Different materials are used to insulate the ceiling surface. In some cases, not only the thermal conductivity of the thermal insulation layer is important, but also its thickness. This is especially important when installing insulation on the residential side. Insulating the ceiling with foil insulation provides many advantages, but the main one is maintaining the height of the room. Let's consider the features, advantages and disadvantages of foil heat insulators, as well as the nuances of their installation on the ceiling surface.

What is Penofol and its analogues

Thin polymer insulation is made from the following materials:

- The main insulating layer is foamed polyethylene 3...10 mm thick with closed air pores. The thermal conductivity coefficient λ of this layer lies in the range of 0.037–0.051 W/(m • °C) depending on operating conditions.

- The outer reflective layer is aluminum foil 14 microns thick, securely glued to a polymer base.

- The third layer on the back side of the polyethylene can be glue for ease of installation or the same aluminum.

Reference. All given characteristics are taken from the official website of the manufacturer. Thermal insulation parameters of other brands may vary. For example, the thickness of a similar material reaches 150 mm.

A special feature of the material is its impermeability to moisture, the declared indicator is simply scanty - 0.001 mg/m • h • Pa. The insulation is quite light - the density ranges from 16...35 kg/m³, and is sold in rolls. Thanks to these parameters, the material serves well as an internal vapor barrier.

"Penofol" is available in 3 versions:

- double layer type A;

- three-layer – the base is coated with aluminum on both sides (type B);

- the same, with an adhesive layer - Type C.

The foil side works as a reflector of the radiant (infrared) component, polyethylene foam resists direct heat transfer. For exterior wall cladding, a perforated version of Penofol, shown in the photo, is offered. Many small holes are designed to allow water vapor to escape from the thickness of building structures.

External wall cladding is made with special insulation with perforation

Advantages of the technique against the background of insulation with mineral wool or expanded polystyrene

In conclusion, I would like to consider the advantages of roof insulation with polyethylene foam from Tepofol compared to popular analogues. The ease of installation here is obvious: easy to cut with a construction knife; a screwdriver, hair dryer and “parachutes” are enough for fixing. The process takes place without personal protective equipment, since no toxins are released during heating, and no dust is generated during cutting and during fastening. The work is done without dirt, and there is practically no scrap left.

Fixation of Tepofol Source userapi.com

The presence of a lavsan coating increases the energy efficiency of a material that already has low thermal conductivity. The canvases additionally reflect heat into the room and keep the cold out. In conditions of high humidity, the properties of the insulator do not change, which cannot be said about mineral wool.

Scope of application

With the help of Penofol, you can significantly increase the energy efficiency of any home - a private house or apartment. Where the material is used:

- thermal insulation of the roof of an attic or cold attic;

- covering ceilings and walls from the inside - as an addition to the “pie” of basic insulation;

- under the finished floor covering laid along the joists;

- strengthening the outer thermal insulation layer;

- internal insulation of balconies and loggias;

- coating of heating pipes and ventilation ducts.

Addition. Many drivers use “penofol” type C (adhesive surface) to insulate the car body – interior floors, doors and roof. The cut blanks are glued to the metal on top of the bitumen vibration insulation.

It is not advisable to use the material as an independent insulation of external fences - you will not achieve the desired effect, only protect the building from wind blowing. An exception is products of large thickness from 20 to 150 mm of the Tepofol brand, suitable for complete insulation of a house.

Frequent mistakes and advice from experts on installing insulation

A common mistake when insulating a wooden ceiling with isolon from the inside is that the strips of material are laid with an overlap. This cannot be done, because condensation will form between two layers without an air gap. Strips of foil insulation are laid only joint to joint. All seams must be taped with reinforced tape. You can use silicone sealant instead.

Attention! Under no circumstances should the seams between strips of insulation be left unprotected.

Do not connect the insulation to the wall surface. It is placed on the walls to a height of 10-15 cm. Also, the foil side of the insulating material must not come into contact with the power supply wires. Since aluminum conducts electricity well, the junction points with the wiring are carefully insulated.

If penofol or isolon is used as an independent insulation, then choose the thickest type of material that has a double-sided foil layer. If the temperature behind the insulated surface drops below zero, then foamed polyethylenes are used only in conjunction with other more effective heat insulators.

Penofol ceiling insulation technology

The product can be laid on a floor made of any material, but operations must be performed in a certain sequence. Deviation from the technology of installing penofol on the ceiling will reduce the expected effect. In addition to the insulation, you will need glue to fix the insulator and metallized tape for the joints. The rules for choosing the components of the insulating “pie” are written below.

Tools and materials for work

If the ceiling is insulated with isolon (penofol) from the inside, then the following materials and tools will be needed for the work:

- wooden slats for lathing;

- drill or hammer drill;

- screws and dowels;

- wood screws;

- hacksaw;

- laser level;

- Ruler and pencil;

- roulette;

- foil insulator (material of the smallest thickness and a product of primary purpose);

- reinforced tape;

- ceiling primer;

- roller;

- putty;

- putty knife;

- containers for mixing solutions;

- scissors or a stationery knife for cutting insulation;

- construction stapler and staples;

- ladder.

Selecting consumables

For reliable insulation, along with penofol, glue is purchased for fixing to the surface and adhesive tape for connecting parts of the canvas. There are several modifications of penofol that can be used to insulate the ceiling:

- Type "A"

. Foil on one side only. Usually used with other thermal insulators as additional insulation. - Type "B"

. Foil film is located on both sides. It has proven itself well as the main heat insulator. - Type "C"

. There is a sticky layer that makes it easy to attach. - Type "ALP"

. The metal coating is protected with polyethylene film. They are often placed on the floors of specialized premises - greenhouses, incubators, chicken coops. Film-reinforced insulation is used in basements where it is not protected by a suspended ceiling.

It is not recommended to buy Penofol-2000. Its cost is low, but it retains heat poorly. Before insulating the ceiling with penofol, check the quality of the product. Pay attention to the following factors:

- The product must be manufactured in accordance with the requirements of TU 2244-056-4696843-98.

- The material is sold in rolls, the length of the product depends on its thickness.

- Tears and through holes are not allowed on the canvas.

- The winding of the rolls is tight, without distortions. The product is packaged in plastic film, the edges of which are secured with adhesive tape.

- Make sure that the product is stored on racks or pallets at a temperature of 20 degrees and a relative humidity of 50-70 percent. It is not allowed to store material closer than 1 meter from heating devices.

Products must have a label containing basic information:

- Name of the manufacturer;

- Basic dimensions;

- Release date and warranty period, usually the manufacturer allows storage of the material for no more than 1 year;

- Thermophysical indicators;

- Scope of application of the material;

- The protective layer on type “C” samples should be easy to peel off.

Characteristics of penofol and isolon

The main foil insulator is foamed polyethylene. The material is covered with foil on one or both sides.

There are several types of such insulation:

- Products of type “A” are most often found on sale. They have a foil layer on one side.

- Class “B” is characterized by the presence of foil on both sides.

- Type “C” coatings have foil on one side and a self-adhesive layer on the other.

- Insulators marked “ALP” have a double-sided foil layer. One of them has a protective film coating.

- Material marked “R” or “M” is a one-sided foil insulator with a relief structure.

- Products marked “AIR” and “NET” are used during the installation of air ducts, for insulating heating mains and pipelines.

For domestic purposes, the first three types of polyethylene foams are usually used for thermal insulation of ceilings and other surfaces. The first type is considered a vapor barrier and is used in combination with other thermal insulation materials. Products marked C or B are usually used as independent insulation.

Insulating the ceiling with penofol from the inside or isolon can reduce heat loss in the room. The insulation strips are laid end-to-end with the seams taped with reinforced tape.

Important! To ensure that the insulator reflects heat, it is mounted with a foil layer inside the room.

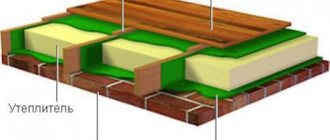

Such insulation is most effective when an air gap is formed on both sides of penofol or isolon. To do this, a sheathing is constructed on the ceiling surface, to which the heat-insulating material is attached. From the outside, foamed polyethylene is pressed against another lathing.

It is impossible to lay foil insulators overlapping, because this reduces the effectiveness of thermal insulation. There is also a risk of condensation accumulating and flowing into the room along the coating.

Polyethylene foams are rarely used as independent insulation. They are usually combined with polystyrene foam and expanded polystyrene. But if there is a room above where the temperature does not drop to extreme values, then type C insulator can be used as an independent insulation.

What is the difference between the materials

Pros and cons of insulating the ceiling with expanded clay in a private wooden house

Isolon is a polymer material with a closed-cell structure. It is used for sound and heat insulation of premises. There are several varieties of isolon:

- self-adhesive tapes;

- products of grade 100 are non-crosslinked polyethylene foams;

- Isolon class 300 is chemical cross-linked polyethylene foam;

- Category 500 material is polyolefin foam that is physically cross-linked;

- reflective insulator – lavsan metallized film (foil polyethylene foam).

Technical characteristics of Izolon insulation:

- protection against penetration of steam and moisture;

- density – 20-100 kg/m³;

- low thermal conductivity;

- reflection of infrared radiation reaches 97%.

Penofol consists of layers of foamed polyethylene with unequal density, porosity and thickness. In addition, the material has a foil layer. This thin and light product is used for heat, steam and waterproofing of surfaces. Reasonable price and easy installation make it quite popular.

Important! The main difference between penofol and isolon is the structure of the material. The first consists of several layers of polyethylene foam, and the second has the structure of physically and chemically cross-linked polyethylene foam.

Advantages and disadvantages of such insulation

Among the advantages of foil insulators are the following:

- Due to the lightness of the material, any base can be insulated without the need for preliminary strengthening.

- The insulators have a small thickness, which allows them to be mounted on the inside of the room without reducing its height.

- Compared to rigid insulation, such as polystyrene foam and expanded polystyrene, foil-foamed polyethylene foams are flexible and elastic. Thanks to this, the base does not require preliminary leveling.

- Foil insulators are multifunctional products. When using them, there is no need to buy vapor and waterproofing films or additional fasteners, which significantly reduces the cost and speeds up the construction process.

- The material is easily cut with ordinary scissors or a stationery knife.

- The main advantage of foamed polyethylene coatings is zero water absorption. Thanks to this, the product itself does not absorb moisture and protects other surfaces from its absorption. Protection from moisture extends the service life of all floor structures.

- Environmental cleanliness and safety. The material does not contain toxic substances and does not release them when heated.

- The product is not susceptible to damage by mold, rot, insects and rodents.

- Reasonable price and simple installation are the common advantages of all foamed polyethylenes.

The disadvantages of foil heat insulators include their flammability. Polyethylene melts and drips during a fire, which helps the fire spread to other surfaces and materials. Another disadvantage of penofol and isolon is their low efficiency as independent heat insulators, so the products are recommended to be used in combination with other more effective insulating materials, for example, expanded polystyrene, polystyrene foam or mineral wool.

Advantages of foil insulation

An important advantage of such insulation is the foam base. Thanks to it, a layer of air is securely retained, which has minimal thermal conductivity. This is what allows maximum retention of warm air inside the room.

It is not necessary to level the surface before using insulation

Other advantages that insulation has:

- The material is not flammable. This makes it possible to safely use it indoors in any room. Including residential ones.

- High sound insulation rate. Foil insulation is often used as additional protection against noise penetration into the room.

- Lightweight and thin. These characteristics allow the installation of canvases in conditions where other types of insulation cannot be installed.

- The structure of the material allows moisture and steam to pass through. Thanks to these indicators, there is no need to use additional moisture insulation around the insulation.

- Good elasticity. Most types of foil insulation have a similar indicator. This saves time on leveling the surface.

- Environmentally friendly. All types of foil-based insulation are absolutely safe for human life. The fabrics are not able to emit harmful fumes during the entire period of operation.

- Relative ease of installation. To attach material, it is not necessary to have special skills or involve specialists. You can do this kind of work yourself. To carry out installation, it is enough to prepare a minimum set of tools (stapler, scissors, stationery knife, tape measure, pencil).

Finishing foil insulation with wooden clapboard

Like all materials, foil insulation has its drawbacks. One of these is the insufficient rigidity of some types. For this reason, canvases cannot be covered with a finishing layer or plastered. This is especially true for foil polyethylene foam. As for fastening, it is not recommended to fix such material with glue. The best option is nails and staples. That’s why, by the way, polyethylene foam manufacturers invented and launched the production of self-adhesive versions of this insulation.

Criterias of choice

The quality of thermal insulation depends on the correct selection of insulation. Therefore, when purchasing penofol, you should pay attention to the following parameters:

- Product type. For basic insulation, only material with double-sided foil coating is used. The purpose of penofol relative to its classification is also taken into account.

- Thickness of the thermal insulation sheet. This parameter is selected for ease of installation. The optimal option is considered to be a thickness of no more than 5 millimeters.

- Material size. Before purchasing, you should calculate the required amount of penofol. The value is determined based on the size of the roll, which on average contains 9 -18 square meters.

- Manufacturing technology. Chemically cross-linked penofol has the best technical characteristics.

- Quality foil coating. The reflective properties of the insulation depend on the thickness of the aluminum coating and the purity of the material used.

- Uniformity of the material. The fabric should not have any stripes or stains. You can check this by unrolling the roll and looking through it at the light.

An important criterion for choosing penofol is its manufacturer. Reliable thermal insulation protection can be provided by material from well-known brands whose product quality meets the stated requirements.

Is it worth insulating a house with foil insulation?

This also helps to reduce external noise levels and get rid of drafts. The anti-corrosion properties of aluminum foil are useful in rooms with high humidity (baths, saunas) or when condensation occurs. Insulating the chimney, in particular with stone wool insulation, will help avoid unnecessary heat loss into the air.

Important positive qualities include low cost with a long service life - up to 50 years. The ability to install the insulator yourself without involving specialists is also appreciated.

The disadvantages of this material stem from its advantages: insulation with foil retains not only heat, but also moisture and odors. These side effects are most noticeable when you want to wrap the entire house in foil: floor, walls, ceiling. In this case, regular ventilation of the premises is recommended.

With maximum use of foil insulation, especially in rural areas, the cellular signal strength is likely to decrease, which can lead to frequent disconnections while talking or using the Internet. Placing the PC or the subscriber itself closer to the window will solve this problem.

Life time

Since foil insulation appeared relatively recently, it is not yet possible to determine the exact expiration date. However, after conducting experiments, we can say that the material does not lose its properties for 200 years.

The service life of the installed insulation depends on the adhesive used. If the adhesive composition has passed its expiration date, then you can re-install it with the same heat insulator.

There are a lot of insulation materials on the construction market. The choice is so wide that the question arises, which is better. To answer, you need to compare the characteristics of the thermal insulation material and the scope of application - street, living room, garage or agricultural building.

How to properly glue foil insulation

Instructions for use of stekloizol and folgoizol

Folgoizol and stekloizol grades K (FK and SK) are intended for the installation of the top layer of rolled carpet on roofs with various slopes and configurations of buildings located in climatic zones 2, 3 and 4.

Folgoizol and stekloizol grades G (FG and SG) are intended for the installation of a protective waterproofing coating for thermal insulation of pipelines.

Work on installing a roof or protective waterproofing must be carried out in accordance with current building codes and regulations (SNiP 3.04.01-87 Insulating and finishing coatings, VSN 32-81 “Instructions for waterproofing bridges and pipes on railways, highways and city roads”) .

The installation of a roof or protective insulation can be carried out on a pre-primed base by melting or liquefying (plasticizing) the binder layer, as well as gluing with hot or cold adhesives. The base surface for roofing or insulation must be properly prepared:

compacted and leveled; cleared. dust free. dried if necessary;

primed with a continuous layer without gaps or breaks.

Insulation and roofing work can be carried out from 60 ° to minus 30 ° C in the environment (with the use of hot mastics - at a temperature not lower than minus 20 ° C; when gluing the binder layer by liquefaction (plasticization) with the simultaneous laying of rolled carpet, liquefaction should be carried out at a temperature air not lower than 5 ° C).

When working in sub-zero temperatures, glass (foil) insulation must be heated to a temperature of at least 15 ° C within 20 hours, rewound and delivered to the place of installation in an insulated container.

Before sticking, roll materials must be marked at the place of installation; The layout of panels of rolled materials must ensure that their overlap is 100 mm. when sticking (on the roof ridge the overlap on the opposite slope should be 250 mm - when sticking panels across the slope and 1000 mm - when sticking along the slope).

Video description

See the progress of the experiment in this video.

The results are shown in the table:

Comparison of insulation - test results Source mycdn.me

Damper tape

Another product that builders cannot do without when working with screeds - dry and cement. An edge strip with a thickness of 5 to 10 mm and a width of 5, 8 or 10 mm is laid around the perimeter of the screed. When used on a wet screed, it promotes more uniform drying.

There are varieties of tape with a polyethylene film “apron”. In the classic version, it goes on sale in rolls of 25 linear meters, but it is also possible to order the material according to individual parameters.

Edge tapes Tepofol Source tepofol.ru

Thermal insulation with foil for pipes

Shell with foil for pipes based on mineral wool.

Foil thermal insulation for pipes is needed when laying communications through the air or underground. Also, to reduce heat loss by the coolant, such material is used even in a room, especially an unheated one, which is not uncommon for a boiler room in a cottage, which is usually located on the ground floor.

Installation does not require special instructions, since using insulation with foil is as easy as shelling pears. You just need to put the shell on the required segment and, in some cases, remove the protective film from the adhesive surface applied along the end of the longitudinal cut. The reflective surface protects communications from solar radiation if it is applied only on the outside. If there is a reflective surface on the inside, then it transfers heat back to the pipe.

What is it for?

High humidity and temperature in the steam room of a Russian bath require a special approach

It is important to protect the heat-insulating layer from moisture. Why protect him? The fact is that basalt wool is most often used for thermal insulation of premises.

In a dry state, it has good heat-insulating qualities, is made from natural materials, and tolerates high temperatures well. But in an important state, its thermal conductivity increases greatly, and it protects less well from heat loss. And if it freezes when wet, it will completely crumble. That is why it is necessary to protect it from moisture in any condition. Both from liquid (waterproofing) and from steam:

- From moisture coming from the room. The humidity in the Russian steam room is very high, the air is oversaturated with moisture, so the steam tends to flow into other rooms and outside (through the heat insulator). And we need to avoid this.

- From moisture formed due to temperature changes in the steam room and in the attic and on the street (and on the interfloor ceiling and on the walls). It condenses even before steam begins to be supplied, during the heating of the air in the steam room.

Finally, about other use cases

Home craftsmen use insulation made from foamed polyethylene for a wide variety of purposes:

- protection of heating and hot water pipes from freezing;

- interior decoration of entrance door leaves;

- reflective screen glued to the outer wall behind the heating radiators;

- inexpensive thermal insulation of outbuildings - sheds, workshops, garages;

- exotic – shoe insoles made of 3 mm thin sheet insulation.

Polymer insulator "Penofol" is a material that deserves attention. If applied according to the instructions, it will serve as a good insulator. But do not try to save money and solve all thermal insulation problems using thin polyethylene alone; use other effective insulation materials.

Best answers

%username%:

Pat doesn't bother me at all, you have to come to terms with it

Roman Shved:

double-sided tape

Dmitry Dved:

There is a special adhesive foam like Penoplex in construction stores, but not Penoplex, it is specially made for this. The cylinders are red (more precisely the color cyan). I bought pistol cylinders with a capacity of 750-800g in Castorama. I don’t remember the name, it can be used as glue and foam. Dissolves with foam cleaner. The packaging indicates that before applying the foam it is worth spraying with water from a spray bottle. Water does not improve adhesion, but is a catalyst for hardening.

Vladimir Nikitin:

88 (such glue... ask the shoemakers)

Complex insulation of a balcony with Izolon

In the photo the balcony is ready for finishing.

Insulation of a balcony with Izolon, like a loggia, should be carried out comprehensively. This means that thermal insulation must be installed everywhere: on the floor, ceiling and walls. Please note that without good, energy-saving windows, no insulation will help. The lion's share of the heat escapes through the glass (this is if everything is sealed). We have already written about how to check heat loss. High-quality insulation of a balcony with Isolon alone is nonsense; thick thermal insulation materials are needed. The best option is foam with a density of 25 kg/m. cube

We present to your attention the fastest and easiest way to comprehensively insulate a balcony:

- foam is glued to the walls and ceiling with adhesive foam;

- guides are placed on the floor level;

- between the guides you can simply put polystyrene foam in two layers with the joints spaced apart, all the cracks are foamed with the same adhesive foam;

- the entire balcony is covered with foil insulation with the shiny side in the middle of the room, the joints are taped;

- Logs are placed on the floor guides, and everything is covered with OSB board - the floor is ready;

- wooden blocks are drilled into the walls and ceiling through the foam plastic - this is the sheathing;

- trim is attached over the sheathing.

This method minimizes the use of an impact drill, and there is no need to dilute universal construction adhesive. It saves time and nerves, and the results are excellent. Everything will hold securely and will never fall off; you won’t even be able to tear it off on purpose.

Now let’s summarize our article today about Izolon. Insulation for floors, walls and ceilings without foil works more as sound insulation, protection from steam and moisture. Often used as a lining under laminate or even linoleum. The thermal insulation qualities of foamed polyethylene are quite high (0.037 W/m*C), but with a small thickness the effect is insignificant. Foil materials emit IR rays, which is very useful, especially in a bathhouse. There should be a gap of 15 mm or more between the foil and the trim.

Basic Operations

As an example, let's consider insulating the ceiling from the inside in a private house for the case when there are beams overhead with a plank ceiling attached to them. The climate is temperate; We will be insulated with mineral wool 50 mm thick.

- Armed with a stapler, we attach plastic film to the ceiling. It will completely stop the flow of moisture to the boards from the room and extend the life of our ceiling. An overlap of ten centimeters is required.

- We stuff the sheathing. We will hem the ceiling with PVC panels; a thin mounting rail is sufficient for them. But let's not forget about the thickness of the thermal insulation and take a 50x50 block.

We will stuff it across the future panels in increments of 60 centimeters: in this case, the panels will not sag, and the mineral wool will not have to be cut to width. Most rolls are this size.

- We fill the gaps between the bars with mineral wool. It is better to wear textile gloves and protect your eyes and nose: cotton wool fibers are volatile.

At this stage our ceiling looks something like this.

Armed with a stapler again, we hem the sheathing from below with a second layer of polyethylene. Additionally, we glue the connections of the sheets with adhesive tape: the greater the tightness we provide, the longer the insulation will retain its properties. Finally, the last stage: we hem the wall panels from below

We won’t focus on how this is done: installation methods have already been described hundreds of times.

Hemming panels to wooden sheathing is a fairly simple task.