If the house has a gas water heater, one day the question of its maintenance will arise. The heat exchanger of such a device gradually becomes overgrown with lime deposits, and particles of soot and soot settle on the burner. It is better to immediately figure out how to maintain the equipment in proper condition so that it does not fail prematurely.

We will tell you how to clean a gas water heater with your own hands, if calling a representative of the gas supply service is not necessary. The article we presented describes methods for removing carbon deposits and other combustion products from important working parts of an instantaneous water heater. Advice on preventing the formation of dangerous deposits is given.

Methods for cleaning an instantaneous water heater

Cleaning a gas water heater does not always mean complete disassembly, down to the screw. But one issue is the prevention of a completely serviceable unit, and a completely different one is the removal of many years of scale from the coil and soot from the burner. A instantaneous water heater can be serviced in the following ways:

- completely disassemble the column, clean the gas burner device and rinse the copper heat exchanger;

- flush the radiator without disassembling;

- clean the working elements of the unit from soot and contaminants - igniter, electrodes, water unit (in common parlance - “frog”).

Note. The passage holes of the “frog” become clogged quite rarely. Usually they are cleaned when it is necessary to disassemble and repair the water unit, for example, to replace an unusable membrane. The design and principle of operation of the elements of a water heating column are described in detail on this page.

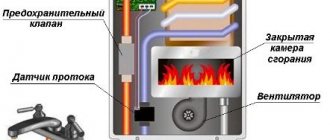

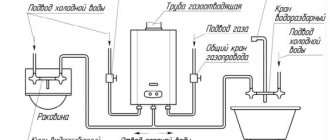

Diagram of an instantaneous water heater using natural gas

If the device has been operated for many years without maintenance, the channels are half clogged with scale, and the flame of the gas burner has turned yellow from blockages, then the first option is definitely implemented - complete disassembly. A similar decision is made when it is necessary to solder a leaky radiator.

Preventative flushing of the heat exchanger of a household water heater is carried out without dismantling (method No. 2). Local soot removal (option No. 3) is carried out when the ignition system malfunctions - the igniter barely burns, there is no spark at the electrodes, loud pops are heard in the combustion chamber when the burner starts.

Typical unit problems

Most often, the unit fails due to poor quality water. Potassium and magnesium impurities settle and clog device parts. Pressure drops in pipes also have an effect. It has been proven that 80% of gas heater failures occur due to failure of the water-gas unit.

Study the main signs and causes of breakdowns.

The water pressure is normal, but the burner does not light

- Check the membrane. The rubber element quickly wears out, breaks, and leaks. It is better to install a silicone membrane instead of the old element.

- The rod is stuck and won't budge. Perhaps he got used to it. Lubricate this area and the oil seal with grease to restore operation.

The cold flow is quite strong, but the hot flow is weak

- The mesh filter is clogged with small debris and rust. Remove and clean the part.

- The nozzle at the entrance to the unit is clogged. Cleaning is also carried out.

When opening the mixer, the column does not start immediately

- The retarder ball channel is clogged. The elements are disassembled and cleaned. The ball is located in the unit cover.

- The retarder ball is not adjusted correctly. You need to tighten the adjusting screw.

After closing the taps, the device does not stop working

- The ball is jammed or its channel is clogged.

The equipment does not operate at full capacity and may go out during operation.

- The membrane was damaged. The faulty element needs to be replaced.

If you discover a malfunction and decide to do the repair yourself, read below on how to remove the gearbox.

How to descale a column

What kind of products do not the owners of private houses and apartments use when cleaning geysers with their own hands - various acids, household chemicals and even electrolyte from batteries. We warn you: most of these compounds are unsuitable for servicing water heating devices; their use will not give results, and can easily cause harm.

We will recommend 2 products whose effectiveness has been tested in practice and confirmed by numerous user reviews:

- An inexpensive powder sold in grocery stores is food-grade citric acid. 50-70 grams of product are diluted in 1 liter of washing water.

- Special liquids designed for cleaning the coils of geysers and plate heat exchangers of double-circuit boilers from scale.

Note. In particularly advanced cases, it is allowed to increase the concentration of citric acid to 100 grams / 1 liter.

Scale is a combination of salts of various metals, representing solid deposits of a light shade. Hydrochloric, sulfuric or acetic acid weakly dissolves this substance, but happily “eats” copper. But the cheap “lemon” works flawlessly, as you can see by watching the comparison video:

Full disassembly service

Do not be afraid to disassemble the water heating installation, the procedure is not that complicated. You will need the most common tools - screwdrivers, pliers, standard wrenches. What to do before starting work:

- Close the taps of the cold water, hot water and gas supply pipelines. Unplug the turbocharged dispenser from the outlet.

- Substituting the container, unscrew the union nuts (American) on the connection of the water pipes. Disconnect the connections from the unit without losing the rubber gaskets.

- For convenience, it is recommended to remove the gas heater from the wall. It is not easy to disassemble and clean a unit that is hung too high or installed in a narrow niche.

- To dismantle the water heater, disconnect the gas line and the chimney pipe. Remove the unit from the hooks.

Lay the hot water column on a horizontal surface and proceed to further work, the order of which is outlined in our instructions.

How to remove the heat exchanger and column burner

We will show the disassembly sequence using the example of a cheap Chinese Novatek water heater. We present step-by-step instructions with photos:

- Remove the control handles mounted on the front panel. Unscrew 2 screws (or 2 plastic clips) and remove the device casing.

- The next step is to remove the smoke collector. To do this, disconnect the wires from the draft sensor and unscrew the screws holding the diffuser box.

- Disconnect the heat exchanger tube from the water unit by disassembling the connection with the union nut. The second pipe must be freed from the lock washer, pressed with 2 screws.

- Disconnect the burner from the gas valve by unscrewing the 2 screws on the flange. Having moved the radiator upward, carefully remove the burner device (pull towards you) and move it to the side.

- Unscrew all screws connecting the heat exchanger to the rear panel of the water heating unit.

- Pull out the radiator completely and remove the burner, disconnecting the wires along with the ignition electrodes.

Note. While removing the heat exchanger, disconnect the wires from the temperature sensor.

Disassembly of geysers from other manufacturers may differ, but not fundamentally. The order of work remains unchanged. Let's list some important points:

- in a chimneyless turbo column, the fan will have to be removed;

- in units of the Italian brands Ariston (Ariston) and some others, the pipes are connected not with nuts, but with self-clamps;

- If the water heater is equipped with an igniter, then before removing the burner it is necessary to disconnect the gas tube connected to the wick.

Important! Be careful not to lose any rubber or other gaskets discovered during disassembly. Before assembling and installing the column, it is advisable to replace these seals with new ones.

Our expert plumber will demonstrate the above process in detail in his video:

Flushing procedure

This operation is very simple compared to disassembly - cleaning the gas water heater begins by immersing the heat exchanger in a container with washing liquid. The procedure is as follows:

- Take a bucket or deep basin, fill it with water and prepare a cleaning solution according to the recipe on the package. The concentration of citric acid is 50-70 grams per 1 liter of liquid.

- Immerse the heat exchanger in the container with the radiator down and the pipes up.

- Using a watering can, fill the coil with detergent. Rinse it periodically by adding new solution.

- Flush the heat exchanger until clean liquid comes out of the tubes without scale flakes. Then run tap water through the coil to remove any remaining product or impurities.

Advice. Using citric acid, heat the solution to a temperature of 50-60 °C. The reaction will be more intense and end faster.

The removed burner can be cleaned from the outside and purged or washed with a solution of citric acid (no more than 50 grams per liter of water). Finally, rinse the element with running water, blow with compressed air and dry thoroughly. Do not ignore other parts of the gas water heater - the mesh filter, smoke collector and combustion chamber, remove soot and other contaminants from them.

After washing and drying, put the heat exchanger back in place, connect the burner and follow the remaining steps to reassemble the water heater. It is important to achieve tight connections: when installing old gaskets, treat them with high-temperature sealant. Check the joints for tightness using water pressure (4-6 bar).

It wouldn’t hurt to blow out the inside of the burner with compressed air at a pressure of 4-6 bar

For reference. The duration of washing depends on the thickness of the scale layer inside the column heat exchanger and ranges from 2-3 hours (prevention) to 2 days.

Pollution prevention

The appearance of scale in the column is associated with the deposition of salts, as well as constant high temperature. In order for pipes to become clogged more slowly and cleaning to be required as rarely as possible, it is necessary to monitor the temperature conditions, choosing the optimal degree of heating.

Often scale accumulates due to the fault of the owner himself, who heats the water in the device to a temperature above 80 ℃. 45 ℃ is usually enough for washing dishes, and even less for taking a shower. Therefore, in order to disassemble the column as little as possible, it is necessary to set it to a temperature of no more than 50 ℃.

The optimal degree of heating reduces the likelihood of scale formation and significantly increases the life of the device without cleaning

You can also fight scale in pipes using a water purification filter. Such a device retains harmful salts, preventing them from contacting the elements of the gas water heater. However, you also need to monitor the cleanliness of the filter by promptly replacing it with a new one.

Another way is to install an electric softener on the water pipe. It sends special impulses that, acting on water, prevent the appearance of scale.

Knowing how to properly clean a gas water heater, as well as following the recommendations given above, you can significantly increase the service life of the device. This, in turn, guarantees an uninterrupted supply of hot water and significant savings on repairs and maintenance of the device.

The main preventive measure is constant cleaning. However, disassembling the column every year is tedious, and in general it is not necessary, so there are a number of preventive measures that can be used in between cleanings. This will allow you to maintain the normal state of the device:

- The strainer should be removed and cleaned once a year. And after 5 years of operation, it’s worth changing it altogether. To get rid of this procedure, you can simply install additional filtration in the form of a filter at the communications input to the column. The best option would be to install a comprehensive filtration system consisting of a main mesh filter and a magnetic filter. Firstly, such devices will extend the overall service life of the intra-house network communications, and secondly, the rate of scale formation in the dispenser itself will be seriously reduced.

- You should only buy a speaker with a draft sensor. If the speaker has already been purchased without this device, it is better to purchase it separately. Also, if possible, it is worth installing a backdraft valve on the chimney. Such a valve will prevent flue gases from entering the house or apartment, and the sensor will simply turn off the column in case of extreme pollution.

- Once every 2-3 months, you can remove the side panels and clean off various types of soot on the heat exchanger and wick with an iron brush.

- It is worth carefully monitoring the water pressure and temperature, because these are the most obvious signs of problems with the column and will help determine the need to clean the column.

All these measures are not so complicated in practice, but as a result, the service life of the gas water heater can be significantly increased. Thus, there is a whole range of gas equipment produced in the 70s, which, under normal operation, still serves its owners today. Therefore, you should not wait for real problems with the dispenser to begin; it is much better and easier to carry out preventive maintenance constantly, without leading to serious problems.

How to remove scale without removing the radiator

To perform this procedure, simply remove the front panel of the water heater and disconnect the heat exchanger tubes from the water unit. Do not ignore the second step and do not rinse the coil together with the “frog”! You don’t know how the detergent will affect the membrane and other parts of the water valve, so it’s better not to take risks so as not to repair the unit later.

There are 3 ways to internally flush a heat exchange device:

- Connect hoses to the heat exchanger pipes and pour the cleaner manually through a funnel.

- Remove the gas heater from the wall, turn it upside down and place it on the floor. Periodically pour a solution of citric acid into the coil and wash away the scale with water through the hoses.

- Make a booster from a heating circulation pump - a device for pumping liquid through a heat exchanger. The scheme is simple: a pump, connecting hoses and an open container with detergent.

Recommendation. To protect the circulation pump of a homemade booster from contamination, install a mesh on the suction pipe to catch dissolved scale.

The burner and the chamber of the gas water heater will have to be cleaned with a brush with long soft bristles. Use a household vacuum cleaner to remove dust.

We service the igniter and water intake unit

If there is a need to clean the water unit, do not rush to disassemble the entire device. Take a look at the operating instructions for the water heater, find the “frog” in the diagram and follow the following algorithm:

- Remove the adjuster knobs and front cover.

- Dismantle the water unit by disconnecting the pipes.

- Unscrew the screws holding the cover, remove it and get to the membrane.

- Clean the filter - mesh and water holes in the frog body using a wooden stick or soft copper wire. Remove scale with a brush.

- Rinse the parts with water and assemble the assembly. Replace damaged or cracked membrane immediately.

Clean the pilot burner jet (wick) with thin copper wire or a toothpick moistened with alcohol. Wipe the ignition electrodes and the flask of the flame sensor (thermocouple) thoroughly from soot, otherwise over time the column will begin to turn off spontaneously.

When to clean a gas water heater

Information about the frequency of cleaning geysers is quite contradictory. Some sources on the Internet recommend maintenance annually, others – once every 6 months, and so on. The homeowner will be guided correctly by the quality of tap water and some signs indicating that the device is dirty:

- heating efficiency and pressure in the DHW line have decreased - the heat exchanger is clogged;

- the pilot light burns with a yellow or red flame (should be blue);

- the color of the fire on the main burner also changed;

- the column does not ignite and turns off on its own at normal pressure in the network.

The average interval between preventive cleanings of instantaneous water heaters is 1 year. But the quality and hardness of the local water should be taken into account. If it is saturated with salts, scale will be deposited much faster. In such cases, it is appropriate to use filter softeners, otherwise all water heating equipment will quickly become unusable.

Causes of clogging

When understanding the reasons, you must first understand that a geyser is a technique that has another name - a flow-type water heater. That is, the design involves two substances - gas and water. The first is the fuel with which the second is heated.

Structurally, a geyser is a heat exchanger through which water moves and a gas burner. The latter heats the heat exchanger with an open fire. The more intensely the gas burns, that is, the larger the flame, and the slower the water moves, the higher the temperature of the latter at the outlet of the column. And vice versa.

A heat exchanger is a long pipe structure that is rolled into a spiral or coil to reduce its size. There are many models of heat exchangers; each geyser from different manufacturers can use heat exchangers of different designs.

But they are all subject to the same stresses. On the one hand, or rather from the inside, it is water, on the outside it is the flame of burned natural gas.

Tap water, namely the heat exchanger is connected to this system, does not always meet sanitary standards. Therefore, scale appears inside the pipes over time. This is a layer of minerals that narrows the cross-section of the pipe structure. After which the pressure inside the heat exchanger drops.

The geyser is designed in such a way that it does not turn on without a certain required water pressure. And this is controlled by a special pressure sensor, which is installed in the pipe system of the device.

The second reason for clogging is soot on the outer planes of the heat exchanger pipes. The carbon layer reduces thermal conductivity. That is, when burning the same volume of gas, less thermal energy penetrates into the water. This leads to excessive fuel consumption, plus the efficiency of the dispenser as a whole decreases.

Soot on the heat exchanger