them onto the pipe and tape them with electrical tape.

Insulation of communications in the attic

Fire prevention measures

It is not enough to know how to insulate a cold attic; it is extremely important to properly protect the attic space and roof from fire. Even if you used fire-resistant materials for insulation, slopes and wooden floors may catch fire

Therefore, you should not neglect the use of fire retardants (specially developed means for protection against fire). When using varnishes and paints, choose those that protect against fire. You can protect yourself and your family if there is a fire hatch on the roof.

Sawdust

Sawdust is a product of lumber processing in the woodworking industry. This is the cheapest insulation for attic floors, since you can buy sawdust at any sawmill for free. Thus, sawdust is still an option as a reliable heat insulator in attic spaces.

On a note! Sawdust is of organic origin, therefore, it is completely harmless to human health. Since ancient times in Rus', sawdust mixed with clay has been used as insulation in attics.

Sawdust has the following advantages:

- Low cost of thermal insulation. Probably, the popularity of such insulation lies precisely because of this factor: its cost is almost equal to the cost of transportation.

- Safety for human health. Wood shavings and sawdust do not cause skin irritation, allergies, or poisoning, which cannot be said with complete confidence about modern insulation materials.

- Low thermal conductivity coefficient. Unlike wood, chips have a porous structure, so they have low heat conductivity.

- Easy installation. To form a heat-insulating layer in the attic floors, no special skills are required. You just need to mix sawdust with clay or lime, and then pour it into the space between the attic floors.

The only significant drawback is the fire hazard of the material, despite the mixture with other non-flammable substances.

Thermal insulation from sawdust

Mineral (stone) wool

Rocks are melted into magma and then formed into hollow fibers using a centrifuge. A binder is added to form rolls or slabs.

Mineral wool is the best choice for insulating the attic floor in a wooden house. It has a low thermal conductivity and belongs to the class of non-flammable heat insulators. Additionally, basalt wool has a high level of sound insulation.

Characteristics:

- Heat transfer coefficient - 0.032-0.04 W/m*K. This is one of the best indicators among insulation materials;

- Fire safety. Basalt wool prevents the spread of fire and does not change its properties when exposed to temperatures up to +1000°C;

- A good sound absorption rate is due to the porous structure of the material;

- Environmental Safety;

- Durability. The interweaving of fibers with each other ensures rigidity and maintains the integrity of the structure for a long time.

Basalt wool allows moisture to pass through, so the installation of vapor barrier materials and a waterproofing layer is necessary.

Brands: Rockwool LIGHT BUTTS, TechnoNIKOL ROCKLITE, Isoroc ISOLIGHT.

Foam

Recently, two types of insulating materials have become popular for insulating attic floors: blown-in wool and ecowool. The latter material consists of 80% cellulose fibers made from waste paper, and 20% from additives, which are fire-fighting and antiseptic components.

This material has low thermal conductivity, it is very light, and looks like regular polyurethane foam. Both types of insulation are usually sprayed onto the boards between wooden beams, but sometimes ecowool is used in granules in a crumbly state. In this case, this mixture, as an option, is simply poured between the floor beams and compacted.

Foam - insulation for the attic

Vapor barrier

The vapor barrier film protects wooden beam ceilings from moisture formed in the air of residential premises. In addition, it protects floors from the appearance of mold and mildew in the insulating material.

Regardless of how the attic floor is made, the vapor barrier for the floor should form a continuous carpet that does not allow condensation to penetrate. Particular attention should be paid at the joints with walls, where there is a high probability of condensation penetration. To do this, the covering film is overlapped and its edges are glued together with tape.

Vapor barrier under insulation

Insulation technology

To apply the insulation correctly, follow the step-by-step instructions:

Step #1 . Carry out an inspection and, if defects are found, eliminate them. Treat boards and timber with antiseptics and fungicides.

Treatment of attic floors with antiseptics

Step No. 2. Lay out the vapor barrier material, seal all gaps with mounting tape.

Attic vapor barrier

Step No. 3. Lay (pour) insulation into the openings of the wooden floors on the floor.

Laying insulation in openings

Step No. 4. Pay special attention to the joints between the slabs of insulating material. If necessary, apply additional insulation.

Step No. 5. Lay the waterproofing film overlapping, and fasten the joints with mounting tape.

Attic waterproofing

Step No. 6. Separately install insulation on the ventilation duct, chimney pipes in the form of basalt wool, perlite, and it is advisable to install a special corrugation on top.

Insulating the air duct in the attic

General recommendations for the preparatory stage

We pay attention to the dimensions of the beams.

If they are made in the form of a reliable frame, this will allow you to fill the slats for subsequent placement of insulation. We correctly calculate the distance between the beams, otherwise the heat-insulating filling may shift

To avoid flaws when measuring, a triangular-shaped material is used to lay the material, which ensures convenient diagonal alignment. According to the letter of the law for the regions of Russia, the thickness of the warm substrate is 20 cm. Along the perimeter of the area, the insulation must be protected from dampness with a roofing membrane of 1 cm. To ensure joining, the insulation is overlapped.

The uniform distribution of the material is controlled. Avoid folds and irregularities. In the window area, the insulation should be located perpendicular to the floor with a smooth transition into the slope. In areas of slopes, thermal insulation is laid in two steps: a layer is laid between the rafter bases with gaps, then the film is stretched overlapping.

Before starting work, it is necessary to check the joints of the floors for the presence of gaps. The discovered cracks are filled with lime mortar and tow. Frame structures should be treated with an antiseptic and fire retardant solution. If ventilation ducts are not provided, you need to take care of this. They should be located around the perimeter of the walls and ensure high-quality air circulation.

Installation of wooden attic beams

The attic ceilings are designed to separate the living rooms from the under-roof space. They do not allow cold air to pass through, so the main task is their thermal insulation. Various equipment is also often installed in the attic.

In this regard, another important task is to create a solid foundation that can withstand this load. Thus, the safety of people, their comfortable living, and also the durability of the structure depend on the high-quality arrangement of wooden floors.

Installation of floors under insulation

Organization of ventilation

The main purpose of ventilation in this case is as follows:

- removal of excess water vapor penetrating through the ceiling from below from the residential part of the building, in order to prevent the appearance of condensation and moistening of the insulation and roof truss system;

- creating an optimal microclimate.

- Ventilation occurs through two types of vents:

- cornices (the air passing through them is called supply air);

- ridge (exhaust air passes through them).

Their total area should be 0.2-0.33% of the roof covering area, in other words for a covering area of 1000 sq.m. The area of the vents should vary from 2 to 3.33 sq.m. This calculation is carried out in accordance with SNiP standards, and it is quite simple to do. It applies equally to various options for roofing pie covered with metal tiles, corrugated sheets or soft tiles.

The basic rule for the location of vents is as follows: the ventilation system operates most efficiently when the inlet and outlet openings are as far apart as possible.

In most cases, a scheme is used with an approximately uniform arrangement of vents around the perimeter of the building under the overhangs and along the entire length of the roof ridge.

Additional ventilation is often performed through dormer windows installed on the gables or roof slopes, which help with enhanced ventilation. When installing them, they are guided by the rule of symmetry: in order to prevent the presence of unventilated areas, dormer windows should be located on opposite slopes.

Typically, dormer windows are made of three types:

They are installed in such a way that the lower part of the window is no more than 1 meter from the floor level, and the upper part is at least 1.75 meters higher from the floor level. Often, dormer windows are used as an exit to the roof for the purpose of inspecting the roof and the elements of the ventilation system and chimneys installed on it. Sometimes a special hatch is installed for this purpose.

In order to prevent birds from entering, the vents are equipped with protective nets or gratings, and blinds are installed on the dormer windows.