Among thermal insulation materials, basalt mineral wool occupies a leading place. It is used to insulate facades, roofs, floors and utility networks of residential and industrial premises, soundproof walls in residential premises and recording studios, and provide fire protection for wooden structures from highly heated building elements, for example, a chimney.

Let's try to figure out why in industrial and residential construction they are increasingly using cotton wool based on basalt fibers for thermal insulation and whether it is worth buying this type of insulation when building a private house or renovating an apartment.

Content

- Why do you need basalt insulation?

- Composition and properties of basalt insulation

- Types of basalt insulation and scope

- Classification of basalt slabs

- Advantages of mineral wool

- Flaws

- Installation rules

- Basalt insulation Izover Master of warm walls

- Insulation for walls based on quartz Izover warm walls strong

Basalt mineral wool is used at construction and industrial sites for insulation of facade elements, foundations, roofs and floors. The material is characterized by a low thermal conductivity coefficient, making it an effective insulator. For ease of use, stone wool is often produced in the form of slabs, sometimes in rolls and cylinders. Izover is the first and only manufacturer of both stone and quartz wool in Russia. Having full expertise, we will tell you about insulation based on basalt mineral wool.

Which one is better for the home and beyond, how to choose the right one

The selection should be made in accordance with the following criteria:

- purpose, whether the work will be performed in domestic conditions or at a professional level;

- which structural element will be insulated; the range of manufacturers includes universal and specialized options;

- density, the lower the density, the higher the ability to insulate;

- thickness determines the thermal conductivity coefficient;

- manufacturer, characteristics and cost depend on the brand.

Composition and properties of basalt insulation

Basalt mineral wool consists of a huge number of short fibers of chaotic orientation, between which numerous air microcavities are formed. Mineral raw materials are pressed using industrial equipment to ensure the required density and shape. To improve the insulation properties, a layer of aluminum foil can be applied over the compressed wool. The reflective properties of thin metal significantly increase the effectiveness of insulation.

Shrinkability

Shrinkage involves sliding or caking of the insulation after some time. If the tendency of the material to shrink is high, then voids without insulation may form and the thermal insulation of the building will deteriorate.

Here, the difference between basalt wool and mineral fiberglass wool lies in the improved structure of the first. Some of the basalt wool fibers are located vertically, which prevents caking throughout its entire service life. The same cannot be said about glass wool, which, if properly installed, can last for a long period, but will still shrink over time. Glass wool placed in horizontal structures is subject to shrinkage the most, where, in addition to caking, sliding of the material can occur.

Types of basalt insulation and scope

Basalt insulation is used in construction. In order to make it convenient to work with, it is given the necessary shape and size. On the Russian market you can find the following types of mineral wool:

- slabs;

- rolls;

- cylinders.

Rigid slabs are able to withstand large mechanical loads during operation without experiencing mechanical deformation.

Rolled wool is one of the most popular types of insulation. It is often used to insulate walls, floors, and attics, and pierced mats in rolls are most often used to insulate pipes passing through the roof and ceilings.

Cylinders are used to insulate small diameter pipes.

Where can I buy

You can get acquainted with the range of materials offered for sale on the websites of companies that are listed in the corresponding section. Enterprises sell an extensive range of thermal insulating basalt products to solve a wide range of problems.

Basalt wool · 12/22/2020 · 0

Classification of basalt slabs

Modern manufacturers produce basalt slabs with various technical characteristics.

Depending on the density, stone wool is divided into four categories (be sure to pay attention to the area of application):

- 15-20 kg/m3 - rolls for ceilings (horizontal structures);

- 35-40 kg/m3 - slabs for insulating walls in frame structures, ceilings and partitions;

- 50-75 kg/m3 - slabs for arranging ventilated facades of buildings, attic floors;

- 75 - 125 kg/m3 - slabs for floors, internal walls, layered masonry and plaster facades for low-rise construction;

- 175-200 kg/m3 - slabs for insulating walls made of metal profiled sheets, reinforced concrete and plaster facades for high-rise construction.

Stone mineral wool with a high density is capable of withstanding significant mechanical loads during operation while maintaining geometric parameters and other performance characteristics. Rigid and heavy slabs with a density of 110-200 kg/m3 are also used as additional fire protection for buildings and structures. At the same time, for quartz wool such density indicators are not needed to perform similar tasks. It's all about different production technologies.

Specifications

The material has the following features:

- Non-flammability. Withstands up to 1000°C and exposure to open fire. It consists of volcanic rocks, so this feature is easily explained. The product retains heat well and insulates heated air. This function is widely used for insulating pipes through which hot water or other high-temperature compounds pass.

- Hydrophobicity. The material can be used indoors. Where the humidity level is high. One of the properties of cotton wool is to repel water. Basalt wool insulation is installed in swimming pools and bathhouses. Basalt wool is slightly harmful to health, or harmless at all. It is worth taking this into account when insulating residential premises.

- Vapor permeability. The characteristic explains the ability of the material to pass air flows. Moist steam passes through the basalt, creating a positive microclimate in the insulated rooms.

- Soundproofing. Sound waves are delayed by the volcanic rocks contained in the structure. The composition can be used not only as insulation, but also as a soundproofing material.

- Strength. The fibers are arranged randomly, which is why cotton wool has high strength. Even after exposure to heavy loads, it is possible to restore the original shape.

Comparative table of characteristics of insulation materials

| Parameter name | Slag | Glass wool | Mineral wool | BTV |

| Maximum temperature of use, o C | Up to 250 | -60 to +450 | -60 — +600 | -190 — +700 |

| Average fiber diameter, µm | 4—12 | 4—12 | 4—12 | 5—15 |

| Humidification per day, % | 1.9 | 1.7 | 0.095 | 0.035 |

| Taunting | + | + | — | — |

| The need to use a binder | + | + | + | + |

| Thermal conductivity coefficient W/m*k | 0,46—0,48 | 0,38—0,046 | 0,077—0,12 | 0,038—0,046 |

| Presence of binder, % | From 2.5 to 10 | From 2.5 to 10 | From 2.5 to 10 | From 2.5 to 10 |

| Flammability class | NG - non-flammable | NG - non-flammable | NG - non-flammable | NG - non-flammable |

| Release of harmful substances | Yes | Yes | Yes | Yes, if there is a binder |

| Heat capacity | 1000 | 1050 | 1050 | 500—800 |

| Vibration resistance | No | No | No | No |

| Compressibility | 60 | 60 | 40 | 40 |

| Elasticity | 50 | 55 | 60 | 71 |

| Sintering temperature | 250—300 | 450—500 | 600 | 700—1000 |

| Fiber length | 16 | 15—50 | 16 | 20—50 |

| Sound absorption coefficient | 0,75—0,82 | 0,8—0,92 | 0,75—0,95 | 0,8—0,95 |

| Chemical stability in water | 7.8 | 6.2 | 4.5 | 1.6 |

| Chemical stability in alkaline environment | 7 | 6 | 6.4 | 2.75 |

| Chemical stability in acidic environment | 68.7 | 38.9 | 24 | 2.2 |

Stone wool can withstand many types of chemical and biological influences. Mold and mildew do not form on the surface, and infection does not spread. It will not react with nearby compounds. Basalite, whose technical characteristics are very high, is considered one of the best insulation materials.

Advantages of mineral wool

Mineral basalt insulation is in great demand in the building materials market due to its advantages, including:

- low thermal conductivity;

- soundproofing (sound absorption);

- non-flammability;

- vapor permeability;

- biostability;

- easy workability.

Stone wool prevents heat loss from the room, and is also an excellent sound insulator (sound absorber) in a comprehensive solution.

This material is not subject to combustion. Basalt fibers allow steam to pass through perfectly. This quality allows for rapid removal of excess moisture from the room.

Basalt-based thermal insulation does not support the development of fungal organisms and is not of interest to rodents, which has been confirmed by tests.

The feasibility of external insulation

When insulating buildings, you should not only provide good thermal insulation performance, but also consider how you can avoid the appearance of condensation inside the walls during the cold season. Due to the change in the temperature of the building wall from minus on the outside to plus on the inside, at the conventional “dew” point, temperature changes turn into condensate, which is contained in the air of water vapor. When you move this point, along the thickness of the wall itself, the material becomes damp, and fungus and mold appear on it.

In the construction industry, the dew point is the temperature at which condensation forms. According to the rules, it should not be inside load-bearing walls.

When using wet facade technology, this point is moved beyond the building wall, thereby maintaining positive temperatures of all load-bearing structures.

Flaws

Despite their manufacturability, basalt insulation materials can generate dust during installation and preparation. To protect the eyes, respiratory system and skin, the worker must use special protective equipment: mask, goggles, gloves and long sleeves.

Another feature of stone wool is the likelihood of getting wet in case of direct contact with water. Basalt does not absorb moisture, but when exposed to rain, it can accumulate it in the voids between the fibers. It will be impossible to dry the insulation after such an incident. Therefore, it is important to store insulating materials in a dry, closed area before starting installation work.

The best manufacturers

According to the ratings, the products of the following manufacturers are in high demand:

- ROCKWOOL (Denmark) is a company with a wide network of representative offices and factories, which allows it to offer materials of European quality at fairly reasonable prices;

- Paroc (Finland) - thermal insulation materials provide excellent sound and noise absorption;

- TechnoNIKOL (Russia) - products are of good quality and affordable;

- ISOVER (France) is a leader in many countries of the world; its products have an optimal price-quality ratio.

Rockwool insulation Rockfacade 100x600x1000 mm 1.2 sq.m. Photo Petrovich

This is not a complete list of large and well-known brands.

Installation rules

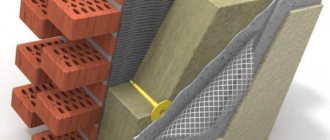

In order to benefit from basalt insulation, it is important to strictly follow the installation technology. Let's consider the procedure for laying insulation under siding, cladding or facing bricks using the example of Izover Master Warm Walls mineral wool:

- Façade preparation – cleaning from dirt;

- Installation of vertical bars for installing insulation or the use of disc dowels (at least 5 pieces per slab, the thickness of the insulation is selected according to calculation); for the greatest energy efficiency, it is permissible to use additional horizontal bars for installing the second layer of insulation;

- Installing Izover Master Warm Walls insulation at the corners with tying the slabs relative to each other as when laying bricks;

- In the case of cladding with siding or block house, a vertical sheathing is installed to form a ventilated gap (if necessary, a windproof membrane is installed over the insulation);

- In the case of brick cladding, a ventilated gap and vents are maintained in the lower and upper parts of the wall;

- When installing siding, follow the manufacturer's instructions.

What it is?

Initially, it should be noted that the type of insulation under consideration is as close as possible to mineral wool in its properties. This largely determines its prevalence in Russia. To understand what exactly basalt slabs are, it is worth paying attention to their main advantages and disadvantages. The list of obvious and most significant advantages includes several characteristics.

- Reduced thermal conductivity coefficient due to the fibrous structure. Thus, a 10-centimeter slab in terms of thermal efficiency is comparable to thermal insulators whose thickness is up to 30 cm.

- High noise absorption, which, along with the previous property, contributes to the creation of the most comfortable microclimate indoors, the walls and other structural elements of which are finished with the insulation in question.

- Increased resistance to aggressive chemical environments. We are talking, in particular, about acids, alkalis and technical oils. Due to this characteristic, the slabs are widely used for insulating blast furnaces, various types of process equipment and pipelines.

- Fire resistance, allowing the material to be used under almost any operating conditions.

- Strength and long service life, which determine the ability of the insulation to maintain its shape for the longest possible period.

- High performance in terms of vapor permeability, which directly depends on compliance with the installation technology of sheet heat insulation. When installed correctly, excess moisture is removed outside the room with extreme efficiency.

- Resistance to biologically active environments. For example, we can talk about damage caused by insects and/or rodents.

- The process of installing slabs is as simplified as possible. The entire complex of work can be completed almost alone, which in itself significantly reduces financial costs.

Naturally, there are certain disadvantages. First of all, we are talking about the need for strict adherence to the rules provided for by technology. The durability of the insulation and its performance indicators directly depend on this.

Often, over time, gaps can form between individual insulation panels. As a result, the sound and, most importantly, thermal insulation of the room is significantly deteriorated.

Basalt insulation Izover Master of warm walls

The slabs are fixed to the wall using special glue. For subsequent fastening of the insulation, a set of dowels is used. It is recommended to choose one manufacturer as the adhesive and insulation, since the possibility of combining home-made products during the installation process is taken into account.

Despite the manufacturability and familiarity of basalt mineral wool, we recommend an innovative product for the above operations - quartz-based mineral wool. Isover Warm Walls Strong will do an excellent job with this. Elastic material is more convenient for installation, does not burn, is environmentally friendly for humans and will last up to 50 years.

"Disadvantages" of glass wool

- It is hygroscopic; fiberglass wool easily absorbs water. When moistened, it loses its thermal insulation properties and contributes to the creation of a humid environment, which can lead to destruction of the insulated surface and rotting. To avoid negative consequences and achieve increased thermal conductivity, 2 layers of vapor barrier are used for its installation: before laying the slabs and on top;

- inconvenient installation; the need to use special equipment: respirator, gloves, goggles, clothing. Glass wool fibers are fragile, they break, crumble, and when they come into contact with the skin, they cause burning and itching.

- short service life without changing the original characteristics, glass wool performs its functions for 8-10 years, after which it “shrinks” and loses its properties.

Photo 3. The disadvantage of glass wool is the need to use special protective clothing during installation