The internal insulation of baths, saunas and hammams has features unique to these objects. In addition to energy saving, “climate” cladding should provide:

- rapid heating of the room;

- thermal inertia (slow cooling after stopping the furnace fire);

- high level of vapor barrier.

Today, foil insulation for a bathhouse is considered necessary, and in some cases, a sufficient element to ensure the above conditions. To understand why this material is a generally accepted standard, it is necessary to consider the physics of heat transfer processes in a steam room.

The need for thermal insulation of the bath

Foil insulation significantly reduces heat loss in the bath.

The steam room is good for health, it promotes skin rejuvenation, dilates blood vessels, and speeds up metabolism. When constructing a bathhouse, builders take into account special design requirements. It should warm up quickly and maintain a high temperature for a long time. To meet these requirements, reflective thermal insulation for the bathhouse is installed. Without high-quality insulation, the steam room will not be able to function, or the heating costs will be enormous. Practical bathhouse owners note the advantages of thermal insulation:

- the service life of the bath is extended;

- the amount of time the temperature rises to maximum is reduced;

- the consumption of wood, coal or electricity for heating the sauna is reduced;

- basalt insulation increases the fire safety of the building.

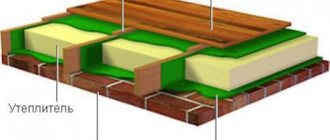

Thermal insulation is installed inside or outside buildings. In the case of insulating a steam room, a material is selected for interior work. Several layers are installed sequentially, including vapor and waterproofing. The use of insulation for baths and saunas with foil allows you to get by with one material that performs all the listed functions.

Useful tips

The cheapest pine wood can be used to build a dressing room, a relaxation room, but not a steam room.

Finishing with wooden clapboard is expensive; to reduce costs, experts give some advice:

- Use slats of short length (up to 1.5 m), which are cheaper, connecting them on a joining strip.

- Hardwood boards should be installed only in the steam room; the remaining rooms should be sheathed with budget-priced softwood lumber.

- Combine types of lining in a steam room, where the quality of the material is important, install extra-class slats, and use class B in other rooms.

- Perform hidden fastening of the lining by driving a nail at an angle of 45° into the groove or tenon. This will prevent metal contact with water and slow down corrosion processes.

- Insulation during the construction phase seems like an extra expense, but it will quickly pay for itself thanks to fuel savings.

A step-by-step plan will allow you to complete all the work yourself.

Criteria for choosing insulation for a sauna

The insulation must withstand high temperatures and humidity.

When choosing the optimal insulation for a bath, you should focus on the basic requirements for the material:

- coefficient of thermal conductivity;

- presence of a reflective layer;

- moisture resistance;

- working temperature;

- thickness;

- flammability.

The specificity of a sauna with high humidity and temperature requires paying attention to the quality of the material. Difficult conditions negatively affect the insulation, reducing its service life. Manufacturers take into account the requirements for thermal insulation of baths and create special series with appropriate markings. An important factor is the absence of harmful emissions when heated. When purchasing insulation, you should read the manufacturer's information.

In bathhouses with wood-burning stoves, it is worth taking into account the flammability of the material. Basalt or mineral wool does not support combustion; polyethylene foam melts.

Suitable wood species

Wood for lining should not contain a lot of resinous substances.

When choosing the type of wood for lining a bathhouse with lining, take into account the purpose of the room. Coniferous boards are not recommended for cladding a steam room. Due to the high temperature, they release resin, which causes burns upon tactile contact, and aromatic components, which in high concentrations provoke an allergic reaction. Steam room decoration uses hardwood:

- Linden - the low heat capacity of lumber, the pleasant aroma and golden hue of the boards ensured the popularity of lining when finishing saunas. The wood is durable, easy to process, and lasts a long time in extreme conditions.

- Alder - the lamellas have a reddish tint, and when heated, they release healing tannins. The wood dries quickly and is resistant to moisture. It has a soft structure with a small number of knots. One of the advantages is the affordable cost.

- Aspen is a light-colored species that does not deform from moisture or temperature fluctuations. The lining heats up slightly and is safe for use in a steam room.

After cladding, the wood is coated with moisture-repellent compounds.

For other rooms, lining the inside of the bathhouse with clapboard can be done with any type of wood:

- Larch is the wood that is most resistant to moisture, has a solid structure and a beautiful pattern. Due to its strength it is difficult to process.

- Pine – has a pleasant aroma and is not subject to rotting. The material is strong and durable, suitable for cladding dressing rooms and rest rooms.

- Spruce board is distinguished by a small number of knots and resin, the light shade does not darken over time. Advantage – low cost.

- Cedar is an expensive reddish-brown material that emits a pleasant aroma with medicinal properties. Wood is not afraid of moisture and has high thermal insulation characteristics.

When choosing a lining, its grade is taken into account. For a steam room, class A or extra material is required. Such lamellas have a smooth surface without knots and defects, which during operation become a source of cracks and deformation. In other premises, the use of class B products with minor defects on the surface is allowed.

Characteristics of insulation with foil

Characteristics of insulation

The use of insulation for a bath on the inside of the walls with foil or a metallized coating allows you to create the effect of a thermos. Heat transfer from heating devices occurs due to infrared radiation. To prevent energy from leaving the premises, a metallized screen is installed to reflect it. It is advisable to cover all areas of the structure with thermal insulation: ceiling, walls, floor. A continuous coating will reduce heat and moisture loss.

It is impractical to install foil without a layer of insulation. This is a thin material that is easily damaged during installation. In addition, aluminum has high thermal conductivity, which is unacceptable in baths and saunas. Correct installation and a layer of thermal insulation material eliminate the problem.

Main characteristics of foil insulation:

- High ability to reflect infrared radiation 90-97%.

- Low thermal conductivity due to the cellular or fibrous structure of the material.

- Vapor tightness – the aluminum layer coating does not allow vapor molecules to pass through, no installation of additional protective films is required.

- Waterproofing - the material does not absorb moisture.

- Resistance to high temperatures - insulation materials are designed for operating temperatures over a wide range, the upper limit being 150-300°C.

- Availability of installation - most insulating materials are available in the form of rolls and mats, which allows you to install them yourself.

In addition to thermal insulation properties, sauna insulation with foil has vapor barrier and sound-absorbing properties.

When is it needed and when is it not?

It is not needed by those bathhouse owners for whom neither fuel economy nor long-term heating are a problem.

It is also not needed by those who completely deny its ability to reflect infrared radiation through a layer of lining, but believe that the thermal conductivity of aluminum is a guarantee of rapid cooling of the bath precisely with the help of foil.

There is no need for it either if the bathhouse is sufficiently insulated using traditional methods, and its heating and cooling completely suits the owner.

It is wrong to assume that it will not find application in bathhouses made of logs or timber, since in wooden buildings only proper insulation of the crowns and high-quality sealing of all cracks is required. If desired, you can insulate any bathhouse. Let this be a repetition, but foil is needed where time and effort are valued.

Useful video

However, despite the above, there is an opinion that the absence of foil makes vaping softer, eliminating the sharp water hammer during paired procedures:

Selection of foil material

Rolled heat insulator

Thermal insulation with foil for a bath differs in technical characteristics and properties. The choice of insulation is influenced by the structural features of the room, fire safety requirements, and the complexity of installation. Mineral wool is recommended for stone and concrete buildings. This is a reliable material of considerable thickness that will provide an appropriate level of insulation.

A building made of timber or logs does not require much effort to maintain temperature. Wood itself is a good heat insulator. In this case, penofol or kraft foil is sufficient. A review of popular options will help you decide which material is best to use.

Rolled heat insulator

Insulation in the form of a rolled sheet can be from 20 to 150 m long. The thickness of the material ranges from 2 to 40 mm. The basis is foamed polyethylene or propylene. Thanks to the thin coating of aluminum, the material reflects thermal radiation. Penofol is popular in the domestic market. The material is produced with one-sided or double-sided foil coating with a self-adhesive base.

Rolled foil without a base is laid on the surface of the walls after the insulation. Strips 1-1.5 m wide are mounted overlapping. The resulting surface is highly resistant to temperature (up to 650°C), moisture and steam.

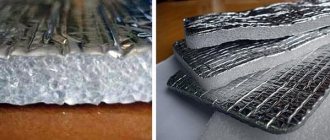

Basalt wool with foil layer

Basalt wool with foil

Mineral or basalt wool is a universal fibrous insulation. It is resistant to fire and moisture, provides excellent thermal insulation of the room. Foiling the outer layer reduces heat loss and creates a vapor barrier. Among the assortment of leading manufacturers Izover, Parok and Rockwool, you can select special materials with foil for insulating a bath.

- For anti-condensation insulation, ROCKWOOL ALU is recommended. The material is supplied in mats. Its fibers are located perpendicular to the surface. During operation, the strength and elasticity of wool is not lost. The Sauna Butts series is designed for insulation of saunas and baths. Mineral wool slabs with a thickness of 50 and 100 mm serve as heat and vapor insulation. The material is intended for indoor installation.

- Izover Sauna roll insulation is quickly installed on walls and floors and provides reliable insulation. It is safe for health and does not produce harmful emissions when heated or wet. The material allows you to save on the installation of membranes and films.

- The popular insulation of the Paroc brand is offered in the form of lamella and stitched mats. They are easy to use and can be quickly mounted on an insulated surface. The aluminum layer is reflective. Basalt wool does not change its thickness during operation.

The quality of thermal insulation depends on the thickness of the selected mineral wool. The optimal option is 5-10 cm. Basalt wool is fireproof, does not rot from moisture, and has a long service life.

Kraft foil

The use of insulation with a layer of aluminum allows for maximum preservation of infrared radiation inside the steam room. The multilayer construction consists of kraft paper and foil, in some cases polyethylene is added to reinforce the material. Common types:

- foilsolone or foil glassine - an elastic material based on cardboard with a corrugated aluminum coating;

- foil-fabric - fiberglass insulation, backed with foil, reflects up to 97% of radiation, withstands temperatures of about 200°C;

- isolar – bath foil 50 and 100 microns thick with the addition of polyethylene film, resistant to fire and temperatures up to 300°C.

Among the types of insulation, it is worth noting a new product - PIR slabs from TechnoNIKOL with a foil lining. The line of bath insulation products creates a reliable barrier between the cold from the street and the hot, humid air of the steam room. The plates are lightweight, low water absorption, and resistant to deformation

Methods for laying lining

Before choosing a method for laying lining, the first thing repair professionals advise to start with is to assess the humidity in the room. If finishing is needed in a steam room, then you should focus on horizontal placement of the slats. Vertical installation is suitable for a dressing room or sauna. This is due to the fact that the “vertical” method has a number of disadvantages:

- There will not be sufficient air circulation between the foil and the lining; this will lead to the formation of condensation and the development of mold on the inner surface of the trim and the sheathing beams.

- The finishing below will begin to deteriorate from moisture faster than the upper elements. With a horizontal mounting method, it will be enough to replace the lower strips. If you decide to attach the trim vertically, in the future you will have to trim each plank from below to replace the damaged area.

- When gaps form between adjacent elements, moisture will get inside and not flow down, as happens when installed horizontally.

The vertical method of attaching planks takes less time, so it is more often used by hired craftsmen. Also, the vertical placement of the lining does not make the room visually lower. Most often, to combine practicality and convenience, two installation methods are used simultaneously. In this case, the lower section of the walls is trimmed with horizontal planks so that, if necessary, they can be easily replaced. And the upper half of the wall is sheathed with vertically arranged boards.

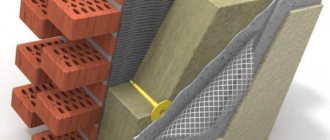

Installation of insulation with foil

The joints are glued with aluminum tape.

When installing foil insulation for a sauna, you must follow the rules:

- The layer with aluminum foil is directed indoors.

- When installing the material on the ceiling, it runs down onto the walls, and from vertical surfaces onto the floor. This is necessary for the drainage of condensate.

- Ventilation is required in the steam room.

- A gap of at least 30 mm is left between the foil layer and the finishing of the bath.

The sequence of installation work depends on the type of insulation. The penofol roll is rolled out, cut into sheets of the required length and secured to the walls with a stapler. For basalt wool, it is necessary to make a frame according to the thickness of the material. The mats are laid in the finished sheathing. The joints of the canvases are glued together with metallized tape. 30×50 mm slats are placed on top of the heat-insulating layer. The lathing will provide the necessary ventilation gap between the insulation and the casing of the steam room.

You can insulate a bathhouse and sauna with your own hands. Popular materials with foil will provide the necessary level of protection against heat loss and allow you to save on heating.

Methods for attaching panels to walls

Using nails or self-tapping screws is the traditional option for attaching panels to walls. A more modern method is the use of clamps. It does not damage the panels, but requires additional costs of both time and money when installing the lining.

Using nails or screws

This method will require a screwdriver or hammer, as well as special nails or self-tapping screws - galvanized or made of copper alloy. Such fittings are more expensive, but if you save on them and buy ordinary nails, they will begin to rust over time. This will lead to the appearance of red streaks on the lining, which will spoil the appearance of the finish and stain the skin and things when touched. The fasteners are driven or screwed into the lining tenon at an angle of 45 degrees. The fastening points will have to be sanded so that there are no burrs or other defects left. The disadvantage of this method is that holes will have to be created on the planks when fastening them with nails. And when you try to remove the lining, the fastening points will be further damaged, which precludes the reuse of the panels if necessary.

Fastening with clamps

Do-it-yourself installation using clamps is safe for lining strips because it does not damage them. A clamp is a special bracket that is attached to the lower half of the lining groove - a recess into which the tenon of the next plank is inserted. The fastenings of the bracket are covered with the next strip in the row. Fixing the staples to the sheathing beams is carried out with nails or self-tapping screws.

With this installation method, the lining is not damaged, and there are no nail heads or screws left on the outer surface of the cladding, which eliminates the risk of getting burned or getting a rusty drip on your clothes after visiting such a bathhouse.

It is also easier to partially replace the lining mounted in this way - just pull the boards out of the grooves and pull out the fasteners. If you do not work carefully, it will be the staples that are damaged, not the boards.

We recommend reading:

Bath decoration

Expanded polystyrene

Whatever you call polystyrene foam, even polystyrene foam, it will not cease to be polystyrene foam. If there is truly folk material that is used everywhere, then this is it.

- easy;

- cheap;

- simple installation;

- perfect heat retention.

How can you resist and not buy into these advantages? Meanwhile, if you are thinking about choosing a material for insulating the ceiling in a bathhouse and choose polystyrene foam, be prepared to face a number of very serious disadvantages:

- at temperatures above 60 degrees, the material deteriorates with the release of substances hazardous to health

- flammable;

- depressingly low vapor permeability;

- not friendly with aggressive substances.

One conclusion can be drawn from all this - it is not recommended

. Unless, of course, one day you want to lose your outlet due to a fire. Or any other accident.

As a compromise for insulating the ceiling in a bathhouse, we can only recommend the so-called extruded polystyrene foam, which, compared to other types of foam, is quite fireproof and can withstand temperatures up to 120 degrees without any signs of deformation. However, it also costs more - from 5.5 thousand rubles per cubic meter

Insulating a bathhouse with aluminum foil is a simple and inexpensive lining

How to use foil in a bath

When choosing a suitable method of thermal insulation, the materials of the bathhouse are of paramount importance. Insulated buildings made of logs, the walls of which have been caulked, do not need a foil layer. Large wooden baths with insufficient heating are protected with thin foil. To speed up the heating of the steam room, the surface behind the stove is also covered with foil.

For aerated concrete baths, any foil is suitable - standard or laminated (consists of an aluminum layer and paper). Insulation of brick baths and frame buildings is also a mandatory step. For cladding, foil materials with the addition of cotton wool or polystyrene are used. When covering the ceiling, foil is selected based on the size of the ceilings and the presence of thermal insulation in the attic.

The procedure for operating the steam room also plays a role. If you regularly use the bathhouse, there is no need to use foil for insulation (if you only go into the steam room for a short time). If bath procedures take 1-2 hours or more, the use of foil is 100% justified.

Foil thermal insulation solves two problems at once: it saves fuel and retains accumulated heat for a long time.

Standard cladding

All surfaces are suitable for protective wall cladding. The work is carried out in the following sequence:

If the entire steam room is covered with foil, then first of all the material is fixed to the ceiling. 10-centimeter overhangs are left along the edges. In the process of covering the walls, the foil is applied overlapping to avoid the formation of gaps.

Sheathing over insulation layer

Before fixing the foil, slats 2*4 centimeters thick are laid on the walls in steps of half a meter. The arrangement of the slats can be vertical or horizontal. When carrying out work, the procedure is as follows:

There is no need to cover the corner adjacent to the stove with foil. The exception is cases of wall cladding with decorative materials. Under such circumstances, the thermal insulation must be cut along the masonry area and reinforced with strips.

https://youtube.com/watch?v=Dg14p8ePMhU

Basic rules of insulation: what should you know?

As a result, we will familiarize ourselves with some important rules that everyone should know about.

- The most important rule is that all work should be carried out only after a preliminary calculation of thermal insulation (and based on it). This is explained by the fact that a lot depends on specific factors and characteristics: for example, on the area of the bathhouse, on the number of people for whom it is designed, on the number of rooms and their intended purpose, on the heating system, materials used in construction, etc. .

- The best option is comprehensive insulation, that is, both internal and external. It is better to take care of insulation during the construction of the foundation, walls, and when arranging the roof. Walls, floors, and ceilings are subject to mandatory insulation. For example, the floor in a bathhouse is often a multi-layer structure consisting of solid insulation, a layer of waterproofing, screed and, finally, decorative finishing.

- For walls, a heat insulator, waterproofing and finishing material that partially retains heat are usually used. The ceiling is quite often insulated by arranging a wooden frame, inside of which insulating material is laid.

The main requirements for materials and raw materials: insulation for a bathhouse on the ceiling, which is better and more reliable

When the entire structure has already been built, and all systems have been well thought out, it is worthwhile to take up insulation, especially if you plan to use the bathhouse throughout the year, regardless of the season. Moreover, in the sultry summer and cold winter, this will be equally useful and simple if all the calculations for insulation are correctly made, especially the ceiling, from where the lion's share of the heat from inside the room can be ventilated. To begin with, before you figure out how you can insulate the ceiling in a bathhouse, you need to understand that this material must meet special requirements, otherwise it’s simply not worth taking it, it will be wasted funds, and now is not the time to risk your own money.

Important

It is worth understanding that, first and foremost, the insulation in a bathhouse on the ceiling, the builders forum is replete with similar statements from real professionals, must be moisture resistant, since all the hot steam first rises. Moreover, you should not hope that vulnerable material that absorbs water can be reliably hidden under a vapor barrier. It will, of course, help a little, but such an insulator can still become unusable and completely lose its properties in just a couple of years, due to the regular appearance of condensation, which is inevitable with temperature changes.

- Also, the insulation for a bathhouse on the ceiling must be completely harmless and not dangerous to human health and life. That is, it should not release toxins, aldehydes, or other dangerous substances, even under the influence of high temperatures that will regularly occur in the bathhouse.

- Fire safety is another important factor that insulation for the ceiling in a bathhouse must have, and which one is better under this criterion, they will help you figure it out, for example, in a store.

- We should not forget about sudden changes in temperature, which the thermal insulation indoors must withstand without much reaction, and over a long period of several years.

- Biological and chemical inertness, as well as resistance to the development of various microorganisms, fungi and other “living creatures” of the material for bath insulation is also extremely important.

Among other things, I would like to definitely note that the heat-insulating layer must be sufficiently tight and elastic, but such that, for example, it itself will not sag over time. Therefore, in order not to be too tormented by the question of which insulation to choose for the ceiling of a bathhouse, it is worth purchasing one that is relatively inexpensive, but in terms of performance and properties is at its best. Moreover, it is worth understanding that this can be done using natural materials, or you can choose synthetic ones, which also “work” quite well.